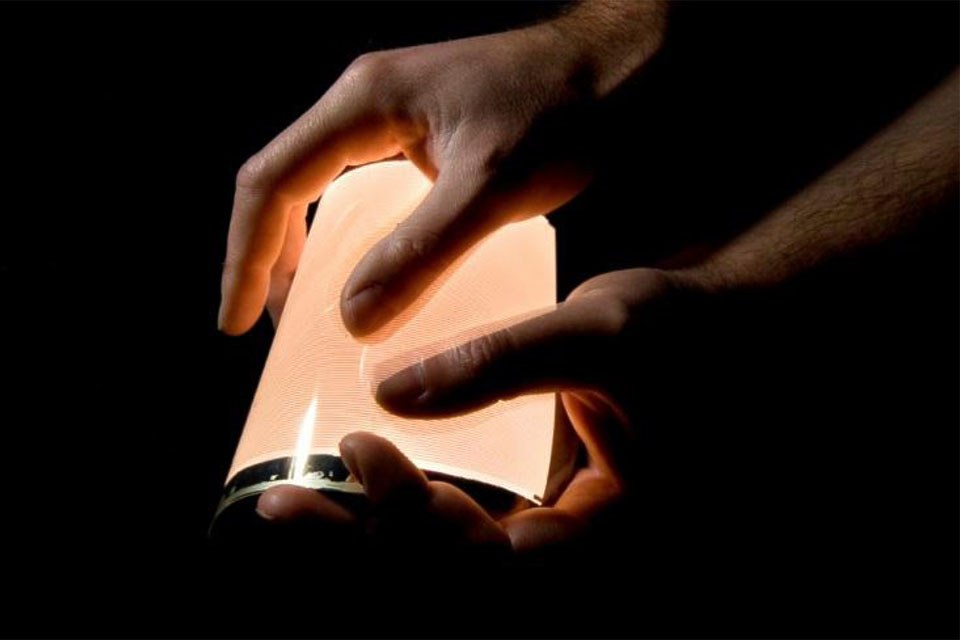

Flexible Organic LED (OLED) Lighting Reaches High Energy Efficiency

Chemical group Solvay and Holst Centre have demonstrated high efficiency flexible Organic Light Emitting Diodes (OLED) lighting tiles with a surface area of 69cm². These large-area demonstrators contain several layers deposited by solution processing at Holst Centre and additional layers applied by conventional vacuum deposition at Solvay.

OLEDs are a new lighting technology enabling flat diffuse lighting sources, and are complementary to inorganic LEDs, which are by nature well suited as spotlights. Current OLED devices are made at pilot scale by depositing many layers on glass by vacuum process. Solvay and Holst Centre were able to deposit several layers of the OLED by solution processing, which brings the use of printing technologies to produce OLEDs closer.

Use of printing technologies on flexible substrates will enable large scale manufacturing of OLEDs for general lighting applications, and will bring some additional features: thin, flexible, and potentially transparent light sources that could be integrated in ceiling, walls, windows…

The highly efficient flexible OLED stack was designed and optimized at Solvay. It is based almost entirely on organic functional materials developed at Solvay and integrates Plexcore© OC Hole Injector Layer (HIL) from Plextronics, Inc. The demonstrators include Holst Centre’s own thin-film encapsulation and large-area transparent anode technologies on plastic substrates from DuPont Teijin Films.

These large-area, flexible, white OLEDs have been characterized at Philips Research Laboratories* and found to have an energy efficiency of 30 lm/W at 1000 cd/m², which is 2 to 3 times higher than common incandescent bulbs.

This measured value is on par with results measured on small (7mm²) equivalent devices made at Solvay on glass substrates, indicating that the device architecture and the unique materials set used in these demonstrators translate very well from small scale, rigid substrates to large area, flexible plastic substrates.

Capitalizing on these exciting results, the partners are already working on a second generation of demonstrators encompassing more solution-processed layers. This achievement clearly demonstrates the potential for high efficacy OLEDs on flexible plastic foils, opening ways to a production of low-cost, solution-processed OLED lighting tiles.

About Solvay:

SOLVAY is an international chemical Group committed to sustainable development with a clear focus on innovation and operational excellence. Its recent acquisition of specialty chemicals company Rhodia created a much larger player, which is realizing over 90% of its sales in markets where it is among the top 3 global leaders. Solvay offers a broad range of products that contribute to improving the quality of life and the performance of its customers in markets such as consumer goods, construction, automotive, energy, water and environment, and electronics. The Group is headquartered in Brussels, employs about 29,000 people in 55 countries and generated EUR 12.7 billion in net sales in 2011 (pro forma). Solvay SA is listed on NYSE Euronext in Brussels and Paris.

About Holst Centre:

Holst Centre is an independent open‐innovation R&D centre that develops generic technologies for wireless autonomous sensor technologies and for flexible electronics. A key feature of Holst Centre is its partnership model with industry and academia around shared roadmaps and programs. It is this kind of cross‐fertilization that enables Holst Centre to tune its scientific strategy to industrial needs.

Holst Centre was set up in 2005 by imec (Flanders, Belgium) and TNO (The Netherlands) with support from the Dutch Ministry of Economic Affairs and the Government of Flanders. It is named after Gilles Holst, a Dutch pioneer in Research and Development and first director of Philips Research.

Located on High Tech Campus Eindhoven, Holst Centre benefits from, and contributes to, the state‐of‐the‐art on‐site facilities. Holst Centre has over 170 research staff from about 28 nationalities and a commitment from more than 30 industrial partners.

Visit us at www.holstcentre.com