Reliability Oriented Design of LED-Based Light Sources

The transition from traditional light sources to SSL systems requires a different design philosophy to achieve the advantages offered by LED light sources. The key approach is based on the parallel design of thermal, electrical, optical and spectral properties of the light source. Matteo Meneghini, Gaudenzio Meneghesso, Enrico Zanoni and Matteo Dal Lago from the Department of Information Engineering at the University of Padova, and Nicola Trivellin from LightCube SRL explain this approach including the importance of the electrical management of LEDs, comparing modulation techniques to constant current, differentiating between versatility and efficiency.

The performance of LED-based light sources is increasing day-by-day, thanks to the continuous efforts of manufacturers and researchers on the developments of this technology. As a consequence, solid-state light sources have higher efficiency and similar color rendering compared to conventional light sources, and have costs that are rapidly decreasing as the market penetration increases. Despite the excellent characteristics of modern power LEDs, several factors complicate the development of robust and efficient LED-based light sources, including a non-trivial thermal management, problems related to chemical compatibility, the need of designing suitable optical and mechanical design, and developing efficient electrical configurations.

This paper analyzes the major issues related to the design of reliable LED-based light sources, by giving an overview of the most important aspects and most advanced techniques required to ensure long-lasting performances of these innovative light sources.

Thermal Evaluation

The thermal management is probably the most important issue related to the development of a reliable solid-state light source. In fact, with a non-adequate heat dissipation, the LED modules can reach extremely high temperature levels which dramatically reduce the luminaire lifetime: every single interface in the thermal path between the active area of the LED and the environment can act as a bottleneck for the heat flow, and then an extremely accurate thermal evaluation is imperative in the luminaire design process.

In the following we describe the most common methods that allow one to characterize the thermal behavior of a light source. The most basic technique is to measure the temperature of the various luminaire parts during operation, through a thermocouple or other type of temperature sensors (e.g. NTC thermistors). This procedure does not extract the temperature reached by the LED junction, but provides information on the temperature reached by the board during operation. For this reason, this method is convenient only for a qualitative evaluation of the self-heating of the devices.

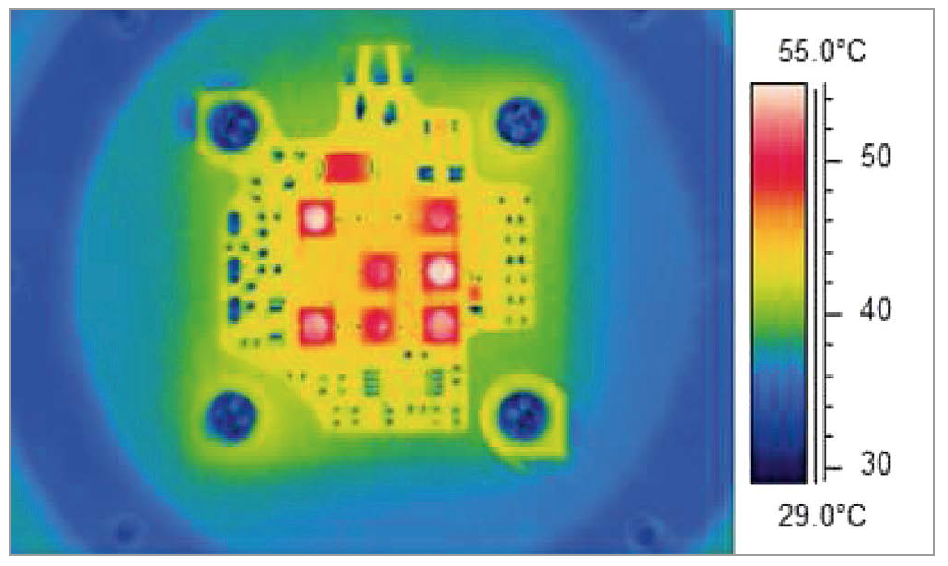

A more accurate thermal characterization can be carried out by means of an infrared camera: the IR camera imaging instantaneously provides several data on the heat distribution across a circuit board or over the lamp body. Figure 1 shows an example of an IR image of a solid-state lamp, where it is clearly visible the heat distribution near some of the LEDs and the driving circuitry. The IR camera is extremely useful for understanding the thermal behavior of the whole lighting system and to identify potential criticalities of the design. The main disadvantage of this technique is related to the different materials of which a LED lamp is constituted: in fact, the various metal and plastic materials have different infrared emissivity values, and – for this reason - it is difficult to compare the temperature levels measured with the IR camera on different materials. Another limit of IR imaging is that the camera detects the infrared emission of the surface of these devices, which – in general – does not correspond to the temperature levels reached by the junction of the LEDs: for example, the IR measurement carried out on an LED gives information about the temperature reached by the plastic lens that covers it, and not on the temperature level of the active area of the LED itself. Figure 1: IR image of a LED board during operation

Figure 1: IR image of a LED board during operation

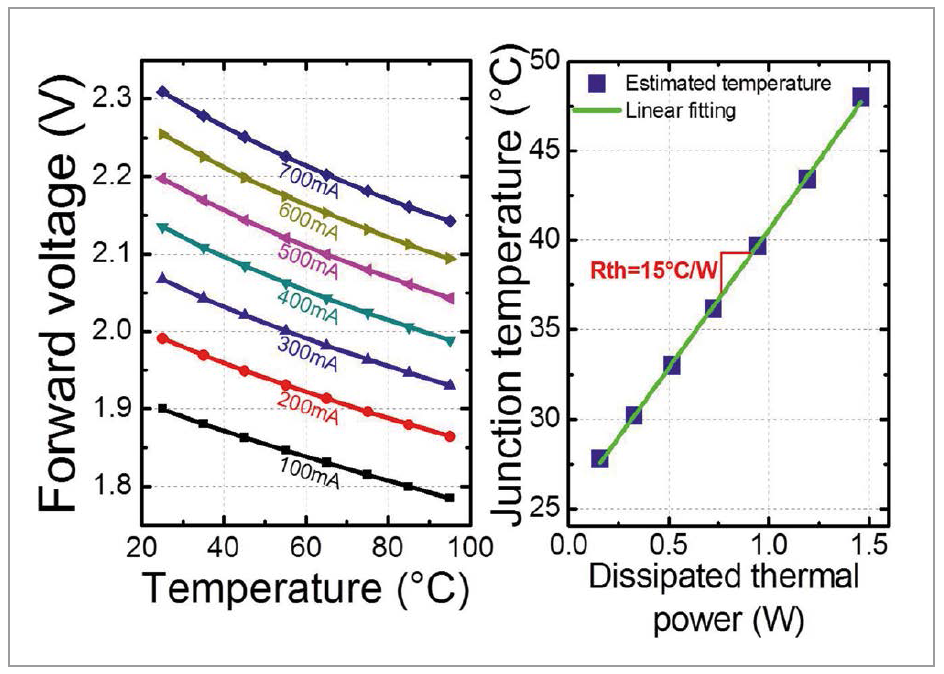

Since it is not possible to directly measure the temperature reached by the junction, the only way to fully characterize the thermal behavior of a lighting system is to use indirect electrical measurements. It is well known that the forward voltage of an LED is strictly related to its temperature. For this reason it is possible to use the forward voltage information to accurately estimate the temperature reached by the chip during operation. In order to establish the relation between the forward voltage and the junction temperature it is necessary to submit the LED to current pulses while varying its temperature by mean of a temperature chamber or a Peltier-cell. The duration of these current pulses must be considerably short in order to avoid a significant self-heating of the device. In the left side of figure 2 is reported one example of this calibration measurement carried out on an LED in a temperature range from 25°C to 95°C at different current levels. Once the calibration measurement is done, it is sufficient to measure the forward voltage of the device during operation to estimate its junction temperature.

Figure 2: Example of a thermal calibration measurement on a power LED (left). Example of thermal resistance evaluation (right)

Figure 2: Example of a thermal calibration measurement on a power LED (left). Example of thermal resistance evaluation (right)

Thanks to this technique it is possible to estimate the thermal resistance of one LED or of an LED cluster, which is obtainable as the slope of the linear dependence between the junction temperature reached during operation and the generated thermal power, as visible in the right side of figure 2. Although this procedure requires a complex set of measurements and is more time-consuming with respect to the IR characterization, it is the most reliable way to carry out absolute temperature and thermal resistance estimates on LED based light sources.

Influence of the Operating Conditions on LED Performance

Despite the excellent performance of the state-of-the-art LEDs, a high-quality luminaire design cannot neglect their limits in order to exploit their full potentialities in terms of efficiency and robustness. Unlike incandescent lamps, a rise in temperature and operating current in LED based light source leads to a worsening of its electrical and optical characteristics. There are several studies that correlate the decrease of the optical efficiency at high current densities to two different physical mechanisms, one temperature-dependent (“thermal droop”) and one related to the operating current (more precisely to the current density, the “efficiency droop”).

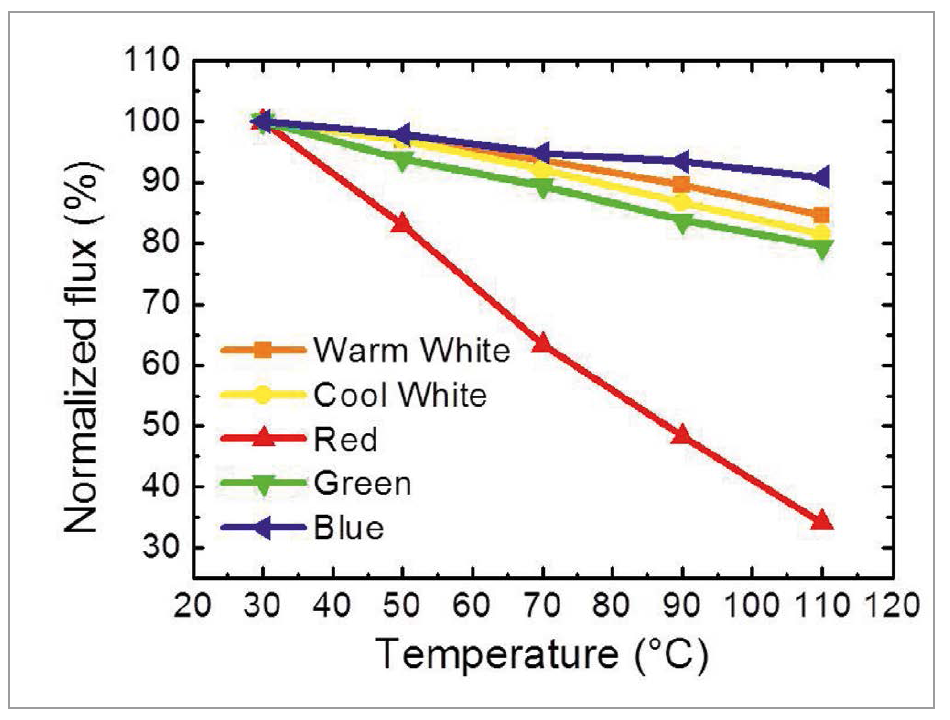

Figure 3: Optical power decay at different temperature levels for different colored LEDs

Figure 3: Optical power decay at different temperature levels for different colored LEDs

Figure 3 shows the optical power decay caused by the temperature rise in different power LEDs with different emission wavelength: this problem is significantly marked in red LEDs (due to the fact that – at high temperature levels – carriers can easily escape from the quantum wells and to an increased non-radiative recombination) and must be carefully considered when the red LEDs are used together with LEDs of other wavelengths in a multi-color light source.

On the other hand, the efficiency droop is supposed to be related to Auger recombination, and/or to carrier leakage. Auger recombination occurs mainly at high injection levels, when an electron-hole recombination transfers its energy to another electron. This excited electron loses then the acquired energy in a series of collisions with the lattice, without light emission. As showed in [3] this type of recombination process is one of the possible causes of the current-dependent efficiency droop.

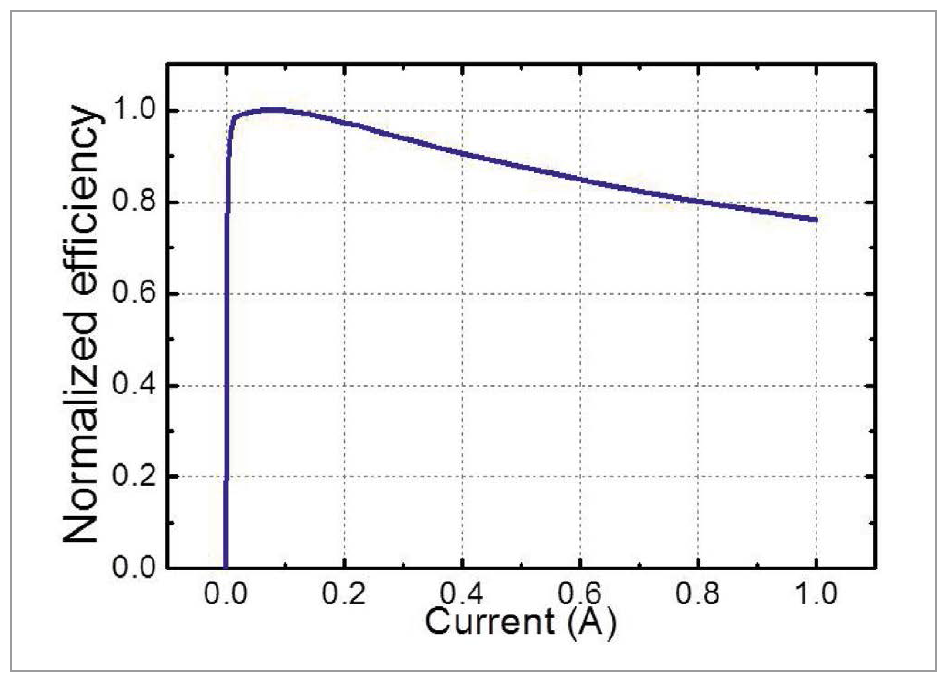

The impact of the efficiency droop on the performance of LED-based light sources is dramatic. Figure 4 shows the dependence of the efficiency on current density for a modern power-LED: this device, which can operate at current levels up to 1 A, loses the 20% of its maximum efficiency at the higher current condition. This type of information is extremely important in the design of an LED-based light source and especially for the choice of an appropriate operating current: since the efficiency is higher at lower current levels, the only way to obtain the maximum efficacy results in LED systems is to reduce the operating current with subsequent increase in the number of required LEDs.

Figure 4: Efficiency of a white power LED at different current levels

Figure 4: Efficiency of a white power LED at different current levels

Operating Conditions and Reliability

The two most important factors that accelerate the degradation of a solid-state light source are temperature and current. Both high temperature and excessive current flow cause long term modifications on the physical structure of the LED die and on the packaging materials. The close correlation between these two factors implies that an appropriate operating current cannot be chosen without an accurate thermal evaluation (as described in the first section of this paper).

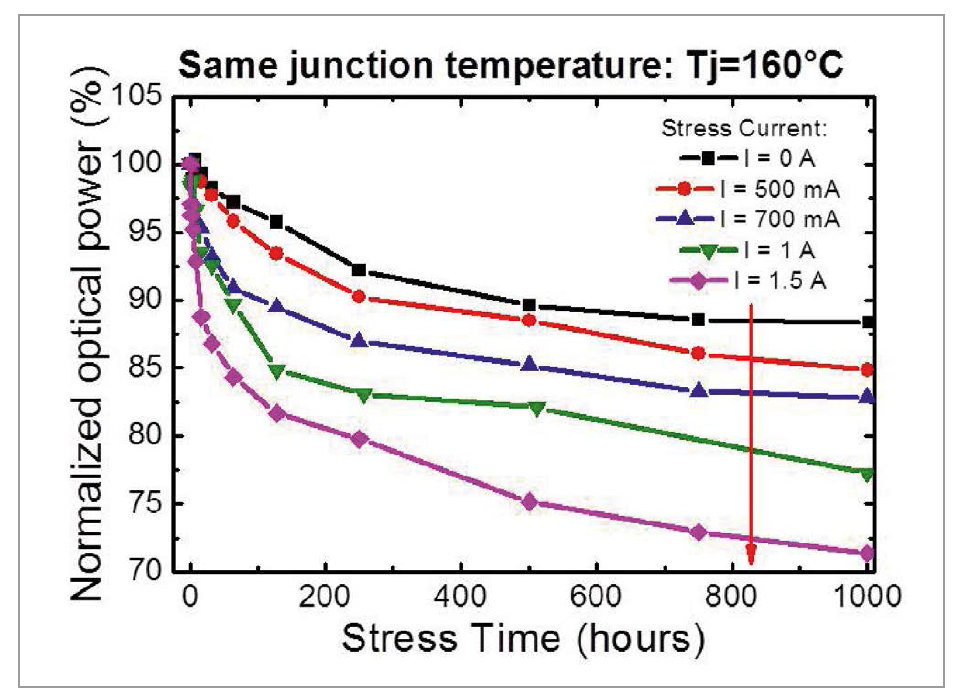

A high current density can cause different types of long-term modifications of the electrical properties of the chip, such as the generation of lattice defects; these modifications have important effects on the electrical behavior of the LED (i.e. I-V characteristics) but also degrade significantly its optical efficiency, as reported in figure 5 which shows the optical power decay on LEDs submitted to different current levels stress tests operating at the same junction temperature. Another important consequence of the operation at high current level is the large amount of heat generated by the device.

Figure 5: Optical power degradation of white LEDs submitted to stress tests at different current levels with the same junction temperature (Tj=160°C)

Figure 5: Optical power degradation of white LEDs submitted to stress tests at different current levels with the same junction temperature (Tj=160°C)

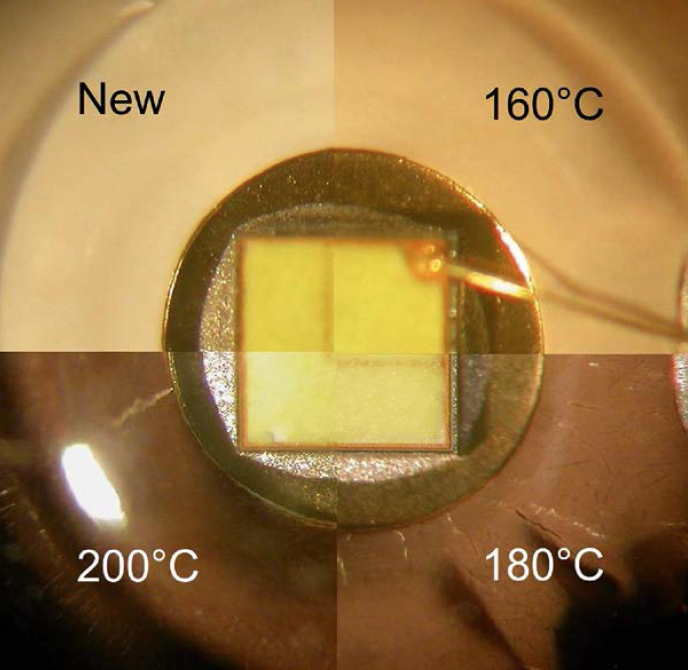

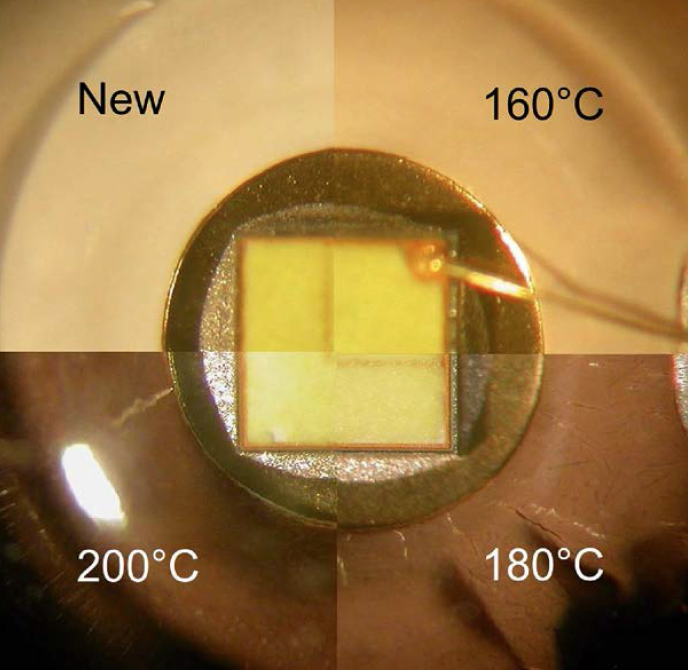

The high temperature levels generated by self-heating (or imposed by the environment) have serious consequences on both the electrical characteristics and the optical/ mechanical properties of the whole materials of the lighting system. Regarding the electrical modifications, high temperature levels trigger several types of degradation mechanisms such as the degradation of the ohmic contacts, and also concur in the defects generation activated by the carrier flow. Exactly as the semiconductor material, also plastics and metals can be affected by the operation at high temperature. In general the plastics used for the optics and for the package, can darken after some thousand hours at high temperature, as shown in figure 6 which reports an example of browning of the plastic reflector cup on a white LED. This material darkening can reduce the LED light emission of a significant part and may also lead to a variation of the colorimetric characteristics of the device.

Figure 6: Package browning after 64 hours of operation at different temperature levels

Figure 6: Package browning after 64 hours of operation at different temperature levels

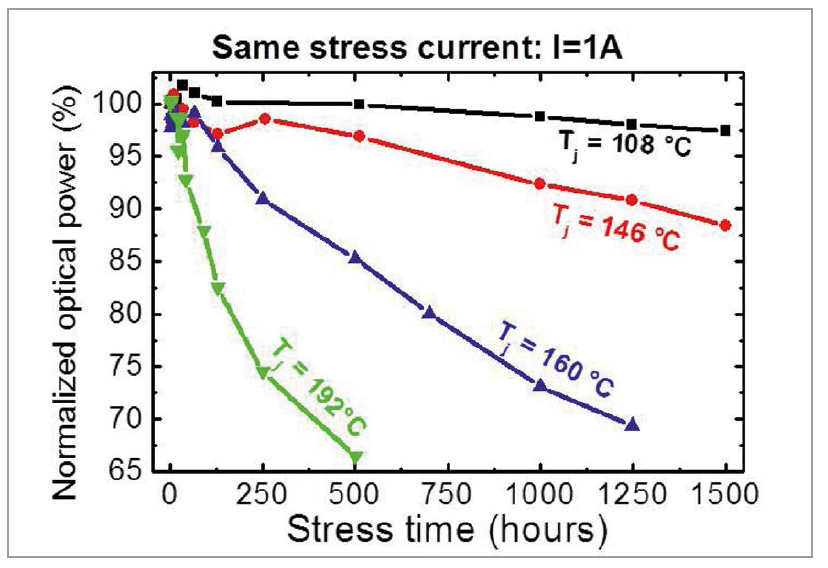

Another problem of operating LEDs at high temperatures is related to the different mechanical expansion coefficients of the various materials that can cause the lens cracking and the detachment of the different mechanical interfaces. Figure 7 shows a comparison between four different stress tests carried out at the same current and different junction temperature.

Figure 7: Optical power degradation of white LEDs submitted to stress tests at different temperature levels with the same operating current (I=1A)

Figure 7: Optical power degradation of white LEDs submitted to stress tests at different temperature levels with the same operating current (I=1A)

The results of the accelerated stress tests reported in figures 5 and 7 show that, even under the limits recommended by the manufacturer, the lifetime of the modern power LEDs can be significantly reduced due to inappropriate design choices.

Types of Failure Mechanisms

In the design of a LED-based light source, the knowledge of the effects of non-adequate operating conditions is imperative in order to fully understand the limits of the currently available technology.

Overvoltage and overcurrent events often lead to the fusion of the bonding wire that connects the chip: this phenomenon can be dramatic in an LED system where a large number of LEDs are connected in series because the failure of single LED can cause the opening of the circuit and then the complete shutdown of the luminaire.

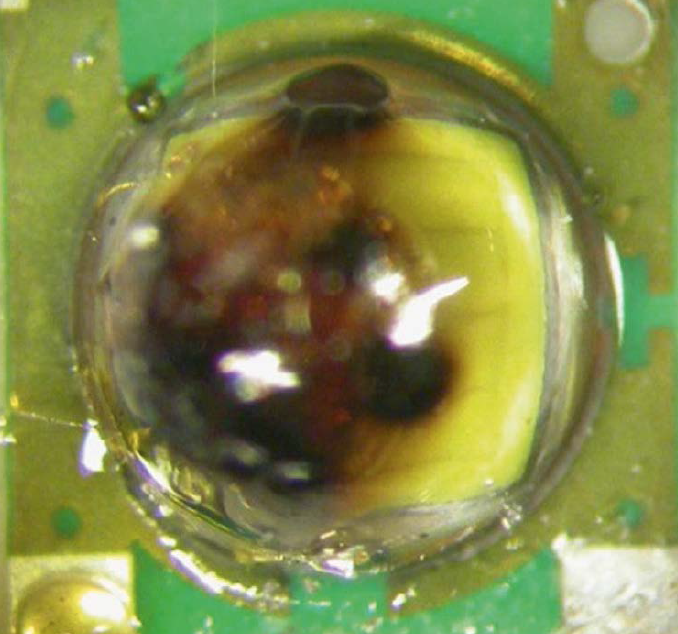

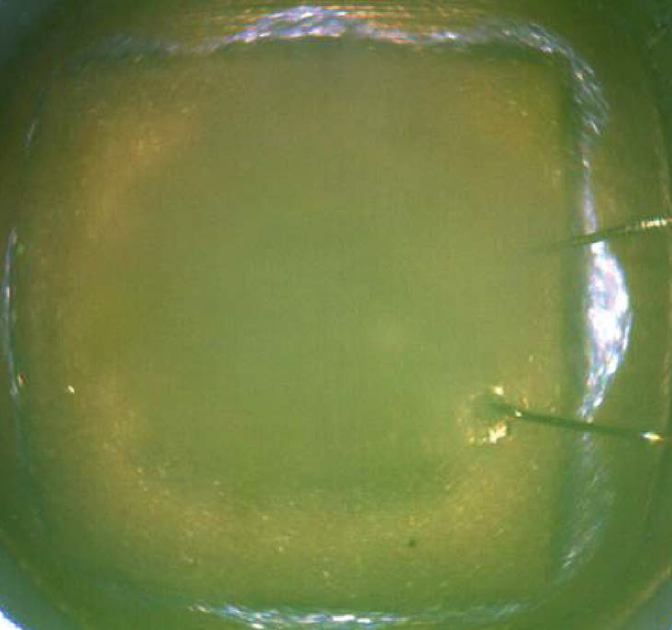

Another type of failure mechanism can be associated to the chemical compatibility with all the substances that can interact with the LED materials: in fact there is a large set of compounds (often indicated in an specific document by the LED manufacturer) that can seriously damage the device. In figure 8 is an example of silicone lens shown that has been in contact with the soldering flux, which becomes darker after the first hours of operation. The picture of figure 9 reports the effect of the moisture penetration below the silicone lens that has caused a gradual blurring of the optical interface.

Figure 8: Silicone lens contaminated with soldering flux after 24 hours of operation

Figure 8: Silicone lens contaminated with soldering flux after 24 hours of operation

Figure 9: Image of the humidity penetration effect below the lens of a white LED

Figure 9: Image of the humidity penetration effect below the lens of a white LED

These are just few examples of the problems that one may encounter when the development of a LED-based light source is not supported by an accurate assessment of all the reliability issues involved.

Multi-LEDs Systems

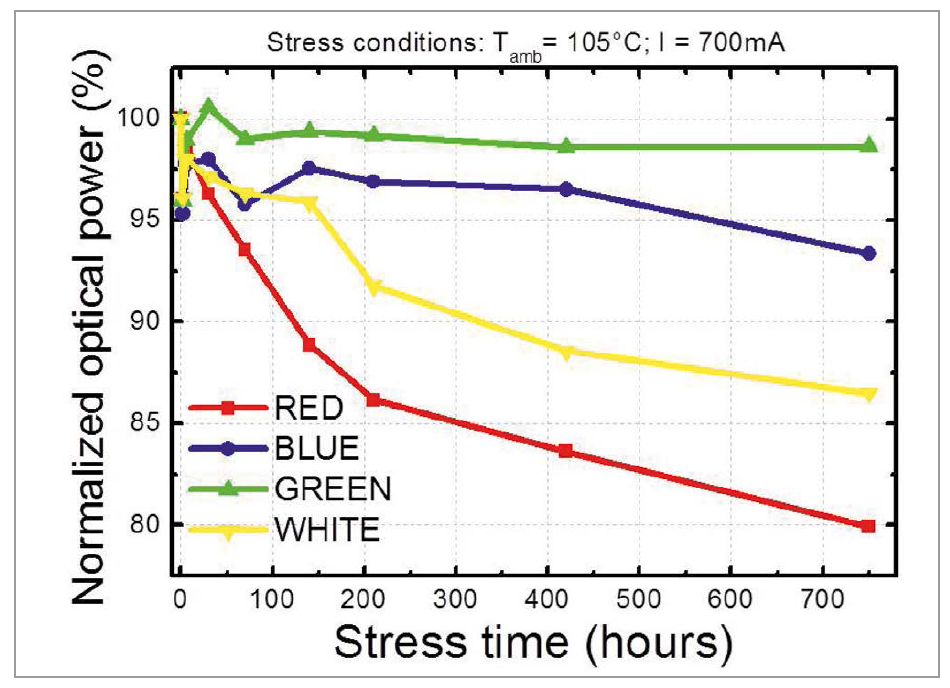

One of the best ways to improve the photometric and colorimetric qualities of the solid-state light sources is to mix devices of different colors in order to enrich the emission spectrum and to increase the CRI. Multi-colors light engines allow also to dynamically changing the light characteristics according to the needs. The behavior of LEDs with different emission wavelengths in terms of robustness and performance introduces serious difficulties to the design of a multi- LEDs light source. In fact as showed in figure 3, different colors LEDs have a different drop in optical efficiency with the temperature increase. Furthermore, different types of LEDs have also different robustness to the operating condition, as highlighted by the graph of figure 10, which compare the degradation of different colors LEDs submitted to the same operating conditions. This aspect leads to the conclusion that without any type of dynamic control, the performance of a multi-LEDs lamp cannot be sufficiently stable due to the variation of the relative intensity of the various colors emissions.

Figure 10: Optical power degradation of different colored LEDs submitted to a stress test at the same operating conditions (Tamb=105°C, I=700mA)

Figure 10: Optical power degradation of different colored LEDs submitted to a stress test at the same operating conditions (Tamb=105°C, I=700mA)

The best way to avoid the colorimetric thermal drift of these types of light sources is to integrate a temperature sensor inside the LEDs circuit board. Hence it is sufficient to automatically modify, through an appropriate algorithm, the biasing configuration of the different colors LED chains according to the detected temperature during operation. However, this technique doesn’t take into account the degradation of the devices during long-term operation. For this reason, in multi-LEDs lighting systems, it is often necessary to introduce a photodiode (single or multi-color) to detect and correct the variation of the colorimetric characteristics of the light source.

Conclusions

This article has presented some of the major issues related to the design of a solid-state light source, with particular focus on the reliability aspects of the state-of-the-art LED technology. Since the LED-based light sources represent the future of lighting in all the different application areas, it is important that lighting designers broaden their knowledge on all issues that must be addressed to develop a reliable and efficient light source. Even if the technological progress leads to the production of more robust devices, some limitations will remain because they are inherently related to the LEDs functioning. Although it requires a few more steps, a reliability oriented design will lead to numerous benefits in terms of performances, maintainability and longevity and certainly it will increase the commercial attraction on the new born light sources.

References:

[1] Kim et al. “Origin of efficiency droop in GaN-based light-emitting diodes”, Appl. Phys. Lett. 91, 183507 (2007)

[2] Bochkareva et al. “Defect-related tunneling mechanism of efficiency droop in III-nitride light-emitting diodes”, Appl. Phys. Lett. 96, 133502 (2010)

[3] Kioupakis et al. “Indirect Auger recombination as a cause of efficiency droop in nitride light-emitting diodes”, Appl. Phys. Lett. 98, 161107 (2011)