LED – Cooling and Thermal Management

As we all know, the life span of an LED depends on the semi-conductor material used as well as the current/heat relationship. The light output of the LED becomes weaker and weaker and once it reaches 50% of its initial value, the life expectancy of the LED has, by definition, been reached. A life span of a few hundred and up to 100,000 hours is possible, but only when avoiding high temperatures which drastically reduce the length of the LED’s life.

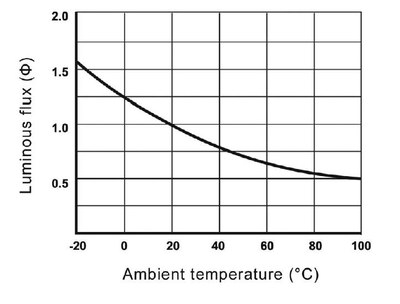

The radiant power or the luminous flux of an LED is very much dependant on the temperature of the semi-conductor. This means that the efficiency of the LED clearly diminishes the higher the temperature is.

Even when an LED is referred to as a “cold radiator”, the entire electric energy in the LED is not converted into luminous power. Here, just like other semi-conductors, a large portion of the electric energy (70%-80%) is converted into heat. This is why; unlike thermal radiators (light bulb) thermal management (cooling) is absolutely necessary. The effectiveness or in other words, the efficiency of the LED is the relationship of radiated luminous flux to applied electrical energy and is specified in Lumens per Watt (lm/W).

All the wonderful characteristics of the white radiating high efficiency LEDs, and with them, the new possibilities for modern lighting technology, can only work trouble free and lastingly when thermal technical boundary conditions are adhered to.

Various designs of light emitting diodes, always adapted to their intended purpose, are available on the market. Wired LEDs as an indicating element, SMT designs in PLCC housings, hexagonal and octagonal designs with diverse production descriptions and especially the COB (Chip on Board) versions, where the LEDs are soldered directly onto the printed circuit board.

The highest possible luminous flux is needed from the high performance LEDs for lighting purposes; semiconductor technical concepts, new designs, multiple chips in one casing, and so on, make optimal thermal management necessary.

Thermal Relationships

The surrounding temperature and with that, the temperature of the chip, directly influences the efficiency and life span of the LED. Semiconductor LEDs change their emission characteristics with time and the intensity of the light yield gets continually weaker. This behaviour is known as ageing or degradation and is related to the increase and enlargement of the impurities in the chip (semi-conductor crystal).

A too high luminous flux from increased electrical power also increases the temperature in the LED and big temperature differences also shorten the life span considerably.

The synthetic materials used for the enclosures and lenses (epoxy resin, silicon, etc.) of the LED are also prone to ageing which can cause cloudiness.

Temperature Related Malfunctions

The ambient temperature and self-warming through electrical current effect the temperature of the chip. The effect on the light yield, light color and forward bias also correlates directly to the LED’s chip temperature.

The luminous flux (Φ) as a function of the temperature is to be calculated

as follows:

Φv(Tj) = Φv (T2) e–kΔTj (1)

Φv(T1) = Φv (T2) e –kΔTj

T1 = Luminous flux for Tj 1

T2 = Luminous flux for Tj 2

k = Temperature coefficient

ΔTj = Change in temperature Tj (T2-T1)

An example of degradation as a result of temperature increase is shown

in figure 1.

The curve shows that a temperature increase from 25°C to 75°C reduces the luminous flux by almost half.

Depending on the temperature, the glass transition temperature of the die enclosures, that is, the transition from a hard-fast to a softer condition has a big influence on the LED. A change in the thermal expansion co-efficiency of the material is basically a consequence of an increase in the enclosure temperature. In order to avoid failures here, it must always be made sure that the junction temperature Tj is not higher than the enclosure temperature.

The known correlations in heat engineering and the observations of Thermal Management lead to a deeper understanding of temperature power loss when calculating the thermal resistance with the formula:

Rthja = (Tj-Ta)/P = ((ΔTj-Ta)-Tα)/P = ΔTjα/P (2)

Whereby: Tj = ΔTj + Ta

Rthja = Temperature loss junction / ambient

Tj = Junction temperature

Ta = Ambient temperature

P = Overall power of the LED ( If * Vf )

In practice, the relevant value of the junction temperature is calculated

like this:

Tj = Rthja * P + Ta

Thermal Management

The optimal heat engineering interpretation for definite cooling is extremely complex because the construction of an LED and the consideration of all of the relevant thermal resistance as the sum of the individual thermal resistance of the materials and junctions have to be taken into account. Only about 20% to 35% of an LED power rating is converted directly into light – the rest of the power is heat loss and has to be dissipated away from the components in the system when running the LED, and emitted into the environment. This can be easily done using an artificial surface magnification of the LED assembly contact zone.

There are three possibilities available for cooling the LED; in the light casing, the printed circuit board (conductor paths, metal-clad PCB) and using heat sinks which are either glued or soldered onto the PCB or mounted separately.

The cooling path over the light casing is made up of two partial paths. One is the junction to the contact pins and one to the light casing, that is, contact pins to the ambient air. These result in a minimal heat sink and are therefore not reliable especially for high performance LEDs.

Another type of cooling is when a heat sink is attached to the PCB on which the LEDs are mounted (if intended). There are diverse scopes for design for the user.

For very little heat, a simple FR4 PCB material with additional pressed on heat conductor paste for better heat transfer may be enough in a very few cases. For more heat a special PCB construction design is used since FR4 is not a very good heat conductor.

The metal-core PCB is used a lot for LED cooling. A basis plate made from aluminium can transfer the heat that comes from the LEDs over the Thermal Vias or Thermal Coins (copper continuous bonding) either directly or over an additional mounted heat sink into the ambient.

Besides the rigid PCB it works the same for flexible PCBs made of PET, PEN, Pl, etc. because there is also the possibility to, for example, glue on an aluminium heat spreading area and a heat sink.

For high performance LED implementations, cooling using a heat sink is imperative. For this there are different basic approaches for the design of the heat sink.

Using heat sinks for free convection is a confirmed concept for cooling high performance (power) LEDs today. For this purpose the LEDs that must be cooled are affixed to the chosen heat sink.

Choosing the Appropriate Heat Sink

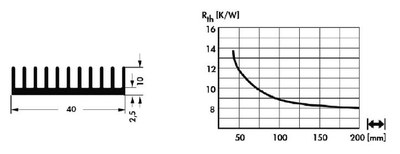

Once the thermal criteria have been set up (the documents and guidelines from the LED manufacturer should always be taken into account), the thermal resistance has been calculated and the mounting situation has been considered along with the space/room that is available, then the appropriate heat sink can be chosen.

Special thought should be given to the orientation of the heat sink in the room. Comb shaped profiles should be installed so that the natural convective buoyancy is not hindered. It should be made sure that the most barrier free air supply and air discharge as possible is used with active cooling. The suppliers of heat sinks for LEDs show the thermal resistance in relation to the heat sink in their diagrams.

Using the data from the calculated thermal resistance, the user can

read the value that can be obtained in the diagram supplied by the heat

sink manufacturer and then choose the appropriate heat sink for the

specific application.

Specially coordinated concepts have been developed for the steadily increasing demand for LED heat sinks. Besides the many standard heat sinks that can be used for cooling LEDs, special modified versions of heat sinks for LEDs and individual LED systems are now available.

For an additional heat spreading area, there is the possibility of a copper coating on the bottom of the heat sink, whereby the copper surface can often be soldered which, in turn, makes direct solder mounting of the LED onto the heat sink possible.

The effectiveness of cooling can be increased with the use of moving air. A heat sink with a ventilator can, depending on the application, improve heat removal by about 40%. The heat sinks used for this are specially designed for good heat removal using moving air.

Active cooling is not noiseless, though. Airing motors and movement of the air create sound waves that are not wanted in many applications like household lighting, concert halls, institution rooms, etc. On the other hand, there are airing concepts today that have slow turning rotors and special fan blade geometrics which have a very low noise level. A soft suspension bracket of the ventilator on the heat sink, with no screw connections, but rather a rubber bearing with an integrated mounting decouples the sound waves and reduces imbalances of noise development of the ventilator bearing. The high quality ventilation motors have already been burn-in tested and have a considerably lower failure rate and a life span expectancy of 200,000 hours MTBF – which is higher than the expected life span of the LED. Some ventilation motors can be controlled by PWM and are therefore well suited for utilization.

Other positive aspects of the air cooling are, besides the low temperatures, the lesser amount of pollution (dust deposits), and especially a more uniform heat distribution when being frequently turned on and off.

See Figure 5 (see LpR magazine)

Other cooling possibilities for a large amount of heat by LED applications

are, for example thermoelectric cooling (Peltier element) or liquid cooling (micro-channel, etc.) however, their use is only marginal because they are very complicated and expensive.

Installing LEDs

Special attention and care must be given to the connection between the LED and the heat sink. If the heat transfer between the LED and the heat sink is poor, the heat conduction reduces the heat transfer and the temperature of the LED is markedly increased. The performance and the luminous power can then be restricted and a rise in temperature high enough to destroy it is possible.

The best possible connection between the LED component and the heat sink can only be achieved when the inevitable irregularities and roughness that occur during production on the surfaces that are to be connected are smoothed out and the air bubbles that hinder heat transfer are avoided.

Especially with a mechanical fastening of the LED using screws, the use of a thermal paste that leads to improved heat transfer is necessary and advisable. An adhesive fastening using a double sided tape or also two component epoxy resin heat conductor adhesive smooth out the irregularities similarly. When using adhesives, though, it must be taken care that no or only very little volatile organic compounds are transpired since they could lead to clouding the plastic covering/lens by condensing on the surface of the LED.

A very good thermal connection to the heat sink etc. can be achieved when for a number of suitable LED models, a solder mounting connection by means of reflow or IR soldering is used.

Basically, by all types of fastenings, it should be taken care that none of the neighbouring or added heat emitting electronic components, resistors, transistors, etc. of the LED hinder heat transfer or even couple additional heat into the system.

LEDs for Lighting

The lighting LEDs can be implemented in many areas due to their low mechanical dimensions and stability, high efficiency and long life.

A light beam without IR and UV rays predestines LEDs for use in the medical sector and everywhere where light –sensitive objects have to be illuminated (museums, galleries).

See Figure 6 (see LpR magazine)

With respect to jolting, shock and vibrations, the relative ruggedness of the LED is a significant factor in its implementation in automotive engineering, from the automobile to the bicycle to rail, ship and aviation engineering.

The long life span of the LED is a big advantage when implemented in seldom used equipment (indicator lights) or difficult to access areas (explosion risk) and high maintenance equipment (street lights and other signal lights). Environmental and price advantages are added to that since LEDs don’t contain any environmentally unsafe substances and operate very energy efficiently. Last, but not least, new and diverse design liberties for lighting purposes offer interesting solutions that were not obtainable with the illuminants available up until now.

Closing Remarks

The LED will establish itself on the market as the universal light source for all types of lighting applications. When taking the different installation conditions into consideration, many applications will need a heat sink. The appropriate thermal management will be there to support fast development and guarantee a lasting and faultless operation of the LED.