Solving the Phase-Cut Dimming Challenge

The evolution of dimmable LED lighting is an ongoing subject and phase-cut dimming is often dissatisfactory. While some weaknesses may be acceptable in residential applications, they are definitely not acceptable in professional applications. Stage lighting, studio lighting, TV and movie lighting set the highest standards. Craig Sharp and Bill Trzyna, Research & Design Engineers at CCI Power Supplies LLC discuss which developments helped to overcome limiting obstacles and led to a solution that also satisfies stringent requirements.

Stage lighting has always been one of the most progressive and advanced lighting applications. Using a vast number of different filters for accurate color appearance or unlimited light levels from zero to full brightness to support different scenes are examples of this. Some of these tasks have become simpler with LED lighting, but others, like dimming, have become more complex and challenging. It comes to no surprise, then, that stage, studio, architectural, and other high-performance lighting professionals are about to raise the curtain on full-range LED dimming again. This giant leap was recently made possible by the introduction of a new LED power supply dimming technology being studied and adapted by LED lamp and fixture manufacturers.

Early Days of Dimming

With the advent of the electric light, the need for dimming was immediate. It was easy to turn down the lights with a simple valve when gas illumination was the rule. But those new-fangled electric lamps posed a challenge. The first method commonly in use placed jars of salt water in series with the lamps. The electrodes could be withdrawn to vary their resistance and throttle the current flow to the lamps. In 1890 Granville Woods invented the safety dimmer, a form of resistance wire rheostat (flow control), which persists in some installations to this day. Both of these methods generated a tremendous amount of heat and sometimes caused fires. In 1933 General Radio announced the invention of the Variac (a contraction of vary AC), a continuously adjustable autotransformer. This was a major improvement in dimmer technology, substantially reducing the power wasted in comparison to resistive dimmers. However, like the rheostat, it is a mechanical device that adjusts slowly.

Phase-Cut Dimming

In 1959 Joel Spira invented the SCR (silicon controlled rectifier) controlled dimmer and a year later Eugene Alessio announced a TRIAC (Triode for AC) controlled dimmer. These thyristor-based controls are the mainstay of dimmer technology today, although the IGBT (Insulated Gate Bipolar Transistor) is used in some of the newest dimmer designs because it is an easier device to drive and control.

All of these devices work by cutting off part of each half cycle of the AC line waveform. The amount that’s cut off is measured by the phase angle. A complete sine wave is 360 degrees in length; a half wave is 180 degrees. If the dimmer cuts off 90 degrees of each half cycle, the effective voltage applied to the lamp is reduced by half because only one half of the waveform or 180 degrees remains. Phase-cut dimmers can operate on the leading edge (forward phase-cut) or trailing edge (reverse phase-cut) of the waveform. Forward phase-cut developed naturally from the thyristor behavior. The SCR or TRIAC is triggered to turn it on and it turns off when the waveform crosses zero voltage. Reverse phase-cut dimming was developed to improve performance of low voltage halogen lamps operating on an electronic transformer, a type of switch mode power supply.

Let’s look at some of the challenges in controlling LED lamps with phase-cut dimmers, because this technology has dominated the market for decades and there’s a huge installed base of these dimmers.

Simple phase-cut dimmers are connected in series (two wires) with an incandescent lamp and can only draw power for its electronics during the period when the AC line is cut off. This is when there is voltage present across the dimmer. More sophisticated dimmers require more power for their electronics and have an added wire (three wires) provided to power their electronics. A dimmable LED fixture has only the two wires from the dimmer to provide power, without the benefit of the full line voltage being present during the cut off part of the phase. Thyristor based dimmers require a minimum load current for proper operation. The dimmable LED fixture has to provide this load current even at low line voltage, which is contrary to the improved efficiency of the LED compared to an incandescent lamp.

Because of these limitations dimming LED fixtures with existing phase-cut systems were generally unsatisfactory. Dimming below 30% brightness was unreliable. Fixtures would pop on as the dimmer control was advanced. Sometimes the fixtures would behave erratically, cycling between zero and full brightness. To overcome these limitations, technology developers have looked to digital methods for LED dimmable control. In many fields of engineering, digital innovation has often removed barriers to improved product performance and application cost. Could a digital solution similarly

be written for LED dimming?

The Digital Dimming Dilemma

Both dimmers and drivers have various requirements that must be met so as to achieve smooth LED operation. Digital dimmers are one of the toughest problems to solve with LED lamps because the microprocessor requires power even while the dimmer is off. This results in a small current, typically around 20 mA that needs to flow through the lamp when the light should be off.

Figure 2: The relative light output curve of a digitally controlled LED dimming power supply fails to produce the low-end, full-range “S” curve that is characteristic of traditional incandescent dimming. This has been characteristic of LED dimming attempts to date

The drivers must convert a chopped AC signal from the dimmer into a steady DC signal for the LED’s in order to emit a constant light, while interpreting the altered waveform to the appropriate dimming level. In other words, drivers must be designed to interpret a duty cycle modulated signal and transfer the information to constant current output levels. As the conduction phase angle is decreased, the output current must also decrease. Providing constant light output requires a balancing act between drawing current through the AC waveform while it is being cut out by the dimmer. Storing power in capacitors and inductors helps provide power when there is none.

Figure 3: A recently introduced LED dimming technology produces an “S” curve that emulates the light output of traditional incandescent dimming. Importantly, low end dimming for scene exits and transitions is closely emulated

How the New Technology Works

The ultimate challenge around LED dimming is to satisfy the aesthetic eye of the technical artist. When it comes to utilizing high wattage stage and television lights, the technical producer is looking for flicker-free lighting with smooth dimming from less than 1% to 100% just as one would experience with an incandescent light fixture. This has been extremely difficult to achieve up until now.

A recently introduced LED power supply dimming technology called DimMasterTM is compatible with phase controlled dimming, resistive or auto-transformer dimming line voltage. The relationship between the PWM signals and effective line voltage is defined in the microprocessor programming to produce the desired dimming curve.

When an AC line dimmer is set for low brightness, the effective voltage applied to the fixture is low. Because of this, the power supply in an AC line dimmable fixture has to operate down to extremely low input voltage. It also has to provide a minimum load for thyristor phase- cut dimmers or they will malfunction. Another challenge is suppressing electromagnetic interference from the switching supply without inducing ringing of the AC line current, which can also cause thyristor phase-cut dimmers to malfunction. Often this malfunction is exhibited as strobing or pulsation, or sometimes the brightness varies erratically like the flickering of a candle. The new LED power supply dimming technology incorporates a power factor corrected front end and matching EMI filter developed specifically for this application. It operates down to extremely low input voltage and presents an appropriate load for phase-cut dimmers, even during the narrow conduction angles necessary for low brightness settings, while meeting FCC Class B conducted emissions limits.

A particularly annoying behavior of some AC line dimmable LED fixtures is called popcorn turn-on. As the dimmer’s brightness setting is increased, the fixtures turn-on at different levels and times, creating the popcorn effect. In the new technology approach, a separate control power supply starts up first then the microprocessor monitors the AC line to determine when the PWM outputs will commence operation. This sequence is not as dependent on the dimmer setting or the main power supply start-up time, effectively eliminating popcorn-turn-on.

For high-end LED fixtures, compatibility with video cameras is also a great concern. Some dimmable fixtures control the LED current by producing a burst of pulses from the LED driver, which causes a flickering brightness of video displays. Other LED fixtures switch continuously, but at a relatively low frequency, which is good for efficiency, but causes a venetian blind effect of light and dark horizontal bands across the video display. Alternatively, the new technology’s PWM output presents a continuous stream of pulses at a frequency high enough to eliminate the venetian blinds effect, but not so high that it reduces efficiency.

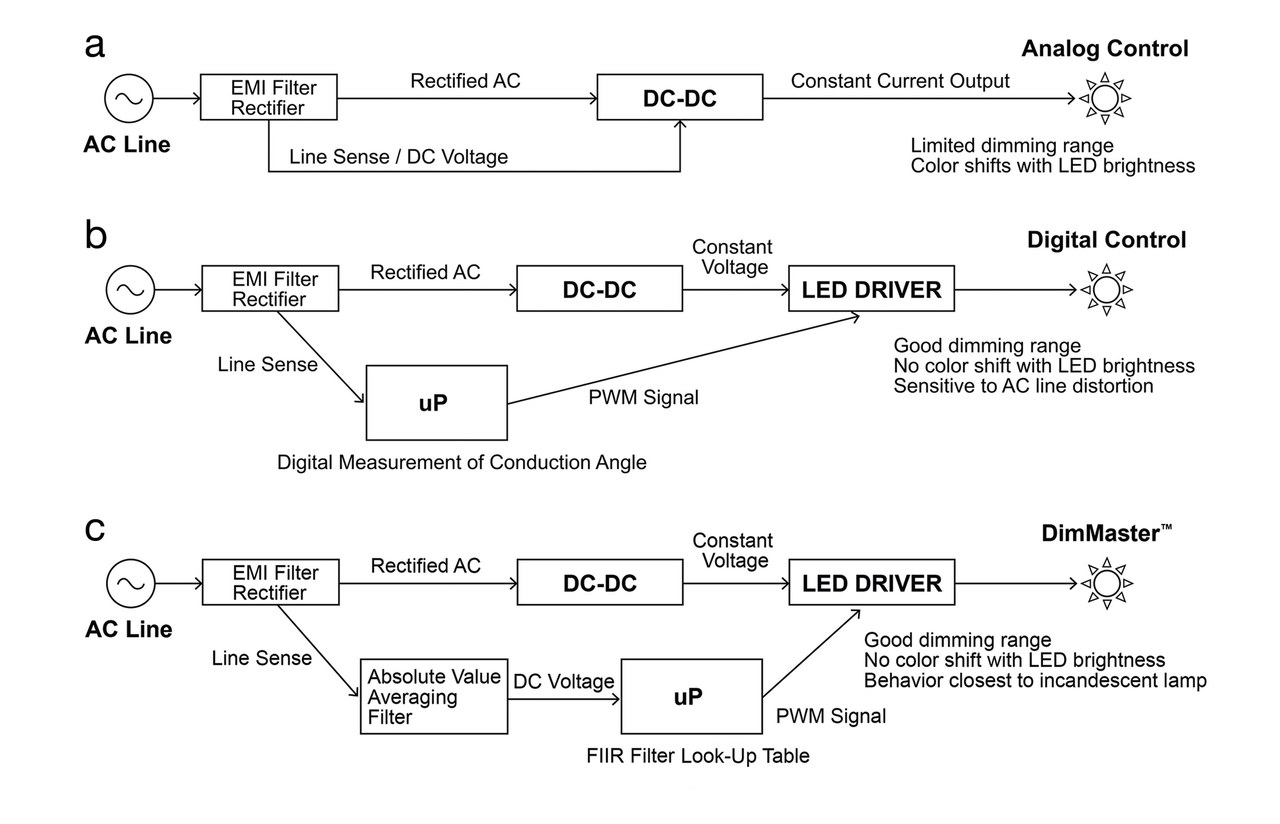

Figures 4a-c: (a) Analog controlled LED dimming. (b) Digital controlled LED dimming. (c) DimMasterTM controlled LED dimming

The first dimmable LED power supplies used an analog control approach (Figure 4a). They sensed the rectified DC value of the line voltage and used this to directly control the output current of a switched mode power supply. The most common topology for the DC-DC stage is the flyback, because it is a good choice for low cost at low power and it can also provide power factor correction as in a single stage. This is still a popular approach for consumer- oriented LED lighting. Often the dimming range is limited and the color of the light shifts as the current to the LEDs is reduced.

Along with higher power LED lighting came the demand for better dimming characteristics. Analog controls for constant current, PWM LED drivers were developed that improved efficiency and eliminated color shift with changes in brightness. Digital controls that generate the PWM signal after calculating the conduction angle from the measured line voltage parameters were developed (Figure 4b). With this approach, the dimming characteristics could be precisely adjusted, but distortion of the voltage waveform and transients on the AC line can disturb the brightness setting. Measuring the conduction duration is attractive, because it is easy to implement in the microprocessor program. However, this measurement is frequency sensitive and it is unable to determine the brightness setting of non-phase controlled dimmers.

The new LED power supply technology uses a hybrid approach to sensing the effective line voltage, which does not depend on directly measuring the conduction duration (Figure 4c). The new approach integrates the absolute value of the AC line voltage waveform and then measures the result to determine the dimmer setting. The approach is compatible with all forms of AC line controlled dimming. If you happen to be using jars filled with salt water as your dimmer it will work with that too.

Conclusions

By closely emulating an incandescent lamp’s dimming behavior, improved LED power supply dimming technology will enable those in the theatrical, stage and TV world to seamlessly blend their differently generated lighting to make the transition from incandescent to LED over a cost-managed duration.

Venue owners and stage managers can incrementally and cost- affordably retrofit their incandescent systems to LED, with no loss in lighting performance. Full-range, high performance LED dimming is about to take center stage.