Sensors and Feedback Control of Multi-Color LED Systems by MAZeT GmbH

To obtain stable and consistent lighting conditions within the black body range with LED systems, especially RGBx systems is a challenging task. Feedback controlled systems are expensive, but the best solution. Here, the question of which type of sensor accomodates the given application best, arises. Thomas Nimz, Fredrik Hailer and Kevin Jensen from MAZeT GmbH discuss different options based on their scientific studies on LED systems with four or more different LEDs considering secondary conditions like color rendering index.

Despite many advantages of the LED in general, the lighting industry is facing difficulties maintaining stable and consistent lighting conditions within the black body range. When combining LEDs of different vendors and quality it has been a general procedure to rely on binning methods to ensure a stable light color value output. The utilization of LED technology is increasing in medical or high quality productions. These applications require not only accurate color value outputs but also need to be stable and consistent in the long-term. By implementing feedback control solutions, it is possible to directly regulate lighting conditions based on color values on the black body curve.

Modern solutions nowadays are the application of color sensors to achieve the feedback control loop. These measure the actual or target color values and trigger the LED drivers to adequate current output values. The most accurate method to measure spectral values is performed via spectrometer. However, this technology is often too slow and expensive to meet market needs. Therefore, color sensors are a cost-efficient solution and during initial phases of prototyping and development, spectrometers are used to determine reference values. The color sensor market knows technologies with various spectral properties. The most ommon are the traditional RGB, or True Color sensors based on the CIE 1931 standard (human eye perception).

The following evaluation is based on a lighting system prototype consisting of multiple LEDs with different spectral values. The pre-selection included ten different LED sources, such as narrowband LEDs like red, green, blue – or broadband LEDs like warm-, cool- and neutral-white. During these studies a pre-selection of possible color sensors was simulated. The goal is to achieve the best possible quality based on accuracy within the black body curve and therefore RGB and True Color sensors will be reviewed and compared. Subsequently, the following question needs to be answered: “Is it possible to improve the overall perception based on the Color Rendering Index by implementing intelligent feedback control algorithms?”

Fundamentals

Why to use feedback control

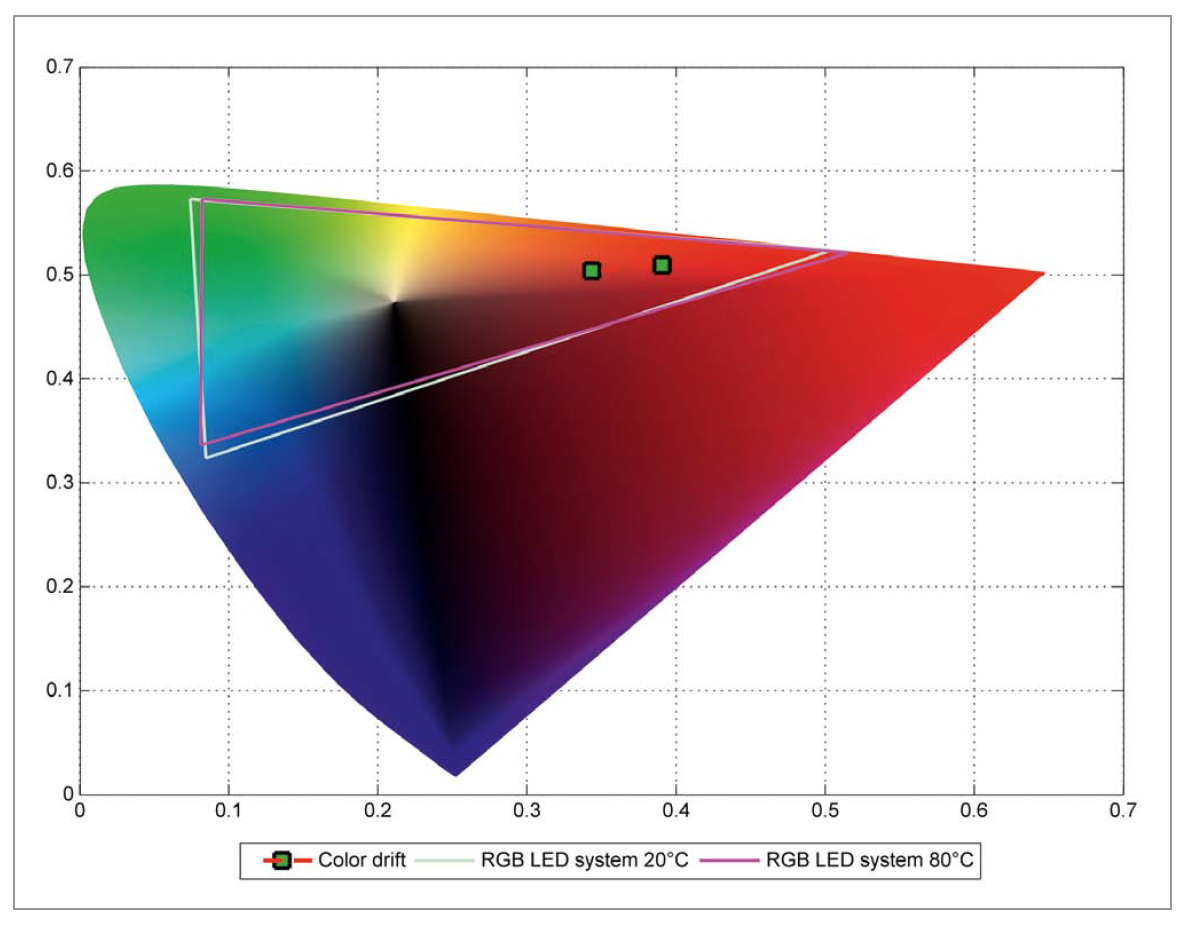

It is common knowledge that temperature and aging effects cause shifts in LED characteristics. The learning curve of the first generation of LED systems has shown that not only brightness, but also the color properties have changes over long-term operating hours. Figure 1 demonstrates the target color shift of a simple RGB LED system based on individual LED drifts. This example is caused by the physical properties of LEDs as they change their color point depending on temperature and the current flow. The LED system temperature increased continuously from 20°C to 80°C (68°F -176°F).

Figure 1: Example of color drift based on RGB system

Solutions via temperature measurements are used to adapt the current and voltage of the LED drivers. This mentioned method is an indirect control of the target color. However, the system has insufficient information about the actual color values. The results are based on approximation rather than active color detection. A feedback control solution based on color detection sensors on the one hand, guarantees to be able to achieve the target color value and on the other hand, to enable an active control option. For example: if a single LED within the system fails it is possible to detect this error and to directly react to the negative side effects. A potential counter measurement in reaction to a red LED failure would be to increase the amber color values. Feedback control loops establish many new options to increase the quality and the operation time of LED systems.

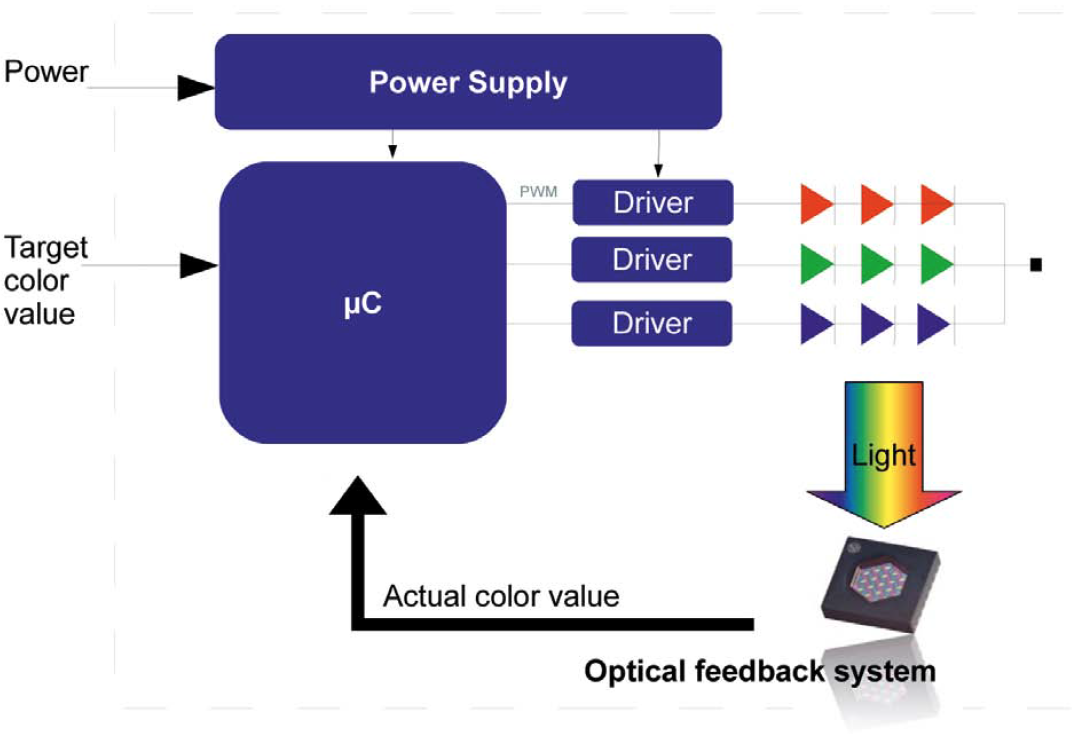

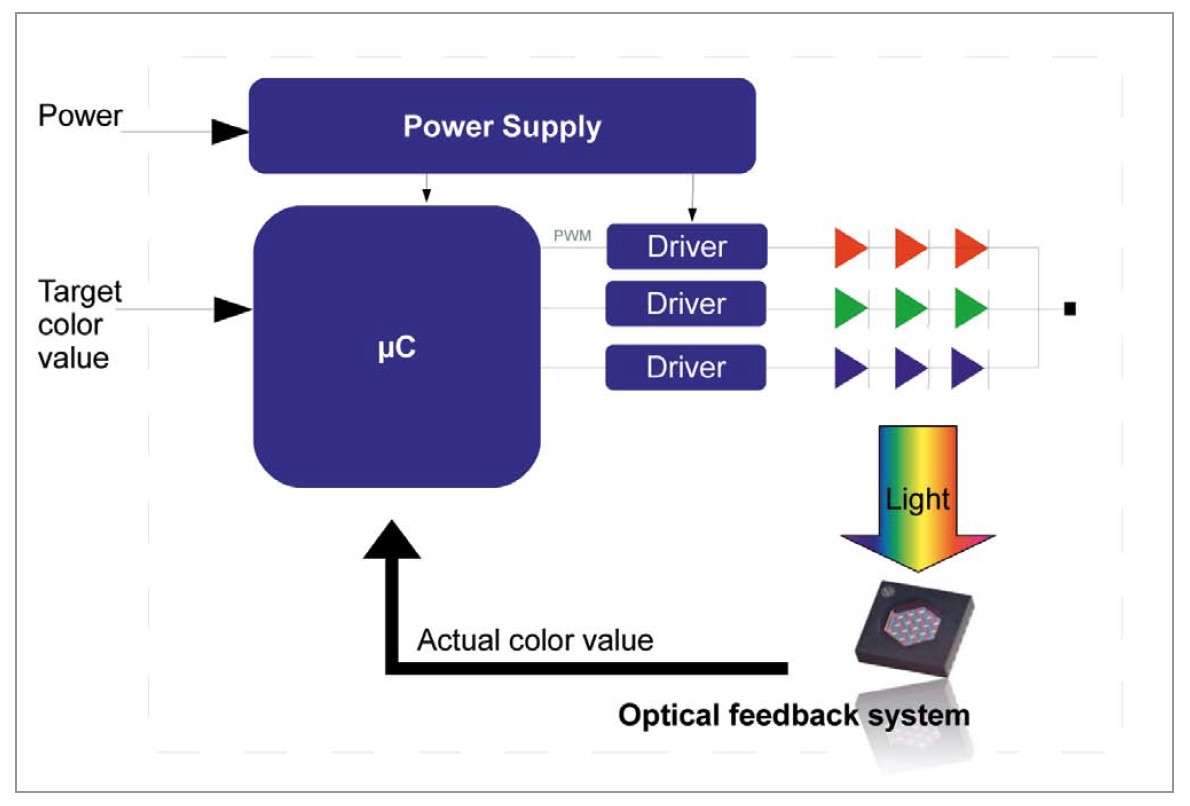

Feedback control system

Feedback control LED systems mentioned in this paper consist of a power supply, LED driver, microcontroller and color sensor. The goal is that the normal user does not need to know information about the feedback control system or algorithm. Normally, the user only sets the color values - for example, color temperature or direct color point. The system calculates the first LED combination and starts the controlled lightning process. Afterwards the color sensor measures the specific color values; the microcontroller compares the actual color values with the target values. If the color deviation is too high the correction algorithm values are used to trigger the current and power supply of the LEDs. In this way the LED system reacts automatically to external influences. Therefore, it is possible to increase the properties like long-term stability or avoid negative temperature drift effects without any visible change to the user.

RGB or true color sensor

The accuracy of the entire LED system mostly depends on the color detection sensor. The system cannot be more accurate or faster than its main component. Because of this, it is important to choose an adequate color sensor for the specific application at hand. As mentioned, the market mainly knows RGB and True Color sensors.

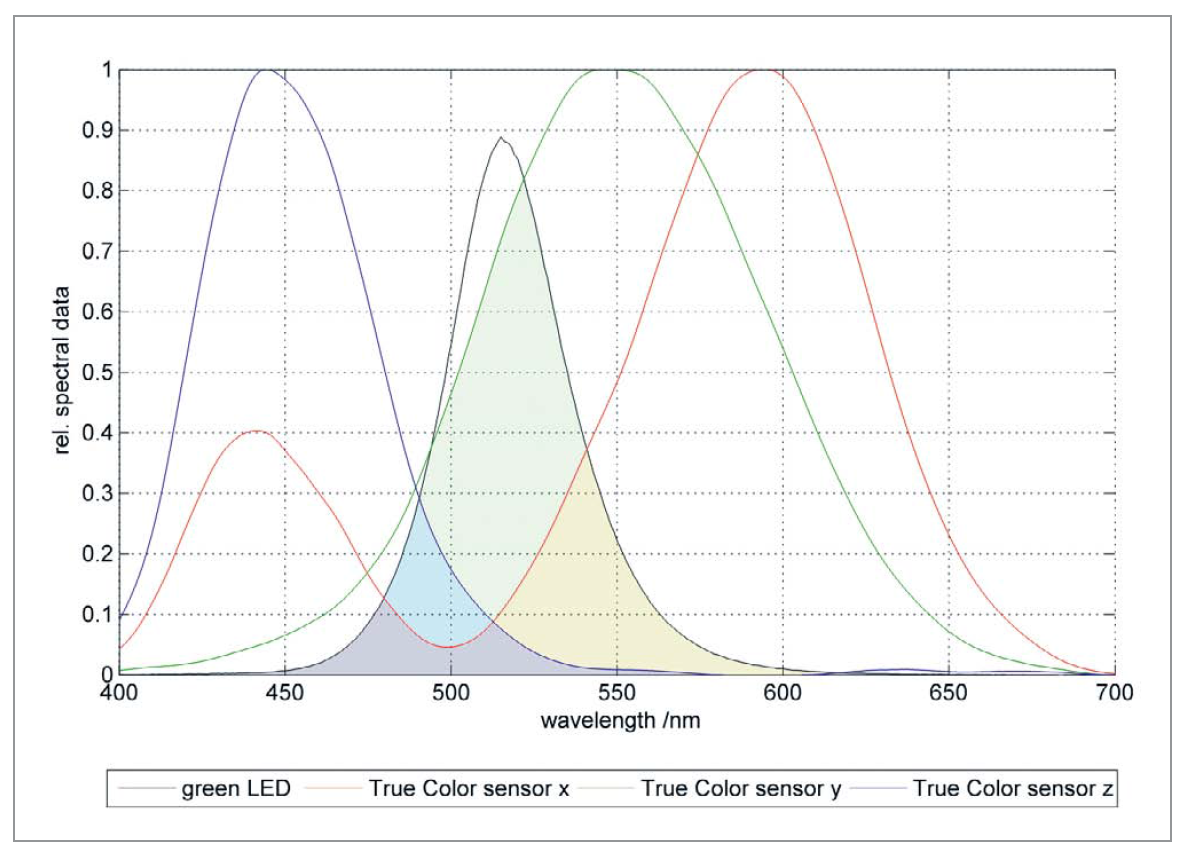

The RGB sensor has three characteristic curves; one for red, green and blue respectively. The measured RGB values can be transferred via the tri-stimulus values X, Y, and Z. The measurement values of a True Color sensor correspond directly to the CIE 1931 standard and the respective tri-stimulus values. The special feature of True Color sensors is that the characteristic curves comply with perception of the human eye. XYZ values enable conversion of the color point into every color space.

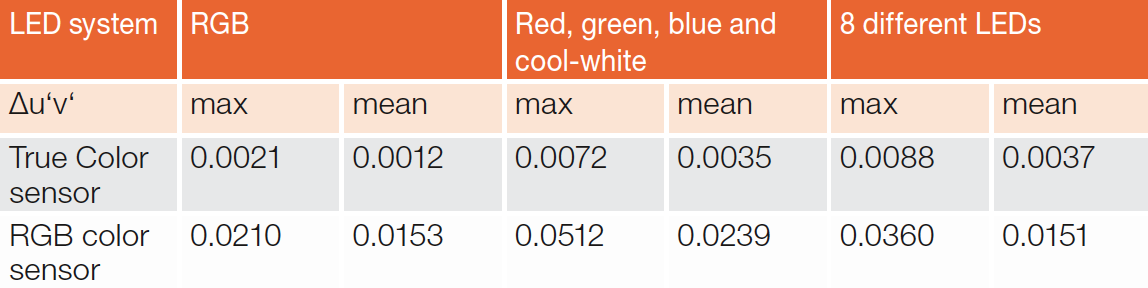

The selection of the ideal color sensor for this paper was performed after various simulations. The goal was to calculate the color measurement along the black body curve via RGB and True Color sensors. Three LED systems have been used, one RGB- LED system (with red, green and blue LEDs), one RGB LED system with an additional cool-white LED and last but not least a LED system with 8 different LEDs. To compensate the manufacturing variances it is required to calibrate the systems. The calibration is based on the color points of the built-in LEDs. Therefore, three calibration matrixes have been calculated for each sensor. The calibration was performed at 20°C, while the measurement was performed at 80°C (68°F -176°F).

Figure 2: Schematic of feedback control system

Figure 2: Schematic of feedback control system

In the next step a spectral calculation of 450 color values along the black body curve for each LED system was performed (at 80°C). Subsequently, the generated spectrum data was measured via an RGB sensor, True Color sensor and spectrometer. The spectrometer results are later used as reference values.

The result of the simulation shows that the color deviation of the True Color sensor measurement was smaller than the color deviation via RGB sensor measurement. It is general knowledge that the human eye cannot detect color deviations smaller than 0.003 Δu‘v‘. The measurements have shown that the RGB sensor is not capable of measuring color values with the required accuracy. If an RGB LED system is used with True Color sensors a standard calibration achieves the limit of 0.003 Δu‘v‘. An LED system with more LEDs than just the red, green and blue generates a higher deviation – this applies both for RGB sensors and True Color sensors. Therefore, within an RGB cool-white LED system the maximal Δu‘v‘ is twice as large as a standard RGB lighting system, for example. Via optimized calibration it is still possible to achieve the required limit of 0.003 Δu‘v’ using True Color sensors. The simulation has shown that True Color sensors achieved the best accuracy for color rendition in high quality applications.

Figure 3: Characteristics of True Color sensors

Figure 3: Characteristics of True Color sensors

Feedback Control Loop

Systems with four or more different LEDs

While utilizing a feedback control loop within a RGB LED system, three input parameters (Color - for example Lu’v’) and three output parameters (PWM of the RGB LEDs) are used for the calculations. It is possible to determine one solution by means of a linear transformation - exactly one solution exists. For a system with more than three different LEDs, for example RGB and warm-white LEDs, multiple solutions are possible. The system has three input parameters - but four output parameters, which leads to an over determined system. Therefore, different combinations for one color point can be calculated. The result is a variation of the spectrum, depending on the PWM frequency of each LED, whereas every spectrum has its own properties. For systems with 5, 6, 7 or more different LED types, even further combinations are possible. Therefore, it is particularly difficult to find the optimal solution without defining specific side conditions.

Table 1: Color variations along the black body curves

Table 1: Color variations along the black body curves

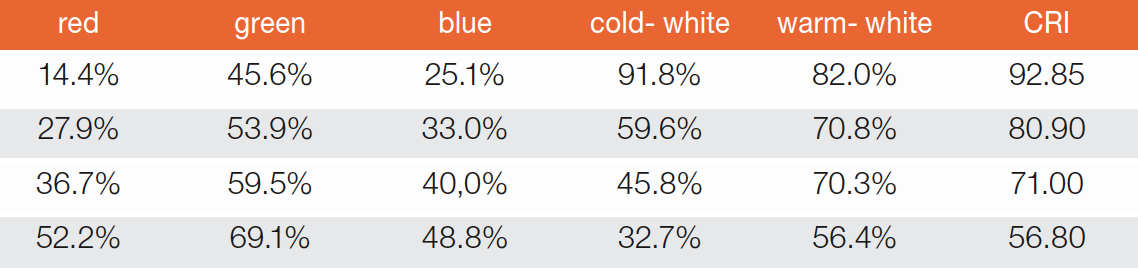

Table 2: LED combinations for D65 /10° observer

Table 2: LED combinations for D65 /10° observer

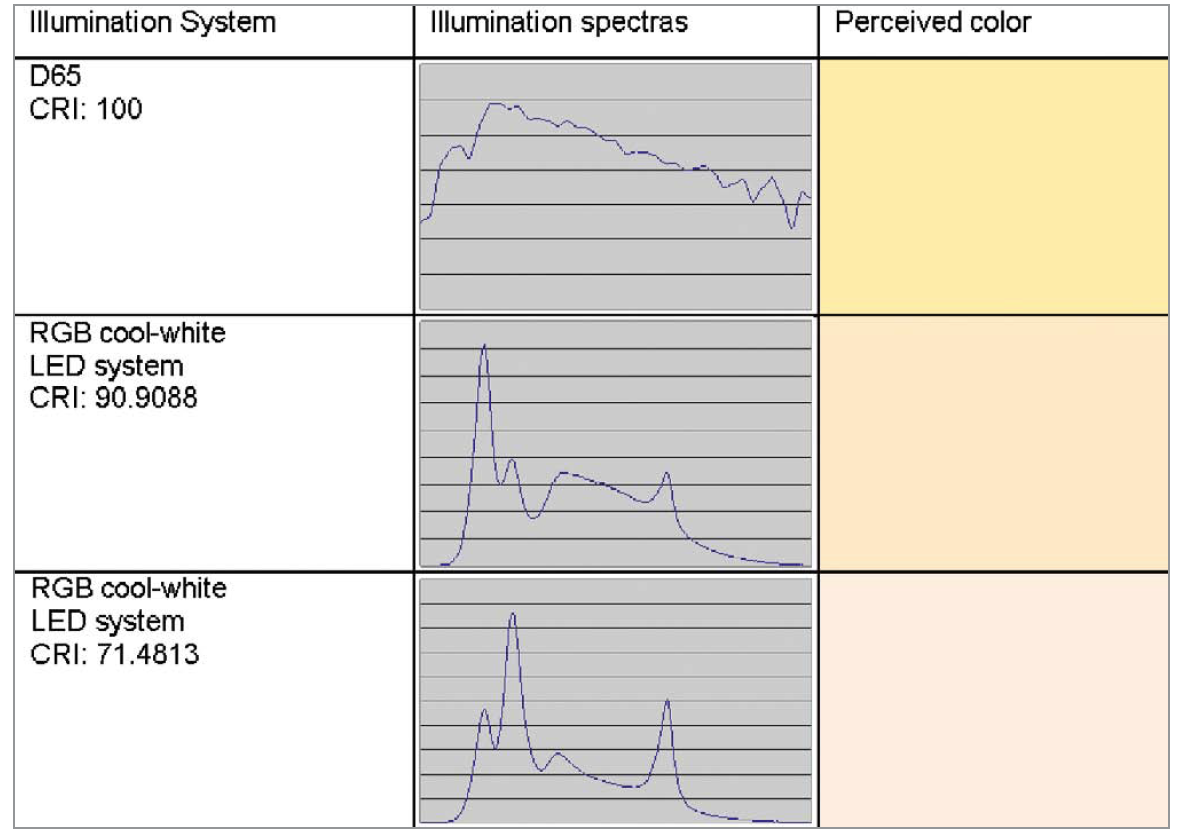

The color quality does not solely depend on the chosen LEDs, but also on the respective LED control solution. Example 5 shows the different color perception in relation to the incoming light spectrum. Even though the same test ‘RGB cool-white LED’ system has been used, the results clearly show color variances within the visible spectrum, when illuminating with different LED combinations for one color value.

The task is to find the best PWM combination considering secondary conditions such as Color Rendering Index (CRI) or luminosity. The algorithm should be independent of the number of LEDs and also should be able to include the physical properties of the LEDs.

Figure 4: Color perception within different visible spectras

Figure 4: Color perception within different visible spectras

Solution approach

A simple algorithm is a solution with a feedback control matrix. This matrix is calculated using a linear ransformation. The input parameters are the sensor values for several color targets.

Usually, the preset LED color values are used for the initial calculation. Sometimes the result can be optimized if extra combinations of multiple LEDs are used, for example, color values along the black body curve. This method has insufficient information about a secondary condition like optimizing the Color Rendering Index. Because of this, it is expected that the quality of the spectra for some color values near the black body curve are suboptimal. It is useful to find improved algorithms, which integrate selected side conditions.

One solution is to split the color gamut of the LED system in many smaller sub-gamuts. Every sub-gamut is formed via three corner points. One corner point corresponds to a color point of an LED. The more LEDs are used the more sub-gamuts will exist. If the target color point is a part of the sub-gamut, the LED combination will be calculated using linear transformation. The results are various combinations for each different sub-gamut. In the second step one combination from the previous results depending on the secondary conditions will be used as calculation basis. For example: using one algorithm to combine the results and to guarantee an optimized Color Rendering Index value.

This resulting combination is used as the initial values of the control system. Via this combination it is possible to approach the target color point. The external effects of the LED system (temperature, flow current and aging effects) cause a minor color deviation. Therefore, to remove the final color drift, only little control calculation needs to be performed.

Conclusion

The simulation and concluding measurements have demonstrated that it is essential to use a feedback control-loop solution if long-term stable color rendition is a main goal of the application. While comparing RGB with TCS, the results have shown that in most cases RGB sensors are not accurate enough to provide optimal input values for accurate color regulation. (For example, medical applications.) To achieve the best quality possible one needs to focus on the following four aspects:

• The right choice of the color detection sensor for the specific application (in this test the TCS were the preferred choice)

• The right choice of LEDs regarding quality, quantity and cost-efficiency

• Calibration of the sensors to the specific application at hand

• Finding an idea control and regulation algorithm

Reviewing the initial question regarding intelligent feedback control algorithms to improve the overall perception based on the Color Rendering Index one must say that the color rendition quality is not solely enhanced by increasing the number of used LEDs. The quality also depends on the spectrum produced by the LED combinations. Via feedback control algorithms optimized with adequate side conditions (like CRI) it is also possible to improve the output quality/ color rendition. When evaluating these aspects during the development of a feedback control solution, it is possible to minimize the required number of LED light sources within a system to achieve an equal or better CRI value. Other options are to reduce the overall number of selected LED light sources while still achieving the required output values. These control options via optimized regulation algorithms make it possible to reduce costs or adapt LED lighting solutions to green technology standards like Energy Star.

References:

[1] Application note, Calibration of JENCOLOR sensors based on the example of LED light sources, MAZeT GmbH, 2012

[2] DIN-Taschenbuch 49, Farbmittel1 – Pigmente, Füllstoffe, Farbstoffe DIN 5033-1 bis DIN 55929, DIN Deutsches Institut Für Normung,2000

[3] Friedhelm König, Die Charakterisierung von Farbsensoren, Logos Verlag Berlin, 2001

[4] Franke, Jahn, Grunert, Krumbein, Sieß and Stüpmann, Moderne Methoden der Farberkennung, TU Illmenau / ZBS e.V., MAZeT GmbH, SilicANN Technologies, 49. Internationales Wissenschaftliches Kolloquium / TU Ilmenau, 2004