Technical Aspects Regarding the Equipment of Show Caves with Modern LED Systems

Caves have an almost magical attraction over people, drawing them again and again into their depths. The first electrification started in the 19th century, culminating in today’s digitalization and “LEDification”. Vladimir Vashkevich, Technical Manager at Cave Lighting CL GmbH & Co KG, describes the tough requirements on luminaires and the whole installation. He explains the advantages for the operators and the ecosystem and finally discusses solutions, practical examples and future prospects.

Man has always been fascinated by the subterranean world with its unusual and mysterious beauty. Show caves play an important role in the tourism of many regions, giving people the chance to discover hidden secrets. Since the first artificial light installations were initiated in the late 19th century, show cave illumination has undergone several stages of modification. At present, the introduction of LED lighting with its digital technology is in full swing.

Caves have always fascinated people. They have been used for shelter, ritual ceremonies and spiritual events. With electrification they have also become tourist attractions. Depending on the hue intensity or direction of the light, the caves change their appearance in an almost mystic way

Caves have always fascinated people. They have been used for shelter, ritual ceremonies and spiritual events. With electrification they have also become tourist attractions. Depending on the hue intensity or direction of the light, the caves change their appearance in an almost mystic way

Specific Features of Show Caves

The main task of a lighting system in a show cave is primarily to ensure the safety of the visitors as well as providing maximum aesthetic effects. The lamps themselves must be suitable for the harsh, damp environment. It should have only the most minimal negative ecological impact and be so installed that it is practically invisible.

Poor and inadequate light can cause irreversible damage to the sensitive ecosystem in caves. Algae and mosses can grow instead of geological structures like stalactites and stalagmites

Poor and inadequate light can cause irreversible damage to the sensitive ecosystem in caves. Algae and mosses can grow instead of geological structures like stalactites and stalagmites

Above all, the growth of so-called lamp flora and the effect on temperature in a closed ecological sphere must be combatted. Natural caves are first and foremost - dark! Artificial light induces the growth of algae, bacteria and plants which often form a carpet of green otherwise not found in a cave. An excessive increase in air temperature caused by the lighting is a destabilizing factor that has a negative effect on the subterranean ecology. A person’s presence alone warms the surrounding air as would a 200 watt heater. The carbon dioxide in expelled breath and any contamination on shoes and clothing are further undesirable factors. Adverse influence on the ecological system should be kept as low as possible. This is one of the greatest challenges when installing a lighting system in a show cave.

Much has been said and written about the advantages of LED lighting. Probably everyone knows its characteristics: reliability, energy efficiency, simple operation, etc. However, its use in show caves provides not only improved visual perception but also meets the rising demands of environmental protection.

At present there are hardly any special solutions for the use of LEDs in show caves. The standards for above ground installation are often just adapted for subterranean application. However, not all such adaptations are successful. In many cases equipment that performs excellently when used in the open often fails after a short period under ground. A good, functioning lighting system for show caves not only depends on an extensive knowledge of lighting technology but also on considerable understanding of subterranean conditions. Developers of LED systems are usually unfamiliar with such an environment, which requires speleological knowledge. The experience of speleologists enables them to develop successful technical solutions and LED systems for underground projects.

Lighting Up Caves

During the last few decades show cave visitors have become accustomed to viewing the Earth’s interior in conventional warm light with a high degree of brightness. However, the introduction of LEDs and the advent of their integration in subterranean illumination systems have changed the approach and ensuing methods dramatically.

Using LED technology the intensity of the light is greatly reduced. Not only for environmental reasons, but also to achieve three-dimensional perception for the visitor. Lighting used at home or in the office that is considered dim is quite adequate for show caves where light and shadow are united to form a three dimensional image when illuminating stalactites, stalagmites and other formations. Moreover, the mystical ambience allows the visitor to experience the underground world like an explorer.

The color temperature of the employed LEDs was changed from 3000 K to colder temperatures. The use of cold (6000 K) and neutral (5000 K) LEDs alters the appearance of a show cave considerably. Daylight lends a unique individuality to formations and wall structure. The combination of small lamps at different angles for accent lighting intensifies the impression of depth.

An important factor when installing lighting systems in a show cave is avoiding any blinding effects on the visitor. The adaptability of the human eye is limited, so special methods to prevent dazzling must be employed: lamp shades, visors, avoidance of direct illumination, the use of scattered light and concealment of the lamps.

Illuminating show caves and exposing the beauty of the fragile ecosystem is a challenge for both lighting designers and luminaire manufacturers

Illuminating show caves and exposing the beauty of the fragile ecosystem is a challenge for both lighting designers and luminaire manufacturers

It should be mentioned that conventional, though modern, techniques for desktop designing of lighting systems for subterranean objects are not always suitable. For example, it is almost impossible to create a model for adequate illumination using a lighting simulation program and to then carry out the concept. The interior of underground cavities is so heterogeneous and unpredictable that it is more practical to implement a lighting concept whilst actually carrying out the installation relying on personal experience.

Protecting the Equipment from External Factors

The most difficult factors to be taken into account during underground installation are 100% humidity, drip water and aggressive alkaline surroundings. These present special demands on the construction and application of lighting technology.

These demands entail:

- Protecting all electrical connections using suitable sealing compounds

- Protecting electronic components using water resistant varnishes und coatings such as Parylene

- Ensuring that no water is able to penetrate lamps and control units when laying and connecting cables

- Minimizing the number of electrical connections

- Taking care that the ends of still to be connected cables do not remain exposed for a longer period

- Filling the interiors of lamps with silicon or polyurethane foam if necessary

- Protecting the climatic condition in electrical cabinets

- Using only corrosion-free materials e.g. stainless steel

Only the complete sealing of all components ensures total protection against the effects of water. Based on long term examination and testing in electrical installations a 2-component sealant such as Tyco Gurosil Gel is recommended.

One of the most important parameters for the operation of LED lamps is the surrounding temperature. For application in a cave this is no critical issue because cave temperatures are almost always stable and usually quite low, seldom exceeding 20°C. There is also no influence by ultraviolet radiation, which is characteristic when used above ground to illuminate architecture. The same applies for wind and snow load.

The System

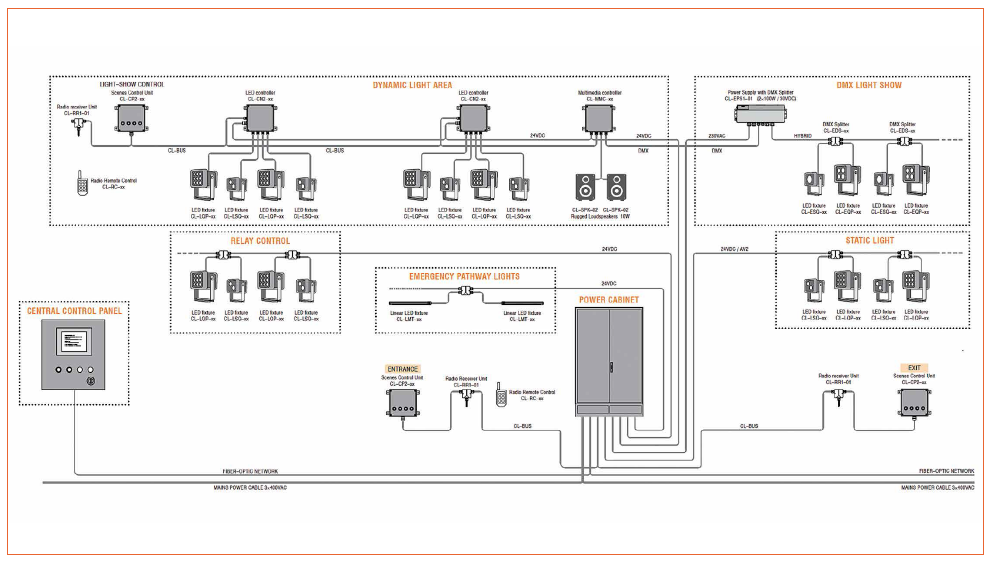

The basic lighting system in a show cave mostly incorporates the following systems: main- and emergency lighting; central and local controlling; electricity supply and multimedia system (with static or dynamic light scenes).

According to experience in the installation of lighting systems it can be said that there are two approaches to the layout of such a system: standard and customized installation. The first comprises inexpensive and standardized solutions that do not take the conditions of use into account. That is, mostly cheap, normal outside lighting units are acquired by show cave operators, such as lamp brackets made of galvanized steel and ordinary outdoor cables, in the hope that the installation will run reliably for a long time. Sometimes such an approach works, even for a longer period of time. However, experience shows that the average faultless running time of such installations is only about one year. Therefore it is of the utmost importance when designing and installing lighting systems in a cave to direct one’s attention to all technical details no matter how small and insignificant they may at first seem.

High humidity levels and alkaline elements quickly corrode lamps that are not protected properly (top). To avoid these types of problems, everything must be sealed accordingly when connecting them (center and bottom)

Modern cave lighting requires a complete system that satisfies different demands including emergency lights, static light, dynamic light and DMX for show lighting

Modern cave lighting requires a complete system that satisfies different demands including emergency lights, static light, dynamic light and DMX for show lighting

The Design of Lamps

As mentioned above, the brightness of the new lighting system should not be too high though the LED system must ensure safe and comfortable movement for the visitor. A great deal of light and wrong positioning of the lamps may dazzle the viewer and also lead to an impairment of the cave’s ecology; e.g. the growth of lamp flora. Therefore, low power lamps of between 1- 17 W are admirably suited for use in underground chambers. The basic principle is: not too much light, correctly and controllably directed and adapted to suit the theme of the guided tour. Reducing the size of the lamps is useful when developing waterproof units with an IP code x8 and helps combat the “heat pump” effect when the LEDs rapidly cool down.

The most important constructional features of the lamps lie in the use of non-corroding materials. The front cover is made of a specially treated polycarbonate; the outer parts of the housing from high-alloyed stainless steel. The inner aluminum housing has an MDO surface and/or an epoxy polyurethane coating, which is important for heat dissipation. Contact between the different materials is avoided completely in order to prevent galvanic corrosion of individual elements.

The unit is connected by the integrated cable. Inside, the screw connection is also sealed. The individual wire ends are protected by a further sealant filling in order to prevent water seeping in between the strands of the connection cable.

The integrated driver is only designed for low voltage: 24 V DC or 30 VDC. With the help of precisely chosen electronic components the lamps are protected from switching faults, overvoltage and overheating.

The lamp housing is categorically not meant to be dismantled or repaired on the spot. The units are manufactured and packed under exclusion of residual moisture. The waterproofing of the lamps is tested under a pressure of 3 bar. All lamps pass through an obligatory MTBF examination.

Technical data of different options:

- Electrical output: 3 W, 7 W, 12 W, 17 W (RGBW)

- Lumen: 240 lm, 500 lm, 1200 lm, 1200 lm (RGBW)

- Light options: Cold, neutral, and warm white, RGB, RGBW, CWA

- Beam angle: Narrow Spot (10°), Medium spot (20°), Wide spot (40°) Flood (70°, 120°)

- Supply voltage: 18 - 36 VDC

- Electrical connection: integrated cable

- IP code: IP68

- Control options: DMX / RDM, PWM

A wide range of settings and options allows the creation of a flexible and versatile system for show cave lighting.

Lighting Controls

One of the great advantages of the LED lighting system is the relatively simple control of light scenes. The lighting should only be switched on when visitors are actually in the illuminated area, apart from when they are experiencing a light show. Otherwise it should remain off. The most effective method for protecting the cave’s ecological system, for example, by combatting the growth of lamp flora, does not lie in the use of chemical or bacteriological technologies but by reducing the periods of lighting to a minimum. The correct use of light control also intensifies the visitor’s emotional perception.

As well as in physical control levels the show cave is also divided into logical control zones. During the tour the control of one area can be transferred to another and each zone may have its own control script. In general, the basic principle is: arrive - switch on - leave - switch off.

When designing the control system various options can be used, depending on the specific demands of a certain object: a simple relay control, brightness control, and dynamic lighting or static-dynamic show. By technical means any combination of these options can be used. The chosen control system is primarily dependent on the cave’s characteristics and the concept of the guided tour. The guide can, for example, influence the lighting by remote control, or it may operate in stand-alone-mode, for example activated by motion sensors.

Three fundamental elements of a cave lighting controls system:

- Lamp control unit CL-CN2

- Light scene control unit CL-CP2

- Multimedia control unit

The LED lamp control unit

The LED lamp control unit supplies the power and controls the brightness and PWM regulation of the LEDs (dimming). The control unit receives commands from the Cave Lighting™ System interface and controls the connected lamps in regards to internal scenes and configuration. Several control units can be employed in one system and programmed accordingly. Stand-alone versions are also possible.

The keypad / light scene control unit

The keypad controller is responsible for the communication between the user and the lighting installation. With a keystroke the user can send commands to the control unit to change light scenes that are stored in an internal memory. The user can manually alter light scenes or scenarios by means of a local keypad. The function of each key can be individually programmed.

The multimedia control unit

The multimedia control unit is an all rounder. The controller unites within DMX512, a player with recording function and an MP3 player. The control unit can actuate the DMX lamps directly via 8 channels. It takes over the task of controlling varying light and music shows, also the controlling of any number of DMX units connected to the system. The unit can be programmed with a notebook. The internal micro SD memory card stores audio and light show sequences.

The units are contained in a protective body made of compressed rubber and achieve protection level IP67. The electronic components of the units are coated with a special paint and protected against overvoltage and switching faults.

The control system also supports other auxiliary units such as DMX splitter, receivers, adaptors and other remote controls.

The light scene control unit, CL-CP2, is one of three different control units. It can be used to accommodate different situations with various light scenes

The light scene control unit, CL-CP2, is one of three different control units. It can be used to accommodate different situations with various light scenes

The Trend to Smart Caves

The present trend, which includes show cave projects, lies in the introduction of smart solutions as in “smart homes” or IoT. Modern show caves are therefore equipped with complex systems on the basis of IP networks using optic fiber communication cables. These systems allow additional equipment to monitor the progress of the guided tour, the microclimate, etc.

The introduction of modern technology also influences the operating conditions in show caves. Today’s means of communication for “intelligent” solutions for wireless interfaces on 2.4 Ghz basis (WiFi, Bluetooth, ZigBee) do not always work well and can be unreliable. This is due to the diffusion characteristics of radio waves under ground. Communication usually only functions up to the first bend or other rocky obstruction. In order to ensure continuity additional cables and repeater have to be employed that have a negative influence on the general reliability of the system.

Industrial receivers with a frequency of 433 Mhz have proven to be reliable for local control of lighting zones but such receivers should be chosen carefully.

As already mentioned, a show cave is a complex object consisting of lighting and other related systems. An important element is the function of the central control and monitoring not only of the technical status (battery condition, backup, fuses, and emergency control). Constant surveillance of tour progress is also necessary in order to prevent possible conflict between separate groups. Monitoring of fluctuations in the microclimate, radon content of the air and water levels are just a few of the system’s further functions.

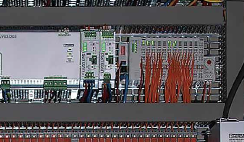

SPS controls computers are often installed to monitor things like air quality, micro-climate and surveillance of the tour progress

A Cave Is Not Just a Cave Anymore

The modern digital world provides new solutions that no one would have thought of even just a few years ago. The world of show caves is becoming multimedia. To improve the aesthetic impression for the visitor, the lighting is supplemented with dynamically colored shows synchronized with sound and music, video mapping on walls and natural formations, the accompaniment of a multilingual audio guide, interactive media displays and 3D laser shows.

One of the latest trends in technical development is the creation of selfie points (Facebook points) - well lit locations where visitors can take photos and immediately post them to social networks.

When introducing new technology it is very important to maintain an appropriate balance between natural objects and the equipment that has been installed.

While artwork, shows and performances have become attractions in show caves, the latest trend for caves is to become multimedia. There are now well lit locations (Selfie or Facebook points) where visitors can take photos and post them online immediately

While artwork, shows and performances have become attractions in show caves, the latest trend for caves is to become multimedia. There are now well lit locations (Selfie or Facebook points) where visitors can take photos and post them online immediately

Power supply

For safety reasons low voltage - 24 V or 30 V - as a main power supply is used for the lighting. In regards to this, certain characteristics must be given consideration. To avoid high power loss, thicker cables with larger diameter cores must be used. When planning the installation, the fact that the incorporated LED drivers serve as power stabilizers (constant current) must be taken into account so that the loss is not linearly dependent on the power. When calculating cable lengths there shouldn’t be more than an estimated 10% loss of the total energy consumption.

Safety

First and foremost the main operational plan for the lighting system must make provision for the safe evacuation of persons in the case of power failure. An emergency power supply must be in readiness in order to allow control of the path lighting system to ensure safe evacuation. The use of low voltage and low power LED lamps simplifies the emergency and back up lighting system and eliminates the necessity for more expensive components. The demands on the emergency and evacuation lighting are specified in the relevant standards and must be observed in the construction of the complete system.

Lightning protection

Subterranean objects that are connected to the surface are highly susceptible to the effects of atmospheric electricity. The prime reason is that the cables and electronic components basically serve as lightning conductors that direct the electrical discharge into the ground. Sometimes it is difficult to predict the possible path of the discharge. Therefore, a correct and reliable lightning conductor must be integrated in all subterranean systems. All protection levels are to be observed. Theory and practice are described in detail in the relevant regulations that must be correctly understood and adhered to. Money should not be saved on safety elements in components of underground installations.

Manufacture, Testing and Quality Control

Correctly conducted tests are the key to good quality and long life of the units employed underground.

A complete testing process consists basically of the following single test elements:

- Test in the natural surroundings over several months

- Tests in the natural surroundings in a subterranean lake

- Tests in accordance with IP67 EN 60529

- Test for resistance against chemicals

- Long term test over 1 year in sea water

- Test in accordance with the demands of IP68

- Submerged test over 6 months

- Battery test over 24 hours

- Seal test at 3 bar for 2 hours

Every manufactured lamp should be tested for seal tightness and subjected to a technological operation test. The light parameters must also be measured. These are necessary procedures to guarantee the quality and long life of the products. When necessary the lamps can be calibrated.

Summary

The main purpose of a lighting system in a show cave is to ensure the safety of the visitors whilst providing a maximum of aesthetic effect and minimal impact on the cave’s ecology. The LED lighting should remain inconspicuous in the show cave but must be protected from the cave’s atmosphere. The use of modern technology and technical solutions bring serious changes to the world of illuminating subterranean points of interest that seemed so simple just a few years ago. When designing and installing modern lighting systems a list of important demands have to be observed.

Important demands that need to be considered:

- A great deal of light is unnecessary. A combination of diffuse and directed light with topical focus suffices

- Lighted periods should be reduced to a minimum. This is necessary not only in order to protect the environment but also to reduce costs through higher energy efficiency. It also enhances the attraction when objects are illuminated separately and not all at once

- The installation should be as invisible as possible. Visitors should be impressed by what they see during the guided tour and not by a display of electrical appliances

- The selected lamps and all other units must be suitable for operation within a cave

- Controllable light should intensify the emotional effects

- The necessary measure of safety for visitors and that demanded by regulations must be ensured

LED light brings a new quality to modern subterranean exhibitions, portrays their natural beauty in a new manner and creates unforgettable, even three-dimensional, effects. It is important to exploit this new quality correctly.

To guarantee the appropriate quality for the harsh environment of caves, many different tests are performed in the lab and in the natural environment

To guarantee the appropriate quality for the harsh environment of caves, many different tests are performed in the lab and in the natural environment