Trends in Horticulture Lighting

Cree has been a leader in general lighting applications for over 20 years and has customers ranging from restaurant chains to global government agencies. Paul Scheidt began his career in Cree in 2005, working on the development of their lighting applications. During this time, he has seen an increase in the horticulture lighting application. LED professional spoke to Paul Scheidt about horticulture lighting and what he thinks is behind this recent trend. He also shares his views of what he thinks the future holds for both Cree and horticulture lighting applications.

LED professional: When we recently met in Philadelphia at LFI you sparked our imaginations when we spoke about horticultural lighting. When did Cree move into this lighting application field, and how did you become interested in it?

Paul Scheidt: I have been with Cree for 12 years and I have been focused on lighting applications for most of this time. Cree is a world leader in general lighting applications but we had seen, from our existing customer base, specifically in the United States, a growing interest in our horticultural lighting applications. This has mainly happened over the last two years. Our customers that were using horticultural lighting started to grow in terms of their production size. It went from our clients having very small accounts, with the niche players, to much larger contracts as the adoption of their products was growing.

The industry as a whole at this point started to pay attention to the application. The process was, if you’ll excuse the pun, very organic. We saw our customers focusing on the application and our customers growing in size. Through that, we then started to learn more about the application; specifically about what kinds of LEDs people are looking for and in what direction the market is headed.

LED professional: It’s fascinating how these trend cycles begin; can you tell us what changed in order for this shift in horticultural lighting to happen? And why now?

Paul Scheidt: The factors driving it depend on where you are. From the US prospective, especially in California, a lot of drivers have come from the continued legalization for medical marijuana. As the restrictions are loosening up you have a pretty big component of pharmaceutical companies that are looking into the properties of marijuana.

However, in the broader picture in Europe, and to a lesser extent in the US, there is a movement centered on indoor crop production and creating huge indoor farming facilities. There is certainly a trend to try and grow more crops and certain types of food indoors for a variety of reasons, such as pest control and environmental control to increase yields.

Agriculture is a much different application than general lighting since in agriculture you are dealing with yield and a measurable, objective quantity. The end users, the farmers, are very much more risk adverse then the general lighting communities. They want to see results and data before they invest and they conduct trial runs themselves. It will be a long adoption process. It will play out very much like municipalities adopting LED street lights.

LED professional: Efforts have begun to make the standardization of horticultural processes around installation as well as for creating luminaries. Do you know how far along this process is and if what the plants require has been gauged and referenced for producers to use?

Paul Scheidt: That is a big question. What I can say is that it is the IP that lighting manufactures want to invest in and hold on to. There isn’t a lot of public information out there on this for this very reason. These are the fundamental questions our clients want to be able to answer for their customers. Cree, as a supplier to those companies, isn’t investing in this type of research.

LED professional: In terms of the market share in general, and in relation to Cree, how important is the horticultural lighting sector?

Paul Scheidt: From Cree’s prospective it is still a relatively small application in comparison to other things, such as indoor and street lighting, but there is still a lot of potential as we are only getting started. The LED luminaires coming out this year will be the products that have a clear value proposition in terms of their cost effectiveness and the returns they can offer versus the incumbent technologies. With adoption curves, you look for the point where things go from being something quite small to where they become mainstream, and in horticultural lighting we appear to be getting close to that point. It is still a niche technology but with the changes we are seeing, and as more people invest, mass adoption will follow.

LED professional: What are the real advantages when using LEDs in these applications? Can you tell us about what improvement factors there are in the crops and maybe a little about the products and installation process?

Paul Scheidt: With LEDs we are at a point now that light source efficiency, forget about putting them in a luminaire; just the raw LED versus a raw lightbulb from a high pressure sodium lamp or a florescent lamp, have caught up and have been able to deliver the same sort of efficiency for plant lighting.

Obviously LEDs have had clear advantages in other lighting applications for quite some time but I think that is one of the reasons why LEDs used in this application have taken so long. The light sources used now are pretty efficient and it took a long time to get to the point where LEDs can offer an efficiency advantage.

Right now, once you put them into luminaires a lot of the power saving you see, especially against the high-pressure sodium lamps, really comes from being able to put the light where it is supposed to go.

So it’s not like your traditional lighting applications where you can save five times the energy. We are at the point where you can save 20%-30% of the energy depending on the application. That is obviously attractive because we are at a point where LEDs have an advantage of going one to one against an existing light source.

The second major advantage of LEDs is the spectral control they offer, specifically over time, to tweak the spectral content to carry out very specific functions: influencing the shape of the plant, influencing the taste of the edible plants and being able to control disease. These functions were all themes discussed in May at The Horticultural Light Conference.

We are at the beginning of figuring out exactly what potential is there. To pull off these kinds of functions requires LED lighting sources, because there is no other technology that can do it.

LED professional: In terms of the efficiency regarding the distribution factor, how important are these dimensions or the form factor of the luminaire when building up production and installation, especially in relation to the heat, as we hear heat is a problem in horticulture?

Paul Scheidt: The heat widely depends on where you are, what season it is and what you are trying to grow. It is similar to the debate that had to happen with LEDs and traffic signals. If you are in a hot climate then you probably don’t want the heat, but then if you go somewhere with extreme cold and snow, heat is somewhat beneficial in a traffic signal application to help melt the snow and ice and to increase visibility.

Heat is very contextual as to where you are, what season you are in and what you are trying to grow. Does the crop like heat or does it not like heat? The heat factor is still up for debate, I don’t think there is a clear answer. LEDs are what they are; they can generate less heat which can be a good thing for certain plants.

With regards to the form factor of the luminaire, this is a consideration in supplemental lighting. By this I mean adding additional light to an environment, like a greenhouse that primarily uses sunlight, then form factor is an issue. You do not want to create too much shading on the plants. However, there are other environments where the artificial light is the primary light source and in these cases the form factor is not so much of a problem.

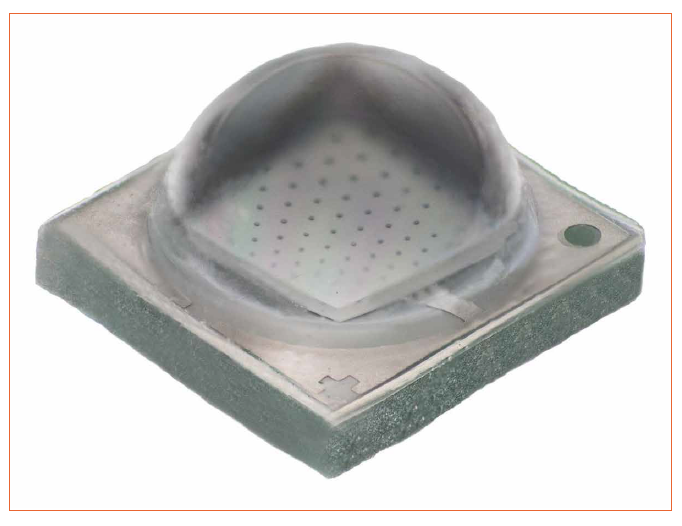

The latest generation of XP-G3 Royal Blue LEDs is an especially efficient horticulture optimized product

The latest generation of XP-G3 Royal Blue LEDs is an especially efficient horticulture optimized product

LED professional: With regards to the other functions that can be built into plants themselves, such as form and taste, where is the research on this at the moment? How does that knowledge effect future components and do you need new components to cover all these new functions wanted from plants?

Paul Scheidt: It’s too early to tell right now. The industry agrees that the research needs to come from the academic institutions. Everyone is looking to the universities around the world to do the fundamental research. I know many of them have been engaged and have been funded to take on these tasks and to try to figure out what the ideal light recipe or growing environments for certain plants is.

A lot of this research is still very fundamental and at its early stages. We are at the beginning of trying to understand it and therefore it is very hard to say at this point in time that there is something very useful about to happen with certain wavelengths. So far, from what I have seen, there have not been a huge amount of people asking for different kinds of wave lengths from those currently available from the LED industry. However, that may change depending on the research that happens.

LED professional: Are there specific spectral ranges that have the greatest effect so far, or is it too early to say?

Paul Scheidt: Again, it depends on the function. There are two specific crops I have learnt about at recent conferences. One was specifically around lettuce production and the growers that are trying to promote a chemical that turns leaves from green to red. They are doing this because it is known to be an anti-oxidant. For the last couple of days before harvest they place the crop under the blue and red light and this promotes the reddening of the lettuce. That is one function where a special LED light combination can increase the value of a crop.

Another example comes from basil crop production. When you grow basil indoors you don’t have bugs, but you still have disease. There is a big problem of controlling mildew that grows on the plants and decreases the yield. There is a study that shows if you turn on a red light in the middle of the night it disrupts the cycle of the mildew, in which case you could effectively control disease by using red light. I think we will continue to see more discoveries like this in the future.

LED professional: What future areas of development in the technology itself do you think there might be?

Paul Scheidt: We are already quite far down the road for LED technology. There has already been a huge effort in the LED industry to increase output, decrease costs and improve efficiency. Unlike with the outdoor lighting applications where we started at one efficiency level and now they are double what they were. We are at the end of that curve when it comes to horticulture applications, there will be no doubling or tripling of efficiency. There will be performance gains, but it is not like LEDs will skyrocket!

LED professional: What was the latest component Cree launched and how do you set these different kinds of LEDs together to reach certain spectrums?

Paul Scheidt: The most recent was the XLamp XP-G3 Royal Blue, which is by far the highest output and highest efficiency blue LED available on the market. It can be used in many different applications, but primarily it is for use in the horticulture applications. Cree’s approach to the market is pretty similar to the general lighting market in that we have a broad portfolio and many performance classes in order to help our customers to make the luminaire they want. From the performance angle, the XP-G3 Royal Blue is the highest performing LED in the market and it is up to 81% wall plug efficiency.

We also excel at long-term reliability and we carry out extensive LM-80 testing to back up our lifetime promises with data, which suits the risk adverse users. It is incredible how the human eye is exceptional at adjusting to brightness, we marvel at it. The human eye can adjust to a 30% difference in brightness. When you go into horticulture application the light output level directly correlates to the yield that you see in the plants. There is no buffer, when lights dim, the yield goes down. If something degrades very quickly and is 100% for one growth cycle then goes down to 90% for the second growth cycle, you will see a reduced yield. There is no room for adjustments. Traditional LED systems are more expensive then their counterparts, so they have to last.

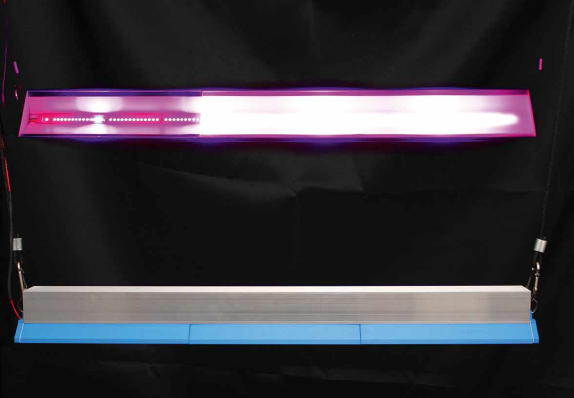

Reference designs with different properties are already prepared

Reference designs with different properties are already prepared

LED professional: With regards to 2018, what can our readers expect to come from Cree?

Paul Scheidt: I can certainly say there will be more package options as we continue to create more platforms across the board for all applications. We will then be making them work for Horticulture applications. We will keep doing what we are good at, which is enabling our customers with many package and performance options. Cree’s strategy is to be a pure component supplier for horticulture and we will be focusing on that in the future.

LED professional: Thank you so much for taking the time to talk to us today and for sharing your thoughts and ideas. There is still so much to discover and look forward to in the application of Horticultural Lighting. The future is set to be exciting and challenging.