On-Chip Beam Forming Optics Paves the Way for New Luminaire Designs

An LED luminaire’s optical system usually consists of primary and secondary optics. This concept always causes a trade-off between light quality, system size, efficiency and light distribution. New concepts to make secondary optics obsolete have already been researched. Paul Drosihn, Head of Modular Products, and Samir Mezouari, Optics & Lighting Design Specialist at Plessey Semiconductors present the first of its kind chip scale beam forming technology, StellarTM. They explain how it works and how it helps to overcome the limitations of traditional optical solutions for LED lighting.

Standardization in the LED lighting industry exerts a powerful force. Thanks to the efforts of industry bodies such as Zhaga, LED-based luminaires are increasingly adopting common form factors and conforming to optical and electrical standards.

In popular product categories such as downlights, track lights and spotlights, standards-compliant luminaires might display superficial and cosmetic differences, but most will tend to share essentially the same components.

Essential standard components:

- A Chip-On-Board (COB) LED package providing a small, intense light source

- A lens mounted on top of the COB LED to shape its beam

- A reflector

- A large heat sink

Comprising so many large components, such as COB LED-based light engine will inevitably be a bulky and heavy unit. Luminaire manufacturers have to accommodate this large assembly inside their end product, giving them little scope to add their own unique design elements or to achieve any valuable differentiation.

Nevertheless, the COB LED-based light engine format has emerged as the standard. But is it actually what lighting designers, architects and users want?

In order to answer this question, it is worth returning to first principles: architects and lighting designers do not actually want to specify and buy luminaires. What they want is high-quality light where it is needed, when it is needed. If they could illuminate a space magically, without a luminaire, they would.

Lighting designers probably would not choose to fix a large, heavy unit in a ceiling void or onto a ceiling-mounted track in order to cast light on a wall or floor if they could achieve the desired illuminance less obtrusively. What if the industry were able to benefit from innovation, from fresh thinking aimed at creating a smaller, less obtrusive fixture?

In fact, today’s standard form factors are simply the result of a series of technology choices - and other choices support luminaire form factors much more in tune with the preferences of lighting designers and architects. The latest LED and optical technologies available today enable the production of light engines with dramatically reduced dimensions, as well as superior quality of light and thermal performance.

New Approach To Beam-Forming

While the COB LED has become a popular type of light source, its use in luminaires which require precise beam forming is problematic. Due to the configuration of the LED die on the board, and the way that phosphor is deposited on the die, a COB LED in a downlight or spotlight requires a very large optical assembly to achieve a directional light output and a controlled beam angle.

The sheer bulk of the optics is not, however, the only drawback. In addition, the performance of the optical assembly is compromised by the light-emitting surface, which is large and non-uniform. This results in visible differences in the color temperature of the light at the edge of the beam compared to the light at the center of the beam if complex optical design is not used.

To compound the engineering difficulties for the manufacturer of a COB-based light engine, the sapphire substrate on which a COB LED’s gallium nitride (GaN) die are grown is a very poor thermal conductor. At the same time, the heat-generating die are concentrated in a small area, creating an intense hot spot, as well as an uneven spread of heat across the light-emitting surface. This results in color variance over angle, and different rates of degradation of the LEDs’ light output over the lifetime of the product. It also entails the use of a very large heat sink, to compensate for the high thermal resistance of the sapphire substrate and ensure the LED die do not exceed their maximum rated temperature.

The choice of a COB LED as the light source in conventional downlight and spotlight designs, then, makes them bulky, heavy and inflexible, and may produce noticeable color inconsistencies.

But this COB LED-based architecture is not the only way to make a light engine with a focused beam. In fact, there is an inherent advantage to an architecture which distributes multiple LED light sources over a large light-emitting surface: the heat generated by the LED die is distributed, so the heat intensity at each hot spot is less intense. This means that the temperature at each LED can be kept safely below its specified value at a much lower rate of heat dissipation. When backed by extra thermal management techniques to achieve a very low thermal resistance at module level, this can enable the use of a smaller heat sink, thus reducing the size of the light engine.

The difficulty with such a distributed architecture in the past has been principally optical; to tightly focus the typical Lambertian output from a conventional LED requires a large optical assembly over each light source. In a light engine for a luminaire such as a spotlight, with a diameter of around 100 mm and multiple LED light sources, this would clearly be difficult. A solution to this problem combines innovative design, advances in processing capabilities for the manufacture of miniature optics and coupling this with specifically tailored LED light sources.

Miniature optics, by way of reflector arrays or collimators over large (cm) areas with precise tolerances to sub millimeter dimensions is now possible and manufacturable at low cost, however, requires coupling with a suitable light source. As described above, conventional LED COBs are typically fabricated from GaN on Sapphire LEDs. However, if such LEDs were utilized in a distributed fashion and coupled with the collimated array they would not prove effective for several reasons. Typically such LEDs are assembled in plastic packages, which increases the effective light source area and subsequently renders the optics to a larger geometric scale, and adds to the already poor thermal performance of a sapphire based LED. Moreover, the light emission pattern is not conducive to an efficient solution with this optical approach, generally being Lambertian in nature.

LEDs based on GaN on Silicon technology offer a cost effective solution to the scale, light pattern and thermal performance required for the distributed architecture described. Such LEDs are manufacturable such that the light emission from the LED is only from the top surface of the structure and can then be modified through light conversion to produce a tailored light emission pattern to allow beam collimation with a miniaturized optic design. The LEDs have inherently better thermal performance and can be designed for a COB solution that requires no packaging, thus reducing the scale of the light source to a minimum.

Two innovative technologies, then - micro-scale beam-forming optics, and GaN-on-silicon LED wafer fabrication - appear to offer scope to luminaire manufacturers to radically rethink their product designs. How might this new design freedom play out in the field of common luminaire types such as downlights and spotlights?

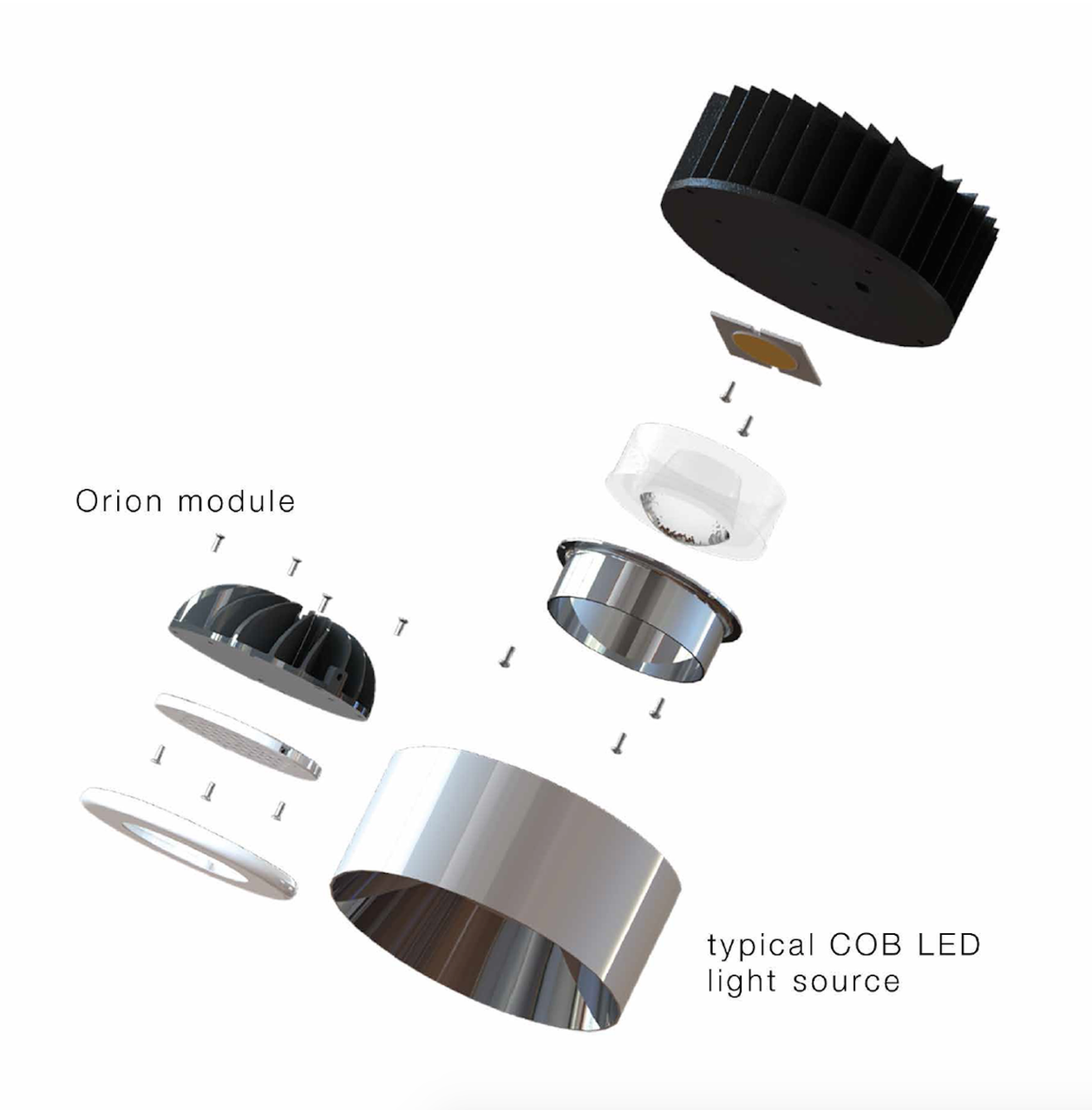

Figure 1: The optical assembly in the Orion module offers a dramatic size reduction

Figure 1: The optical assembly in the Orion module offers a dramatic size reduction

An example of the possibilities is suggested by a new light engine drawing on Stellar beam-forming technology.

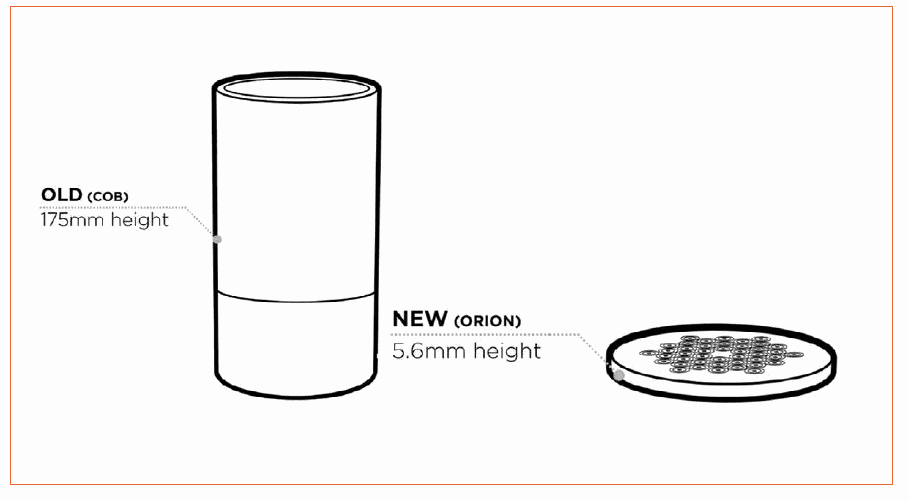

The module produces more than 3,000 lumens, is just 5.6 mm thick and 82 mm in diameter. The tightly controlled beam has an FWHM angle of 25°, and the color temperature of the beam is visibly consistent throughout, from the center to the edge. Its housing is divided into multiple cells, with a single LED light source per cell. The multiple beams are blended at a distance of less than 1 m from the surface of the module. A comparison of the dimensions of the new module and a typical equivalent light engine based on a COB LED is shown in Figure 1.

Figure 2 illustrates the scope for luminaire manufacturers to re-imagine their product designs. The Stellar technology allows for a distributed LED architecture while still tightly controlling the beam pattern with miniature optics directly adjacent to the light-emitting surface. This in turn offers improved thermal characteristics, enabling the use of a small heat sink.

The total assembly is thus:

- Smaller

- Less obtrusive

- Easier to fit into a wide variety of end-product housings and fixture styles, supporting luminaire manufacturers’ attempts to achieve valuable differentiation

Because light is emitted from a large surface area, the problems with glare that users of COB LED-based spotlights and downlights experience are eased or eliminated.

There is also a commercial benefit to luminaire manufacturers and distributors: by making a much smaller end product, they can markedly reduce shipping and storage costs, since more units can be accommodated in a ship, truck or warehouse. Figure 2: Complete light engine assemblies, including heat sink, based on the Orion module and a typical COB LED light source

Figure 2: Complete light engine assemblies, including heat sink, based on the Orion module and a typical COB LED light source

Potential for Smarter, Better-Performing Lighting Equipment

This article has suggested that innovation, rather than standardization, is today responsible for important product developments bringing valuable benefits to lighting designers, building operators and the users of lighting.

And the potential for innovations in luminaire design based on GaN-on-Si and micro-scale beam-forming technology does not stop with the introduction of new, smaller spotlights and downlights.

In the relatively near term, one possibility is to integrate intelligence - sensing and control - into the light engine. In a light engine with a distributed LED architecture, it should be possible to replace one LED with a photo sensor or other small image sensor. If housed in a cell, like the LEDs in the Orion module, it will be optically isolated from the neighboring LEDs, so that it will not be able to directly sense the light emitted at the LEDs’ light-emitting surface, but only the light reaching the illuminated plane.

This gives luminaire manufacturers a new way in which to respond to the industry’s demand for color tuning capability and human-centric lighting. With the addition of color tuning and control circuitry in the luminaire, it will be possible to adjust the color temperature and intensity of the light output in response to local changes in the ambient light or other environmental factors, as well as to attune the color temperature to Circadian rhythms, or align to other time-based patterns.

In all such endeavors, the purpose must be to provide lighting designers with what they want - the right light in the right place - rather than what they are used to getting - an obtrusive luminaire providing a light output with a pre-determined configuration.

Another development which is in sight is the implementation of optics-on-chip. That is, the lens may be fabricated on the wafer or during the chip manufacturing process, producing an LED die with a collimated light output. This offers scope for even greater space savings and even lower-profile LED lighting modules, with a tightly controlled and focused beam. This development is made possible by the use of the silicon substrate in GaN-on-silicon LEDs.

Indeed, the ability to grow GaN LEDs on a silicon substrate could be the key to a host of additional moves to integrate functions on to the chip, and thus to reduce the size and cost of the luminaire. Silicon is the material in which nearly all of today’s integrated circuits (ICs) are built, and the intellectual property and fabrication know-how is readily available for integrating microcontrollers, analogue signal chains and other electronics functions into monolithic silicon devices.

In the longer term, therefore, the potential with GaN-on-silicon LEDs should be to integrate more of an intelligent light engine’s light-emission, light-control and user-control functions into an integrated circuit. This offers extraordinary possibilities for space and cost saving. And by reducing the number of components in a luminaire, silicon technology also promises higher reliability and a reduced failure rate.

In this, as in most technological developments, it is innovation which delivers value to the lighting industry. And as this article suggests, there remains much more scope to innovate further, even in apparently standard fixture types such as downlights and spotlights.