LDS Process Allows for New LED Lighting Product Layouts

Due to technical progress with LEDs, ever more luminous semiconductors are coming onto the market. However, in order to replace the conventional light bulb, there are still some obstacles to be faced. One of them is now being overcome: MID technology and laser direct structuring are being presented with interesting new concepts at the “International LED professional Symposium.”

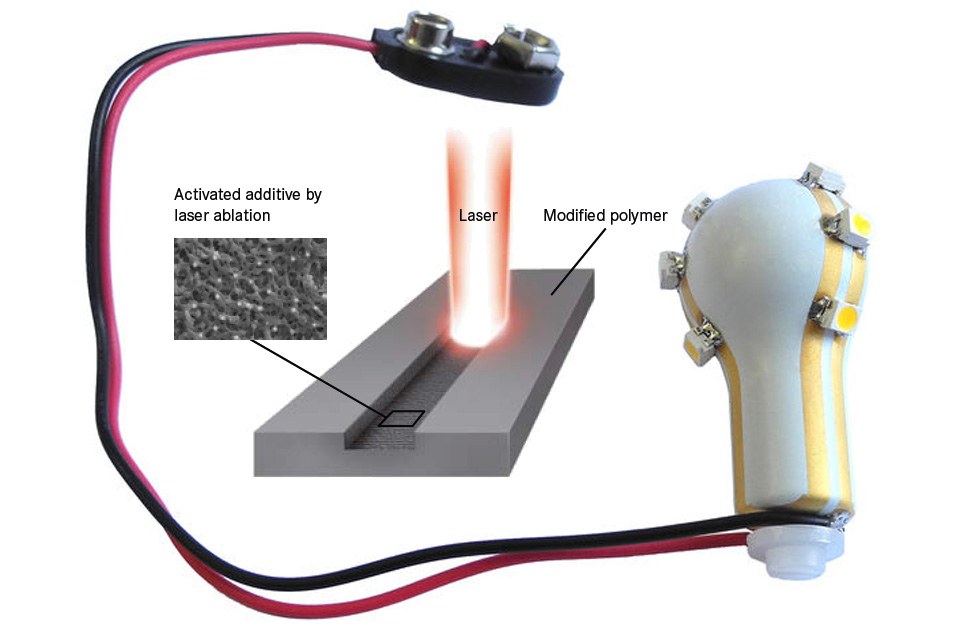

The LDS process takes place in four steps

The “Three-dimensional Arrangement of LEDs – Innovative Production Technologies” workshop at the “3rd International LED professional Symposium” (LpS 2013) will cover laser direct structuring (LDS) of 3-D molded interconnect devices (3-D MID) and the associated opportunities for LED lighting from September 24 to 26 in Bregenz. Specialists will present the LDS process, along with the available materials and automatic assembly. The presentation of the technology will be supplemented by a talk on specific customer applications. Specialists from LPKF Laser & Electronics AG, Essemtec AG, MidTronics GmbH and RF Plast GmbH will appear as presenters.

Upgrading of three-dimensional plastic bodies with strip conductors is the domain of LDS. The conventional component thus takes over electronic functions. Components that are manufactured with this technology can be found in more than half of the smartphones available today. The advantages are obvious: The LDS components are much smaller and lighter, can be quickly adapted to new requirements and also cut down the need for separate components.

With LDS components, two important requirements for LED lights are met. LED lights achieve a 3-D directional characteristic and using heat-conducting plastics as the carrier material solves the temperature problem.

LPKF will present another innovation in Bregenz: a metallic carrier is coated with an LDS-capable coating powder and can be provided with metallic conductors after laser structuring. Completely new areas of application thus result: metallic bodies of any shape are transformed into carriers for LEDs, and also act to discharge heat. A first sample built using this technology also serves as the cover picture of the invitation – an LED light that is similar to a conventional car lamp in size and appearance.

Find more information on the symposium at www.LpS2013.com and register for the workshop at www.Lps2013.com/registration (participation fee 180.00 euros).