Form Factor Luminaires and Light Effects

If luminaires designed for traditional light sources are simply retrofitted with LED light sources like it occurs in the so-called “1st wave of LEDification”, they will always fall short of expectations in many points. Herbert Weiß and Thomas Noll from Osram GmbH, Martin Möck from the University of Erlangen-Nuremberg, Martin Creusen from Philips Lighting, and Friedhelm Holtz from Insta Elektro GmbH explain why these shortcomings were addressed and which solutions were developed in the EnLight project.

One thing that all shortcomings of the “1st wave of LEDification” have in common is that a sustainable solution implies resolving fundamental contradictions which are based on the fact that the retrofit lamp does not fit the luminaire since it was originally designed for another technology like incandescent, halogen or fluorescent lamps, but not for LED lamps.

Examples for the Shortcomings of Retrofit Solutions

Screw base as disabler for minimizing junction temperature

It is quite obvious that incandescent lamp designs like those with an Edison screw base cannot fulfill one of the elementary LED lamp design criterions, namely to minimize the LED junction temperature. One key design aspect of the Edison socket has been to keep the heat in the system. The heat transfer path actually ends at the Edison lamp base. In contrast, for LED lamps and luminaires optimization of the heat transfer from the LED to the environment is essential for high efficacy and lifetime.

Luminaire optics are not suitable for light shaping of retrofit

If we consider, for example, a troffer luminaire using linear fluorescent lamps, it is an important design aspect for luminaire manufacturers to optimize the light output ratio by use of highly reflective materials for the reflectors and also by use of specially shaped reflectors. A classical example is an evolvent design, which allows for guiding the reflected light around the lamp and minimizing absorption of the reflected light by the light source itself. With these technologies it is possible to realize light output ratios of up to 90%. The problem arises when a linear LED retrofit lamp is used as a 1:1 replacement. The LED light source whose light distribution is now far from rotationally symmetric no longer fits the luminaire design. As a consequence the reflector might have no effect at all. Light distribution that is not desired by the user occurs or the luminaire glare rating is out of specification.

Wall switch/dimmer not in line with customer expectations

Retrofitting a luminaire also means that classical user interfaces - like the common wall switch or dimmer used to switch or dim the lamp - are generally maintained.

On the other hand LEDification and digitalization of luminaires open up far more possibilities for interaction. Automatic adjustment triggered by sensors or remote adjustment of light and light scenes by various user interfaces like a customized app via a smart phone are examples. Retrofits will never meet customer expectations arising from these possibilities for control.

Office Luminaires

For office applications, the focus is traditionally on high luminous efficacy, short return of investment and long maintenance factors. In this project emphasis was put on high light quality, i.e. high color rendering, pleasant appearance, the possibility for color and color temperature adjustment and exact control of the light distribution. All luminaires were built as intelligent luminaires, letting each individual luminaire make lighting decisions based on presence, occupancy events or ambient light information detected by its own integrated sensors, or events and information from other nodes in the network.

The following luminaire prototypes were designed accordingly.

Intelligent “PowerBalance”

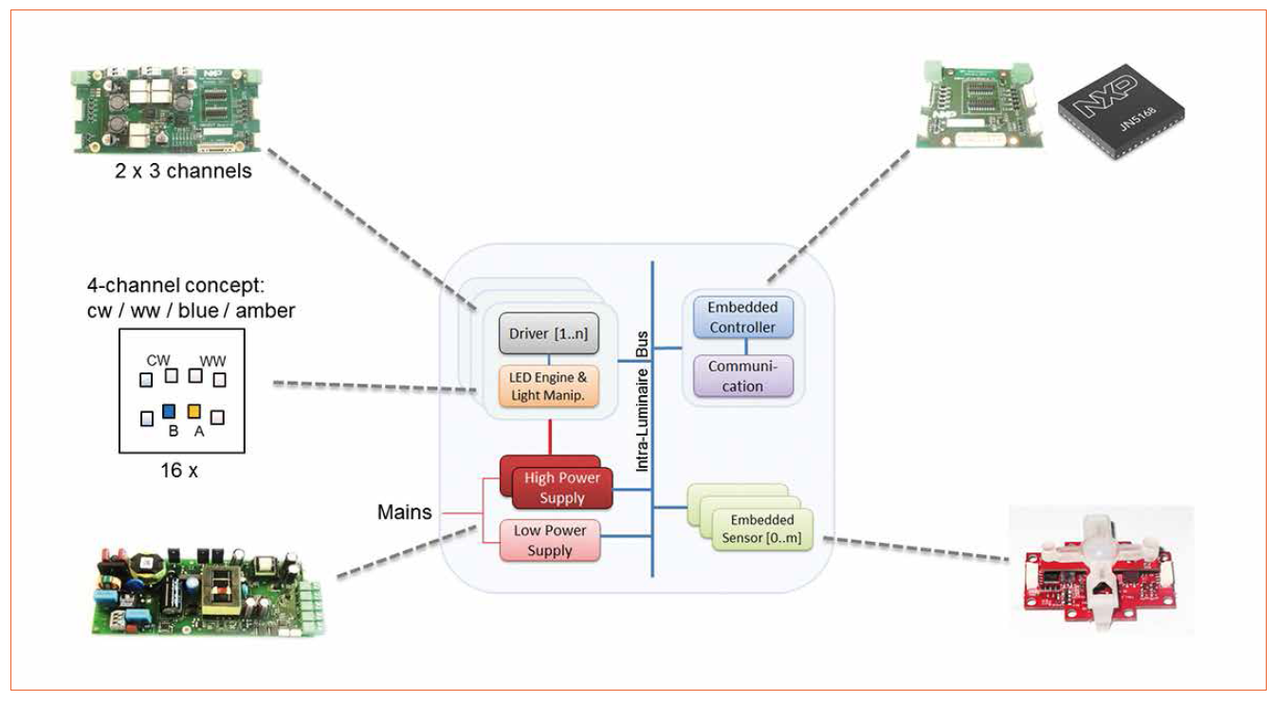

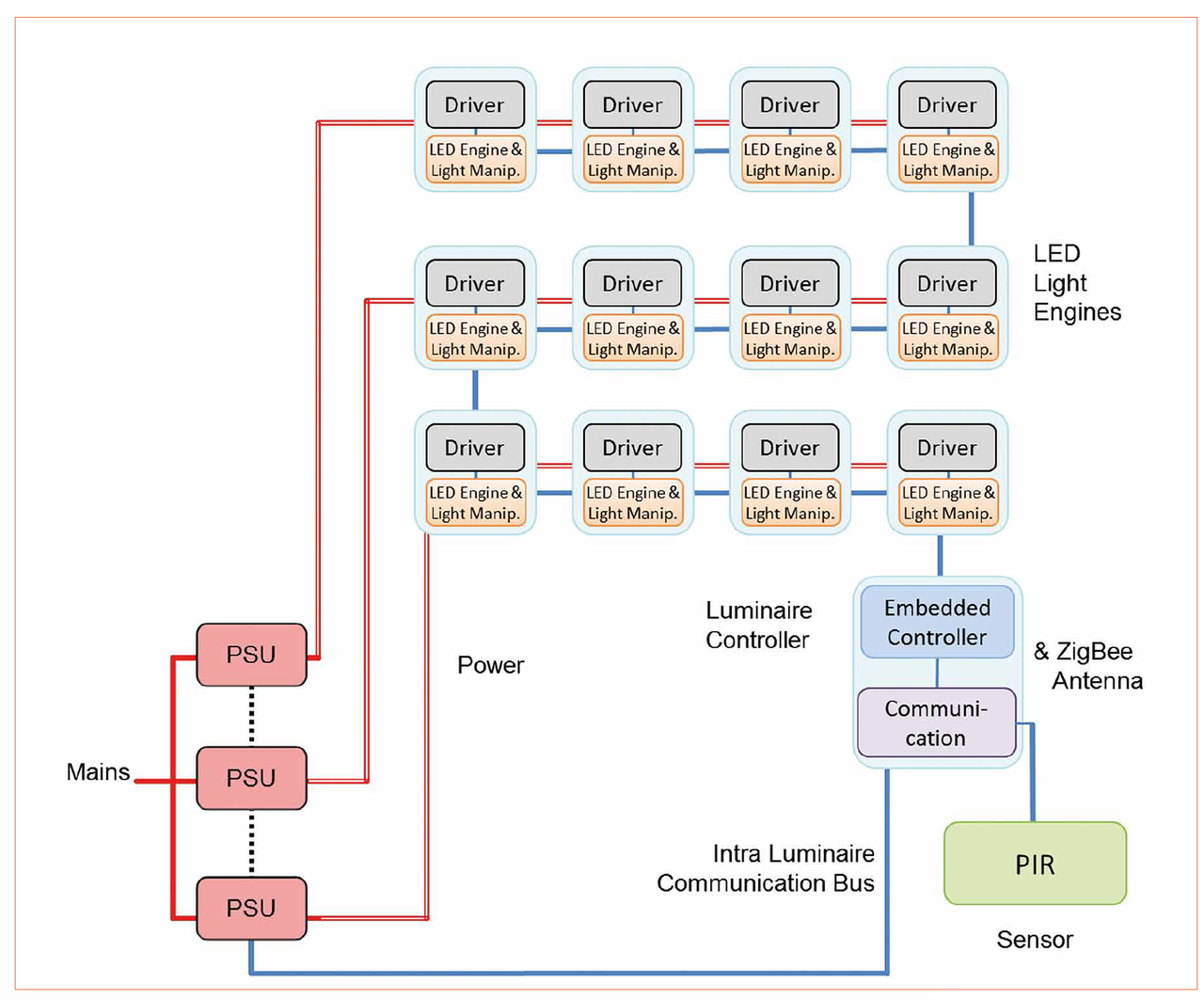

The “PowerBalance” luminaire family from Philips consists of state-of-the-art energy-efficient office-norm compliant LED luminaires (Figure 1). These luminaires offer good-quality lighting solutions for direct replacement of T5 luminaires in most indoor office applications. The two form factors applied in the demonstrator installations, a standard troffer size with 2 x 8 reflector cups and a mini- “PowerBalance” with 2 x 2 cups, contained tunable-white EnLight compatible LED Light Engines (LLEs), and an embedded temperature, light and PIR multi-sensor from Valopaa. The outer dimensions were 1200 x 300 mm2 and 300 x 300 mm2, respectively. The 4-channel LLEs (warm white, cool white, blue and amber LEDs) using high power LEDs were driven by two 3-channel UBA3077 driver boards from NXP. The tunable white light output for the 2 x 8 cups “PowerBalance” (at 350 mA LED current) was >3000 lm for warm white and >4000 lm for cool white with an overall luminous efficacy of 105 lm/W. The Intra-Luminaire Bus (ILB) was used for internal communication between the different embedded components (i.e. LED driver, multi-sensor and controller board). All mentioned components were connected in a daisy-chain configuration (Figure 2).

Figure 1: “PowerBalance” luminaire with 2 x 8 reflector cups (left). Mini-“PowerBalance” luminaire with 2 x 2 reflector cups (right)

Figure 1: “PowerBalance” luminaire with 2 x 8 reflector cups (left). Mini-“PowerBalance” luminaire with 2 x 2 reflector cups (right)

Figure 2: EnLight architecture of the “PowerBalance” luminiare

Figure 2: EnLight architecture of the “PowerBalance” luminiare

Figure 3: Instalight Glow luminaire

Figure 3: Instalight Glow luminaire

Intelligent “Glow”

In contrast to the flush mounted PowerBalance recessed luminaire, the intelligent instalight Glow luminaire contributed by Insta Elektro GmbH is a linear pendulum luminaire with direct / indirect LED light output. The light distribution of the direct outlet is controlled by lenses which resemble big drops of water protruding from the luminaire. This notable design makes the luminaire suited not only for the illumination of workplaces but especially for reception areas, lobbies and conference rooms.

The drop-shaped optics of 80 mm diameter is made of clear acrylic glass. Optics is optionally available in an internally satined version that gives the luminaire a less technical and more smooth and classical appearance. Four LED and lens modules are arranged at each end of the 1500 mm long luminaire. This task light component is available in color temperatures 3000 K or 4000 K. It provides > 3100 lumens and a color rendering index of > 85. The overall luminous efficacy of the task light component is 87 lm/W.

Separately dimmable indirect illumination was provided by RGBW LED modules concealed on the back side of the luminaire. The user was free to choose from the entire RGBW color gamut range.

The luminaire complies with standard EN 12464-1 regarding omnidirectional glare reduction.

The luminaire had embedded sensors for motion, illuminance and color temperature control. The luminaire architecture followed the same concept as depicted in figure 2 but with different numbers of LED and driver boards. The Glow luminaire had a one-channel LED board for direct and one four-channel LED board for the indirect light output.

Luminaires for Hospitality Applications

For a hospitality environment EnLight provided much more than just conventional luminaires. Prototypes demonstrated in this project proved that, by exploiting the design freedom enabled by LED, luminaires can be realized which provide more than just illumination for a visual task. They became not only the actual creative element but even merged into building structures and took over part of their functional properties.

“Luminous Door”

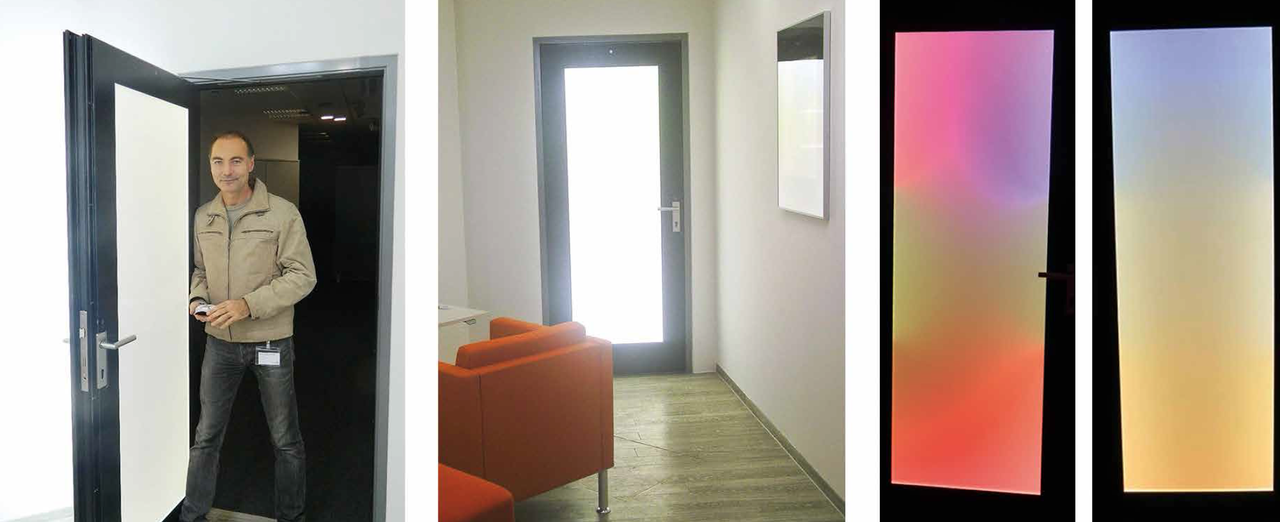

The luminaire with the highest functional versatility and functional integration into building components realized in this project was a luminous door (Figure 4) developed by OSRAM. Both back and front sides emitted light and could be controlled individually, including individual control of all four frame parts (top, bottom, left, right). Colors and color temperatures could be varied within a large gamut range, which is achievable with warm white, red, mint and blue LEDs. The door was virtually mimicking a window and is thus ideal for places like windowless rooms deep inside a building. Due to its very large light emitting surface this luminous door allowed for the creation of a wide set of scenes like sunrise or favorite color patterns for mood lighting. The physiological impact can be used for light therapy such as alleviating jetlag or treating seasonal affective disorders. Glare was not an issue despite a very high maximum luminous flux up to 10,000 lm depending on color temperature or color settings. The maximum luminance was 4000 nits (cd/m.).

Figure 4: Luminous door with two light emitting sides. Examples of homogeneous daylight as well as of a colored pattern is shown

Figure 4: Luminous door with two light emitting sides. Examples of homogeneous daylight as well as of a colored pattern is shown

The door was equipped with embedded PIR sensors from Valopaa for interaction with a preconfigured light level and varying colors and patterns. One sensor was placed near to the door handle. Luminaires or other devices in the room were thus activated as soon as someone was using the door handle. In the same way sensors in the room checked for occupancy when the door handle was touched upon leaving the room.

Another option was to use the luminous door for showing a hotel guest the way to his room by raising light output, or tuning color.

The luminous door was made of linear multicolor LED boards, which were hosted inside the doorframe. Their light was guided into the edges of special PLEXIGLAS® sheets which homogeneously coupled the light out of the sheet’s surface. Light exiting towards the inside of the door was redirected to the outside by a white sheet with predominantly diffusive reflectivity of about 99%. Thermal management was highly efficient since LED boards as well as heat sensitive driver components were coupled to the metal door frame which had a large cooling surface.

“Wedge” luminaire

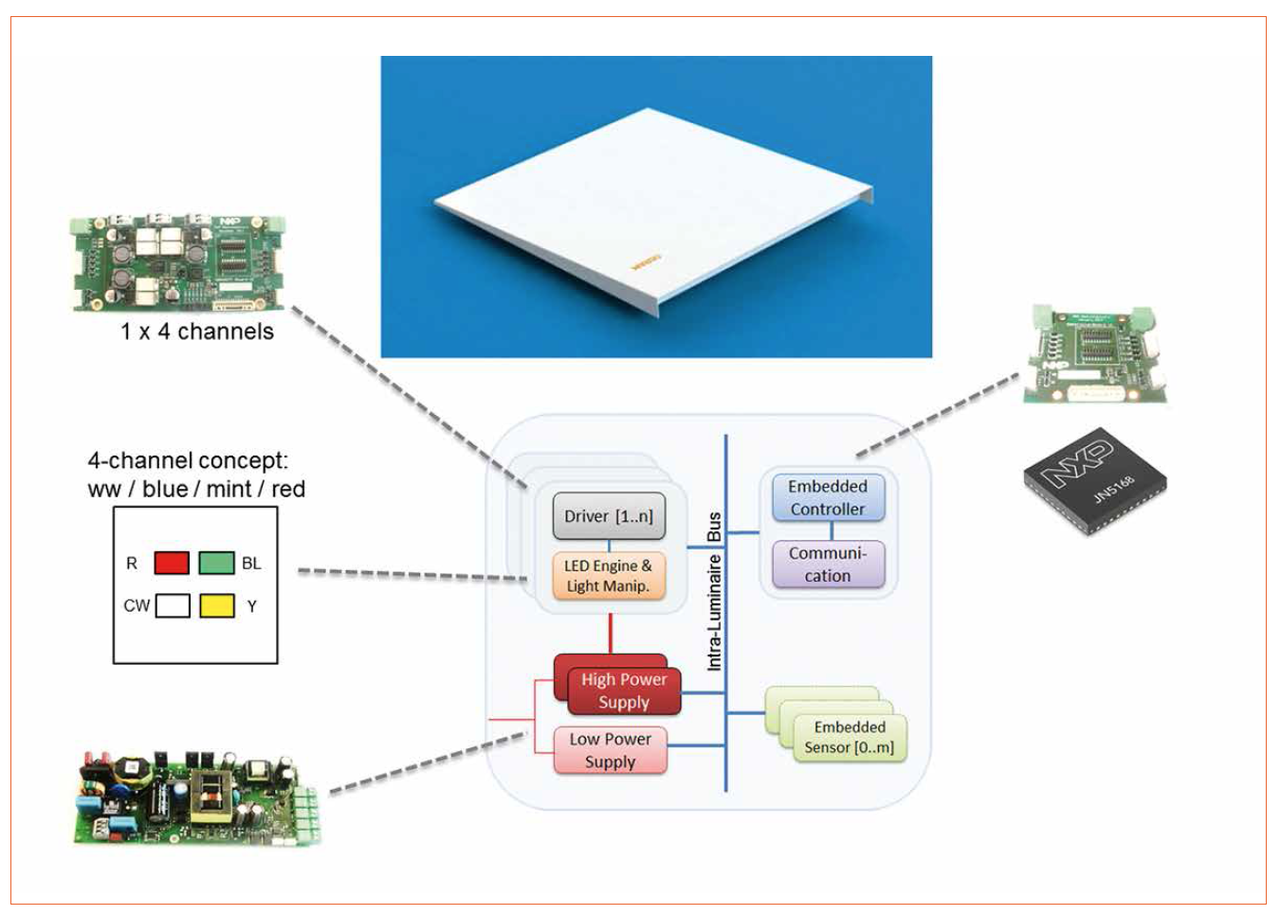

A luminaire developed by OSRAM which served as a platform for a wide range of room lighting and decorative designs was dubbed “Wedge” for its wedge shaped design. Light was emitted at the wide edge of the “Wedge” which is ideal for mounting the luminaire on vertical surfaces to light a desk (task lighting), on the ceiling or just for a wall-wash effect. With a maximum height of only 25 mm the luminaire was exceptionally flat and required little mounting space. The unobtrusive appearance made the luminaire almost disappear, and directed the user’s attention to the light and the illuminated object.

Similar to the luminous door, multicolor LED modules consisted of warm white, red, mint and blue LEDs for full color tunability. LEDs were placed in a highly reflective mixing chamber which was optimized for high light output, homogeneous color mixing and prevention of direct glare from direct view into the LED light source. Since the housing was made of metal, it was effectively used for heat spreading and cooling of LEDs and electronic components. In order to enable emission and reception of radio signals within the wireless EnLight communication network a plastic window was inserted into the metal housing just above the radio antenna.

Figure 5: “Wedge” luminaire and luminaire architecture

Figure 5: “Wedge” luminaire and luminaire architecture

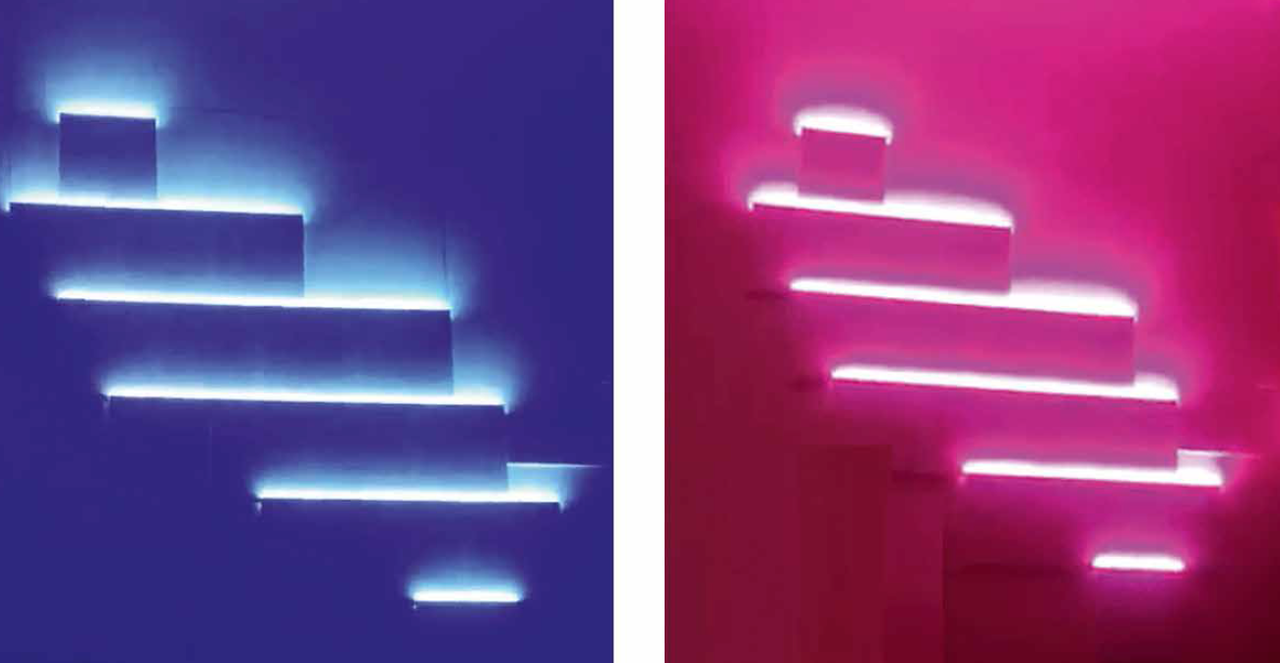

“Wedge Wall”

The side emitting design of the “Wedge” luminaire was especially suitable for light arrays, where multiple panel configurations allowed design freedom. Together with the variability of color temperature and color combinations an infinite number of scene settings can be achieved. A selection of different settings, which were chosen for the installations, is shown in figures 6 and 7.

Figure 6: “Wedge Wall“ scene settings at the office demo at VTT, Finland

Figure 6: “Wedge Wall“ scene settings at the office demo at VTT, Finland

Figure 7: “Wedge Wall” scene settings at the hospitality demo at Osram GmbH, Germany

Figure 7: “Wedge Wall” scene settings at the hospitality demo at Osram GmbH, Germany

Similar to the luminous door, the “Wedge Wall” allowed glare free illumination and mood lighting. Indirect lighting was dynamically tuned and adjusted. The wedge wall and the luminous door substantially contributed to vertical lighting. Horizontal lighting is a mainly functional property requested by standards with regard to the execution of a visual task on horizontal surfaces. Vertical lighting is more and more recognized as a vital prerequisite for spatial experience. The wedge and door luminaires not only enabled the architectural construction of spaces with light but also provided a pleasant experience where people came to meet and talk. With a high component of vertical lighting, faces were well illuminated and not obscured by shadows.

“Wedge Wall” architecture

The “Wedge Wall” provides a good example of how the modular architecture can be employed for most flexible configuration of multiple components and luminiares (Figure 8). The entire “Wedge” panel was regarded as a single luminaire which is composed of modular building blocks. For the hospitality demo shown in figure 7 a total of 12 “Wedges” were used in one panel. Three 75 W power supply units supplied the entire panel. Wireless communication from outside the panel was done by ZigBee to the luminaire controller. If the intra luminaire communication bus, developed in the course of the project, was used for communication from the luminaire controller to the LED driver controllers, luminaires, sensors and user interfaces could be readily added or removed without further need of re-commissioning.

Figure 8: Architecture of the “Wedge Wall”- a panel with 12 “Wedge” luminaires is shown in this example

Figure 8: Architecture of the “Wedge Wall”- a panel with 12 “Wedge” luminaires is shown in this example

The “Wedge” luminaire panel was installed in different configurations with 8 “Wedge” luminaires at the office demo at Philips, Netherlands and with 16 “Wedge” luminaires at VTT, Finland (Figure 6). In these cases branches of 4 “Wedge” luminaires were simply removed from and added to the configuration in figure 7, respectively.

The “Wedge” wall concept demonstrates how an apparently complex intelligent luminaire can be configured by just “stock-picking” ingredients” from the building block inventory (Figure 1 in the “EnLight Intro-Overview”) without a special need for customized development.

Luminaire for Accent Lighting

Spotlight luminaire

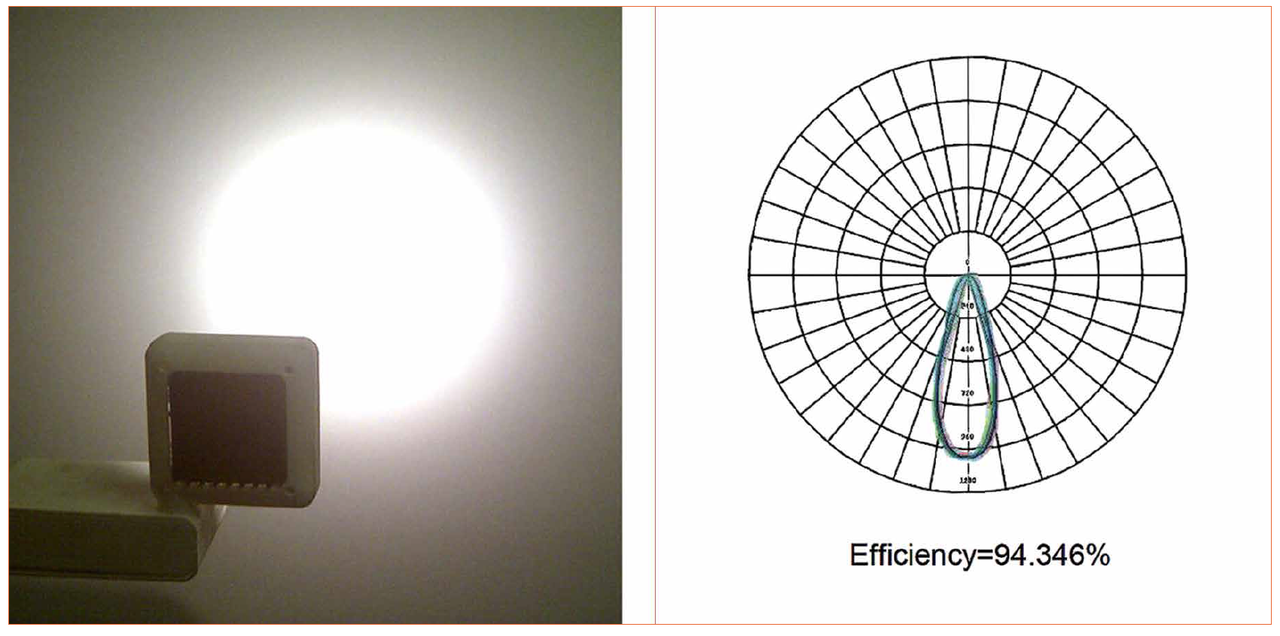

A spotlight luminaire suitable for track light mounting was developed for the purpose of adding accent lighting to EnLight installations. This luminaire demonstrated that with the use of LED technology luminaires can be given thrilling designs to which we had not been used to in traditional lighting systems. Spotlight luminaires designed for the use with legacy light sources are usually associated with elongated cylinders and long parabolic reflector shapes. For the luminaire an extremely small LED light kernel with a diameter of only 6 mm was used. The étendue which governs the size of the entire optical system was thus very small. In combination with a Fresnel TIR lens, which was optimized for maximum flatness the whole luminaire aspect ratio represented the extreme opposite of conventional designs. Lighting module and track light body were both cubically shaped which gave a consistent style and harmonic overall appearance.

Efficacy was not sacrificed by this design. The flat design rather improved thermal management. The light kernel was mounted directly on a heat sink at the back of the luminaire and an open structure allowed for air flow through the lighting module and enforced convective cooling.

The high lens optical efficiency led to a light output ratio of close to 95% for the used light kernel. The total luminous output was 500 lumens with an overall luminous efficacy of 80 lm/W.

The light kernel provided a red, blue and mint color combination. Light mixing was done by a diffuser cast on the light kernel level. In combination with the lens optics a perfectly homogeneous light distribution of beam angle FWHM = 30° was achieved (Figure 9 - right).

Figure 9: The light distribution of a spotlight on a projection surface (left) and the measured light distribution graph (right)

Figure 9: The light distribution of a spotlight on a projection surface (left) and the measured light distribution graph (right)

As with all other EnLight luminaires, color and color temperature tuning was implemented. Electronics driver and control components were placed in the track light body.

Conclusions

The project partners developed various luminaires that followed the same modular building block concept of the EnLight component inventory. These luminaires were integrated into the office and hospitality installations. All luminaires demonstrated that this new luminaire system architecture with a high degree of modularity and extensibility, enabled by the intra-luminaire communication bus, is working. The new level of freedom in configuration and combination was used to realize concepts which would have been much more complex and less configurable in the past.

In contrast to the retrofit approach, EnLight luminaires widely exploited design possibilities dedicated to LED technology. LED light source efficacy was optimized by thermal management concepts, which minimize the LED junction temperature by making use of functional and design structures of the luminaire without adding bulky cooling bodies. High light output ratios added to the overall luminaire efficacy by means of optical designs which fully take into account the light source properties and the desired luminaire light distribution.

New form factor luminaires were demonstrated that break completely free from conventional designs and take the notion of a luminaire to a level that would have hardly been considered with traditional light sources.

Figure 10: EnLight spotlight luminaire

Figure 10: EnLight spotlight luminaire