More Efficient Plant Growth with Quantum Dots by Nanoco Lighting

Using LEDs for plant growth lights is nothing new, nor is the use of QDs in LED lighting. While it is already proven that LED systems have big advantages over conventional plant lighting technologies, it is not common knowledge that Cd-free QDs are ideal candidates for optimizing the light spectrum for plant growth systems. Dale Needham, Business Development Director-Lighting at Nanoco Lighting, explains the opportunities and advantages based on Nanoco’s proprietary and patentprotected CFQD® cadmium-free quantum dot LED grow lighting systems.

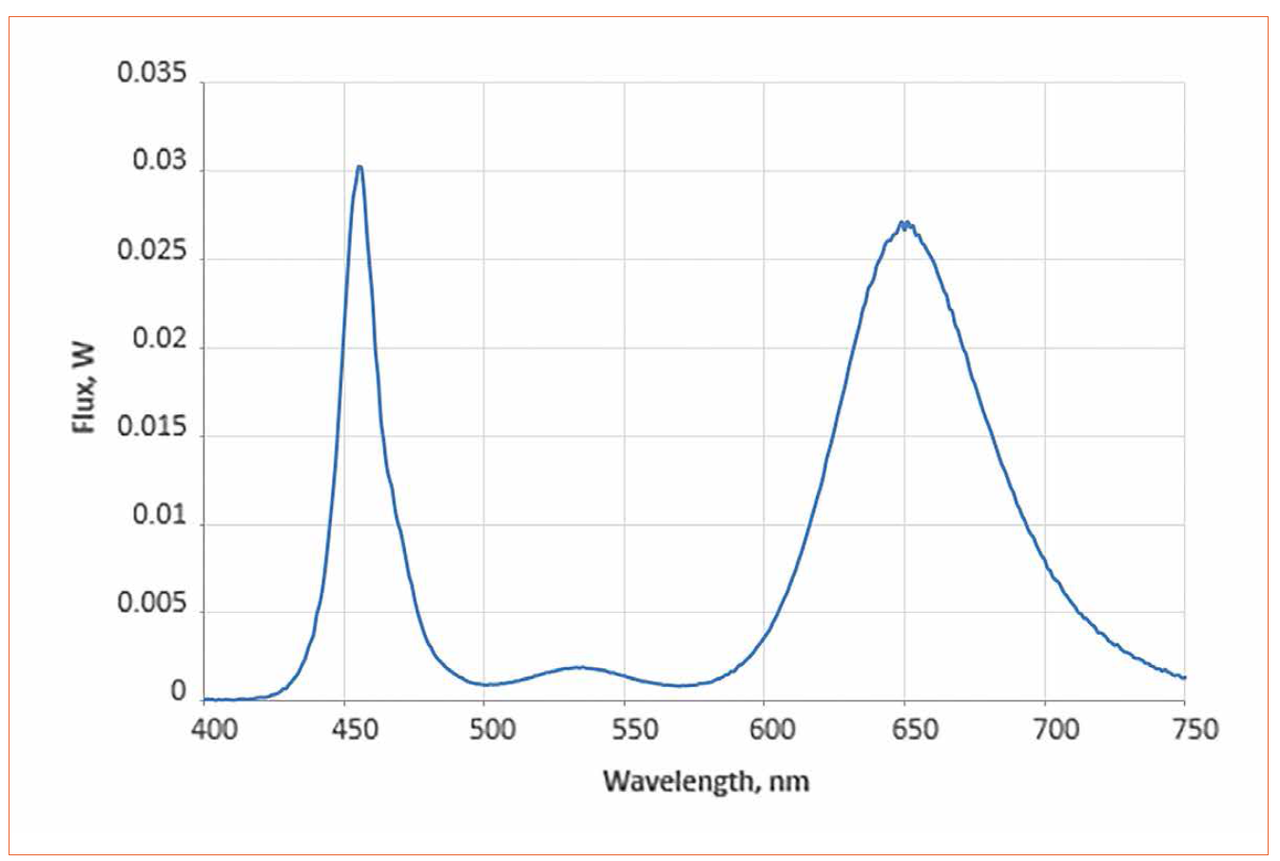

For plants to thrive, they require the full-spectrum light of the sun; chlorophyll in the foliage absorbs sunlight to provide energy for all of the plant’s needs, while photosynthesis - using wavelengths between 400 and 700 nanometers (nm) - is the plant’s process of converting light energy from the sun. Most plants do not need all of the color bands in the visible spectrum. For instance, flowering plants use the full spectrum of visible light, but some wavelengths are more important than others. Red light is crucial for hormone activation, which powers the flowering and fruiting processes, while blue light encourages the compact “bushy” appearance of healthy plant growth. For this reason, growers relying on artificial plant lighting such as LEDs concentrate on the blue and red parts of the spectrum.

Precise spectrum light, along with the intensity and duration of that light, simultaneously triggers plant flowering, growth, and reproduction, yet plants are quite selective in the light they use. Generally, their requirements are limited to small, specific bands of light, and they reject any additional light that’s not needed. This might suggest that sunlight is rather inefficient as a plant’s energy source, but, due to its abundance of light energy, wastage is hardly noticed. In grow lighting environments, however, the exact amount of lighting that’s needed for plant growth must be provided artificially, while too much lighting can be harmful to plants, inefficient, and quite costly for vertical system farmers.

Figure 1: Lettuce growing under LED lighting

Benefits of LED Lighting

LEDs provide particular benefits to the grow light and horticulture industries because, unlike traditional sources such as incandescent, fluorescent, halogen, or high intensity discharge lamps, they can be customized to encourage chlorophyll absorption in plants. By promoting healthy development through wavelength specificity and linear photon output, consuming far less energy, and casting less heat, LEDs are not only a cost-effective solution, but also improve the agriculturist’s ability to control their growing environment. However, challenges exist in easily tailoring existing LED fixtures to meet direct specifications in color for plant variation and different stages of growth.

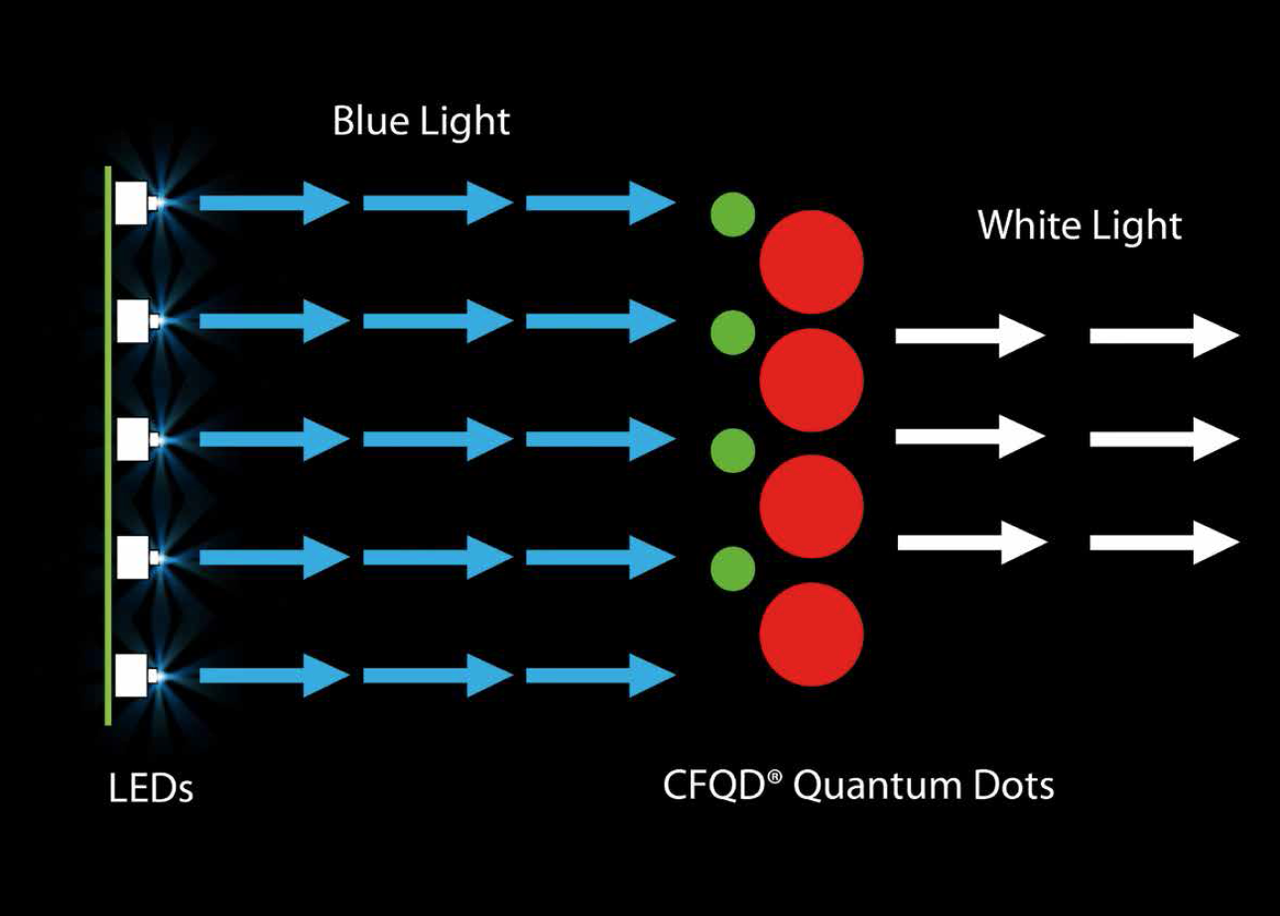

A new technology with unique optical qualities is poised to take on this challenge. Cadmium-free quantum dots enable emission wavelength precision that consistently produces the clear and concentrated color essential for vertical grow systems. Tuning the size of these brilliant nanoparticles makes it possible to tweak the light emitted from an LED system to any color in the spectrum, while maintaining the energy efficiency of the LED.

Development of LED Grow Lighting

If growing potatoes to survive on Mars sounds like a science fiction plot, consider that much of the early research into LED grow lighting was conducted by scientists affiliated with the National Aeronautics and Space Administration (NASA). As early as the 1980s, researchers began to evaluate how LED lighting systems might ensure healthy plant growth in hostile conditions, and the impact this new technology could have on serious concerns such as drought, pestilence, and world hunger.

Since blue-emitting LEDs were not yet available, the earliest experiments were limited to arrays of red LEDs. Research into industrial applications for LEDs accelerated during the 1990s, resulting in a stream of technological innovations that boosted luminous efficacy and increased the range of available colors to include blue, green, white, and more.

These developments are of tremendous benefit to scientists working in horticultural lighting, for whom LEDs represent “the first light source to have the capability of true spectral control, allowing wavelengths to be matched to plant photoreceptors to provide more optimal production and to influence plant morphology and composition.” [1]

Greater spectral control is one of several advantages that LEDs maintain over traditional grow lighting systems. To achieve the ultimate spectrum for grow lighting, color temperature, measured using the Kelvin scale at a given wavelength, is one of the most important considerations. As a standard definition, the color temperature of a light source is the temperature of an ideal blackbody radiator that radiates light of comparable hue to that of the light source. The sun closely represents a blackbody radiator with a color temperature of about 5,900 K. Respectively, when discussing LEDs, colors above 5,000 K are known as cool blues and closely resemble natural sunlight, whereas colors below 3,000 K are known as warm reds.

In search of this ideal spectrum and most sufficient and efficient light source for indoor agriculture, the lighting market has evolved with various solutions triggering different responses from the plants - blue light inducing vegetative growth and red light inducing flowering. Some of these traditional grow lighting systems specialize in certain parts of the spectrum, while others span multiple wavelengths.

Figure 2: Blue LEDs excite red and green cadmiumfree quantum dots, resulting in high-quality white light

All Present limitations

Incandescent lighting, though inexpensive to set up, can overheat plants, waste energy, and offers limited red and blue color necessary for vegetative cultivation and plant health.

Halogen systems, although very close to the spectrum of natural sunlight (6,000 K) and boasting a longer life span than incandescent lights (up to 15,000 hours) are also hampered by overheating and inefficiency. They can only provide light to a narrow area, ultimately burning or damaging plants by providing too much light to certain sections and not enough to others.

Fluorescent grow lighting is popular but tends to lack the red emissions essential for plant flowering. Full-spectrum fluorescent systems require specialized fixtures as part of their high upfront cost, deeming them inefficient.

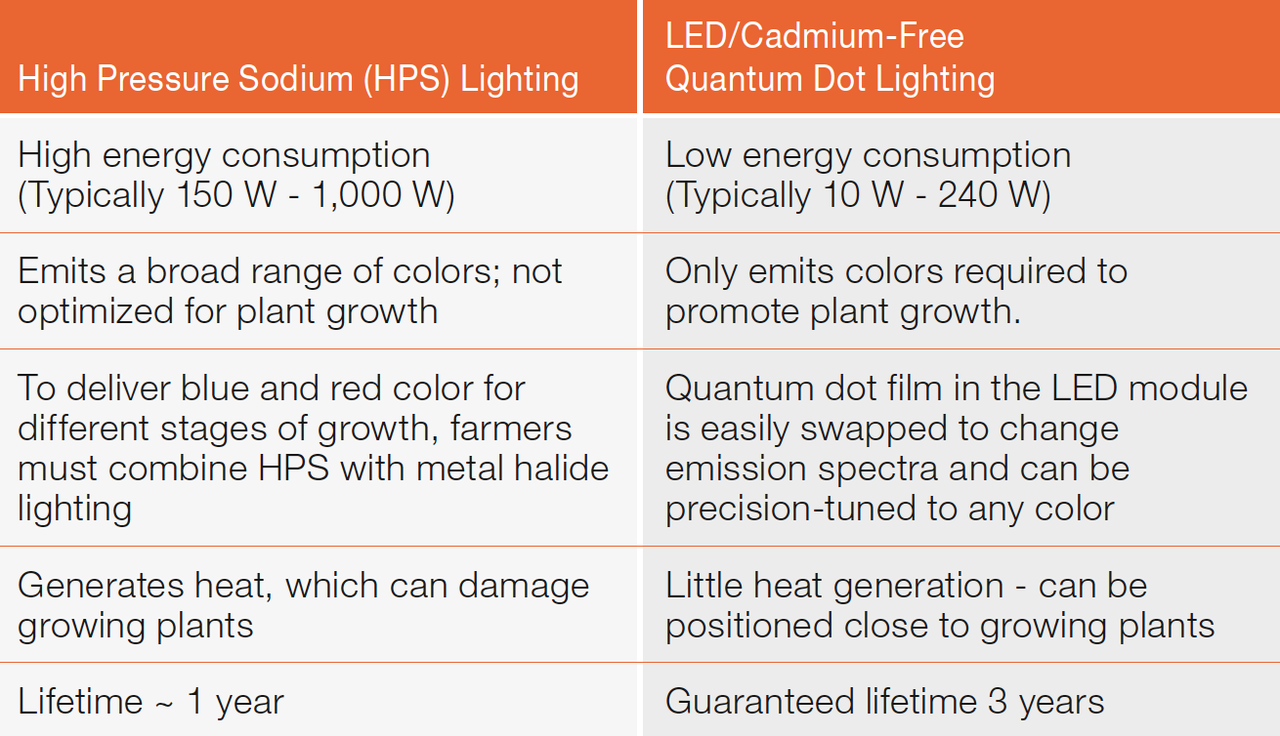

High-pressure sodium (HPS) and metal halide lamps are examples of High Intensity Discharge (HIDs) lighting, a leader in the horticulture industry. Because HPS rigs produce light in the warm, red end of the spectrum, they are superior in flower production compared to metal halides or florescent lamps, but the plants appear washed out and nitrogen-starved due to the bulb’s poor color rendering of cool, blue light. Further, two types of HPS must be combined in order to produce both red and blue light.

LED Limitations

Fast forward to 2016. With the ability to produce the wavelengths of desired light at minimal heat production and exceedingly high-energy efficiency, LED lighting has quickly been adopted for indoor grow operations. While their popularity is increasing exponentially, LED grow systems still have limitations in their available emissions wavelengths, which can lead to less-than-optimum photon absorption for plant growth and, therefore, wasted energy. This almost defeats the purpose of adopting LED technology for vertical farming endeavors.

Current grow systems utilize a combination of red and blue LEDs to stimulate chlorophyll absorption and supplement plant growth. However, this requires multiple SSL fixtures of differing wavelengths to achieve the various red, green, and blue emissions. A single LED with a red emission is not optimized for energy efficiency while only offering the warm light for specific plants and or reproductive stages. A strip light may have a combination of alternating red, red, blue, red, red, blue LED bulbs and so on. Yet, growers must move the light far enough from the plants for the color emissions to mix, so that each plant receives the correct ratio of blue to red; hence causing more energy output and inefficient light distribution.

The phosphors in standard LEDs are broad and vary in emission, which means that the plants do not receive the same spectra. While there is new narrow phosphor technology available on the market today, it is prohibitively expensive and built for display applications only. Since tolerance of the LED is large, the emission can shift and lack in replicating the desired light performance from luminaire to luminaire, which does nothing to maximize coverage over the absorption spectra.

Until recently, growers lacked the ability to precision-tune their LED systems required for different species of plants or growth stages. With the introduction of cadmium-free quantum dots, the next wave in LED-based grow lighting technology has arrived.

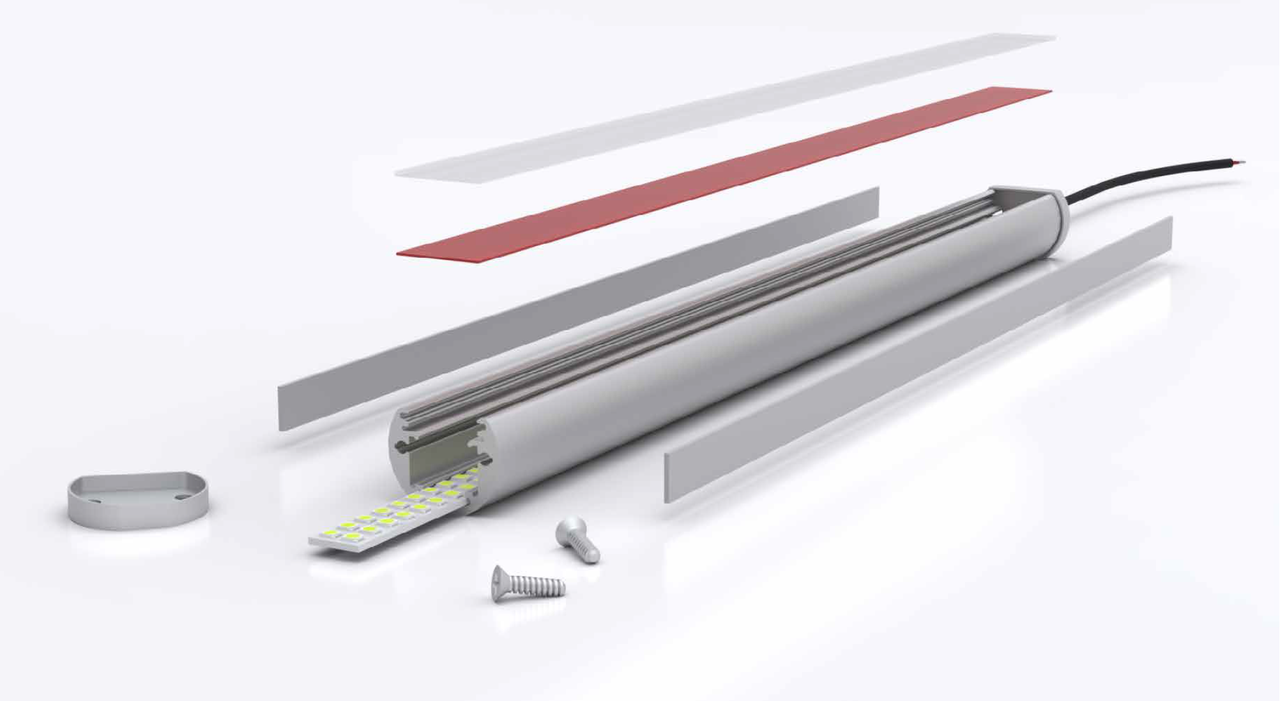

Figure 3: Grow light fixture with 3 array LED lamps with cadmium-free quantum dot film

Big Solution in a Tiny Package

Quantum dots are tiny fluorescent semiconductors -so small, you would need 10,000 to span the width of a human hair. If excited by an external light source, they absorb the energy and re-emit the light in a different color, depending on the size of the particle. When quantum dots were first introduced to the market, manufacturers immediately recognized their potential for enhancing LEDs in the lighting display category, where quantum dots, acting as a narrow band red phosphor, have a great advantage to give manufacturers excellent color quality (CRI, R9), without the large loss in efficiency they see with typical red phosphors.

Because cadmium-free quantum dots can be easily tuned to any color of the spectrum, they offer a breakthrough in grow lighting over traditional LED fixtures.

To date, most quantum dot technology, widely known for its use in the TV display market, contained cadmium, a toxic heavy metal that is highly regulated in the European Union. Due to the health and environmental threat that cadmium presents, the European Union’s Restriction of Hazardous Substances Directive (RoHS) limits the amount of cadmium, lead, and mercury that can be included in electrical and electronic equipment sold in that market.

Heavy metal-free quantum dots are a fully RoHS-compliant option for manufacturers and consumers that provide all of the benefits associated with the technology in a safer and more sustainable product. They are available in custom sizes and shapes and are designed to work in conjunction with LEDs from 405 nm - 455 nm as required.

LED Growing Made Greener

For horticultural lighting, cadmium-free quantum dot film is the optimal choice. These non-toxic, highly efficient materials can be easily incorporated into various LED lighting formats to assist in the propagation and vegetative stage of plant growth. They can be manufactured in such a way that the blue-to-red emission ratio varies per film, which, again, is ideal for different species and stages of plant growth.

Figure 4: 1:1 ratio of blue to deep red cadmium-free quantum dot panel light

Traditional red and blue LED grow systems have the problem of diffusion, and therefore must be placed high above the plant so that the red and blue light illuminates the plants evenly. A LED system enhanced with cadmium-free quantum dot films can be easily tuned to the desired color of the spectrum. Because the emission originates from a single location, this reduces the cost associated with the increased circuitry of multiple SSL arrangements.

With cadmium-free quantum dots, the deep red emission of LED light can be tuned to stimulate optimal absorption of both type A and type B chlorophyll - important for crops such as basil and lettuce. By working with nature and permitting fine-tuning wavelengths to climate conditions and plant specifications, the technology ensures farmers have greater control over healthier and vibrant plant growth, such as creating a crisper or softer texture of lettuce.

Quantum dot films also provide excellent uniformity of light with much-reduced heat output compared to traditional sources, allowing the lights to be placed in closer proximity to the plants for maximum yield and plant quality, while saving space and energy. Uniformity also eliminates glare and hot spots from the growing environment. Growers can easily switch emission spectra by simply swapping the film while using the same LED module. This is a major advantage for farmers trying to maintain efficient indoor crops at low cost.

Comparison: HPS vs. Cadmium-Free QD LED Grow Light

Table 1: Comparison of HPS and the CFQD® cadmiumfree quantum dot LED grow lighting systems

Easy Integration into Existing LED Products

As the cadmium-free quantum dot film is the latest in lighting technologies, the materials have been developed to act as a platform technology, enabling all users to incorporate the film within their devices. With the correct concentration of blue light, users may manipulate their luminaire to emit the desired ratio of light at the deep red wavelength. Other spectra can be produced to the customers’ individual requirements.

Using standard blue or UV LED components as the energy light source, cadmium-free quantum dot films are easily integrated into existing LED products, enabling the customization of individual color selection based on the particular plant or product being grown. The advantage of using film is that the quantum dots are broad absorbers; any blue LED from 430 to 460nm will excite the film. This offers a cost-effective and simple solution for manufacturers of horticulture lighting. Furthermore, using only blue LEDs as a light source greatly reduces the complexity of the light fixture, makes it easier to assemble, and enables manufactures to reduce stock holdings.

Cadmium-free quantum dot film typically slides into a groove within the LED light fitting (Figure 3) and sits about 2-5 cm away from the LEDs to allow for adequate mixing of the light.

Figure 5: CFQD® patent protected cadmiumfree quantum dot deep red linear strip light

A Growth Industry

With the vertical farming industry projected to reach USD 3.8 billion by 2020 [2], there is an urgent need for innovative technology to support this burgeoning global market. Driven by factors like year-round crop production in urban environments, pesticide-free high-quality fruits and vegetables, and the power to control their growing climates, vertical farmers can benefit greatly from the unprecedented spectral precision of LED grow lighting enhanced with cadmium-free quantum dots. Encapsulated in film and free of cadmium, these powerful dots can be fine-tuned to ensure healthy plant growth at every stage of development. LED lighting manufacturers who adopt this technology will be able to offer farmers a consistent, cost-effective method of growing that’s safe, reliable, energy- and cost-effective, and satisfies customer needs worldwide.