OSRAM researchers nominated for the German President’s prize for technology and innovation

OSRAM, together with the Fraunhofer Institute for Applied Optics and Precision Engineering, is one of the four teams nominated for the German Future Prize. The German Future Prize, which is now in its eleventh year, will be presented by Federal President Horst Köhler in December to celebrate outstanding technical, engineering and scientific achievements that have practical applications, are marketable and create jobs.

“With this new LED technology we have succeeded in producing bright and extremely efficient LEDs that have the potential to become established in general lighting applications”, said Dr. Rüdiger Müller, President and CEO of OSRAM Opto Semiconductors.

“The nomination highlights our position as a company with enormous powers of innovation in Germany”, he added. He sees the nomination above all as an opportunity to draw the public’s attention to the technologies developed by OSRAM Opto Semiconductors and their practical applications. The nomination applies to thinfilm chip technology and its use in the Ostar family of LEDs. The Ostar LED has been adapted for a wide range of applications, including mini-projectors and rear projection televisions, night vision equipment in automobiles and for general lighting. An Ostar version will be launched in 2008 for use in automobile headlights.

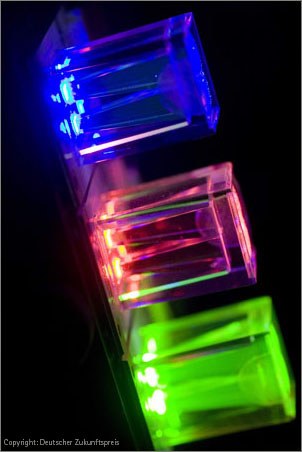

The technical innovation of the Ostar light emitting diode lies in the perfect interplay between various technologies – a new manufacturing process for high-power chips, a perfectly matched package platform and special optics developed in cooperation with the Fraunhofer Institute for Applied Optics and Precision Engineering. “These technologies enable us to achieve particularly high luminances for LEDs of all colors and for infrared light. This is a pioneering innovation”, said Dr. Klaus Streubel, spokesman for the development team at OSRAM Opto Semiconductors.

Light emitting diodes consist of semiconductor crystals that grow on a substrate during manufacture. Up to now this substrate stayed in the diode after manufacture where it absorbed much of the light produced. Now, with thin-film technology developed by OSRAM Opto Semiconductors the top surface of the light-generating layer can be successfully coated with metal. This metallized side is soldered onto a thin carrier material and serves as a reflector. The original substrate is removed. The result is a thin light-producing layer that lies very close to the top of the LED. The light emitting diode can therefore emit almost all of its light at the top – this represents a major advance in brightness for LEDs. The Ostar packages are precisely designed to take full advantage of these thin-film chips.