Manufacturability of OLED Encapsulation and Light Extraction

Applications for OLEDs in lighting are opening unique possibilities for designers; however, the organic materials make OLEDs more fragile than LEDs. A higher-index Luminit Light Shaping Diffuser® developed into a barrier film could be an excellent substrate for OLEDs, encapsulating them while simultaneously supporting them.

Although organic light-emitting devices (OLEDs) don’t currently enjoy the commercial success in general lighting of its more established parent, the inorganic light-emitting diode (LED), applications for OLEDs in lighting are opening unique possibilities for designers. While an OLED is similar to a traditional LED, the light-emitting region in OLEDs is a layered set of organic materials related to plastics. In LEDs, this region uses layers of crystalline semiconductors. The use of organic materials gives OLEDs certain advantages over LEDs. For example, OLEDs can be flexible, while LEDs cannot. The active areas of OLEDs can be much larger than the active areas of LEDs as well, covering square meters instead of millimeters.

Unfortunately, the organic materials make OLEDs more fragile than LEDs – after all, soft plastics are easier to damage than hard crystals. OLED materials are also particularly sensitive to organic solvents, water (humidity), and oxygen. To protect OLEDs from these chemicals, an OLED can be encapsulated in a material that (1) does not use organic solvents, (2) prevents transmission of humidity and oxygen, and (3) does not support a static electric charge (which would destroy the OLED).

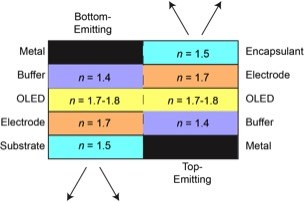

OLEDs can be configured as either bottom-emitting or top-emitting; the difference between turning a top-emitting OLED upside down and calling it a bottom-emitting OLED is the thickness of the substrate layer vs. the thickness of an encapsulant or barrier film (Figure 1).

Figure 1: Top- and Bottom-Emitting OLED Configurations

The substrate is usually much thicker than the encapsulant – hundreds of μm compared with hundreds of nm. The encapsulant, if used as a barrier film, normally consists of several layers, alternating between organic polymers and inorganic oxides The metal electrode is shown in Figure 1 and is a light reflector as well as an electrode, but direct contact between the OLED material and metal usually results in damage to the OLED and hence a loss of efficiency.

Optically, the refractive index of the buffer is unimportant, but the refractive indices of the OLED, transparent electrode, and substrate (or encapsulant) are critical. The reason is that, when light passes from a region of higher refractive index into a region of lower refractive index, light propagating at an angle greater than a critical angle (θc) with respect to the surface normal are reflected back into the material. This total internal reflection (TIR) occurs both at the interface between the electrode and the substrate or encapsulant, and at the interface between the substrate or encapsulant and air. One way to avoid TIR is to ensure that all materials have the same refractive index (this is impractical, seeing as the electrode material has a known refractive index of ~1.7 and the air has a refractive index of ~1.0). Another is to vary the surface normal by patterning the surface – which is what Luminit does with its Light Shaping Diffusers™ (LSD).

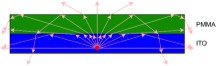

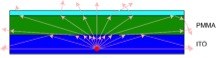

To demonstrate the effects of the LSD on light extraction, we set up a system for raytracing in Zemax. We modeled this system as if the OLED were a point source emitting into a half-space, and embedded in indium tin oxide (ITO), the electrode material. On top of this we placed a layer of poly(methyl methacrylate) (PMMA or acrylic) as an encapsulant or substrate. We then compared the output for a smooth surface at the PMMA-air boundary or an LSD surface (Figure 2).

Figure 2: Raytrace Layout for (top) Smooth Surface and (bottom) LSD Surface

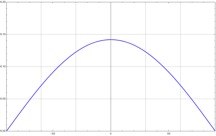

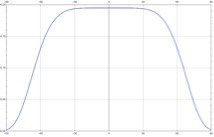

The LSD has a randomized pattern embossed on the surface, resulting in randomly-oriented surface normals; this significantly reduced losses due to TIR. In addition, the LSD spreads the light farther as a function of angle; the smooth surface produced a Lambertian output, with light intensity falling off as the cosine of the angle between the surface normal and the direction of illumination, while the light coming from the LSD was nearly constant over the center 90° (Figure 3).

a)

a)

b)

c)

d)

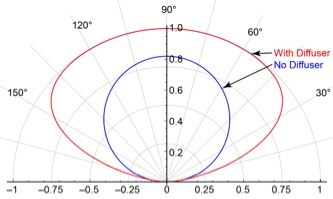

Figure 3: Plotting Light Intensity vs. Illumination Angle. (a) A smooth surface produces a Lambertian output, while (b) an LSD both increases maximum intensity by ~50% and broadens the illumination area; (c) the smooth surface has a standard solid output angle while (d) the larger solid angle of output provided by the LSD includes more than twice the light extraction as the smooth surface

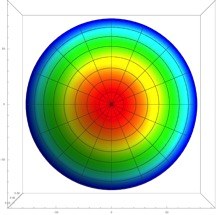

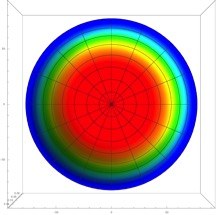

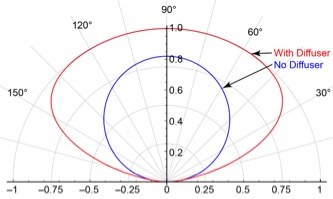

Using the model shown in Figure 2, slightly over twice as much light was extracted from the OLED using the LSD pattern than if the surface were left smooth. We ran the model again with PMMA replaced by a material whose refractive index matched that of ITO, and found that in this case the LSD-patterned surface extracted 3× as much light as the smooth surface. We plotted the results of Figure 3(a, b) in the standard polar plots used by lighting (Figure 4), normalized to the LSD output, and found that the patterned surface provides better results at all angles.

Figure 4: Polar Plot of Relative Intensity for Smooth Surface (blue) and LSD Surface (red)

The polymer that we currently use for LSD manufacture is free of organic solvents, and we have developed versions that provide some barrier against humidity and oxygen (with greater success blocking oxygen). Its refractive index is ~1.5, as modeled here, which results in lower potential output than we would get with a higher refractive index, and we are working on increasing the refractive index of our polymer. A higher-index LSD, developed into a barrier film, could be an excellent substrate for OLEDs, encapsulating them while simultaneously supporting them.

For more information on Luminit Light Shaping Diffusers®, contact sales@luminitco.com