Key Milestone Reached in OLED Development: cynora Presents New Flexible Prototype

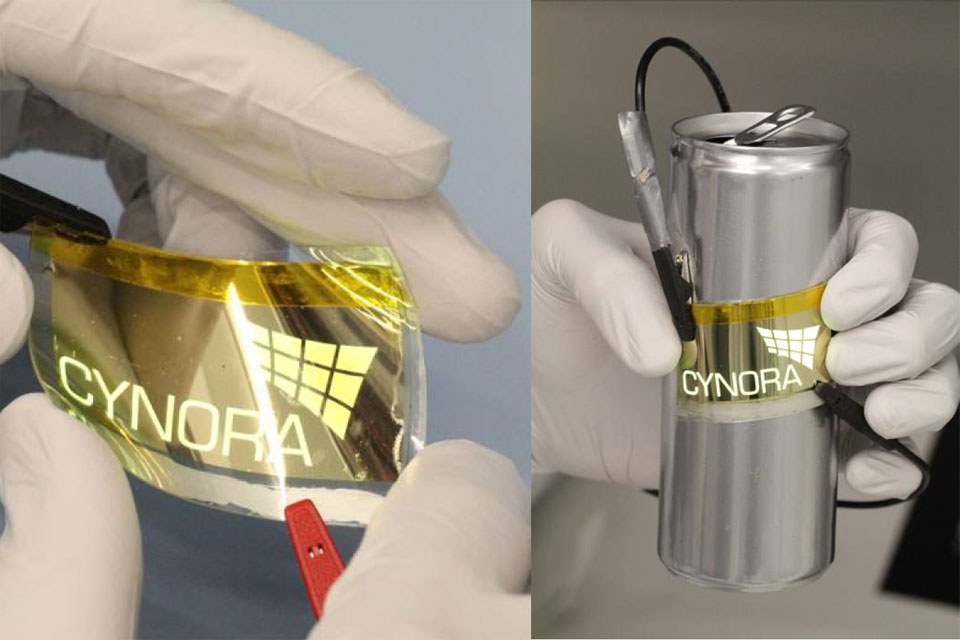

cynora today unveiled a new flexible OLED prototype, demonstrating yet again the huge potential of OLED technology. One key aspect that sets organic light-emitting diodes (OLEDs) apart from conventional LEDs, is that they are two-dimensional light sources. Additionally, they are extremely thin. This property makes them ideally suited for lighting systems and flat screen displays. So far, however, OLEDs have only been used in rigid form in these application areas.

cynora’s new prototype represents a major milestone in the development and use of flexible components, opening new application fields such as smart packaging, for instance. “Many people owning a smartphone are already experiencing OLED technology. The diodes used for those displays, however, are absolutely rigid. The potential of flexible foil-like OLEDs has so far remained untapped,” says Dr. Thomas Baumann, one of cynora’s CEOs.

Prototype opens new possibilities for packaging and lighting industry:

The new prototype offers a glimpse of what flexible light-emitting film layers will soon make possible: “Further enhancement will in the near future enable the manufacturing of, for instance, beverage cans, smart packaging or posters that feature light-emitting film components,” Dr. Thomas Baumann ventures to predict. In further step, cynora will therefore tackle the integration of the wiring into the thin film layers.

The major part of cynora’s prototype is made from a liquid solution. Solution-based manufacturing is particularly suitable for mass production because it enables substrates to be coated with thin light-emitting elements quickly, efficiently and cost-effectively using printing processes. “Using solution processing to produce components instead of conventional vapor deposition is a prerequisite for bringing production costs down to a level where flexible OLEDs are viable for mass-market applications,” explains Dr. Tobias Grab, the other cynora CEO. In addition, the cynora emitters used are based on readily available copper precursors which in itself further support the material’s suitability for mass production.

The prototype was developed as part of the cyFlex project. It won the 2012 SME Award of the Forum Organic Electronics Excellence Cluster initiated by InnovationLab GmbH in Heidelberg, Germany.

About cynora:

Founded in 2003, cynora GmbH came under new management in 2008. The company focuses on researching innovative organic semiconductors whose physical properties as white illuminants destine them for organic light-emitting diode (OLEDs) applications. From designing new functional molecules for OLEDs and solar cells all the way to manufacturing these components in a lab environment as well as testing them for physical suitability with advanced measurement technology and methods, cynora covers the entire spectrum of material and component development.

Besides exploring new ways of achieving additional efficiency gains, the young and dynamic team behind cynora with at the moment 14 employees also works on improving key aspects of OLED applications, such as cost-effective processing and lifetime. Printing optoelectronic components requires new, intelligent materials and approaches. Resulting products can be used as displays, light sources, design objects and solar cells for energy generation.

For additional information: www.cynora.com