Get Your Thermals Sorted

Long-lasting LED solutions require superb thermal design – Forge ensures the thermal design is a fundamental design process for every LED solution they manufacture.

Whilst LEDs are very efficient there is still an amount of electrical power that is converted into heat. To harness the best possible performance from an LED this heat needs to be effectively moved away from the LED chip at the heart of the device and dissipated into the ambient environment.

Effective thermal management is fundamental to the design process of an LED solution. We need to understand the application. Space limitations, the installation environment and power requirements can have an impact on heat dissipation. We also need to understand the performance, cost, and efficiency targets to enable effective design. The design should balance all requirements and achieve an LED solution that does what you want it to.

Why is removing heat important?

LEDs are semiconductors; they are extremely versatile but require careful treatment to ensure that their complex highly-organised makeup is not disrupted or damaged. Exposure to elevated temperatures can also damage other elements in the LED, for example, the phosphors necessary to create white light or the materials used to encapsulate the chip within the device.

What damage can heat cause?

LEDs that overheat can exhibit accelerated degradation in terms of:

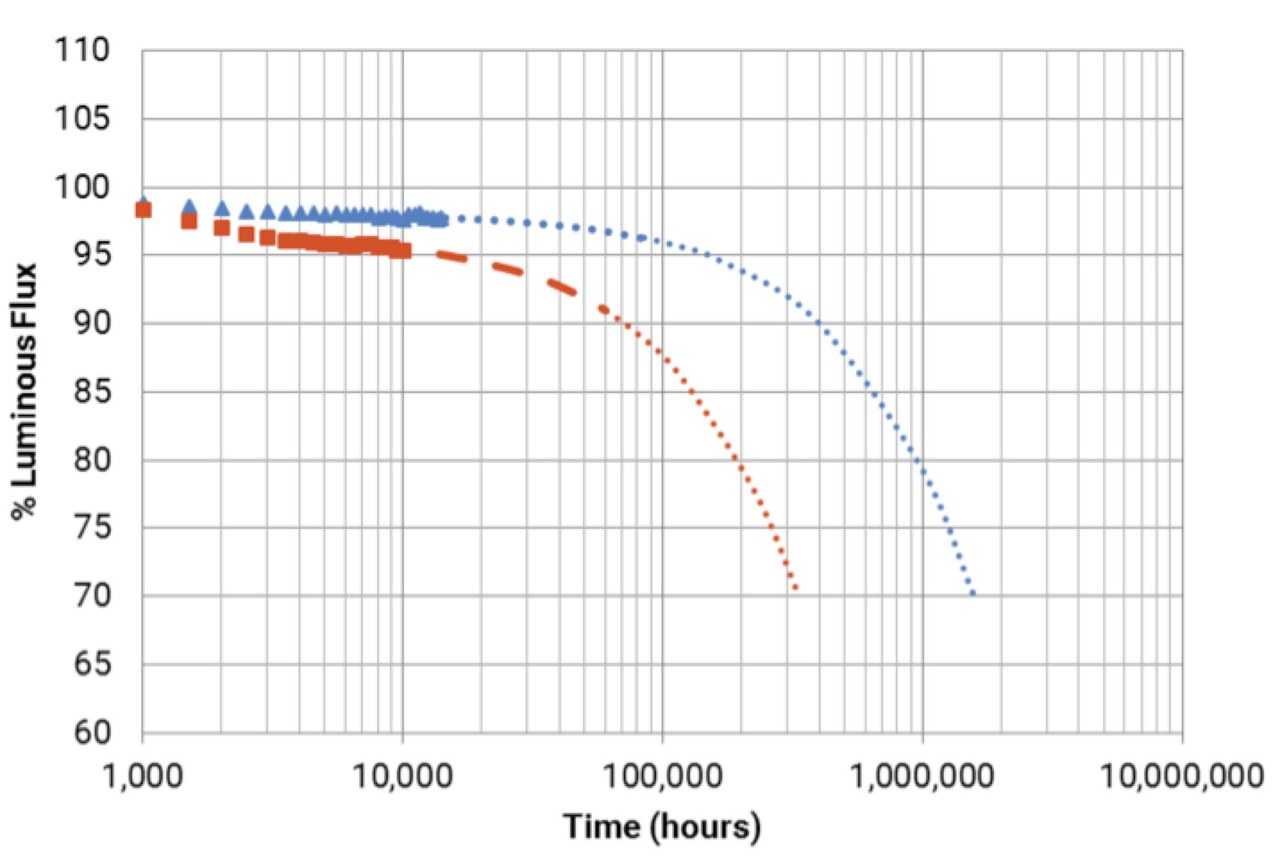

- Light output – so-called ‘lumen maintenance’ – put simply, over time an LED will lose its ability to produce photons, this is inevitable ‘wear-and-tear’, but heat accelerates this process.

Fig.1 – Typical LM-80 graph showing lumen depreciation over time

- Colour change over time – this is especially true for white LEDs. Temperature can cause changes to the phosphor leading to visible colour changes in the LED.

-

In extreme cases overheating LEDs can result in physical damage to the LEDs themselves, plastic lenses, wires, connectors, printed circuit boards, drive electronics etc.

How to get your thermals sorted

Thermal design is intrinsic to every element of design including LED selection, PCB design and layout, and electronics design. When choosing the LED, the power, LED junction temperature and thermal resistance are all considered and compared.

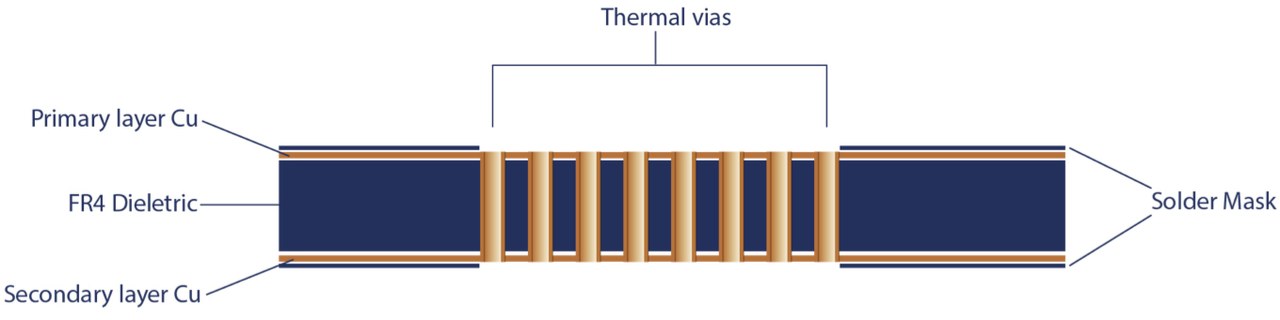

The specification and layout of the PCB is another way to conduct heat away from the LED. PCB materials have varying thermal characteristics, whilst enlarged solder pads and thicker copper layers help to distribute heat across the PCB. The addition of thermal vias – drilling holes and copper plating them - can also improve the thermal resistance of FR4, thus enabling FR4 to be considered in applications where metal substrate-based PCBs may have seemed the only option.

Fig.2 – Thermal vias within a PCB

Design with Thermal Simulations

A heatsink transfers the heat generated from the LED board to the ambient air using a combination of conduction, thermal radiation and natural convection. When we design heatsinks our aim is to minimize as much as practically possible the thermal resistance between the LED and the environment, making best use of the available airflow and ultimately improving the thermal efficiency of the complete LED solution.

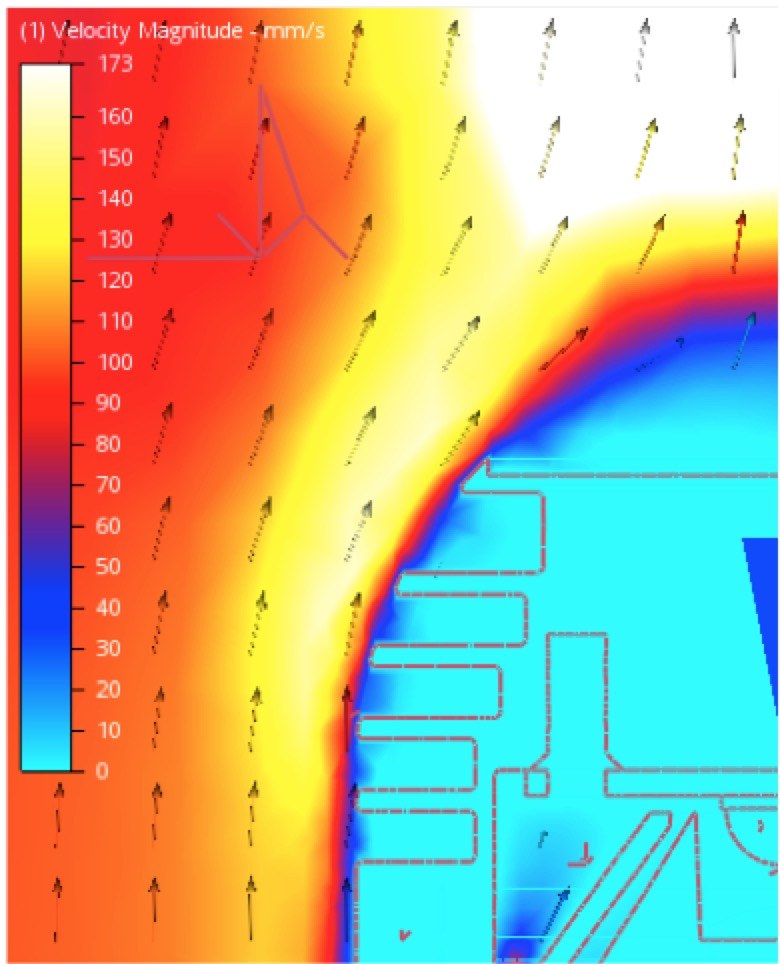

Working from first principles our engineers begin by creating 3D models of potential heatsink designs that fit within the space envelope available. Within these models, it is important to capture key mechanical features such as bezel configurations, retaining clips and cable strain relief components, as these all have an influence on the thermal mass of the luminaire and the flow of air around the fixture. It is also important to specify materials of construction and surface finishes within these CAD models to ensure that the next stage, computational fluid dynamics (CFD), is as accurate as possible.

CFD is a powerful software-based toolset that combines complex mathematics with high-performance graphics rendering. The CFD suite enables our engineers to visualize the transfer of heat through the materials of the luminaire and then how this heat is dissipated into the surrounding fluid that is the ambient air. With the ability to literally see how the design is performing it is possible to make quick, informed decisions on the viability of a design; choosing whether to finalise, modify or discard a concept, before moving into more costly prototype production.

Fig.4 – CFD simulation of heat transfer

The confidence of CFD modelling depends crucially on the accuracy and fidelity of the CAD to the product that will be manufactured. By involving Forge from the outset of the design process through to volume manufacture we can provide you with the best possible support, guidance and added value, to enable you to deliver a product that is efficient, reliable and cost effective.

by Forge Europa Limited, UK

+44 (0)1229 580000

sales@forge.co.uk

www.forge.co.uk