Ending the Invisible Threat - Confronting the LED Flickering Issue

One of the topics in 2014 International LIGHTFAIR DOE training was “SSL Flicker Fundamentals and Why We Care“ (Michael Poplawski and Naomi Miller 2014),this reignited the industry’s discussion on light modulation. This topic was already raised by ASSIST earlier, where research on human’s level of tolerance to high-frequency flickers have been done and published in several lighting magazines by Rebekah Mullaney, hoping to encourage LED manufacturers and distributors to put more emphasis on finding a permanent solution that is more suitable for people’s well-being. - Andy Fei and Nina Chen from ALT-LED summarize these flicker research results and explain how to avoid flicker issues.

Did you know that most of the light sources in office buildings do not provide continuous light? High frequency flickers are hardly noticeable to the naked eyes, but research has proven that certain levels of exposure to flickering lights could become hazardous to health.

However, a fierce price war took place after the year 2012, rendering smaller and medium, as well as larger corporations to prioritize cost over quality; leaving the question as to how many manufacturers are left to prioritize quality over cost.

Characterizing Light Source and Flickers

All light sources operating on alternating current (AC) to modulate light output will inevitably create flickers from current fluctuations; fluorescent tubes, high-pressure sodium lights (HPS), and LED lights all share the same luminous characteristic causing flickers along with current flow simultaneously. Direct current (DC) input through the power circuit became necessary to ensure the most comfortable lighting experience. Electricity frequency commonly runs at 50 Hz or 60 Hz, the flickering rate of fluorescent tube is the multiplier of electricity frequency which is usually 120 Hz. Normally the flickers occurring at frequency of over 100 flickers per second are unnoticeable unless the flickering is below 100 Hz; anything above 100 Hz could only perceived through stroboscopic effects.

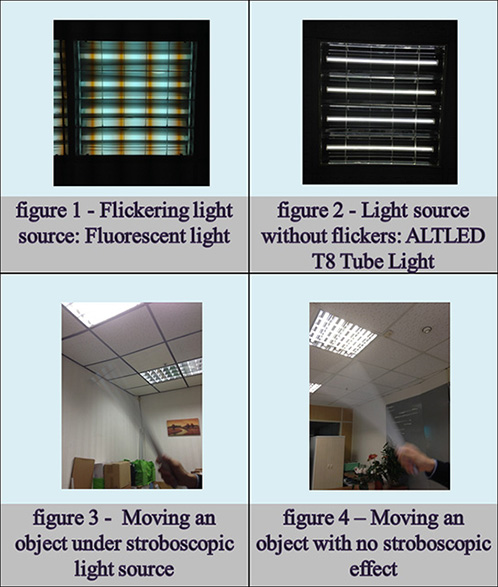

Stroboscopic Effects can be observed through several phenomenons, while the easiest way is by taking direct shot at the light source, the result shows distinctive ripple effect as per figure 1. The multiple shadow as shown in figure 3 of a moving object is the presence of Stroboscopic Effect. Stroboscopic effects may result in false interpretation of machinery with indistinctive slow motion or motionless while operating.  Figures 1-4: Stroboscopic effect explained

Figures 1-4: Stroboscopic effect explained

Referring to figures 1 & 2. Figure 1 taken from a phone camera showing the ripple effect of a stroboscopic light source, whereas figure 2 does not. Figures 3 & 4 show that when an object in motion is shot under a stroboscopic light source, it creates overlapping shadows. If taken without the stroboscopic effect, the image will display a continuous motion without the presence of overlapping shadows.

The effects of flicker on humans

According to the Solid-State Lighting Technology Fact Sheet (U.S Department of Energy 2013), low frequency flicker may induce epilepsy; and the magnetically ballasted fluorescent lights used in the office are also associated with headaches, fatigue, vision blur, and vision impairment. Stroboscopic effects may even induce illusions when driving at night, causing moving objects to appear as slowing down or stopping; moreover, such effect is also potentially hazardous in the industrial settings to which it may cause construction safety concerns.

There are certain groups of people that are more vulnerable to negative impacts of the flickers, including children, autistic patients, migraine sufferers, and epileptic patients. Because flickers are only perceivable through naked eyes, people do not normally realize that the cause of discomfort may have originated from the flickering itself; but by changing light quality, certain degree of fatigue can be reduced and at the same time improve overall work efficiency.

Flicker Analysis in Commercially Available Lights

We know the fluorescent tubes lights have serious flickering issue in general, but we are still unclear whether LED lights have the same problem as well; the following research conducted by the US PNNL might just give us a jaw-dropping point of view.

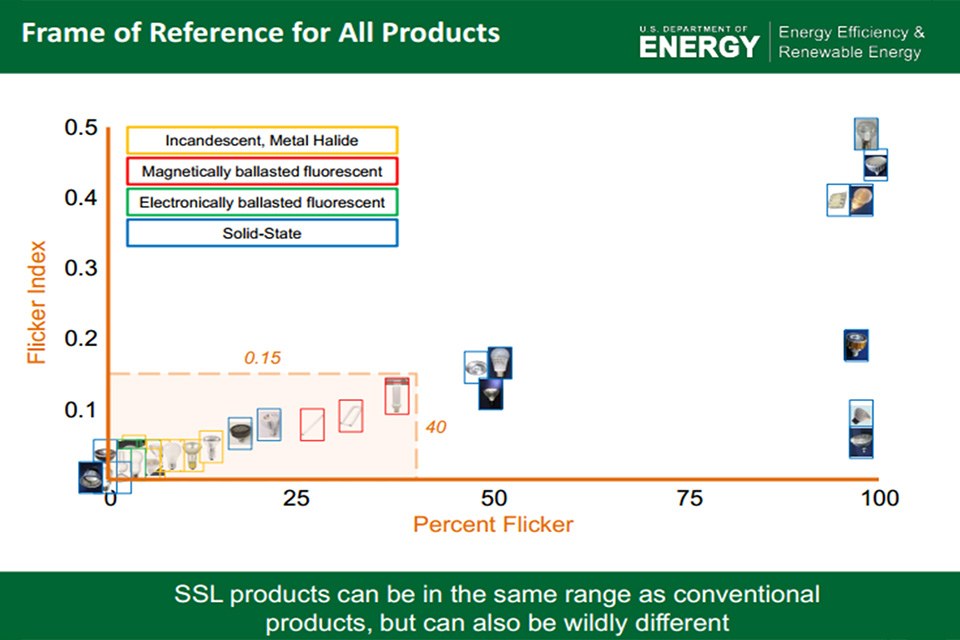

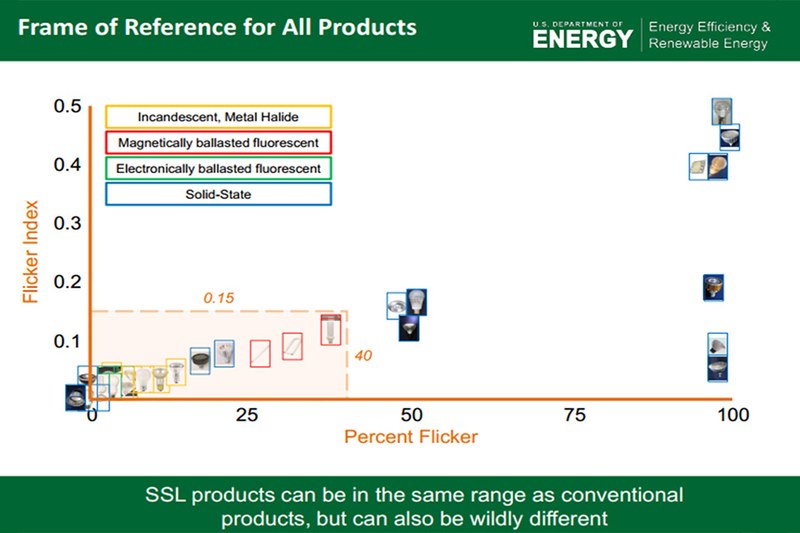

PNNL investigated 25 lighting products currently in the market now (figure 5), ranging from traditional incandescent bulbs, metal halide lamp, and fluorescent to LED lights to analyze the differences in flickers. In the diagram, the closer the picture is to the bottom left, the minimal the flicker; and more severe the flicker when it is closer to the top right.

Among incandescent, metal halide, and fluorescent lights, fluorescent lights pose the severest flickering issue. But for other traditional lights that belong in the same categories, their flickering severity seem to be pretty close to one another regardless of their manufacturers; which would explain majority of the manufacturers have similar levels of technical skills in tackling the flickering issues.

Taking a closer look at the intriguing test result on LED lighting products, the flickering variance across the light sources is unexpectedly large, especially when four samples found flickers severely located on the upper right corner of the diagram, even worse comparing to most conventional lighting; however, three samples were found with almost zero flicker located the lower left corner.  Figure 5: The flicker comparison of lighting products (Sources: Michael Poplawski and Naomi Miller, ”SSL Flicker Fundamentals and Why We Care” - U.S Department of Energy, 2014)

Figure 5: The flicker comparison of lighting products (Sources: Michael Poplawski and Naomi Miller, ”SSL Flicker Fundamentals and Why We Care” - U.S Department of Energy, 2014)

Solving LED Flicker issues

According to the market research and studies above, we can see that certain manufacturers could achieve flicker-free performances, but there are still a handful of manufacturers out there that have severe flicker issues. In other words, LED flicker issue is a solvable problem; it’s just the matter of how much the manufacturers are willing to invest in its materials and productions. Taiwanese high-power LED manufacturer Aeon Lighting Technology’s (ALT) general manager states that: “the key to creating flicker-free LED light sources is dependent on whether or not the LED driver is built with double stage circuitry; but manufacturers are deterred to invest additional resources in integrating such technology due to the current market price war.”

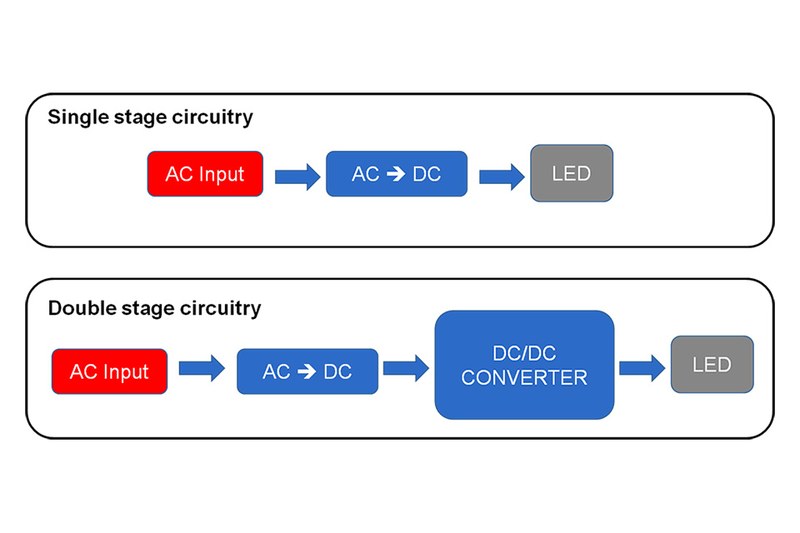

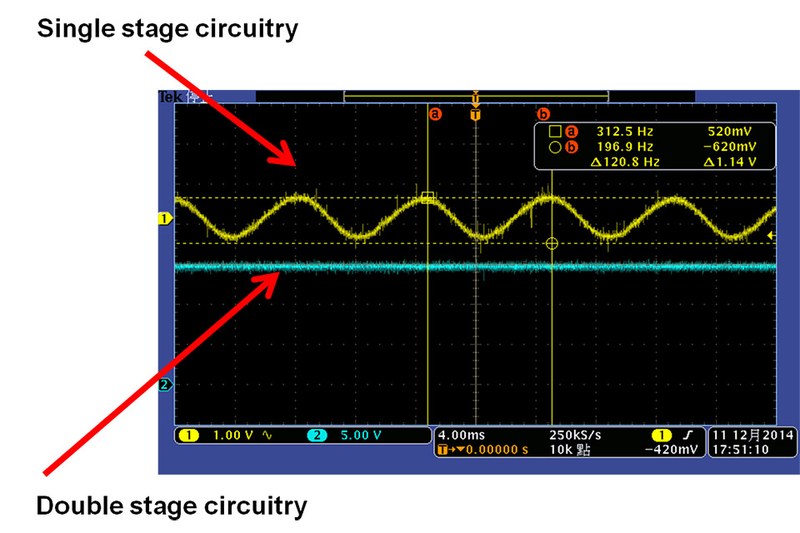

In reference to figure 6, the applied current is AC; but LED chipsets must go through circuit switching since they operate on DC. Currently there are 2 circuit structures: single and double stage structures. Single stage structure consists of unsophisticated circuit design and simple circuitry that only processes one conversion from AC to DC; and although it reduces the cost significantly, it is inefficient in minimizing ripples generated from alternating waveforms. Further, because LED chipset has a forward voltage to current ratio; even the smallest fluctuation in voltage could have a major impact on both the current and the light output, which might also result to severe flickering. A circuit with double-stage structure design could effectively filter the ripple current and convert it into a stabilized current flow, which will then be used to power the LED chipset with greater stability and reduced flickering; thus the high cost.

To fit two-stage structure’s extended PCB surface volume into the power source is another challenge that puts manufacturers’ circuit designing skills to the test. Additionally, safety regulations dictate that the components within the power source must have a fixed distance in between, making compliance to safety standards another challenging technical threshold. Manufacturers must invest higher capital to integrate the double-stage circuit structure to tackle the flicker issue, thus the pricing is reflected upon the quality of the components in which the high quality LED lights are made.  Figure 6: Single and double-stage circuit structure comparison

Figure 6: Single and double-stage circuit structure comparison  Figure 7: Single and double-stage structure power output comparison

Figure 7: Single and double-stage structure power output comparison

Conclusions

Flickering was never a new topic; it began since the traditional lighting was introduced. But the increasing presence of the LED lighting in the market has reignited another controversy in flickering, except this time worse than before. Some of the existing LED products in the market now have flicker issues far more serious than traditional fluorescent lamps; which would make us wonder what other impacts it might inflict on humans after prolonged exposure to such detrimental light source.

Unfortunately, most consumers’ primary concern is whether or not the pricing fits their profile, without understanding that many existing manufacturers would lower their cost and quality and potentially put consumers’ health at risk, just to cope with their price demands in exchange for market dominance.

Ultimately, it all comes down to consumers to consider whether they want to reduce cost at the expense of risking their physical and mental well-being, or provide the most suitable lighting environment that could evoke positive mood and increased productivity.

References:

Michael Poplawski and Naomi Miller, 2014, SSL Flicker Fundamentals and Why We Care. U.S Department of Energy, http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/miller_poplawski_flicker_lightfair2014.pdf, accessed Dec 8, 2014

Rebekah Mullaney, 2011, Studies Published on Minimizing Flicker from SSL Systems; ASSIST to Release Related Recommendation, http://www.lrc.rpi.edu/resources/newsroom/pr_story.asp?id=205#.VIrDGyuUcQ0, accessed Dec 8, 2014.

U.S Department of Energy, 2013, Solid-State Lighting Technology Fact Sheet, http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/flicker_fact-sheet.pdf, accessed Dec 8, 2014.

About Aeon Lighting Technology:

Aeon Lighting Technology (ALT) is a leading high-power LED manufacturer that focuses on precision and quality. ALT has acquired hundreds of patents, including state-of-the-art heat sink technology and has been awarded numerous international awards, including M Technology Award (2009), iF Product Design Award (2010), Red Dot Design Award (2011), and Good Design Award (2012). ALT has also passed international safety certifications such as Energy Star, DLC, UL, ETL, CE, PSE, C-TICK, LVD, FCC, TÜV, etc. ALT’s team of designers, engineers and sales strive for perfection and provide premium quality products and service for customers worldwide.

For further information, please visit Aeon Lighting http://www.aeonlighting.com.