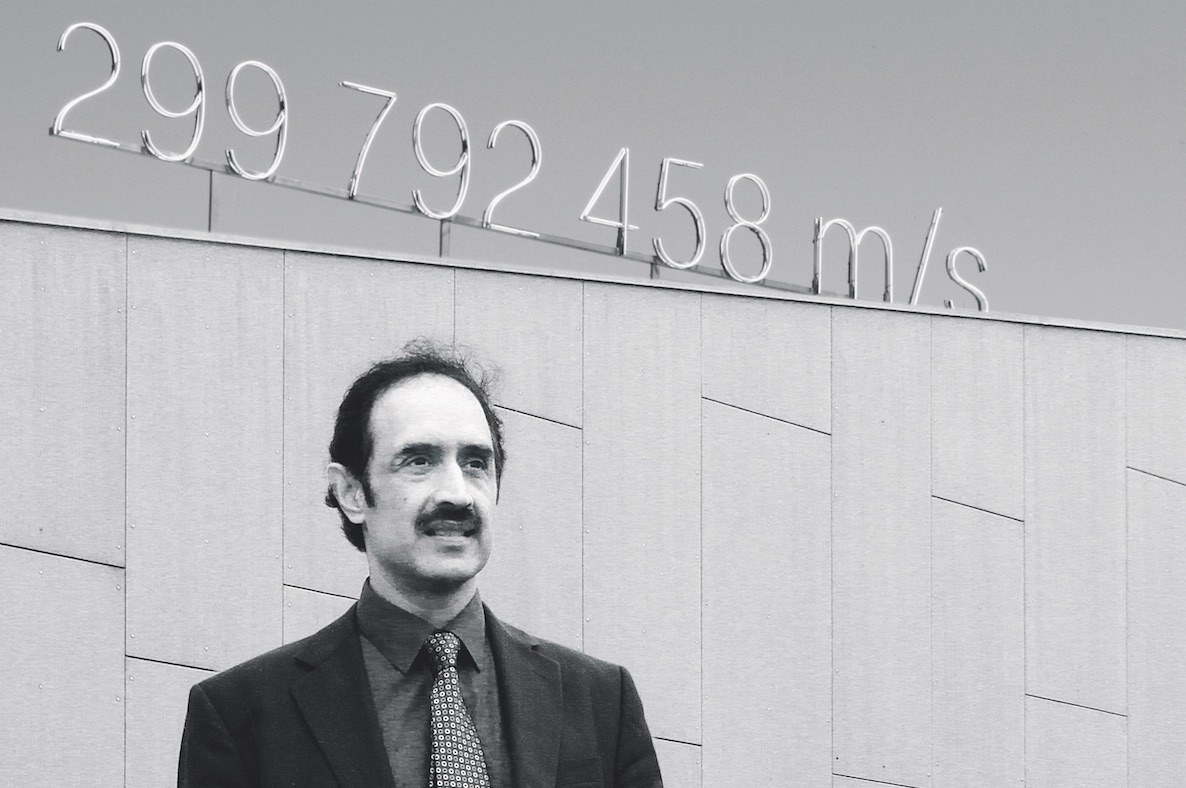

Tech-Talks BREGENZ - Dr. Jy Bhardwaj, Lumileds, CTO

Dr. Jy Bhardwaj, CTO at Lumileds, held a keynote speech at the 5th LED professional Symposium +Expo (LpS 2015) on September 22nd in Bregenz. He talked about “Trends and Challenges for System Integration” and pointed out further steps and phases of how lighting technologies will evolve. Arno Grabher-Meyer and Siegfried Luger talked with Dr. Bhardwaj about his view on embedded lighting, color LED technologies, substrate and light source technologies.

LED professional: Yesterday, in your keynote you mentioned a very interesting perspective of lighting trends based on a three-phase model. Could you elaborate?

Jy Bhardwaj: Phase 1 is socket replacement. Here you would just change the bulb in the luminaire. In phase 2 you’re taking LEDs out of the lamps and putting them onto boards - creating very flexible architectures. In phase 2 we see very beautiful designs but also connectivity and the integration into networks. Phase 3 is the future vision. LEDs get integrated into the infrastructure, or let’s say, embedded. Instead of points of light there will be ceilings of light or walls of light. LEDs will be integrated into work surfaces, tables and all kinds of different things.

LED professional: How will this embedding of LEDs work with different end product manufacturers?

Jy Bhardwaj: Let’s look at some examples: One is the integration of LEDs into tiles; the other is their integration into carpets. For example, when you turn the LEDs on you can write messages on the carpet or lead the way with arrows. The light sources are in the products; they are embedded into the final products. So, it’s not about an LED manufacturer making a carpet it’s about the carpet manufacturer adding LEDs to his product, or a clothing manufacturer integrating LEDs into his products, or the ceiling tile manufacturer adding LEDs to his products. Right now, Philips is working with a tile manufacturer to create ceiling tiles. They look like every other ceiling type until you turn them on.

LED professional: Will most of the light sources be embedded in phase 3? What about the transition into the embedded lighting world?

Jy Bhardwaj: Not every light source will be embedded. The reason is that we always want point light sources as well for designs or to create moods. The luminaires play a very important role there. If you look at how lighting evolves, it is a huge legacy business. Replacing existing sockets will take a long time. The brown field, which is the retrofit cycle of what is there already, is the far bigger market than the green field. The green field, which is new buildings, is much less. The question is when to design this into buildings. It’s about starting to have confidence in the reliability and the longevity of the LEDs; it’s a question of redundancy, robustness and the adaptability of LEDs. When that is real, then the designers will build it into the applications and then go further into the next phase. Maybe semantic light is an example of the end place it could be. And the solution should be within the light to carry information. But you want that information to provide value and semantic light can provide value when you are shopping. You can see that in retail; particularly high-end design where they can afford something like this. It can work.

LED professional: What do these trends mean for Lumileds as a component manufacturer? Do you have to adapt your portfolio to these developments or do you work with completely new clients?

Jy Bhardwaj: What it means for Lumileds is that we have to continue to make a range of LED solutions that can be used across a very broad range of applications, like, for example, stadium lighting or street lighting, where we need the directionality of the product and where we need very high lumen outputs. But people are beginning to become aware of glaring and we’re trying to limit that. That limits how much power you can put into some of the lighting applications. The other range is distributed lighting. When I look at the ceiling I only want to see distributed light. That’s mid-power and low-power LEDs.

LEDs are being attached in a certain way in a certain form factor for boards. Whether it’s mid-power, high-power or low power, they are all designed for board engineering. And we are moving towards SMT so you can use automatic pick-and-place tools in production. Now the challenges become how to use the same SMT techniques in a ceiling tile manufacturers or carpet manufacturers line in a volume-manufacturing set-up.

LED professional: Are you familiar with the approach from iMac? They have the small LEDs on a bendable subgrade.

Jy Bhardwaj: Philips has developed the exact same type of thing. You can attach the LEDs on a small form factor and then you can stretch it and you create whatever dimension you want and you can light it up with a certain amount of current to make it as bright as you want. Those types of technologies are being developed, but again, our job as an LED manufacturer is to make sure that for these form factors we can provide reliable LEDs that are the right size and that perform right with the right power ranges. In particular, it’s LEDs that we can then supply with high consistency and very high volume, because that’s what these applications are going to demand.

LED professional: Will you offer manufacturing service support for these new technologies and applications?

Jy Bhardwaj: We are not in the business of, let’s say, carpet manufacturing, so we will stay in the component business and its support. Don’t forget that these things take a long time to develop and become significant in volume. So in order to get the whole industry comfortable with LEDs as a robust, reliable product it is important to adapt standards that allow people to mix different vendors as well.

The most the critical aspect is controlling LEDs remotely and to power them in a way that is distributed. Now we are trying to bring the industry up to speed. We need to consider how we power LEDs and drive standards because unless we do this, whatever we design will be a single design, which has no chance of any broad market acceptance.

LED professional: Are there any results available coming out of this standardization process so far?

Jy Bhardwaj: Well we are just starting. But first of all the message is that we need to push for building standards, network standards and APIs for power distribution. Then I think we’ll get the industry in the right place to begin to consider volume applications of distributed light embedding.

LED professional: Let’s touch on another topic. Lumileds launched the LUXEON C product portfolio here at the LpS 2015. Could you give us some background information?

Jy Bhardwaj: The LUXEON C is a very important product for the color lighting industry such as architectural lighting, mood lighting, even functional lighting for emergency vehicles. What makes it unique is the flexibility in arranging the LEDs and being able to use the LEDs like any other device. The LUXEON C Color Line is an optically advanced portfolio of color and white LEDs. Designed for flawless color mixing, LUXEON C has one focal length for all colors, which provides consistent radiation patterns from secondary optics and it maximizes optical efficiency. We have developed a very small dome that leads to the best compromise with extraction, efficiency and being able to maintain the beam angle. With a big dome the light comes out in all directions. This leads to the halo effect. The LUXEON C eliminates this effect. On the packaging side we have designed the LEDs, so that every single part has the same thermal resistance to optimize the board design.

LED professional: Why did you launch this color product line right now and how long did the development take?

Jy Bhardwaj: It’s really taking us a while to work with people who are at the forefront in the fields of architectural lights and mood effects. Trying to engineer the colors in a particular way, trying to reduce the form factors, reduce the optics and hit all these challenges. In total the LUXEON C development was about 18 months.

LED professional: Is the base substrate of LUXEON C still sapphire? What about other substrate materials like silicon?

Jy Bhardwaj: The base material of the LUXEON C for growing the EPI is still sapphire for the blue and green LEDs and obviously gallium oxide for the AlInGaP red type. We don’t see any changes here. Silicon versus sapphire is an interesting discussion. We actually invested very heavily in GaN on silicon. We came to the conclusion, a couple of years ago, that this was not going to be the right solution. And the reason we came to this conclusion was that even over the five years that we were working in this technology, the sapphire performance always stayed ahead of silicon. We’re producing all our LEDs on 6-inch wafers, even the red ones. 6-inch wafers are the maximum and the optimum size, we think. We applied that very early on when sapphire was very expensive at 6-inch. It was a factor of 3 to 5 higher than silicon and at that point silicon looks very attractive. Sapphire costs have come down so fast, as we ramped up in volume and developed the supply chain. Now the difference between the two substrates is maybe a factor of less than two. When you get to a factor of less than two, and you look at that in terms of cents per square millimeter, the difference is just a fraction of a cent per square millimeter.

One final point on Silicon, which is the punch line of the story: I was explaining how the silicon wafer is cheaper, wafer fab is cheaper, maybe saves you half a cent or a cent, but the performance is worse. The rule of thumb is that 15 percent decrease in efficacy costs you double the EPI area.

LED professional: How do you compare sapphire LEDs to GaN-on- GaN technology?

Jy Bhardwaj: GaN-on-GaN becomes very interesting when you are driving it with very high current densities. The breakeven is around about two to three amps per square millimeter. That’s very high. So above that you begin to see some advantages. If you look at our improvements in droop that is being pushed out. We estimate within a year the breakeven will be about three amps per square millimeter. So now, how many devices am I going to operate above three amps per square millimeter? The negative thing is, I begin to make smaller and smaller devices. The problem isn’t how hard I can drive this device; the problem is the thermal distribution underneath it. I’ve got to take the heat out, so I can’t drive it harder than the thermal dissipation and the problem is that the phosphors are temperature sensitive as well. Also the silicone is temperature sensitive. 150°C is about the threshold limit.

LED professional: Do you think that laser light will come into general lighting applications in buildings or will it stay for automotive and for high beam focused applications?

Jy Bhardwaj: For general lighting, some people are saying that you could see some applications coming in with laser light where you want very high light intensity. Maybe for stadium lighting but for street lighting, I doubt it. You exchange one sort of problem for another sort of problem- ending up with more glare.

LED professional: It’s the first time you are at the LpS. What is your impression of the show so far?

Jy Bhardwaj: I think the show is excellent. It has a lot of very good papers. The quality is good. The people who are attending are certainly in touch with the industry and participating very deeply within the industry. So you have the key suppliers here, you have major customers here. It’s a very good eco system.

LED professional: Thank you very much for this interview and enjoy your stay in Bregenz.