Thermal Issues Posed by Compact Packaging and IoT for Next Generation SSL

Besides general lighting, LEDs are penetrating many areas. At the same time, Internet of Things (IoT) has been rapidly evolving. Added electronics are expected to add an additional 70% to overall heat generation. Therefore, solving thermal problems will become more important again; on a par with footprint area and cost. Prof. Mehmet Arik, Director of EVATEG Center for Energy Efficient Electronics and Lighting Technologies at the Ozyegin University, and Umut Zeynep Uras, master student at the Ozyegin University, present some of the current, local, hotspot thermal issues caused by tight packaging. The severity of the problem for future lighting systems with added IoT will also be discussed. Finally, possible technologies to meet those challenges will be shown.

While light emitting diodes (LEDs) have been penetrating in many areas of general lighting and automotive lighting, display applications are some of the first adopters of the technology. White and many color offerings as well as high quality characteristics provide unique advantages to end customers. However, thermal management is still one of the major bottlenecks due to impact on light extraction and lifetime as well as weight adder in the physical system. Internet of Things (IoT) has been rapidly evolving, and lighting systems with over 550 Billion fixtures globally are seen as a great opportunity for a widespread application space.

Added electronics for communication, control, sensing and power for IoT features are expected to contribute an additional amount of over 70 percent to overall heat generation. It will be shown how a big problem becomes more critical at the same volume, footprint area and cost. In this paper, some of the current local hot spot thermal issues due to LED tight packaging for a number of applications with attention on IoT added future lighting systems and the severity of the problem will be shown.

Introduction to the Set of Problems

Light emitting diodes (LEDs) bring unique advantages to a wide range of lighting applications such as automotive lighting, security lighting and display technologies. Due to their various color options with high luminous efficacy, LEDs have dominated the lighting industry. Although LEDs are considerably high energy efficient sources compared to conventional old-fashioned systems, still 70-80% of input electrical input power is converted to heat [1, 2]. If released heat cannot be transferred to ambient, it causes elevated junction temperatures of LEDs which lead to optical losses, catastrophic defects and lifetime problems [3, 4]. Therefore, thermal management is a significant concern for sustainability of LED lighting systems. Several thermal management solutions have been studied in the literature. According to the ambient conditions and requirements of problem, passive or active cooling technologies can be used to overcome some of those thermal issues. Internet of Things (IoT) has gained tremendous attention during the last decade and more focus on how to utilize IoT in LED systems for the last five years. Though smart sensors and network capabilities are some of those first technologies in smart lighting systems, they will offer tremendous opportunities in upcoming years. However, none of the current LED lighting applications reach the dream of IoT goals yet. Therefore, it would be interesting to see some of those high ends and high functionality features in possible LED systems. As thermal management is still a major challenge in LED systems, more functionality with IoT will pose substantially harder problems for scientists and design engineers. It is important to review some of the current approaches to understand the thermal issues in LEDs, and then attention will be turned to IoT embedded LED systems.

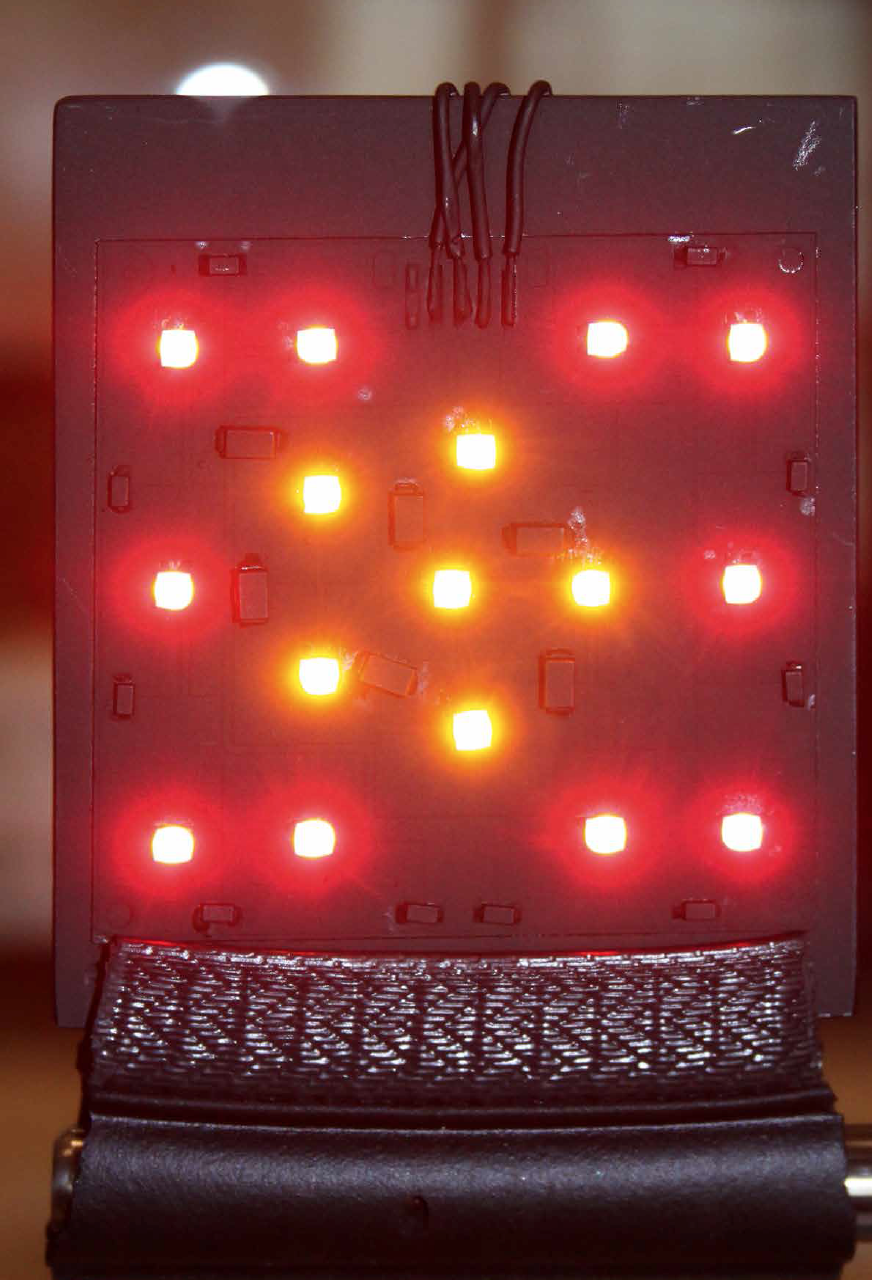

A current automotive rear lighting system is perhaps the closest LED technology in a compact packaging form factor that will IoT features will pose on new systems. A double sided LED light engine houses LEDs at the front side, while densely populated electronics and sensors are used in the backside of the board [5, 6]. A detailed study has been presented by Uras et al [5] on the thermal management issues of an LED automotive lighting system. The system has tight packaging problems, limited lifetime, vibration issues, aggressive power needs. It cannot easily adopt active cooling technologies, so they have chosen to investigate passive thermal management solutions. As a passive thermal management technique, thermal performance of conventional PCB can be enhanced via high thermally conductive PCB substrates [7]. Due to poor thermal conductivity of conventional FR4 PCBs, LEDs and electronic components cannot diffuse excessive heat. Therefore, local hot spots occur over the PCB and junction temperature gets higher. In this regard, metal core PCB improves thermal performance of the system because of its higher thermal conductivity [8]. However, in compact and dense lighting engines, MCPCBs are not efficient to meet operational requirements of LEDs as well. Thus, a novel heat spreader technology is required.

Tamdogan et al. [9] reports that high power LEDs and electronics require novel thermal management techniques such as micro jet, micro channel and immersion cooling methods. They studied computationally and experimentally thermal characteristics of a high-power LED light engine utilizing various cooling methods with different coolants. Despite of the fact that multiphase liquid cooling performs better, bubble generation around the LED chip leads to significant lumen degradation. However, light engine with single phase liquid cooling showed efficient thermal performance while enhancing light extraction by 15%. Therefore, the study reveals that single-phase immersion liquid cooling is a possible cooling method to enhance the thermal performance of high power LEDs. In another study, Arik et al. [10] presented synthetic jets as novel cooling devices for high power electronics. Synthetic jets are practical for many applications due to their small sizes compared to other forced convection devices.

![Automotive lighting system: LED side (a), electronics side (b) [6]](https://www.led-professional.com/media/resources-1_articles_thermal-issues-posed-by-compact-packaging-and-iot-for-next-generation-ssl_screen-shot-2017-10-31-at-09-48-26.png/@@images/image-1280-93c8bfd885cbfc68d5f0fa3beb5c282a.png) Figures 1a&b: Automotive lighting system: LED side (a), electronics side (b) [6]

Figures 1a&b: Automotive lighting system: LED side (a), electronics side (b) [6]

IoT will bring along many sensors and communication features so electronic component density of the PCBs, possibly light engine, will increase significantly while power consumption of the present electronic components rises. IoT is an environment that smart devices, sensors and actuators are connected and able to communicate with each other via an Internet platform [11]. In recent years, IoT has been rapidly evolving, and it is expected that in five years 50 billion smart devices will be connected [12]. Smart devices will be effective in many different areas such as healthcare, energy, lighting, automotive, smart grids and home automation [12, 13]. IoT will also integrate these individual areas. Such as smart buildings will manage energy efficiency of houses, it will also analyze the comfort and health of households [13]. Although IoT provides many benefits, it also has some challenges and concerns such as privacy, security, openness [14, 15] and power consumption [16]. As mentioned, by 2020 approximately 50 billion smart devices will be connected to each other. Therefore, the number of smart sensors, communication devices and electronic components will be considerably higher than today and their power consumption will be higher. Thus, power will be a significant concern for the IoT applications. For IoT devices, mobility is very important so they should operate with batteries [11]. However, present batteries have limited lifetime and energy storage problems. With the enhancing utilities of smart devices, more power requirement will occur.

In order to solve the high power consumption problem, Ju and Zhang [16] suggest that energy harvesting for low power IoT devices with small size and proper energy storage volume is a need and they propose Internet of Battery-less Things (IoBTs). One of the major goals of the Internet of Things is to enhance the capacity of devices and electronics while reducing their energy consumption. In this regard, besides investigating novel low power technologies, minimizing the power loss of the components is crucial. New devices have been developed with the concept of low power consumption. However, due to small size constraints and high usage of sensors, actuators and electronics, increase in total heat flux of the system constitutes efficient thermal management requirements. As mentioned before, even today thermal problems in electronic systems, with the increasing number of sensors and electronics that provide connectivity of things, heat flux over electronics is expected to increase over 70%. Because of poor thermal conductivity of conventional PCBs, local hot spots which affect the reliability of the system will occur. Thus, novel PCB solutions should be improved.

Lighting systems with over 550 billion fixtures globally are seen as a great opportunity for a widespread application. Lighting systems are used almost in all living spaces and a large number of outdoor areas. IoT applications will also be active in all of these places so lighting fixtures may constitute a platform. According to Lowe [17], automobiles have a great number of microcontrollers, and due to their mobility, they can be recognized as ultimate smart mobile devices so the automobile industry will take a critical role in IoT conversion. Lighting fixtures of automobiles can be enhanced to collect and sense data from the environment due to their present electronic structure and the place where they mounted on the automobile. Therefore, in this study an automotive rear lighting system is studied. Thermal challenges which are caused by the increase of heat flux from components with IoT will also be faced in automotive lighting systems. Due to size and cost concerns, LEDs and electronics are integrated on the same board. Moreover, all lamp functions, stoplights, signals and positions operate on a single PCB. Therefore, even in the present condition, complex thermal problems occur on the selected LED lighting system. When IoT added over traditional lighting fixtures are considered, hard problems will be harder at the same volume and footprint area.

In this study, thermal properties of an FR4 light engine with compact packaged electronics is analyzed, then as an alternative solution a metal core PCB is investigated. When it is understood that MCPCB is not adequate for compact light engine, a heat spreader which consists of an advanced nano-structured vapor chamber is studied due to its high thermal conductivity. It can provide solutions for the current thermal issues by abating local hot-spots. Later, attention is turned into mimicking the same system adding IoT features like imposing a higher heat generation rate. Computational models are developed and results are discussed in detail.

Figure 2: FR4 based LED engine while all functions operated simultaneously

Figure 2: FR4 based LED engine while all functions operated simultaneously

Experimental Study

Vehicles are expected be one of the major parts of the IoT due to their current electronics infrastructure [17]. Electronics have already been used in several purposes in a number of areas in vehicles. For instance, power electronics are used in lighting systems of automobiles in order to drive LEDs. These electronic systems can establish a substructure for IoT applications. Therefore, in this study, an LED light engine which is used in automotive rear lighting system will be analyzed. Rear lighting systems consists of three different functions which are signal, stop and position (Figure 1). Conventionally, for these three functions, three separate light engines are typically used. Due to the unique advantages of LEDs, to integrate all these functions on a single light engine is possible. Although LEDs are energy efficient sources, if all three functions operate simultaneously, heat generation of the combined LEDs and driver electronics increase. Industry preferred PCB material for light engines is FR4 due to availability, ease of processing and cost. However, due to poor thermal conductivity of FR4; heat generated from components over PCB cannot diffuse uniformly so local hot spots occur over components and PCB. Thus, junction temperature of LEDs can surpass 100°C which is the critical temperature for most LEDs [3]. Therefore, LEDs and driver electronics are placed over separate PCBs due to thermal limitations of conventional boards. However, this study aims to combine electronic components and LEDs on a single compact PCB. When IoT features are added into the current system, the number of electronics and their power consumption will increase so thermal problems will continually increase. Therefore, a novel heat spreader board technology should be developed to overcome these thermal issues.

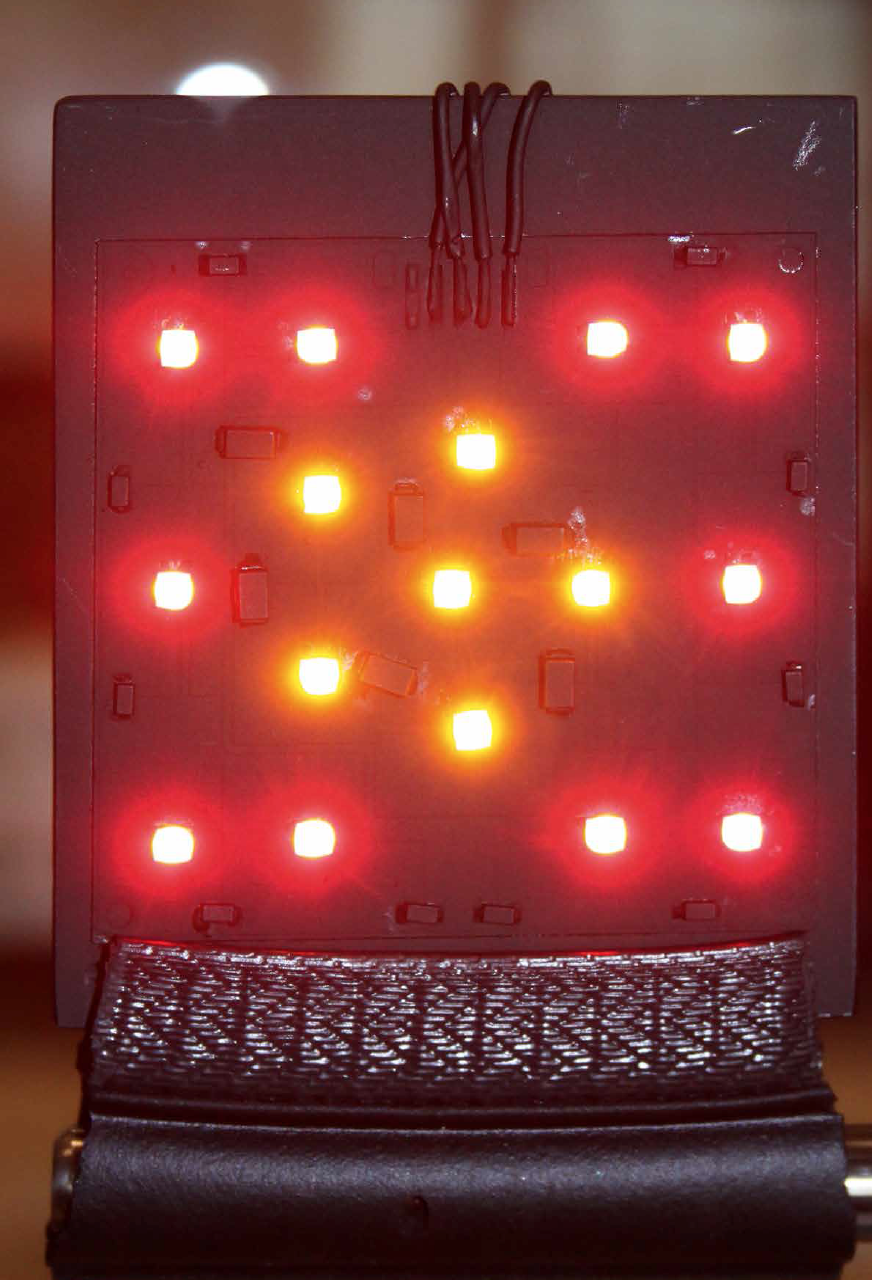

In order to develop a novel heat spreader board, understanding the current problem in conventional FR4 boards via observing its thermal performance is the first step. Metal core printed circuit boards (MCPCB) have also been used in recent years to improve the thermal performance of LED light engines. Therefore, initially, three identical 66x80x2.75 mm light engines with FR4, Al and advanced heat spreader base are produced. Flex PCBs are designed for each substrate because vapor chamber surfaces are not convenient for printed circuits directly. Flex PCBs consist of 40 μm copper layer and 160 μm epoxy-glass fiber layer. Highly conductive double-sided adhesive with thermal conductivity of 0.60 W/m·K is used to assemble flex PCBs to front and back of each substrate. Then, 16 LEDs; 10 red LX E6SF and 6 amber LXG6SP LEDs; are mounted in the front of the PCBs. Electronics that drive LEDs are placed at the back of the PCB as figure 3.

Figure 3: Schematic of the front and back of the LED engine

Figure 3: Schematic of the front and back of the LED engine

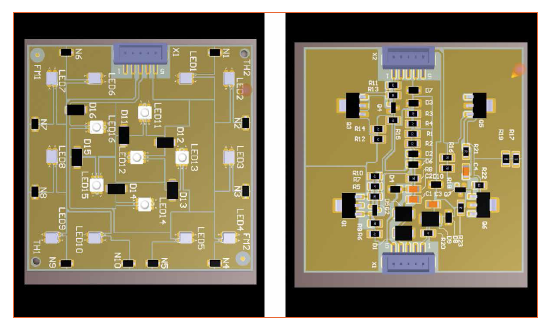

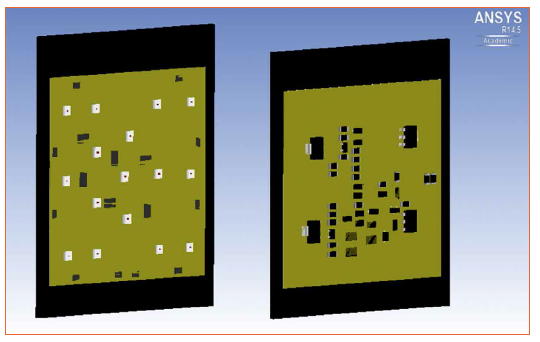

Figure 4: Computational model of the compact light engine - front view (LEDs) and back view (electronics)

Figure 4: Computational model of the compact light engine - front view (LEDs) and back view (electronics)

Computational Study

In order to observe the thermal effect of a possible power increase on driver electronics of LED light engine when IoT applications are adapted to the current system, a computational study has been conducted in the commercially available computational fluid dynamics software, Icepak 14.5 [18]. CFD simulations allow users to change model parameters and experimental conditions easily. Therefore, the computational study consists of four cases that represent expected scenarios when IoT applications are integrated to LED light engines. The first case stands for current performance of the LED light engine without any smart features addition. In the second, third and fourth cases, only power levels of driver electronics are increased by 25%, 50% and 70%, respectively. Geometrical models of the LED light engines are identical for all cases.

In the computational study, thermal performance of the FR4 based LED engine is modeled. Therefore, substrate material is chosen as FR4 with thermal conductivity of 0.35 W/m·K, while type thermal conductivity of flex PCB is chosen as orthotropic and thermal conductivity of the material is 12, 12, 0.35 W/m·K (kx, ky, kz). LEDs are modeled as LCC package with its original geometry according to the manufacturer’s specifications. Transistors Q1, Q3, Q5 and Q6 are modeled as package SOT223 and transistors Q2, Q4 and Q7 are modeled as SOT23 package. Radiant powers of red and amber LEDs are measured with the integrated sphere method. Hence, red and amber LEDs’ efficiencies are obtained as 27% and 4.9%, respectively. Efficiencies of the electronic components are accepted at 10%. In order to increase the mesh accuracy, separate assemblies are created for almost all LEDs and electronic components. A mesh sensitivity study has been performed before each computational model.

Results and Discussions

IoT features integration to current technologies will soon be essential. These new features will cause an increase in the number of electronics and their power consumptions in the same or smaller footprint areas. It is expected that overall heat generation of electronics may increase as much as 70%. Therefore, this study aims to investigate advanced heat spreader substrate technology to solve possible thermal problems of new generation electronic systems.

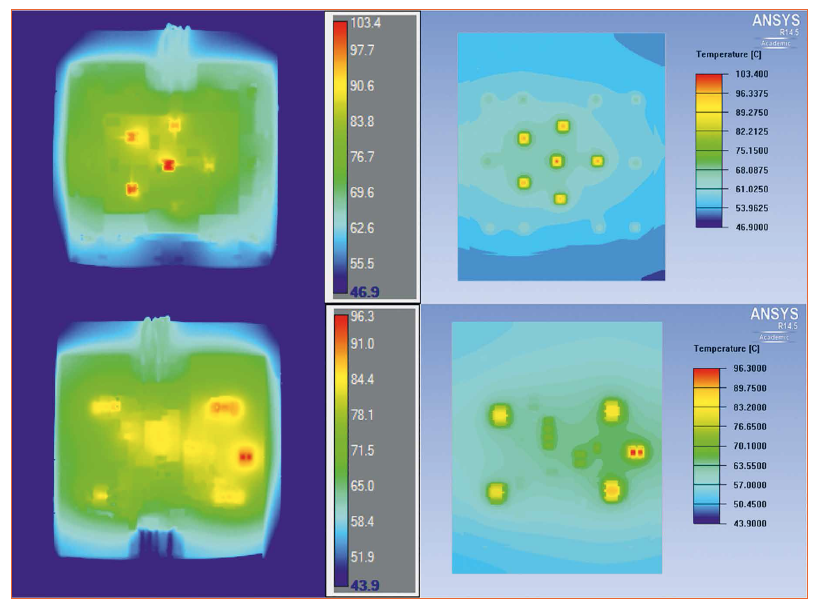

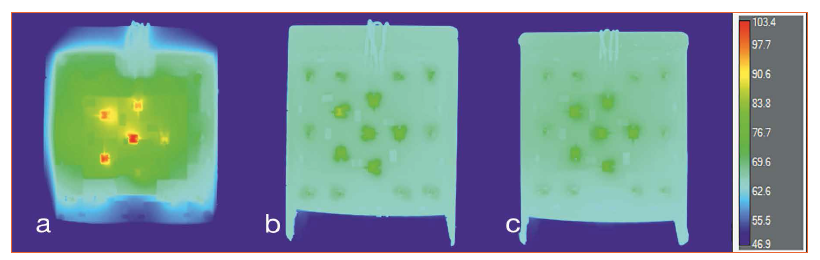

To understand the impact of IoT on the system, first the thermal performance of a baseline system, three FR4 based LED light engines, utilized in automotive rear lighting systems is analyzed via infrared thermography technique. With the help of IR thermography, surface temperatures of the front and back of the engine are captured while ambient temperature is 25°C. While maximum and minimum surface temperatures in the front of the engine are observed on amber LED- LED12 as 103.4°C and on PCB as 46.9°C, respectively, maximum and minimum surface temperature at the back of the engine are observed on resistor- R17 as 103.4°C and on PCB as 46.9°C. Figure 4a indicates the thermal distribution over the PCB based on infrared thermography. Due to the low thermal conductivity of FR4 PCB material, heat cannot diffuse uniformly over the PCB so hot spots occur over the PCB as well as on the LEDs and electronic components. During the operation, the junction temperature limit for typical LEDs and electronics is about 100°C. However, as thermal performance of FR4 based LED engine is analyzed, at the LEDs side maximum temperature of some LEDs exceeds this critical temperature. Moreover, at the back side of the board, temperatures of two resistors are very close to operational temperature limit.

Figures 5a&b: IR thermography results (a) and CFD temperature distribution (b) of FR4 based light engines operate simultaneously during all functions (LED side at the top and electronics side at the bottom)

Figures 5a&b: IR thermography results (a) and CFD temperature distribution (b) of FR4 based light engines operate simultaneously during all functions (LED side at the top and electronics side at the bottom)

In order to validate experimental data and investigate possible thermal effects of IoT addition to the current system, the light engine is modeled in CFD software with higher power generation rates. Firstly, CFD model of FR4 based light engine with its original power is solved. Then, for the validation process, CFD results are compared with experimental results as figures 5 and 6. For comparison, 10 points are selected from LEDs and electronics. As it is presented in figure 6, among these ten points, the maximum difference is experienced on transistor Q5 as 4%. During CFD model creation, original geometry of the LED engine is simplified which caused differences between experimental and computational results.

Figure 6: Comparison between IR thermography and simulation results

Figure 6: Comparison between IR thermography and simulation results

Since a very good agreement between computational and experimental results is observed, the model is solved for other CFD cases to analyze thermal performance of the current LED engine with smart applications. It is expected that IoT features leads to a 70% increase in power consumption of electronics. Thus, the model is modified via increasing power consumptions of electronics by 25%, 50% and 70% which represents future smart LED engines.

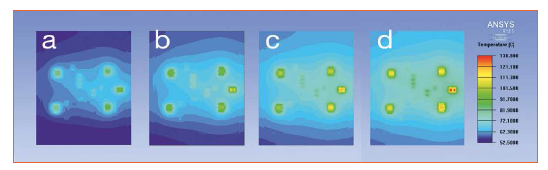

Figures 7a-d: Temperature distribution of electronic components placed over light engine: (a) Baseline without IoT added heat generation (b) 25% (c) 50% and (d) 70% added heat generation rates over electronics

Figures 7a-d: Temperature distribution of electronic components placed over light engine: (a) Baseline without IoT added heat generation (b) 25% (c) 50% and (d) 70% added heat generation rates over electronics

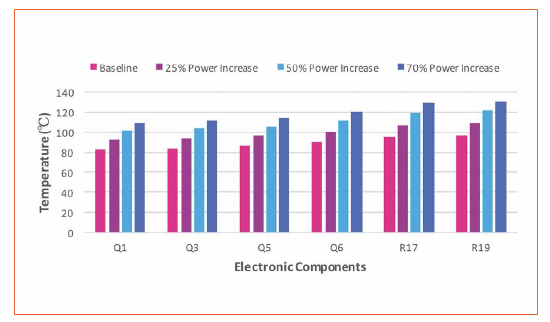

Significance of the thermal problem can be seen from figures 7a-d. While the power consumption of the electronics increases by 70%, the maximum temperature that is experienced on the electronics increase by ±25%. Temperature rise on the electronics is indicated in figure 8. The maximum temperature on the light engine goes up to 130.9°C which can lead to catastrophic failures.

Figure 8: Temperature increase of electronic components as a result of power increase

Figure 8: Temperature increase of electronic components as a result of power increase

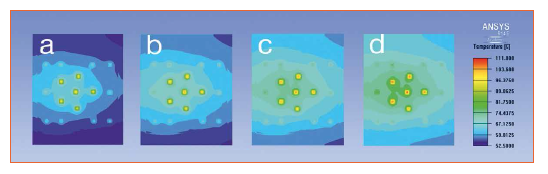

Figures 9a-d: Temperature distribution of LEDs placed over light engine: (a) Baseline without IoT added heat generation (b) 25% (c) 50% and (d) 70% added heat generation rates over electronics

Figures 9a-d: Temperature distribution of LEDs placed over light engine: (a) Baseline without IoT added heat generation (b) 25% (c) 50% and (d) 70% added heat generation rates over electronics

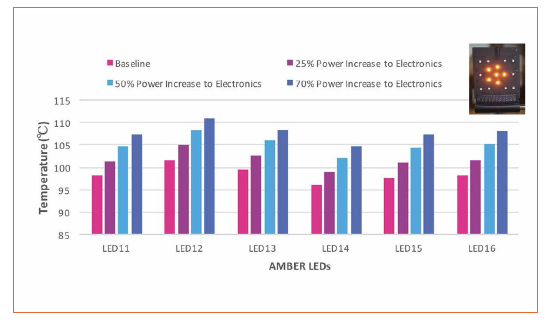

Figure 10: Temperature increase of amber LEDs as a result of power increase to electronic components

Figure 10: Temperature increase of amber LEDs as a result of power increase to electronic components

Although power consumption of LEDs are not changed in different cases, as it is shown in figures 9a-d, temperatures of LEDs and thermal distribution over the board is changed due to power addition to electronics. As it is indicated in figures 9 and 10, while maximum temperatures of amber LEDs increased by +8.5%, a +12% temperature rise is experienced on red LEDs respectively. While with 25%, 50% and 70% power addition to electronics, maximum temperature experienced on LED-12 reached from 103.4°C to 104.9°C, 108.4°C and 111.0°C, respectively. Because of the fact that when FR4 material used as substrate, the junction temperature of LEDs exceeds critical temperature even in the current situation when there is no IoT added power, an additional heat generation in electronics gets this situation more critical.

It is found that the highest temperature is observed at the centerline LED (LED-12) due to the fact that local heat generation is highest and the heat transfer path is rather limited compared to other LEDs on the light engine. Although there is approximately 13% elevation in temperature, this can be perhaps eliminated by improving the conduction performance of the board by having either highly conductive boards or vapor chamber based systems.

Figure 11: Temperature increase of red LEDs as a result of power increase to electronic components

Figure 11: Temperature increase of red LEDs as a result of power increase to electronic components

Figure 11 presents the results for red LEDs which has the minimum driving power requirements and the lowest heat generation rates. Although the heat generation at the electronics is increased by 70%, temperature rise only increased about 12%. When real automotive environment is evaluated, ambient temperature will be considerably higher than room temperature. It can be inferred that if IoT features are added to current system, the system will be more compact than today so current thermal problems will be harder. Therefore, while FR4 substrate is not adequate for even current application, for future more complex technologies, novel heat spreader PCB substrates should be developed.

Figures 12a-c: IR Thermographs of (a) FR4, (b) AI and (c) Advanced heat spreader based light engines, operate simultaneously during all functions (LED side)

Figures 12a-c: IR Thermographs of (a) FR4, (b) AI and (c) Advanced heat spreader based light engines, operate simultaneously during all functions (LED side)

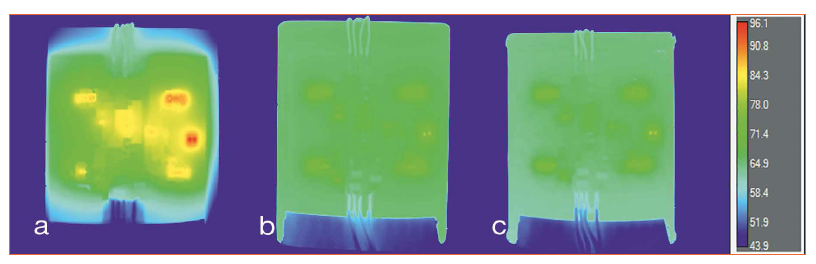

Figures 13a-c: IR Thermographs of (a) FR4, (b) AI and (c) Advanced heat spreader based light engines, operate simultaneously during all functions (electronics side)

Figures 13a-c: IR Thermographs of (a) FR4, (b) AI and (c) Advanced heat spreader based light engines, operate simultaneously during all functions (electronics side)

In recent years, metals have been used as PCB substrate material to enhance thermal performance of the LED engines. MCPCBs allow heat diffusion in three dimensions while FR4 PCBs conduct heat only in one dimension [8]. An alternative solution with an Aluminum board is designed. While all three functions operate at the same time, maximum LED temperature is measured as 84.1°C. Besides, maximum electronic temperature is obtained as 78.6°C. Thus, at the LEDs’ side and the electronics’ side, Al based board performs 18.7% and 18.2% better than FR4 based LED engine. According to figures 12 and 13, over the Al based board, more uniform thermal distribution is observed compared to FR4 based board.

Although metal based board improves thermal performance of the light engine significantly, for IoT added applications it may not still be adequate. Therefore, in this study, a heat spreader substrate which comprises vapor chamber structure proposed as a possible substrate for new generation IoT features added LED engines. Thermal performance of the advanced heat spreader substrate can be observed on figures 12 and 13. Maximum temperature of the LED is experienced as 77.9°C as the maximum temperature of the electronics is obtained as 79.4°C. Therefore, at the front side, advanced heat spreader board shows 24.7% better thermal performance than FR4 based board and at the side of the board advanced heat spreader board shows 17.4% better thermal performance than FR4 based board. Most uniform temperature distribution is observed in advanced heat spreader technology. In this regard, advanced heat spreader substrate can be an applicable solution to overcome expected thermal problems of future technologies.

Summary and Conclusions

Unique advantages of LEDs such as high lumen efficiency, wide range color alternatives and nontoxic structure, brings LEDs into the forefront. Automotive, general lighting, and display industries are dominated by LED applications. Although their electrical energy to photons conversion rate is considerably high compared to conventional light sources, still about 20% of power supplied to LEDs turns into heat which causes thermal problems. In recent years, the paradigm of Internet of Things which will be effective in all areas of our lives is in the foreground and lighting systems with over 500 billion fixtures globally are seen as a great opportunity for a widespread application. In addition, automobiles may constitute a platform for IoT applications due to their current electronics system and mobility feature. Thus, in this study, a possible candidate automotive rear LED lighting system is evaluated in terms of thermal performance for new generation IoT added applications. Firstly, thermal performance of FR4 based LED engine is evaluated and it is modeled in a CFD program. Then, the computational model is solved for different cases such as; 25%, 50% and 70% power addition to electronics to determine the adverse effects due to IoT power needs. Metal and advanced heat spreader substrate technologies are presented as a solution to overcome thermal problems.

Consequences of the study can be listed as follows:

- While power consumption of electronic increases by 70%, maximum temperatures that is experienced on electronics increase by ±25%. Maximum temperatures of amber LEDs increased by ±8.5%, when temperature rise of ±12% is experienced on red LEDs

- In case of 25%, 50% and 70% power addition to electronics, maximum temperature experienced on central LED reaches from 103.4°C to 104.9°C, 108.4°C and 111.0°C respectively

- At the LEDs’ side and the electronics’ side, metal board performs 18.7% and 18.2% better than FR4 based LED engine

- At the LEDs’ side, advanced heat spreader board shows 24.7% better thermal performance than FR4 based board and at the side of the board advanced heat spreader board shows 17.4% better thermal performance than FR4 based board

- With the usage of advanced heat spreader substrate, the most uniform temperature distribution is achieved

- As conventional FR4 substrate is not adequate for future electronic systems, advanced heat spreader board technology which consists of vapor chamber structure can be a possible substrate technology for new generation smart applications

While IoT is slowly getting into smart lighting systems, EVATEG research center is working on possible technology scenarios and thermal implications. Developing novel technologies and implementing for rapid deployment of the technology is the primary goal for EVATEG team.

References:

[1] Shanmugan, S., Mutharasu, D., and Kamarulazizi, I., 2013, “BN Thin Film as Thermal Interface Material for High Power LED: Thermal Resistance and Optical Analysis”, Optical & Quantum Electronics, Springer Science & Business Media B.V.

[2] Pounds, D., and Bonner III, R. W., 2014, “High Heat Flux Heat Pipes Embedded in Metal Core Printed Circuit Boards for LED Thermal Management”, 14th IEEE ITHERM Conference

[3] Arik, M., Becker, C., Weaver, S., and Petroski, J., 2004, “Thermal Management of LEDs: Package to System”, Third International Conference on Solid State Lighting, Proceedings of SPIE, Vol. 5187, pp.64-75. Jones, J., 2000, Contact Mechanics, Cambridge University Press, Cambridge, UK, Chap. 6. ISBN: 978-3-16-148410-0

[4] Jang, S., and Shin, M. W., 2008, “Thermal Analysis of LED Arrays for Automotive Headlamp with a Novel Cooling System”, IEEE Transactions on Device and Materials Reliability, Vol. 8, No. 3, pp. 561- 564

[5] F. S. Khosroshahi, M. Arik, C.S. Tüfekçi, “Conduction Driven Cooling of LED Based Automotive LED Lighting Systems for Abating Local Hot Spots”, 11th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, 2015

[6] Zeynep Uras U, Arık M, Tamdoğan E. Thermal Performance of a Light Emitting Diode Light Engine for a Multipurpose Automotive Exterior Lighting System with Competing Board Technologies. ASME. J. Electron. Packag. 2017;139(2):020907-020907-8 doi:10.1115/1.4036403

[7] Kafadarova, N., and Andonova, A., 2009, “PCB Thermal Design Improvement through Thermal Vias”, Recent Advances in Circuits, Systems, Electronics, Control and Signal Processing

[8] Yung, K.C., Liem, H., Choy, H.S., and Cai, Z.X., 2013 “Thermal Investigation of a High Brightness LED Array Package Assembly for Various Placement Algorithms”, Elsevier 2013, Applied Thermal Engineering 63 (2014), pp. 105-118

[9] Tamdogan E, Arik M. Natural Convection Immersion Cooling with Enhanced Optical Performance of Light-Emitting Diode Systems. ASME. J. Electron. Packag. 2015;137(4):041006-041006-8. doi:10.1115/1.4031480.

[10] Arik M, Utturkar YV. A Computational and Experimental Investigation of Synthetic Jets for Cooling of Electronics. ASME. J. Electron. Packag. 2015;137(2):021005-021005-10. doi:10.1115/1.4029067

[11] D. Thomas, R. McPherson, G. Paul and J. Irvine, "Optimizing Power Consumption of Wi-Fi for IoT Devices: An MSP430 processor and an ESP-03 chip provide a power-efficient solution," in IEEE Consumer Electronics Magazine, vol. 5, no. 4, pp. 92-100,°Ct. 2016. doi: 10.1109/MCE.2016.2590148

[12] H. Jayakumar, K. Lee, W. S. Lee, A. Raha, Y. Kim and V. Raghunathan, "Powering the Internet of Things," 2014 IEEE/ACM International Symposium on Low Power Electronics and Design (ISLPED), La Jolla, CA, 2014, pp. 375-380. doi: 10.1145/2627369.2631644

[13] T. Islam, S. C. Mukhopadhyay and N. K. Suryadevara, "Smart Sensors and Internet of Things: A Postgraduate Paper," in IEEE Sensors Journal, vol. 17, no. 3, pp. 577-584, Feb.1, 1 2017. doi: 10.1109/JSEN.2016.2630124

[14] J. A. Stankovic, "Research Directions for the Internet of Things," in IEEE Internet of Things Journal, vol. 1, no. 1, pp. 3-9, Feb. 2014. doi: 10.1109/JIOT.2014.2312291

[15] Bandyopadhyay, D. & Sen, J. Wireless Pers Commun (2011) 58: 49. https://doi.org/10.1007/s11277-011-0288-5

[16] Q. Ju and Y. Zhang, "Predictive Power Management for Internet of Battery-less Things," in IEEE Transactions on Power Electronics, vol. PP, no. 99, pp. 1-1. doi: 10.1109/TPEL.2017.2664098

[17] G. Lowe, "Driving the Internet of Things," in IEEE Design & Test, vol. 31, no. 2, pp. 22-27, April 2014. doi: 10.1109/MDAT.2014.2316207

[18] ANSYS Icepak, Icepak Tutorials, Release 15.0, ANSYS, Inc., Nov. 2013

(c) Luger Research e.U. - 2017