Osram Reports Record Figures for Green InGaN-Based and Conversion LEDs

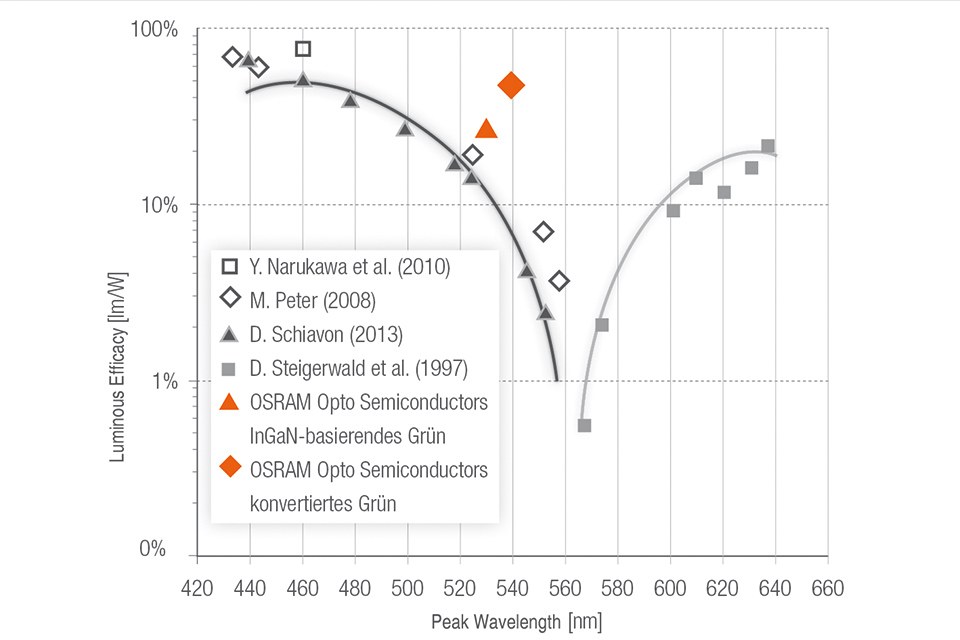

The “Hi-Q-LED” project funded by Germany’s Federal Ministry of Education and Research (BMBF) has made pioneering advances with green LEDs, greatly diminishing what is known as the “green gap” phenomenon – the significant drop in efficacy in the green spectral range. The result is a green-emitting LED based on indium gallium nitride (InGaN) semiconductors which achieves a record efficacy of 147 lumens per watt (lm/W) at a wavelength of 530 nanometers (nm) and a spectral width of 35 nm. In addition, another green LED developed by combining a blue chip with a phosphor converter has achieved a record-breaking efficacy exceeding 200 lm/W.

As part of the “LED Lead Market Initiative” funded by the BMBF, the working group for “Efficient LED Solutions with High Color Rendering Indices” in the “Hi-Q-LED” project headed by Osram Opto Semiconductors has developed two pathbreaking green LED prototypes.

Green all-InGaN LEDs close the “green gap”:

Conventional LEDs show a significant efficacy drop at wavelengths above 500 nm – a phenomenon known as the “green gap”. Research activities in the framework of the project have enabled the development of a narrowband green LED with a record efficacy of 147 lm/W for a chip size of 1 mm² and a driving current of 350 mA (current density: 45 A/cm2). The LED has a central wavelength of 530 nm and a forward voltage of 2.93 volts (V) at this current density. A reduction of the carrier density in the light-emitting layers and a significantly improved material quality were the key factors behind this breakthrough. Thanks to a significantly reduced dependency of the efficacy on the operating current compared to conventional green LEDs, the LED prototype shows significantly improved performance at higher current densities and achieves as much as 338 lumen (lm) at 125 A/cm2. “InGaN-based LEDs, in which the light output is generated by an InGaN semiconductor exclusively, offer a much more narrowband emission with a spectral width of approximately 35 nm compared to green LEDs that are based on phosphor conversion. This breakthrough is an enabling technology for highly efficient projection systems requiring a high color rendering index”, stressed Dr. Andreas Löffler, Project Manager at Osram Opto Semiconductors. After all, a high color rendering index or an increased color gamut means a more vivid, higher-quality image.

Record-breaking efficacy of >200 lm/W achieved with a green full conversion phosphor solution The second approach of the project, which was to create a new, even more efficient green LED, comes into play in cases where the spectral bandwidth of the LED is not critical. Record-breaking figures demonstrated were 209 lm/W (210 lm) with a chip size of 1mm2, a central wavelength of 540 nm, a forward voltage of 2.88 V and a driving current of 350 mA (current density: 45 A/cm²). For a current density of 125 A/cm2, it proved possible to increase the light output to above 500 lm. Despite this high current density, the efficacy of these devices amounts to 160 lm/W. The efficacy peaks at 1.5 A/cm² with a maximum of 274 lm/W. According to Osram research engineer Dr. Thomas Lehnhardt, these exceptional performance figures have been achieved thanks to the optimized interaction of chip and converter technologies: “Continuous improvement of the blue LED chips, an optimized excitation wavelength and an increased degree of conversion of the phosphor converter are the winning combination underlying the new record-breaking LED.”

From prototypes to series production:

At the moment, the unprecedented figures achieved by the two LED prototypes still can only be ranked as development data. Further time will be needed to develop products based on the findings of the research project with optimized price and performance and which are well suited for mass production.

About Osram Opto Semiconductors:

Osram, with its headquarters in Munich, is one of the two leading lighting manufacturers in the world. Its subsidiary, Osram Opto Semiconductors GmbH in Regensburg (Germany), offers its customers solutions based on semiconductor technology for lighting, sensor and visualization applications. Osram Opto Semiconductors has production sites in Regensburg (Germany), Penang (Malaysia) and Wuxi (China). Its headquarters for North America is in Sunnyvale (USA). Its headquarters for the Asia region is in Hong Kong. Osram Opto Semiconductors also has sales offices throughout the world. For more information go to www.osram-os.com.