Tech-Talks BREGENZ - Julia Frohleiks, Researcher, University of Duisburg-Essen

In his commentary on technical progress and innovation, Dr. Sejkora said: “In the early stage, in the first phase of its life cycle, technology is mainly driven by fundamental research.” He went on to say that we can never predict how a technology will develop. Researchers from the University of Duisburg-Essen, working in the Nano Energy Technical Center (NETZ), worked on this type of fundamental technology and their submission received the LpS 2017 Scientific Award. Ms. Julia Frohleiks, a Ph.D. student, was a major contributor to this research in the group led by Dr. Ekaterina Nannen and accepted the award in Dr. Nannen’s name. In the following interview she gives some background information and discloses future research possibilities.

LED professional: Thank you very much for agreeing to this interview. Dr. Ekaterina Nannen was named as the head of the group that worked on the paper that won the LpS Scientific Award 2017 and you are representing her here, in her absence.

Julia Frohleiks: Yes, that’s correct.

LED professional: Could you tell us a bit about your workgroup and the environment you work in? Who is Ekaterina Nannen and who is Julia Frohleiks?

Julia Frohleiks: Our workgroup is located at the University of Duisburg-Essen. A cooperation between the University of Duisburg-Essen and Osram on novel concepts for solid state lighting was initiated by Professor Bacher, Department of Electrical Engineering, and in 2012, Dr. Ekaterina Nannen was selected to head the group. It’s a junior research group located at the Nano Energy Technical Center (NETZ), which is devoted to nanomaterials and technologies for energy applications. NETZ hosts a lot of different groups from different fields including mechanical engineers and chemists as well as physicists and electrical engineers, and everyone is working on Nano-materials within their fields.

In the beginning, our group had two PhD students - one doing light-emitting electrochemical cells (LEC’s) with nanomaterials for increased performance, the other one working on quantum dot LEDs. I joined the group about one year later and develop luminescent device combining quantum dots with LEC’s.

LED professional: You are working on your PhD, is that right?

Julia Frohleiks: Yes, all three of us are working towards our PhD’s and Ekaterina Nannen is our group leader. I studied NanoEngineering at the University of Duisburg-Essen. The university has a new study program on NanoEngineering with specializations in Nanoprocesstechnology and in Nanoelectronics/Nanooptoelectronics. I focused on the latter and received my master degree in this field in 2014.

LED professional: Do the groups inside of NETZ collaborate?

Julia Frohleiks: Yes, that’s the central idea. The NETZ is part of the Center for Nanointegration Duisburg-Essen (CENIDE). So collaborations between the single groups within the university and especially within the NETZ are strongly supported. In-house, we also have the Interdisciplinary Center for Analytics on the Nanoscale (ICAN), which offers its service to every working group and even external scientists. They have, for example, high-end transmission electron microscopy and other specialized tools and we can go there and give them samples for characterization.

LED professional: Is NETZ the biggest center or research institute for nanomaterial in Germany?

Julia Frohleiks: It is the only one focusing on the combination of “nano” and “energy” - this is unique in Germany. It was built in 2012, so it’s quite new. Nanotechnologies are, in general, quite timely and our university has an outstanding experience on Nanomaterials for the past 15 or 20 years. Nanosciences are even one of the four key research profile areas of our university.

LED professional: Maybe you could tell us a little about Ekaterina Nannen.

Julia Frohleiks: Yes, of course. She was born in Russia and came to Germany when she was 15 years old. She finished university in Duisburg-Essen where she studied electrical engineering and did her PhD in electrical engineering. Afterwards, she headed the junior research group in collaboration with OSRAM. The focus of the group is large area light emitters, solution-based, for low cost applications later on. Here we develop, on the one hand LEC’s, and on the other hand push the implementation of quantum dots in lighting applications, paying particular attention to environmentally friendly materials.

LED professional: I’d like to go on now to the research program itself. LEC is something that isn’t very well known. Some people even think that LEC is a typo and it should say LED! So could you give us a bit of background including the physics and state-of-the-art of LEC?

Julia Frohleiks: Sure. LEC is a large-area emitting device so you can compare it to organic LEDs (OLEDs). It has comparable active light emitting species so it’s also organic and can either be a polymer or a transition metal complex. But the difference to OLEDS is that ionic species are integrated within the active layer of the LEC. These species start moving when voltage is applied to the device. Due to the accumulation of the ionic species at the electrodes, electrical double layers form, that facilitate the charge injection. So all the additional supporting layers that are typically needed in organic LEDs can be omitted and LEC’s can be made, in the easiest case, out of one layer. The concept is really attractive, for example, for printing fabrication and flexible devices.

LED professional: When I hear about electrochemistry I always think in the direction of anodizing aluminum or batteries, or something like that. So I have a kind of solution - something fluid. But when you talk about LEC it sounds a little different.

Julia Frohleiks: Yes. The name comes from a second effect that is important in the LEC. When you continue applying a voltage to the LEC, the ions separate and form p- and n-doped regions close to the electrodes by interaction with the lighting molecule. And this process is called electro-chemical doping. This doping is the reason why you have the name - electro-chemical cell.

LED professional: But it doesn’t work in the fluid phase, does it?

Julia Frohleiks: In our case, the final layers within the device can be called solid. We prepare the solutions in the fluid phase but then we spin coat and let them dry - a similar process as for QD-LEDs and solution-based OLEDs.

Thrilled with having won the LpS Scientific Award, Julia Frohleiks was happy to be interviewed by Dr. Sejkora and Arno Grabher-Meyer for the Tech-Talks Bregenz

Thrilled with having won the LpS Scientific Award, Julia Frohleiks was happy to be interviewed by Dr. Sejkora and Arno Grabher-Meyer for the Tech-Talks Bregenz

LED professional: What is the difference between the LEC and the OLED?

Julia Frohleiks: The main differences are the incorporation of ionic species and the resulting easy fabrication process. You can do it solution-based, in one layer and it’s not too sensitive to the air. OLEDs typically degrade very fast when they come in contact with water and air. Although the light emitting species are quite similar, in the case of LECs we can omit the injection and transport layers and even use air-stable electrodes for the electrical contact, like, for example, aluminum.

LED professional: About the quantum dots: Can you give us some background information about the physics of the quantum dots you are using?

Julia Frohleiks: When we talk about quantum dots, we mean colloidal semiconducting nanocrystals. These tiny semiconductor crystals are typically less than ten nanometers in size which leads to quantum confinement effects: the band gap increases and can be tuned by the nanoparticle size. So you can create robust, semiconducting emitters that are tunable in emission color.

LED professional: And are these quantum dots in the LEC layer or is there a special layer?

Julia Frohleiks: In the hybrid device that we introduced at LED professional, it’s a special layer. We prepared them in dispersion, whereby they were stabilized by organic ligands. Then we spin-coated them on top of the active LEC layer.

LED professional: What we heard in your lecture is that the current efficacy of the hybrid LEC is not very high and you improved it by using the QDs. In the lighting domain we already have the OLED and the LED with really high efficacy and you should follow. How do you see the future?

Julia Frohleiks: Our goal is not to compete with the LEDs - it’s already hard for OLEDs to reach their benchmarks. I think there are just different types of applications waiting for the LEC family. You can’t light up a stadium with LECs - but you might realize cheap and flexible lighting elements for consumer electronics, for example. I don’t think it will be necessary to become as efficient as the LED and OLED but still we will need to have better performance compared to now.

Efficiency is related to the balance of holes and electrons in the device. What we already did is to improve this balance - in our case, push the electrons because standard devices are usually hole dominated. So I think we have to go more in that direction. And you also have to think about the behavior of these LECs with time: because of the ion movement, the device characteristics are quite dynamic and this has to be stabilized for reliable application. This is the big challenge for the LECs, I think.

LED professional: Do you already have something in mind, when you say that you need to think about different applications? And what would be the advantage of using an LEC with quantum dots?

Julia Frohleiks: I think the LEC is really interesting for low cost / disposable applications: Maybe for light-emitting stickers or smart tags. Because one can print them using every kind of printing technology and they are particularly tolerant against thickness variations, for example. They can be prepared in ambient conditions so you can basically use printers, which means they are quite cheap to produce. You can think about doing stickers for milk bottles that change color when the expiry date has been passed. The color might change from green to red and everyone can see that it shouldn’t be sold anymore. Maybe an LEC in combination with quantum dots on a sticker would be a good application - so it’s not really lighting up a room.

LED professional: Would you need an electrical voltage source on each bottle or pack of milk? A battery or a solar cell?

Julia Frohleiks: Yes, or an RFID transponder or something similar. It’s a vision I heard about.

LED professional: This leads me to my next question. Are you driving the LEC with low voltage?

Julia Frohleiks: There are different ways to drive the LECs. The best performance is typically reached when the LEC is driven with pulsed current for better ion movement stabilization. And what I did with the hybrid device - I drove it with constant voltage for better understanding of the working mechanism behind.

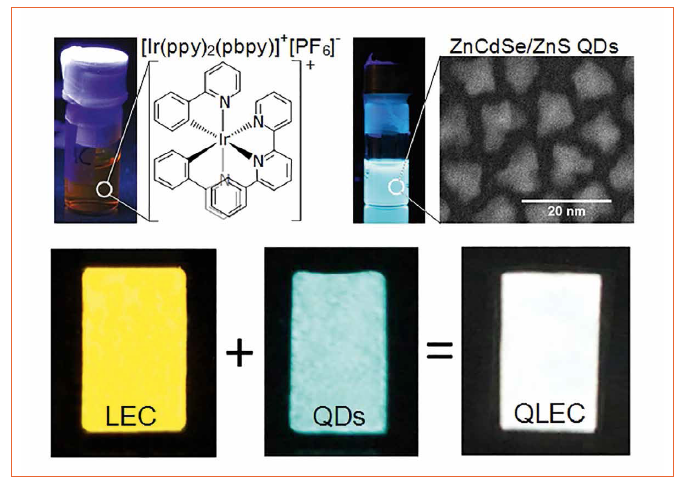

Principle structure of a white QLEC device

Principle structure of a white QLEC device

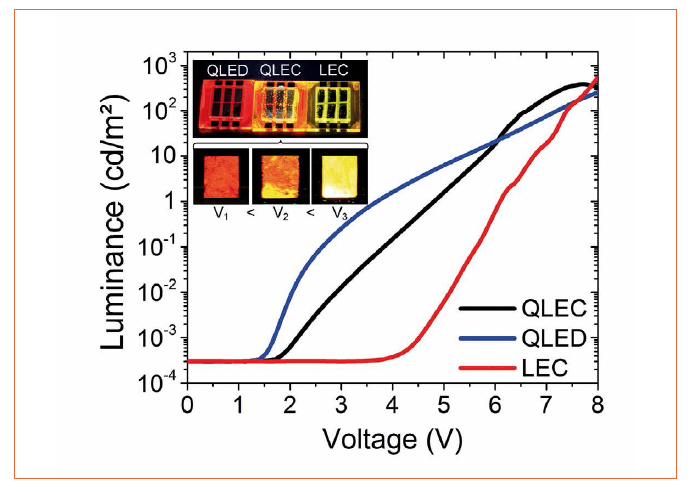

LED professional: In one of the images you showed during your talk was this hybrid combination. Is it more the quantum dots that contribute to illumination at a lower voltage?

Julia Frohleiks: Yes, that’s right. And the LEC becomes dominant at higher voltages.

LED professional: So, in general, the brightness of the LEC is still driven by the voltage, correct?

Julia Frohleiks: Actually it’s controlled by the amount of electrical charges (current) flowing through the device and recombining radiatively. This is, at the same time, coupled with the electrical field because the electrical field is forcing the ions to move.

LED professional: But can you control brightness with a hybrid system?

Julia Frohleiks: I think you could also control the brightness. At first you have to increase the quantum dot efficiency because when I did it, I had quantum dots that weren’t perfect. But now they are much brighter. So if such devices are prepared again with improved quantum dots, I believe you could increase the brightness of the whole device. And then ideal driving conditions for efficient excitation of both light emitting species have to be found.

LED professional: In which frequency domain do you work?

Julia Frohleiks: The LECs are normally pulsed with one/a few kilohertz. But it depends on the thickness of the layer and the amount of ions you have inside. One always has to find the optimal driving conditions for the device. It depends a lot on details.

LED professional: Can you give us some ideas on the parameters for driving the light sources?

Julia Frohleiks: At the moment they are only prototypes so they are slightly below 10 square millimeters. The typical current for getting really bright emission is about some milliamps in the device. The light-emitting devices based solely on quantum dots as light emitters in our group have an external quantum efficiency of a few percent. In literature, it is shown that this also depends on the device architecture, with a lab record up to 22% external quantum efficiency- but for lower brightness. LECs highly depend on the driving conditions. We reach about 4 to 6 % for the best yellow and green ones. The white one, I think, is about 0.2% external quantum efficiency, but the blue quantum dots aren’t as good as the red ones.

LED professional: Yesterday during your talk you mentioned that you’d like to take the direction of focusing on quantum dots that are not activated by light, to convert light but that are activated by current.

Julia Frohleiks: Actually in the hybrid device they are directly activated. Our vision for the future is to replace the organic emitter completely. So we would keep the concept of the LEC where there are mobile ions that are moving and facilitating the charge injection and the transport. We move away from the organic emitter and take quantum dots as the only light-emitting species because they are more robust and then combine this in an LEC architecture resulting in a novel “QLEC” device.

LED professional: What would that look like? In terms of color it’s clear - you control it by the size of the quantum dots. But in terms of white light - would the sizes of the quantum dots be mixed or would there be single layers?

Julia Frohleiks: Actually, that is what I’ll be working on when I get back. I think we will definitely work with different colors. As known from the OLED industry, both mixed and stacked device architectures have their advantages. We have already shown that it is possible to fabricate QLECs with one color so we did it with copper indium sulfide based quantum dots and with an ionic liquid all mixed together within an organic matrix for charge transport. The next step is to go for more colors, paying particular attention to cadmium free material systems: their luminance isn’t yet as good as of the “traditional” cadmium based QDs, but the environmental safety plays a more important role, especially in targeted applications.

LED professional: Do you and your institute have a roadmap? Or is there a roadmap of these quantum dots within the industry? In all areas, whether OLEDs or LEDs there was a roadmap of expectations to reach a certain efficacy level quite early on.

Julia Frohleiks: I know that there has been a lot done in the research field but I don’t know if there are roadmaps for the industry yet. I do know that there are three main fields. One is the field of converters as an alternative to phosphors. Another one is displays - because of the small full width half maximum of the quantum dots. I believe that they already have a roadmap because Samsung is really focused on displays and TVs. They already started selling the TVs with quantum dots. But in the field of lighting, the application of QDs remains yet exotic - at least currently.

Voltage versus luminance comparison between LEC, QLED and QLEC. The inset shows the prepared QLED, QLEC and LEC devices under UV illumination with increasing voltage from left to right

Voltage versus luminance comparison between LEC, QLED and QLEC. The inset shows the prepared QLED, QLEC and LEC devices under UV illumination with increasing voltage from left to right

LED professional: I would like to know a bit more about the physics behind LEC plus quantum dots. Is it a unique idea to combine them and are there other research groups working on this? And how did the idea of combining them come up?

Julia Frohleiks: The idea to combine the iTMC based LEC with quantum dots is unique. No question. One other group showed the combination of a polymer based LEC with quantum dots two years ago but they mixed them into one layer. We did it layer by layer and forced each component to become active within one and the same device, so it’s a bit different.

LED professional: When you say they mixed it - do the quantum dots in the mixture work as an emitter or as a converter?

Julia Frohleiks: They did not discuss that issue deeply, to my mind the operation as a (down) converter is very probable in that case.

LED professional: How did the idea come about? If you’re in the field - is it a big change of mind or is it a logical consequence?

Julia Frohleiks: Actually, our group leader - Ekaterina Nannen - has an endless number of ideas and there are many, many more things that she wants to try. After her PhD she wanted to work with quantum dots because she had already done light emitting nanocrystals based on zinc oxide and she knew that the efficiency is always limited but that quantum dots have the potential to have good efficiency. And then she learned about the LECs from Osram - so, it was pretty straightforward for her to combine these two fields.

LED professional: But now she wants to discard the LEC and go back to the quantum dots.

Julia Frohleiks: Yes, but keep the idea of the working principal of the LEC.

LED professional: How far will you go with your research? I think what you are doing here is basic research, is that right?

Julia Frohleiks: Yes, that’s correct.

LED professional: So going on to applied research - I don’t think it will be done in your group - are there other groups interested in going on in this area?

Julia Frohleiks: Not that I know of. We are at a point where we could go forward and we are currently checking some ideas at the moment. We are also open for collaborations with someone who is interested in the scale up of the technology or long-term testing.

LED professional: If I understood the technology correctly, you said that currently your samples are very small but it’s easier to scale up your samples than it would be to scale up an OLED because in a simple version you have one layer or maybe a couple of layers but a high quality OLED has quite a lot of layers.

Julia Frohleiks: Yes, that’s correct. That is one of the advantages of the LEC. And the layer is not sensitive to the thickness. So it’s not 3 nm or 4 nm like it sometimes is for the OLED but can be as thick as 50 to 400 nanometers. And thickness variations on tens of nm scale don’t really matter much. I think it would be easy to scale it up.

LED professional: You said that you could do it in almost any environment - so it’s almost like adapted equipment.

Julia Frohleiks: Yes. And we do it in a normal lab - so we don’t have a clean room or anything. You just have to be careful when you drive them because during operation they can degrade. So ideally you have to encapsulate them afterwards. You can process the whole device and then, for example, pour glass epoxy on top of them and they’re fine.

LED professional: I know from speaking to you before that one of the issues you have is funding. What could you offer someone if they were interested in funding you?

Julia Frohleiks: Funding is always hard to get. It’s especially hard to get funding for quantum dots in Europe at the moment because the focus in Europe is not as high as it is in the U.S. or Asia. This makes it very hard for us to compete.

LED professional: Is there a reason why quantum dots are getting so much more attention in Asia and the U.S.?

Julia Frohleiks: I think interest is growing in Europe. In fact I believe there was another lecture here at LpS concerning quantum dots. I think the industry is becoming more and more interested in it and I hope that it’s not too late for us to catch up to especially Asia where a lot of the industry is active in the field. And as interest grows in Europe, I hope funding will also grow.

We are very grateful for the Scientific Award - it will help us to become more well known in the industry and possibly help us to get more funding.

LED professional: One of the ideas behind the Scientific Award is to help research groups, especially young scientists, that are involved in topics that don’t comply with what everyone else is doing. We want to reward them for all the work they do. So we hope that this will help to turn the focus more on QDs in Europe.

Julia Frohleiks: Yes, this will really help us. Thank you.

Julia Frohleiks

Julia Frohleiks, M.Sc., is a member of the Junior Research Group “Solid State Lighting”, located at the Nano Energy Technical Center at the University of Duisburg-Essen. She studied NanoEngineerg and received her bachelor degree in 2011 and her master’s degree in 2014 at the University of Duisburg-Essen, with specialization in the field of Nanoelectronics/Nanooptoelectronics. Currently, she is developing luminescent devices combining colloidal quantum dots with light-emitting electrochemical cells, which is the topic of her PhD.

(c) Luger Research e.U. - 2018