Quantum Dot Based White LEDs for General Illumination

Colloidal quantum dot based white LEDs can be integrated into commercial products meeting the stringent reliability requirements for general illumination and providing LED efficiency gains of 5% to 15% over commercial phosphor based LEDs at CCT’s ranging from 5000 K to 2700 K. Unlike earlier demonstrations, the QD material is applied in an on-chip configuration resulting in drop-in fit, form, and function compatibility to existing LED based luminaires and lamps. Ken T. Shimizu, Director, Novel Technologies and Devices, Research and Development, M. Böhmer, D. Estrada, S. Gangwal, S. Grabowski, H. Bechtel, E. Kang, K. J. Vampola, D. Chamberlin, O. B. Shchekin, and J. Bhardwaj from Lumileds showcase the advantages of on-chip QD LEDs: A commercial lamp at 3000K color temperature and 90 CRI is substituted with QD based LEDs resulting in a system level efficiency gain up to 17%, attributed to the reduced blue LED droop from the lower drive current and the lower heat sink temperature when compared to the standard phosphor based LED lamp output.

Colloidal quantum dots (QDs) showcase the unique feature set of a tunable band gap that can span the entire visible spectrum with nm resolution by modifying the particle size and a narrow FWHM owing to the direct transition from the band gap edge. Moreover, they exhibit fast radiative excited state lifetime and high quantum efficiency approaching unity in solution [1-4].

The recent commercial success of Samsung QD based LED TV products in high gamut ultra-high definition (UHD) televisions [5] has brought mainstream familiarity to this quantum mechanical phenomenon of a “particle-in-a-box” to everyday reality. The benefit of a narrow FWHM red and green QDs allows for more saturated colors and efficient transmission through the color filters. The same benefit of a tunable and narrow FWHM red QD in general illumination can have even greater impact in terms of color quality and LED efficiency. Although there are no RGB color filters in illumination products, the CRI and R9 requirements to provide high color quality also dictate that the spectrum of white light contain sufficient red photons that are less sensitive in response to the eye. The precipitous change in the photopic response represents a virtual filter where a narrow red emission is needed to maximize both the color quality and light source efficiency.

In the commercial display products, the solution processed QDs are embedded in a polymer film with oxygen barrier coatings applied to both sides. The QD film is placed remotely from the blue LED in the screen of the display and optically excited by blue LEDs in a separate light bar component. This allows the QDs to operate with blue light intensities at or below 1 W/cm2 [6] and at temperatures below 50°C. To date, QDs have failed as a drop -in solution into the LED package because the LED operating temperature and blue flux intensities caused dramatic thermal quenching and fast photo - degradation [7-9]. Although the TV display manufacturers have modified the TV package to accommodate a QD converter layer, an on-chip phosphor application is preferred over remote phosphor configurations as it provides the lowest cost and lowest complexity solution for LED use, especially in cost competitive lighting applications.

We report on the on-chip application of QDs where the QD temperature exceeds 100°C and the blue flux intensity reaches 20 W/cm2 in mid-power LED packages that demonstrate the necessary reliability requirements for commercial use and provide double digit performance improvements. The red QDs offer the greatest benefit when producing high CRI light to bring LED lamps closer to the high color quality of incandescent light sources [10]. To illustrate this effect, 90 CRI LEDs comprising of a red QD based LEDs, red nitride based phosphor LEDs, and a hybrid LED module mixing a red AlInGaP LED and a phosphor converted off-white LED are compared for their efficiency performance.

Experimental

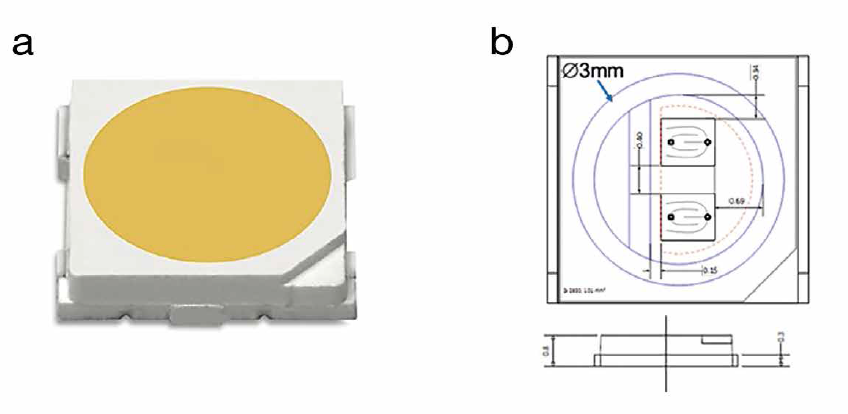

For all experiments described in this paper, engineering builds of Luxeon 3535L HE Plus LEDs were used to validate the performance and reliability. Figure 1a shows a photo of this industry standard mid-power LED and Figure 1b shows the schematic top and side view where two 0.5 mm2 LED chips are attached and wire bonded in parallel to a molded lead frame package. The package dimensions are 3.5x3.5x0.8 mm, the emitting surface diameter is 3 mm and the internal volume for the phosphor slurry is approx. 3 μL [11]. Red (625 nm) QDs in solvent-free, dry powder form with ~36 nm FWHM at 25°C (40 nm at 100°C) were received from Pacific Light Technologies. The QD, phosphor, and silicone mixture was dispensed into the LED package and cured for 4 hours at 150°C in an oven. The LEDs were solder attached following JEDEC J -STD -020D reflow procedures using SAC (tin-silver-copper) solder to a starboard for measuring light output and stress testing. Red nitride phosphor based LEDs for the same CCT’s and CRI’s as the QD based LEDs were fabricated in a similar fashion for direct comparison of performance and reliability.

Results and Discussions

Modeling

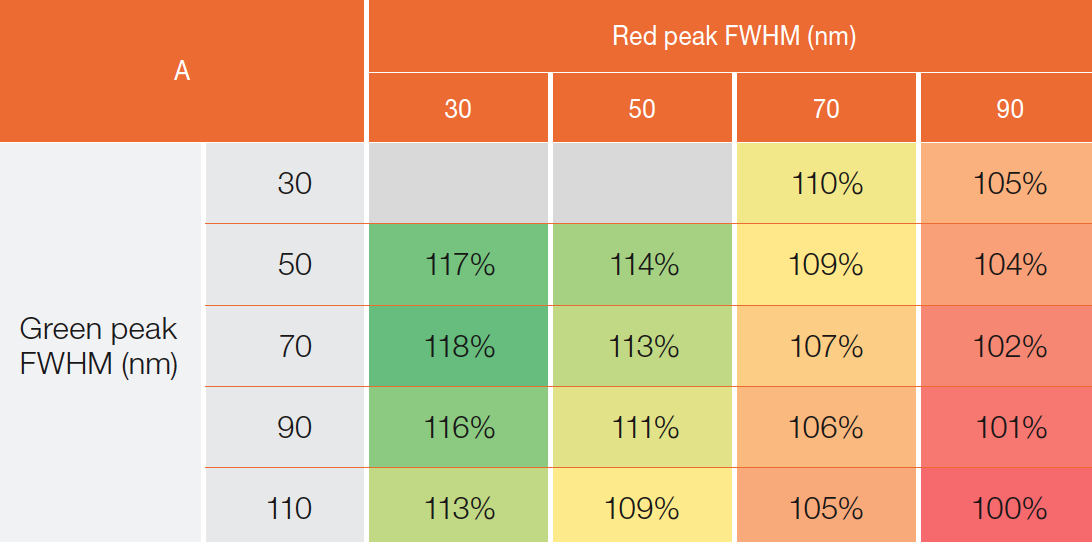

Table 1 shows the expected relationship comparing the impact of the peak Full-Width-Half-Maximum (FWHM) for red and green emitters to the lumen equivalent (LE) or lumen efficacy of radiation (LER) of white LED spectra. For simplicity, the data is normalized to the corner case of 110 nm green and 90 nm red.

Table 1: Simulated FWHM dependence for LE at 3000 K and 90 CRI. Each color curve represents a fixed red emission FWHM

Table 1: Simulated FWHM dependence for LE at 3000 K and 90 CRI. Each color curve represents a fixed red emission FWHM

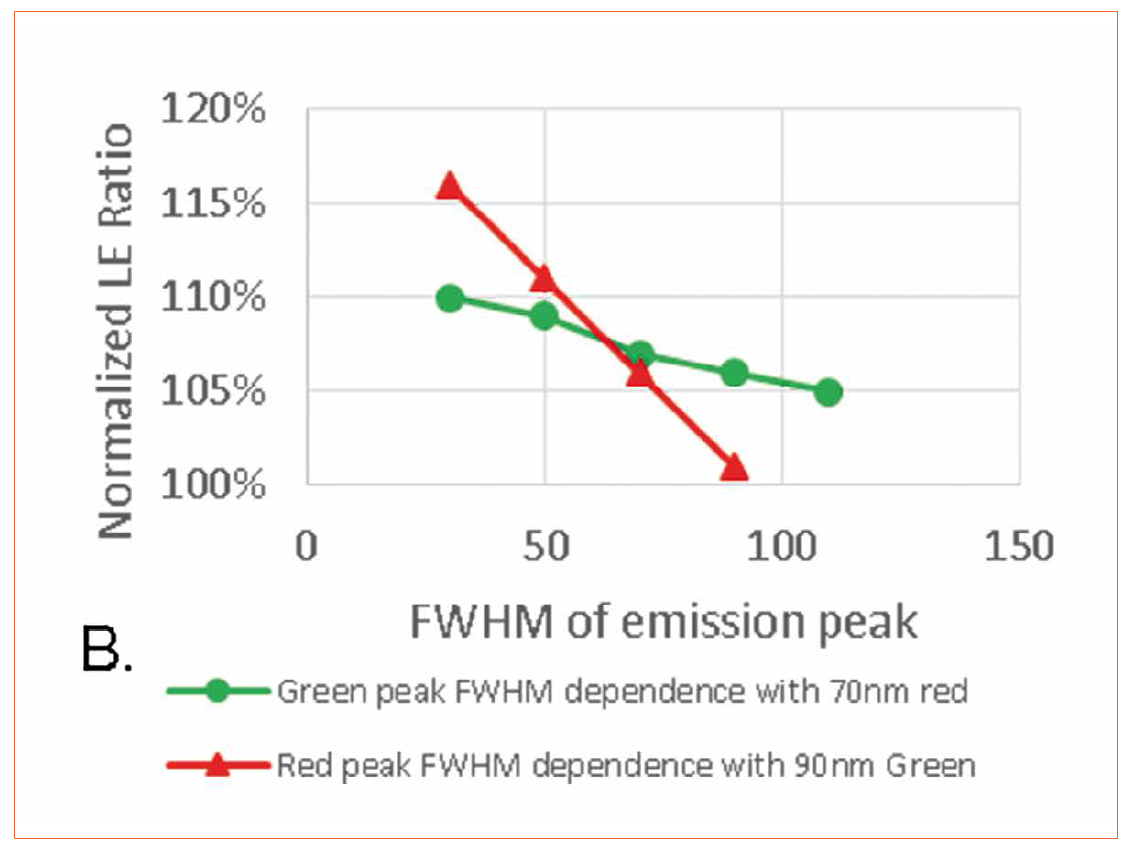

The optimal LE while still achieving 3000 K CCT on the Planckian and CRI and R9 greater than 90 and 50, respectively is dramatically influenced by both the FWHM and the peak wavelength value. The blue LED peak wavelength was fixed at 450 nm with a constant FWHM of 16 nm. Figure 2, clearly illustrates the stronger FWHM dependence of the red peak on LE compared to green peak FWHM. In this example, the reduction of red FWHM from 90 to 30 nm improves LE by 15% at 90 nm of green FWHM whereas the same 60 nm reduction in the green from 110 to 50 nm improves LE by only 5% for a 70nm red FHWM value. The 30 nm green with 30 or 50 nm red FWHM were not calculated as there are no solutions to meet the required CCT and CRI for a single red and green Gaussian emission mixture.

Figure 2: Plot of green and red FWHM dependence at a fixed 70 nm red FWHM and 90 nm Green FWHM, respectively

Figure 2: Plot of green and red FWHM dependence at a fixed 70 nm red FWHM and 90 nm Green FWHM, respectively

Even though the LE increases significantly as the red FWHM becomes narrower, the sensitivity of this maximum performance to the peak wavelength also increases. For the QD based LED case (40 nm FWHM red QD peak and 110 nm FWHM green YAG peak), the LE is reduced by ~1% for each nm of wavelength red shifted from the optimal position. QDs offer the advantage of sub-nm resolution in customizing the peak emission wavelength during the QD synthesis process but also requires careful management of the peak wavelength as a function of the temperature which can shift ~1 nm per 10°C.

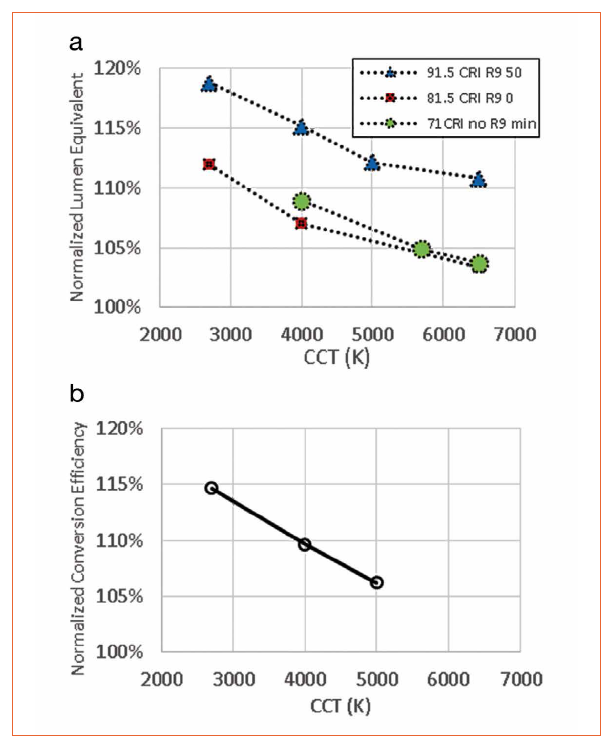

Figure 3a repeats the modeling over the range of warm (2700 K) to cool (6500 K) white CCTs at 70, 80 and 90 CRI values and compares the predicted maximum LE for a 40nm red FWHM and 110nm Green FWHM to measured LE performance of commercial LED phosphors. This shows that the theoretical LE gains are highest for 90 CRI due to the demanding spectral matching to the blackbody source. At 80 and 70 CRI the LE gains over conventional LEDs are reduced but still meaningful even up to 6500 K at CRI 70 or 80. The increasing LE gains for lower CCT values makes intuitive sense since there is a greater portion of red photons that make up the warm white light spectrum.

Figures 3a&b: Modeling results showcasing LE performance expectations based on a 40 nm FWHM red QD compared to red nitride based phosphor converted LED (pcLED) (a). Experimentally measured QD based LED CE normalized to a commercial red nitride based pcLED at different CCT values (b)

Figures 3a&b: Modeling results showcasing LE performance expectations based on a 40 nm FWHM red QD compared to red nitride based phosphor converted LED (pcLED) (a). Experimentally measured QD based LED CE normalized to a commercial red nitride based pcLED at different CCT values (b)

LED efficiency

In figure 3b, we show experimental data of QD based Luxeon 3535L HE Plus white LEDs at 90 CRI and various CCT’s at a heat sink temperature of 60°C driven at 65 mA [12] typical for a downlight application. The QD based LED shows significant conversion efficiency (CE) improvement over the commercial red nitride based phosphor converted LED (pcLED). The CE is defined as the product of the package efficiency, lumen equivalent, the quantum efficiency of down conversion, and the Stokes shift efficiency at the longer wavelengths. The CE gains are highest at 2700 K approaching 15% gains and still above 6% at 5000 K. In comparing the LE gains of figure 3a and the CE gains of figure 3b, the CE gain is about 5% lower than the theoretical maximum LE gains calculated from the model. This difference can be attributed to a combination of QE and optical scattering differences between the QD and the red nitride phosphor and the non-optimization of the QD peak wavelength for each CCT, CRI and operating temperature.

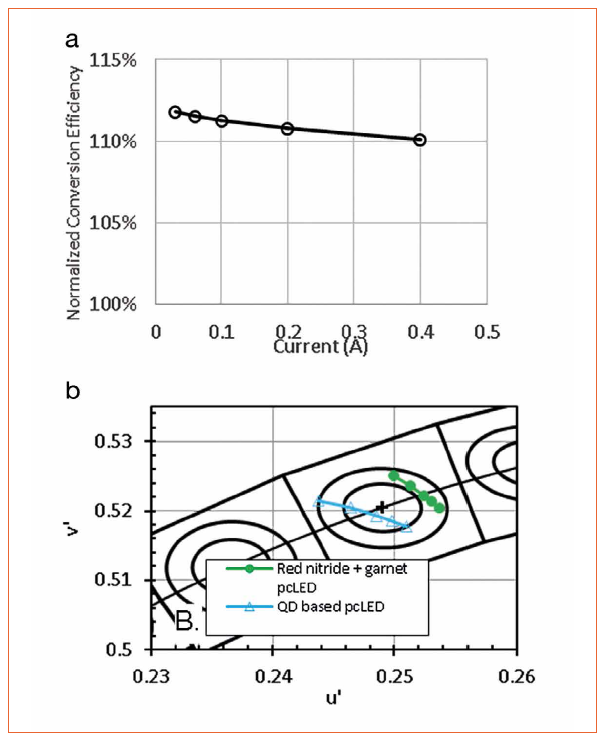

Figures 4a&b: Measured CE performance vs drive current (a) and color point shift comparison (b) between red nitride phosphor and QD based LED at 3000 K, driven in DC mode and 85°C heatsink temperature

Figures 4a&b: Measured CE performance vs drive current (a) and color point shift comparison (b) between red nitride phosphor and QD based LED at 3000 K, driven in DC mode and 85°C heatsink temperature

In figure 4a, the CE performance of a 3000 K, 90 CRI QD based LED over a conventional pcLED are measured to higher drive currents and at 85°C heat sink temperature that would represent operating conditions for a retrofit light bulb. The comparison between the QD and the red nitride based LED shows 10~12 % gain at drive currents ranging from 30 to 400 mA. The QD based LED color shift over this range, shown in figure 4b, is u’ = -7 pts and v’ = +4 pts in CIE 1976 color space which is comparable to the red nitride phosphor based LED. The slightly larger color shift for the QD based LED is due to more reversible photo thermal quenching of the QDs which will be discussed in more detail later in the paper.

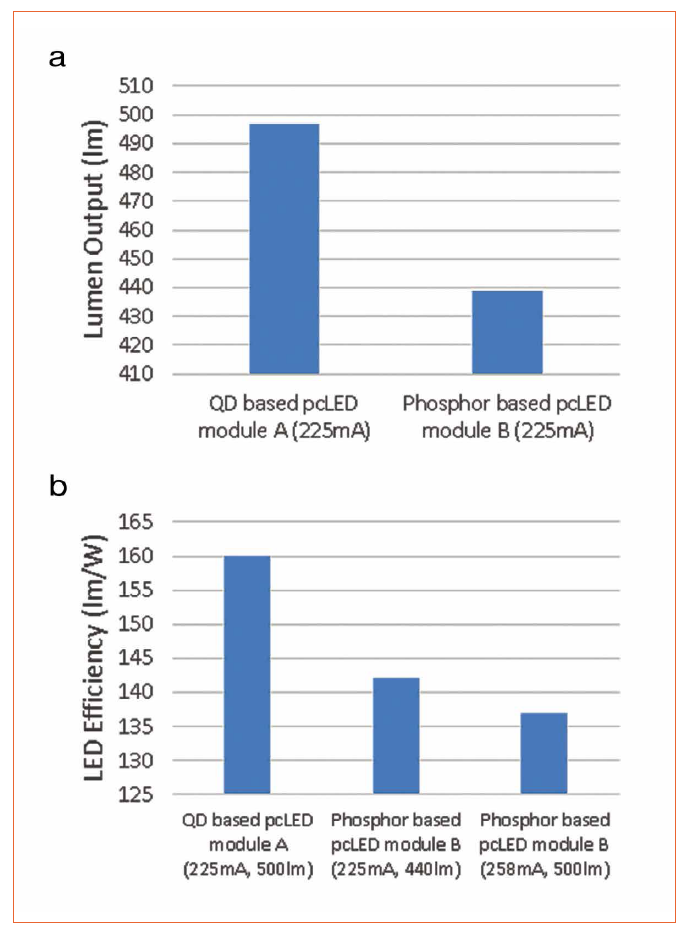

Figure 5 shows external testing results from LEDs in figures 4 and 6 that were assembled into a LED module. This example module contains an array of 15 LEDs on PCB with 3 strings wired in parallel. The QD and the red nitride phosphor based LEDs were matched with blue LED chips within 2.5 nm wavelength distribution so that the difference in performance can be attributed to the white light conversion only.

Figures 5a&b: External testing results of a QD based LED and a pcLED module on PCB board - lumen output (a) and efficiency (b)

Figures 5a&b: External testing results of a QD based LED and a pcLED module on PCB board - lumen output (a) and efficiency (b)

Care was taken to ensure that the LED modules measured similar color points, CRI and R9 values. When driven at the same current density, the QD based LED module produced a 13% luminous efficiency improvement compared to the red nitride based module, consistent with the results from Figure 3. In the case where the LEDs are compared at the same lumen output, the red nitride based LEDs need to be driven at a higher drive current to match the lumen output. The QD based LEDs then provide 17% efficiency gains over the red nitride based LED. Because of the significant current density droop effect of InGaN LEDs the changes in conversion efficiency have a nonlinear impact on the total LED module. Additionally, as the total efficiency of the module improves, the LED heatsink can be reduced in cost and size.

Alternatives to QDs

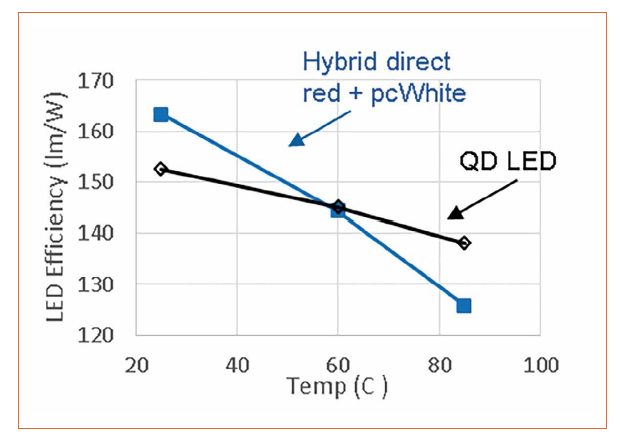

The first commercial 60 W equivalent LED lightbulb was the Philips L-prize bulb introduced on Earth Day 2012. The combination of a red LED and an off-white garnet based pcLED allowed for high color quality and high efficiency performance. A case study was completed to compare the L-prize bulb to the QD based pcLED. To represent the now discontinued L -prize bulb with updated commercial LEDs, a red -orange, 1 mm2 Luxeon C LED (618 nm peak WL and 15 nm FHWM at 25°C) was combined with a garnet phosphor filled Luxeon 3535L HE Plus whereby the spectral mixing was applied from separate LED measurements following the procedure and simulator from Y. Ohno [13]. Using a direct red LED eliminates the Stokes energy loss mechanism associated with phosphor conversion. However, the red and white LEDs are spatially separated therefore requiring additional mixing within the LED module using secondary optics to produce a uniform white light for the consumer

In figure 6, we plot the luminous efficacy of 16 off -white LEDs mixed with two red LED against 18 QD based LEDs. We calculate an optical mixing efficiency penalty of 13% for the hybrid LED system [14]. Both modules were driven to produce ~1000 lumen output at 3000 K and 90CRI. The hybrid direct red LED system shows higher efficiency compared to the QD based LED at 25°C even after accounting for the optical mixing penalty, but as the temperature increases to 85°C, the red LED requires much higher drive current to maintain the same color point due to the thermal quenching of the AlInGaP LED. The dramatically reduced red LED performance translates into a higher overall efficiency for the QD based LED at nominal conditions. An additional advantage of the QD based LED is the simplicity and cost savings of the electronic components for the overall light fixture since the L-prize bulb requires two drivers, one for the red LEDs with temperature compensation and a second for the InGaN pumped off -white LEDs.

Figure 6: LED efficiency comparison between QD based LED and Hybrid direct Red + pcWhite LED modules at different temperatures

Figure 6: LED efficiency comparison between QD based LED and Hybrid direct Red + pcWhite LED modules at different temperatures

Reliability

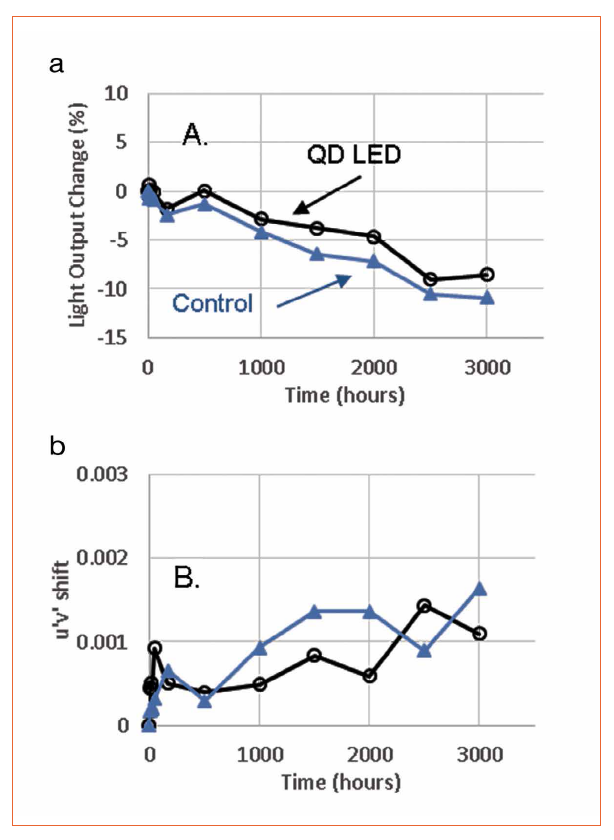

In Figure 7 and 8, we show the high temperature operating life (HTOL) and high humidity or wet, high temperature operating life (WHTOL) stress testing results. Figures 7a and 7b show LED HTOL stability in terms of light output power and color shifts after operating at 95°C and driven at 200 mA for 3000 hours.

Figures 7a&b: Reliability of QD LEDs under 95°C and 200 mA HTOL conditions. Light output maintenance (a) and color shift (b) over 3000 hr duration

Figures 7a&b: Reliability of QD LEDs under 95°C and 200 mA HTOL conditions. Light output maintenance (a) and color shift (b) over 3000 hr duration

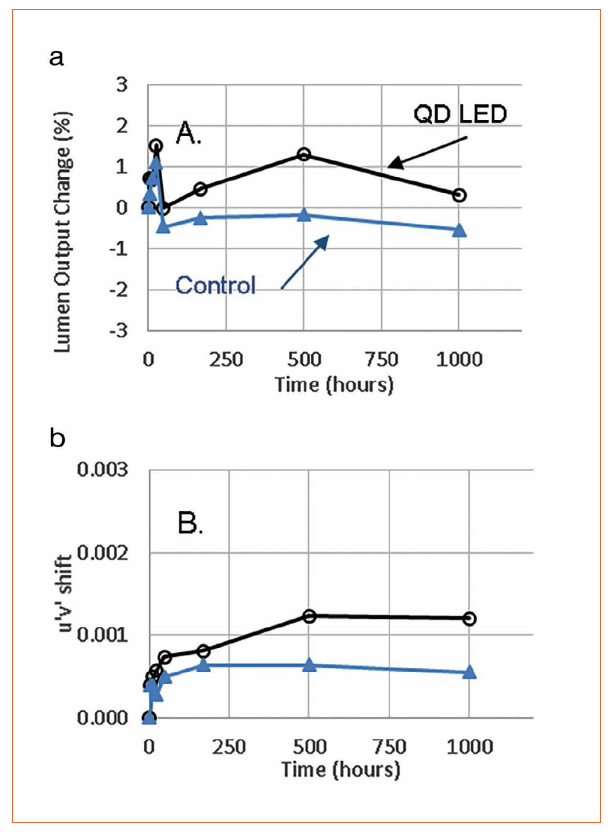

At these conditions, the QD temperature can reach over 110°C under blue flux intensities of 20 W/cm2; however, the comparison to the red nitride phosphor based LED shows that the QD based LED can maintain light output and color stability in a similar range and within specifications. Although the long term testing is not complete at the time of preparing this manuscript, the 3000 hrs of testing show great promise that the color maintenance of du’v’ < |0.007| marked in the dotted line should exceed 6000 hrs. Figure 8 also shows LED WHTOL stability in terms of light output power and color shifts after operating at 60°C and 90% relative humidity and driven at 65 mA for 1000 hours where the dotted line marks the maximum color shift allowed under WHTOL testing. Both the WHTOL and HTOL tests show color shifts below du’v’ <|0.002| at 1000 and 3000 hrs respectively. This shows that the QDs are meeting the required lifetimes and the prior limitations from the surface sensitivity to oxidation and defect generation have been addressed [15, 16].

Cadmium

The QDs utilized in this paper are based on II -VI semiconductors and contain Cadmium. In the QD based LEDs, the Cd concentration ranges between ~100 ppm and ~1000 ppm based on CCT; this equates to a range between ~0.3 μg and ~3 μg of Cd per LED. QDs made with alternative non -Cd materials suffer from lower quantum efficiency and insufficient reliability. Among those systems are Si [17], InP based [18], Pb perovskite [19], CuInS2 [7], and Mn-doped ZnSe QDs [20].

Other challenges with alternative non -cadmium material are limitations in achieving narrow FWHM, full tunability of the emission, or insufficient absorption at 450 nm. New materials such as Pb perovskite QDs may have similar toxicity concerns. Nonetheless, the path is clear to reduce or eliminate Cd from the QD materials in the coming years as QD material development continues at its current pace. Figures 8a&b: Reliability of QD LEDs under 60°C/ 90% RH WHTOL Stress Conditions. Light output maintenance (a) and color shift (b) over 1000 hrs duration

Figures 8a&b: Reliability of QD LEDs under 60°C/ 90% RH WHTOL Stress Conditions. Light output maintenance (a) and color shift (b) over 1000 hrs duration

Conclusions

The stellar performance of the on-chip LED with Cd based QD material at high temperature, high humidity, and under high intensity light flux is a truly remarkable accomplishment in the evolving QD technology landscape. The combination of narrow FHWM and tunable peak wavelength of red QDs have resulted in 17% efficiency improvement of QD based LEDs compared to commercial red nitride based LEDs. The LED stability with 20 W/cm2 of incident blue light and QD temperatures over 110°C have exceeded 3000 hrs and continue to show no degradation. This existence proof paves the way for improved stability of alternative QD materials and for QDs of various colors such as in display or horticultural LED applications.

Acknowledgements:

The authors would like to thank Helen Gan, Jacques Heuts, Frank Jin, Sheila Morgan, and Mark Spencer for all of their assistance, and Pacific Light Technologies for their collaboration in providing the QD materials and thoughtful technical discussions.

References:

[1] D. V Talapin, A. L. Rogach, A. Kornowski, M. Haase, and H. Weller, “Highly Luminescent Monodisperse CdSe and CdSe / ZnS Nanocrystals Synthesized in a Hexadecylamine − Trioctylphosphine Oxide − Trioctylphospine Mixture,” Nano Lett., vol. 1, no. 4, pp. 207–211, 2001

[2] S. F. Wuister, I. Swart, F. van Driel, S. G. Hickey, and C. D. Donega, “Highly luminescent water-soluble CdTe quantum dots,” Nano Lett., vol. 3, no. 4, pp. 503–507, 2003

[3] Y. Gao and X. Peng, “Photogenerated excitons in plain core CdSe nanocrystals with unity radiative decay in single channel: The effects of surface and ligands,” J. Am. Chem. Soc., vol. 137, no. 12, pp. 4230–4235, 2015

[4] P. Reiss and A. Pron, “Highly Luminescent CdSe / ZnSe Core / Shell Nanocrystals of Low Size Dispersion,” Nano, pp. 21–24, 2010

[5] E. Virey, “From Technologies to Market Phosphors and Quantum Dots LED Downconverters for Lighting and Display Applications,” 2015

[6] Q. Hong, K.-C. Lee, Z. Luo, and S.-T. Wu, “High-efficiency quantum dot remote phosphor film,” Appl. Opt., vol. 54, no. 15, pp. 4617–4622, 2015

[7] H. Kim et al., “Characteristics of CuInS2/ZnS quantum dots and its application on LED,” J. Cryst. Growth, vol. 326, no. 1, pp. 90–93, 2011

[8] S. R. Cordero, P. J. Carson, R. A. Estabrook, G. F. Strouse, and S. K. Buratto, “Photo-activated luminescence of CdSe quantum dot monolayers,” J. Phys. Chem. B, vol. 104, no. 51, pp. 12137–12142, 2000

[9] S. Jun, J. Lee, and E. Jang, “Highly luminescent and photostable quantum dot-silica monolith and its application to light-emitting diodes,” ACS Nano, vol. 7, no. 2, pp. 1472–1477, 2013

[10] T. Erdem, S. Nizamoglu, X. W. Sun, and H. V. Demir, “A photometric investigation of ultra-efficient LEDs with high color rendering index and high luminous efficacy employing nanocrystal quantum dot luminophores.,” Opt. Express, vol. 18, no. 1, pp. 340–347, 2010

[11] Lumileds, “Luxeon 3535L Line,” 2016

[12] A. R. Duggal, A. M. Srivastava, L. M. Levinson, and S. J. Duclos, “Color tunable light source.” Google Patents US6357889 B1, 2002

[13] Y. Ohno, “Spectral design considerations for white LED color rendering,” Opt. Eng., vol. 44, no. 11, p. 111302, 2005

[14] N. Bardsley et al., “Solid-State Lighting R & D Plan,” 2016

[15] J. Cui, A. P. Beyler, T. S. Bischof, M. W. B. Wilson, and M. G. Bawendi, “Deconstructing the photon stream from single nanocrystals: from binning to correlation,” Chem. Soc. Rev., vol. 43, no. 4, pp. 1287–1310, 2014

[16] C. Pu and X. Peng, “To Battle Surface Traps on CdSe/CdS Core/Shell Nanocrystals: Shell Isolation versus Surface Treatment,” J. Am. Chem. Soc., vol. 138, no. 26, pp. 8134–8142, 2016

[17] C. Tu, J. H. Hoo, K. F. Böhringer, L. Y. Lin, and G. Cao, “Red-emitting silicon quantum dot phosphors in warm white LEDs with excellent color rendering,” vol. 22, no. March, pp. 1978–1980, 2014

[18] S. Kim, K. Taehoon, and S.-W. K. Kim, “Highly Luminescent InP/GaP/ZnS Nanocrystals and Their Application to White LED SI,” no. Ii, pp. 1–9, 2011

[19] A. Swarnkar, R. Chulliyil, V. K. Ravi, M. Irfanullah, A. Chowdhury, and A. Nag, “Colloidal CsPbBr3 Perovskite Nanocrystals: Luminescence beyond Traditional Quantum Dots,” Angew. Chemie - Int. Ed., vol. 54, no. 51, pp. 15424–15428, 2015

[20] N. Pradhan and X. Peng, “Efficient and Color-Tunable Mn-Doped ZnSe Nanocrystal Emitters : Control of Optical Performance via Greener Synthetic Chemistry,” no. 16, pp. 2532–2540, 2007

(c) Luger Research e.U. - 2017