LED Light Spectrum Enhancement with Transparent Pigmented Glazes

While LED bulbs have the distinct economic advantages of using less energy, producing less heat and lasting years longer than traditional incandescent bulbs, when objects are viewed under LED light, they frequently appear to be of different colors than when viewed in sunlight or with incandescent lights. Jan-Marie A Spanard from Light Spectrum Glazes proposes and explains an approach to optimize the spectral distribution of LED light to overcome this weakness.

“White light,” is the visible uncolored light which allows the human eye and brain to maximize the perception and recognition of extant color values when viewing objects. Recognized sources of white light are the sun and stars, incandescent lights, and some specialty light bulbs. We officially define white light as being made up of red, orange, yellow, green, blue, indigo, and violet light, which corresponds to the assumption that all humans are trichromatic beings. With increasingly refined measurement capability of human vision in recent years, we now know that all not humans have trichromatic vision. Researchers have identified a range of human color vision capability that stretches from absolute color-deficiency at one end of the continuum to tetrachromacy or pentachromacy and beyond. Non-trichromatic humans are now thought to make up as much as one-third of the world’s population. Recent colorimetric research in human vision has shown that white light is processed as either a broader or narrower assortment of visible wavelengths by individual humans with non-trichromatic vision. This is relevant to our understanding of how to create and measure the quality of LED light for as many viewers as possible.

Creating LED Generated White Light

Manufacturing low cost LEDs with “whiter” white light

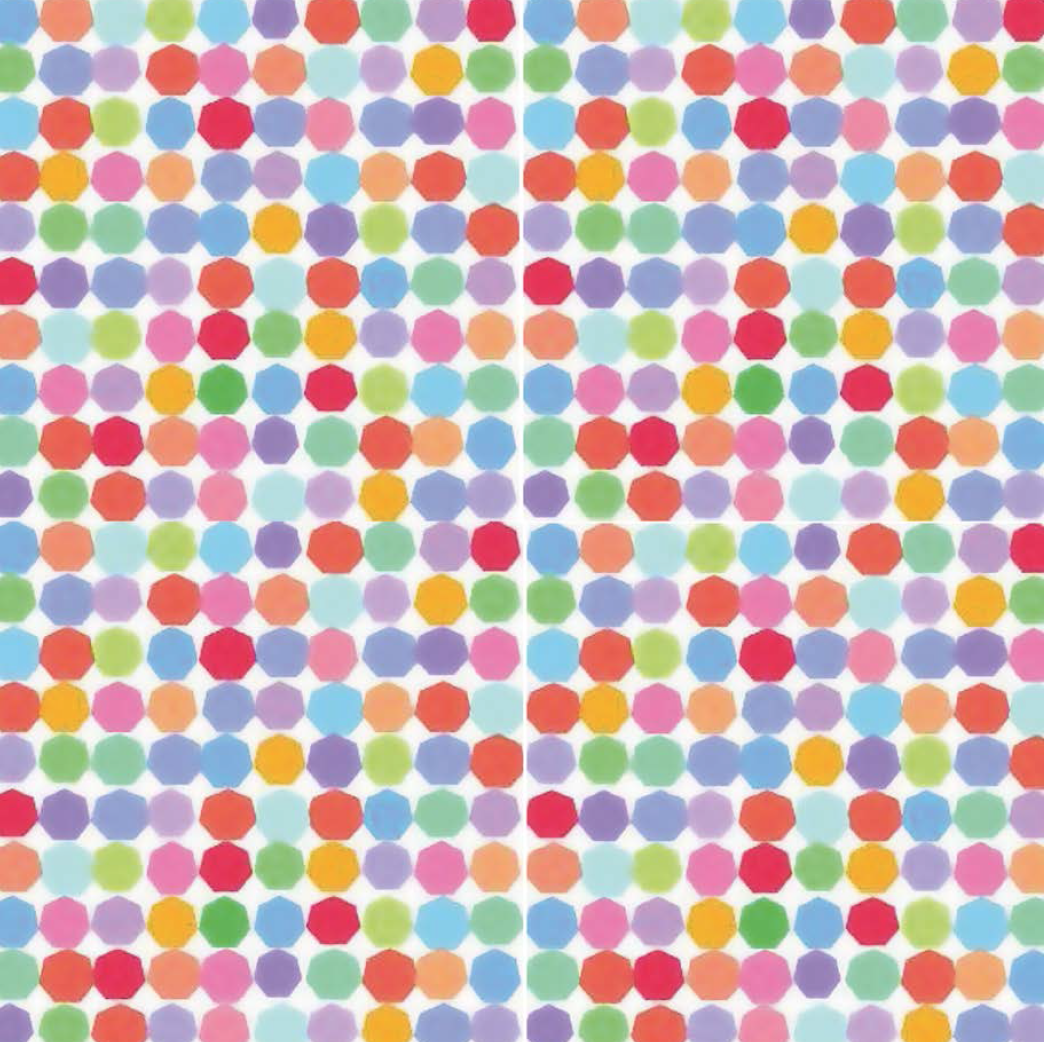

Manufacturers have had limited success in producing inexpensive “white light” bulbs. Affordable LED bulbs cannot yet accurately portray the full range of tints, tones, and colors of objects. More expensive technologies have had better success, but the manufacturing costs put these bulbs out of the price range of household shoppers. There are mainly three LED light tempering techniques used in inexpensive to moderately priced, mass-market LED bulbs (Figure 1).

Figure 1: Creating white light with LEDs, U.S. Department of Energy, Energy Efficiency and Renewable Energy Division

Phosphor film and resin-embedded solutions are the dominant method of warming the naturally cool light of an LED chip to more closely mimic white light. This adjusts the Kelvin temperature of the light into the warmer range, but the LED is still missing many wavelengths of the white light spectrum. Both the low cost of this technology and the general adequacy of the light color make this invention the most commonly used in manufacturing LED bulbs. Multiple LED chip solutions combine three or more individual LED chips of different colors into one multi-chromatic bulb and blend their output to replicate white light. Newer bulbs that permit users to adjust the color temperature of a multi-chip LED bulb generally entail maximizing or minimizing the output of a warm-white converted chip and a second cool-white converted chip, but the spectrum of wavelengths emitted is still limited to the spectral emission of the two embedded chips. The most successful attempts with this process have used six or more different LED chips, each emitting a different wavelength of light, in order to more closely approximate natural light. This can be a more effective, but much more expensive solution to creating LED white light. Hybrid of using both multiple phosphors and multiple chips involves marrying these two partially successful techniques into one bulb.

Measuring a bulb’s ability to produce white light

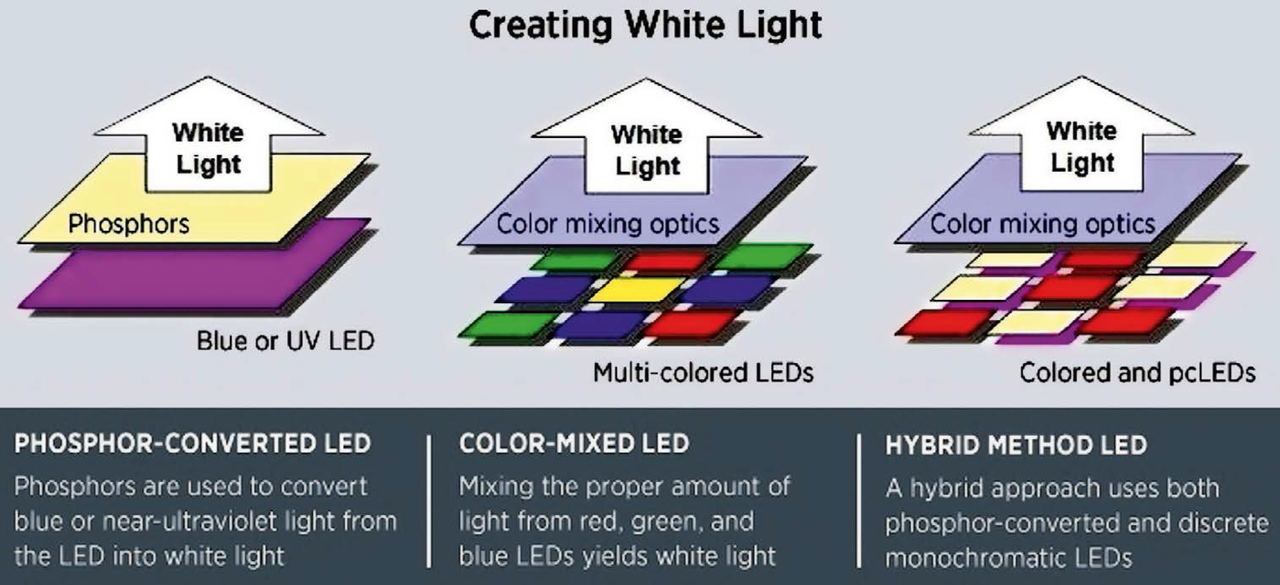

The Kelvin temperature rating of LED bulbs provides no useful information about the color quality of that light although it is the most prevalent measure on retail packages for consumer decision making. The Kelvin temperature tells us nothing about the spectrum of wavelengths emitted and hence the lamp’s ability to permit viewers to accurately identify or experience the same colors that they would find if viewing an object in white light. The Kelvin temperature rating is essentially a flat measure of coolness or warmth that does not differentiate between a single, narrow color spike or a broader, better quality color range.

Mechanical measures of LED light quality such as the Color Rendering Index (CRI), the Color Quality Scale (CQS) and the Metamerism index (MI) are meant to rate a lamp’s ability to produce light that will faithfully reveal the colors of various objects as they are seen under white light conditions. The CRI is calculated by determining how well any lamp renders a very small sample of eight bland colors in the visible spectrum. It makes no difference to the CRI score if a lamp can produce a light that will render any of the other seven to ten million colors a tri-chromatic human is thought to perceive. The CQS attempts to evaluate the faithfulness of illuminated color with several additional calculations and an increase in the color sample palette to 15 Munsell color samples from the CRI’s eight. Most recently developed, the MI matches the visual perception of a color between two light sources through a series of mechanical measurements and calculations. All three of these measures are based on the trichromatic basis of colorimetry. While the accuracy of these three measurement systems are of varying use in predicting the visual experience for those humans who are tri-chromatic, they are of extremely limited usefulness for the other, large, non-trichromatic segments of the human population.

Figure 2: Kelvin color temperature scale showing readings for various levels of daylight and incandescent lights

Figure 2: Kelvin color temperature scale showing readings for various levels of daylight and incandescent lights

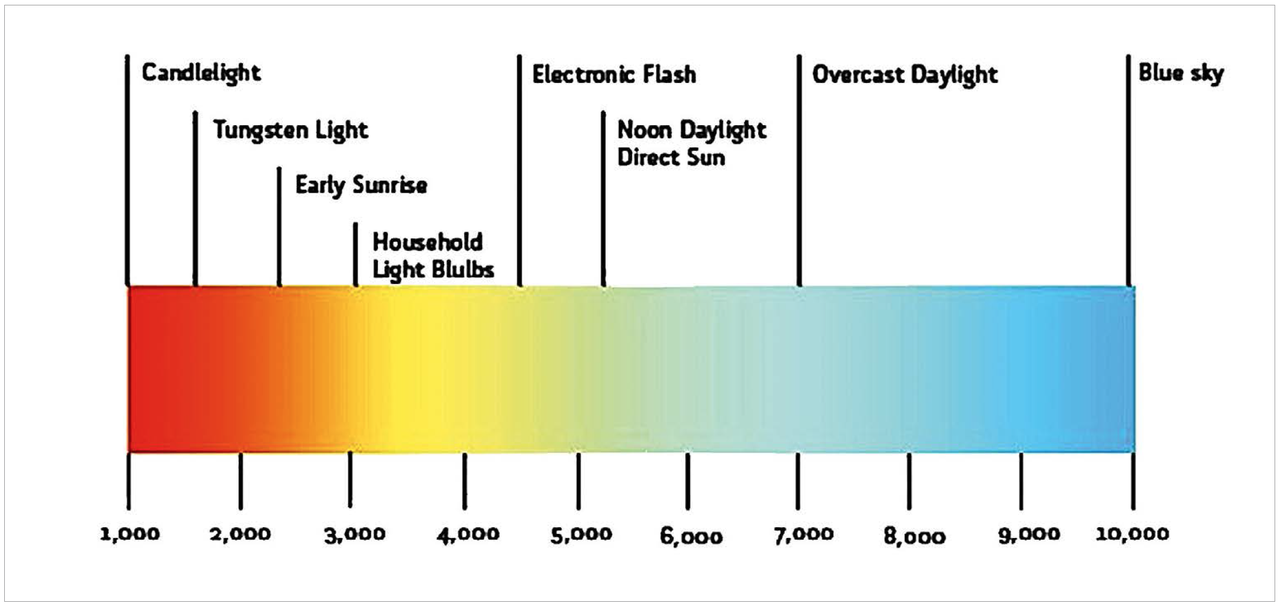

If we cannot know how non-trichromatic viewers will perceive the colors of objects, the only truly accurate measure of whether a lamp will produce a faithful rendition of the color of an object as seen under white light is to create a bulb that produces a fuller spectrum of light waves, a ‘whiter’ white light. Without knowing how much of the visible light spectrum each person can interpret, the greater the range of wavelengths that are present, the better the perceived quality of light will be for all viewers. A spectrogram of emitted light from any LED source is the only true test for whether a lamp will produce a full range of light waves that will permit viewers of all abilities to identify colors that are consistent with those seen under white light.

Color range of light sources in nanometers

The broader the production of all color wavelengths, the better the perceived quality of light for all viewers. Sunlight, as depicted in figure 3, below, emits a rich spectral array of wavelengths that allows the eye, human or animal, to maximize the perception and differentiation of color. Artificial light sources all have a somewhat limited spectral production. When a color looks different under LED lighting than it would in daylight it is simply because some of the light waves that must be present for the human brain to register the object’s full color range are not being produced by the LED bulb.

Figure 3: Color spectrum recognized wavelengths emitted by sunlight, phosphor-doped LED, incandescent and CFL lights (Ultimate Light Bulb test: Incandescent vs. Compact fluorescent vs. LED, Popular Mechanics, November 25, 2012)

Figure 3: Color spectrum recognized wavelengths emitted by sunlight, phosphor-doped LED, incandescent and CFL lights (Ultimate Light Bulb test: Incandescent vs. Compact fluorescent vs. LED, Popular Mechanics, November 25, 2012)

Traditional incandescent light is the indoor light to which we have both (1) grown accustomed, and (2) decorated and furnished our homes, businesses and public places. Incandescent bulbs produce a warm white light with a unique color spectrum. When we replace the bulbs in our buildings with LED bulbs, we have both a cooler light and a light with an abbreviated spectral color output. In short, furnishings, objects, fabrics and even people look different in LED light. Anecdotal evidence identifies LED bulbs as the most likely light source to be purchased, installed in the home, found unappealing and then uninstalled. Many viewers express negative emotional and even visceral responses to the color character of the limited LED spectral palette when used both in interiors: homes, work places and commercial venues, as well as in exterior LED street lights and flood lights. LED lights are viewed by many consumers as the quinoa at the salad bar: we know it’s good for us, but it doesn’t taste very good.

Solutions from Art Restoration Technology

Art restoration is a discipline that requires knowledge of an artwork’s visible and material structure, including both the substrate and surface materials. Damaged or age-diminished paintings, sculptures and constructions are treated so as to restore not only their structural integrity but their original visual appearance as well. Artists materials can similarly be used to fine tune the color output of LED lighting devices to more efficiently and cost-effectively attain a fuller light spectrum emission from an LED lamp. In short, artist’s pigments can be used to produce a “whiter” white light by tuning the light emitted by the LED bulb. The method of selectively adding transparent color filtering to the emitted light is described below.

Step 1: Compare the chosen light’s spectral emission with a desired spectral emission

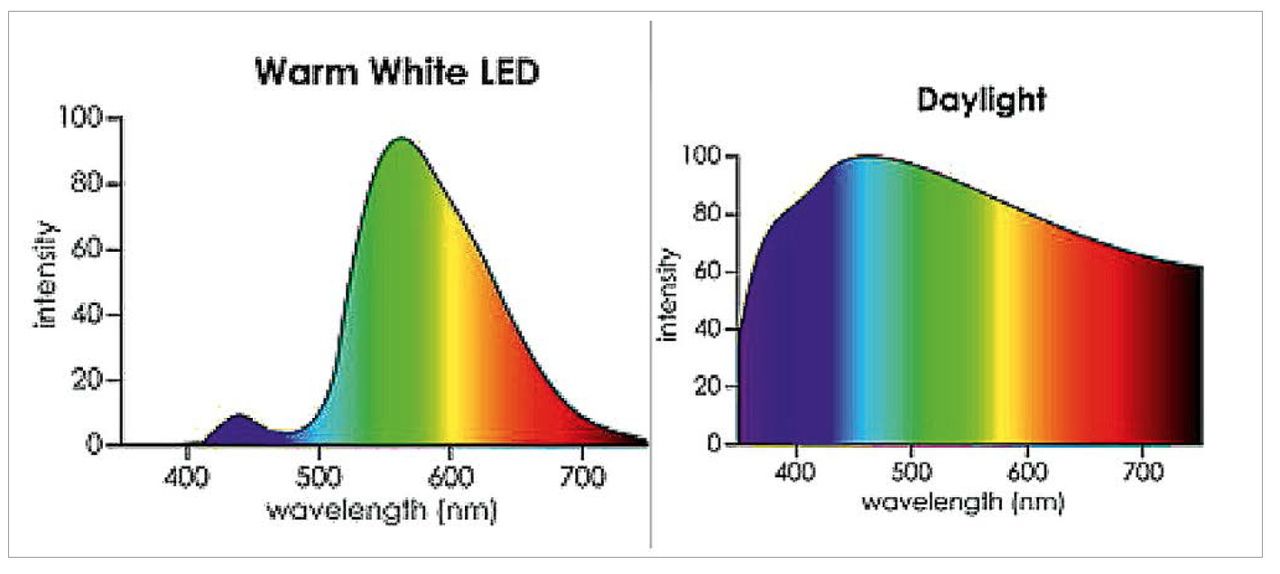

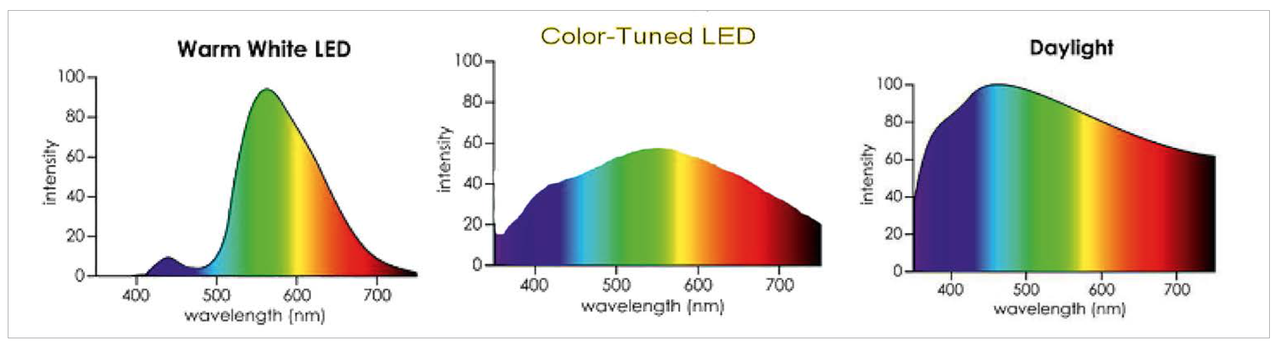

For this example, we will compare a warm-white LED lamp that is very common on the consumer market and compare it with a sample of natural daylight. Figure 4 shows the emission spectra of the warm white LED lamp and of natural daylight. Note the different array. This has a powerful impact on what we perceive when we view objects under each lighting source.

Figure 4: Comparing light emission from warm white LED (left) and daylight (right)

Figure 4: Comparing light emission from warm white LED (left) and daylight (right)

The primary adjustments needed for the LED emission to better replicate the daylight emission include the addition of light waves in the 380 - 550 nm and the 600 - 750 nm range. So, an approximation of the quantity and distribution of daylight wavelengths missing from the warm white LED that we want to add can be roughly expressed as:

+ 24% 380-425 nm

+ 18% 425-460 nm

+ 17% 460-500 nm

+ 18% 590-640 nm

+ 23% 640-730 nm

Step 2: Convert the light wavelengths to color

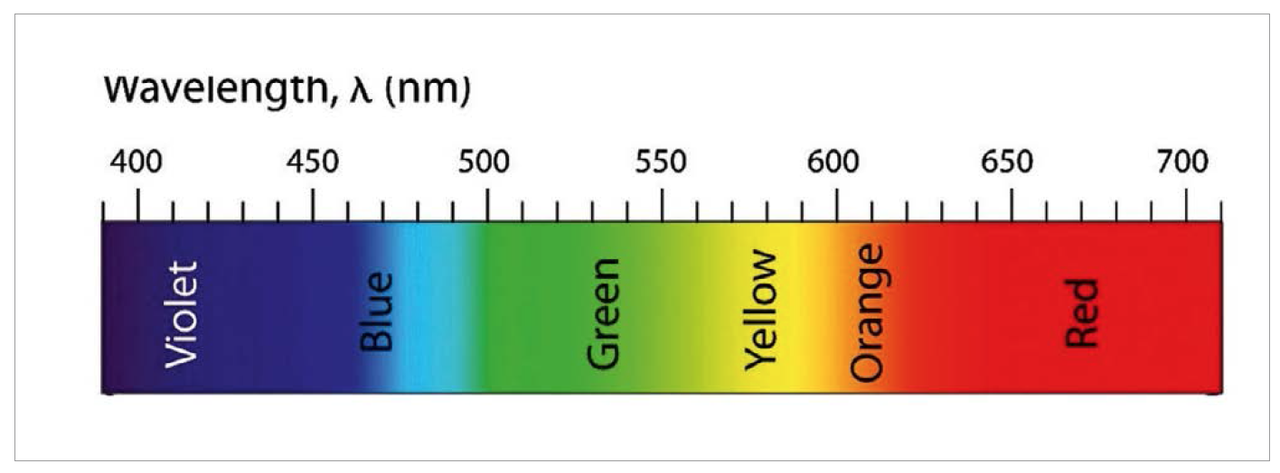

When the human eye perceives light, the brain interprets that light in colors. Figure 5 shows the match between visible light wavelengths and how humans perceive those different wavelengths as colors. Other animals perceive colors in wholly different ways, so this example is only useful for human perception.

Figure 5: Visible spectrum wave lengths and light color

Figure 5: Visible spectrum wave lengths and light color

Matching the missing light wavelengths with how the human eye and brain convert those wavelengths to perceived color, our correction formula for the light waves can now be expressed as:

+ 24% violet 380-425 nm

+ 18% indigo 425-460 nm

+ 17% blues 460-500 nm

+ 18% oranges 590-640 nm

+ 23% reds 640-730 nm

Step 3: Create pigmented transparent filter in the solution formula desired

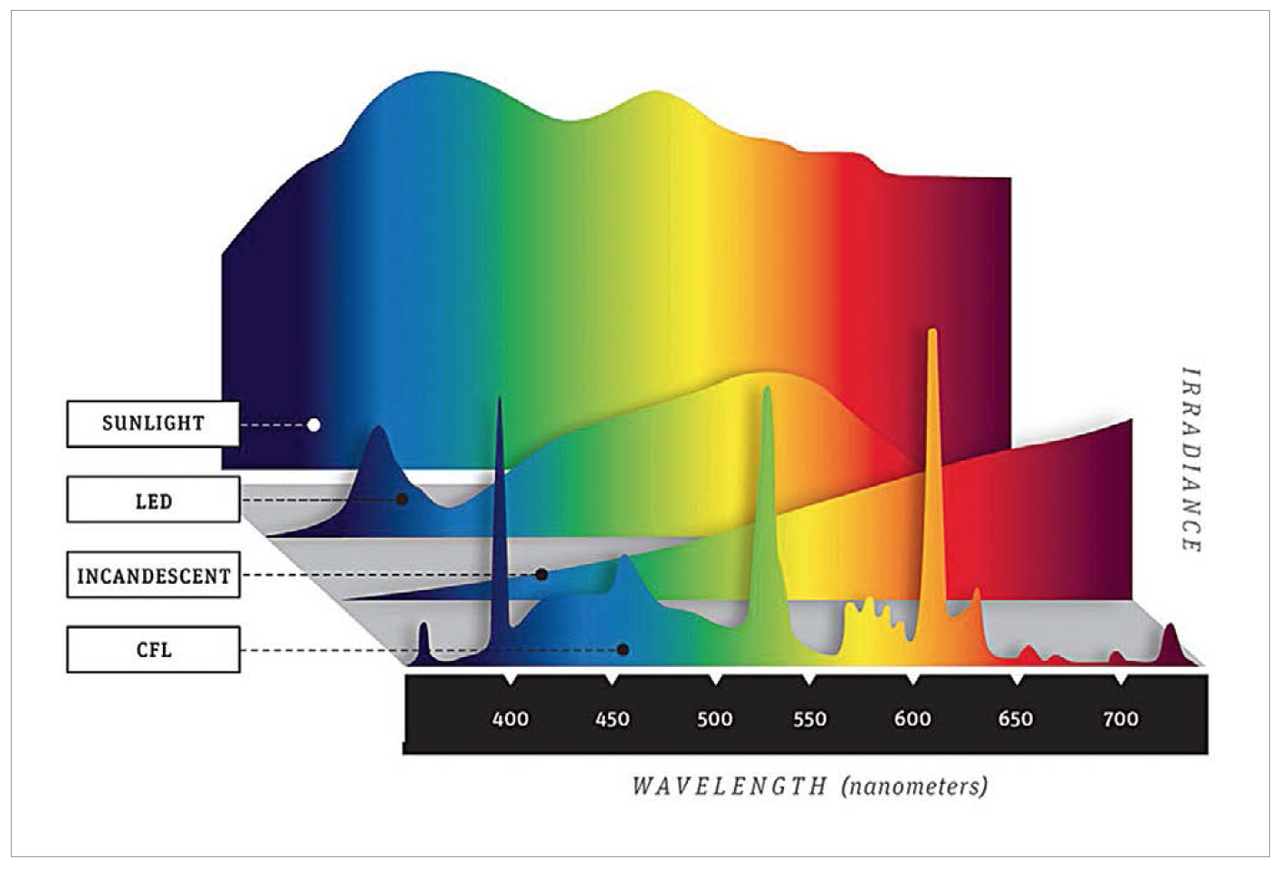

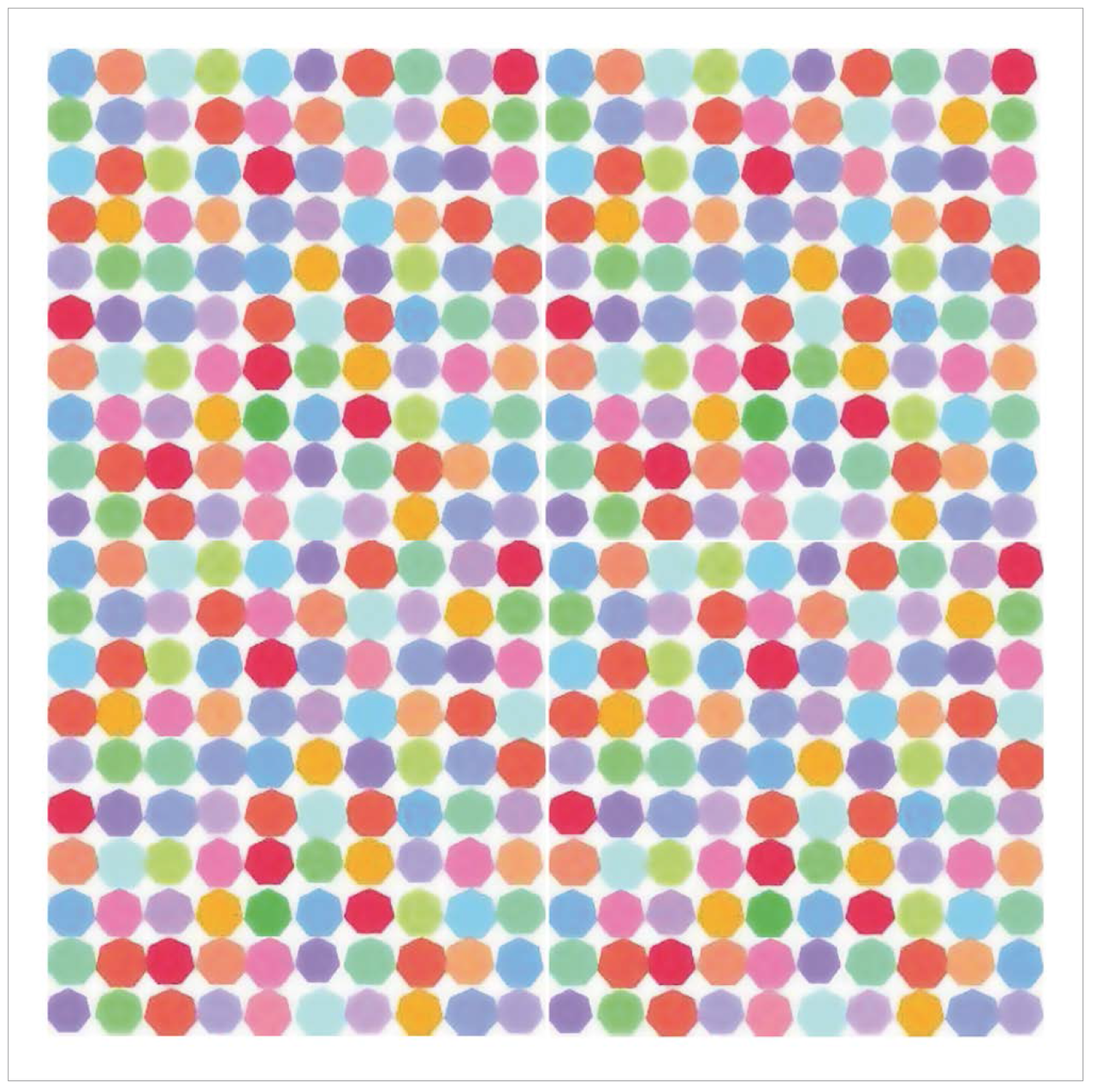

By introducing pixel-sized dots of pigment on a transparent substrate, we can “tint” the light spectrum emitted by the warm white LED bulb to better mimic the daylight emission. Figure 6 is an artist’s rendering of what the pigmented glaze color array for our example might look like when magnified.

Figure 6: Pigmented glaze solution for tuning the warm white LED to better replicate daylight (magnified)

Figure 6: Pigmented glaze solution for tuning the warm white LED to better replicate daylight (magnified)

Step 4: Balance spectral augmentation with lux maintenance

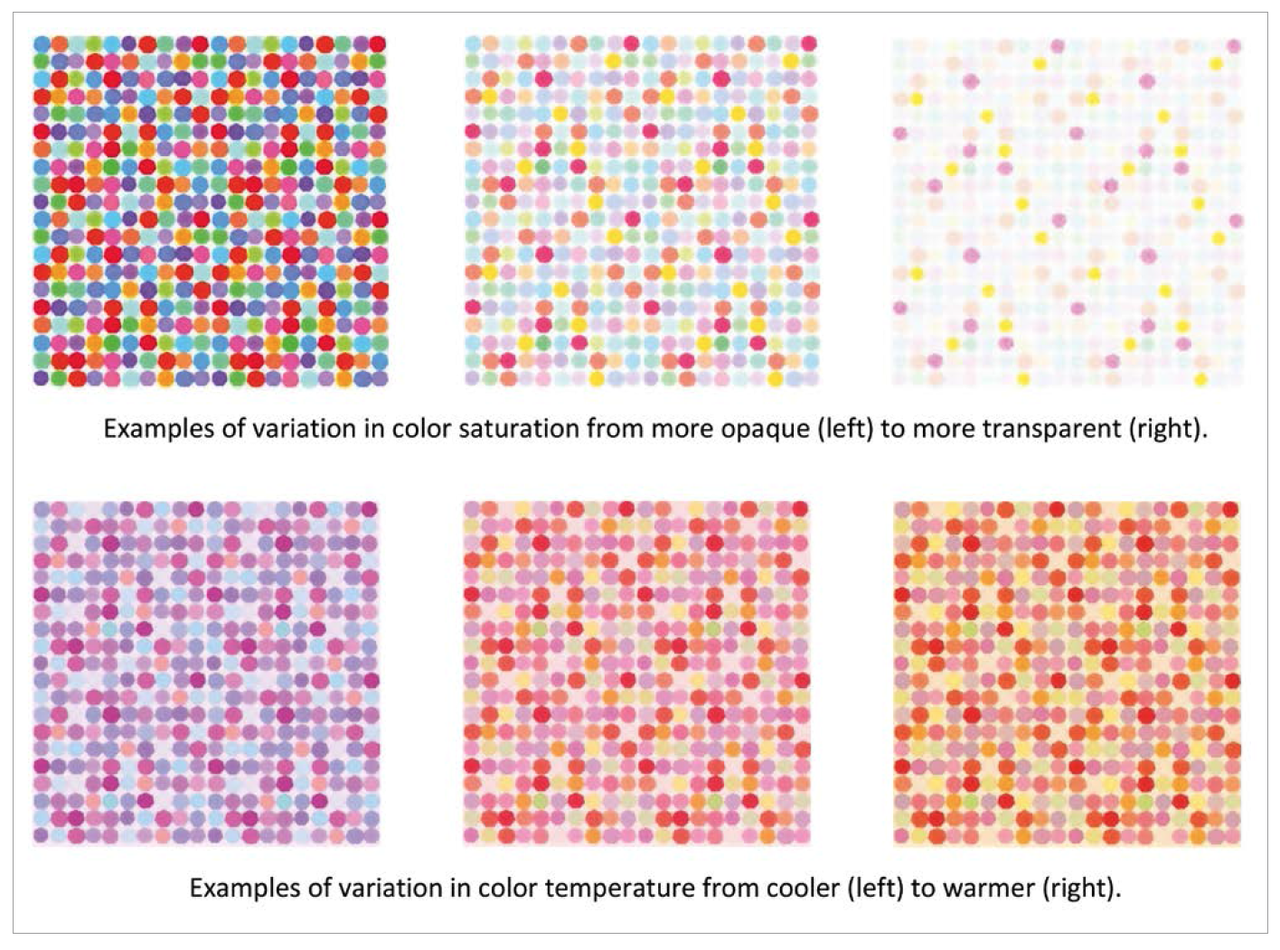

The greater the saturation of color added, the broader the spectral color array produced. This is good. But the more saturated the density of color added, the greater the loss of luminosity, or lumen output. This is not good. We want to maintain as much luminance as possible while increasing the range of light waves emitted by the bulb. A balance of these two factors, color change and lux maintenance, is key to successfully improving the light quality while maintaining as much luminance as possible.

Figure 7: Transparent pigmented glazes can be produced in a wide range of pigment saturation and color arrays

Figure 7: Transparent pigmented glazes can be produced in a wide range of pigment saturation and color arrays

Determine an acceptable luminosity-loss: color-improvement ratio by varying (1) the opacity/transparency and (2) the color temperature range of the pigment mix. The more transparent the color glaze, the more unfiltered light will pass through untreated. Fewer new waves will be produced but lux maintenance will be higher.

Step 5: Select application surface(s) for transparent pigmented glazes

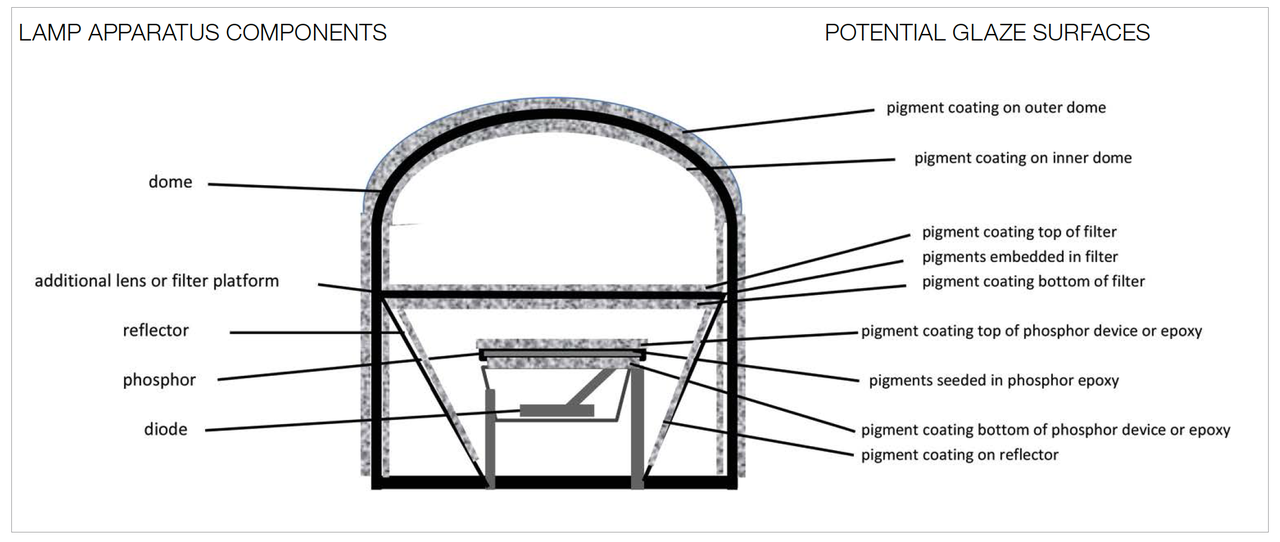

Select one or more placement areas in or on the lamp or lighting device for the pigment addition. In the structure of an LED device, areas where pigments may be added as either a pass-through glaze or as a reflective filter include, but are not limited to the areas in Figure 8.

Figure 8: Possible physical surfaces on interior and/or exterior of lamp apparatus for pigment glaze placement

Figure 8: Possible physical surfaces on interior and/or exterior of lamp apparatus for pigment glaze placement

Step 6: Select an optimal pigment source and a binder (medium)

Pigments can be (1) completely transparent, which are best suited for interior filters, lenses, pass-through surfaces, and exterior bulb surfaces or (2) translucent, better suited for reflective surfaces on the interior of the lamp. Binders which hold the pigments in place, include resins, silicate binders, acrylic polymers, oil-based binders and water-based binders. Different binders offer different physical properties. Poly-resins and potassium silicates provide the most desirable characteristics for use in an LED lighting device. Neither is adversely affected by heat, by humidity at any level, to deterioration over time, or to damage by direct handling. Silicate and resin glazes will not crack, flake, or craze.

Pigments can be applied either as a dry material or a liquid suspension to the lamp surface(s), interior and/or exterior, as selected. The potassium silicate glazes are chemically bonded to the substrate without any further treatment. The resin glazes can be heated to 165 degrees C to permanently thermobond the material to the bulb surface. The liquid tinting compounds are water soluble, non-flammable and non-hazardous.

Pigmented glazes can be applied directly to an extant lamp surface or may be applied, printed or embedded on an additional lens or filter surface placed inside the bulb envelope.

A glaze can be applied to any shape or size bulb because it is in liquid form. The glaze can be used on current bulb forms and any new bulb forms introduced in the future. The pigmented glazing liquid can also be applied in graduating density around the base of a bulb so that when dimmed, the color temperature of the light emitted changes as the light intensity diminishes. The pigments chosen can be adjusted in spectral range. In fact, any color scheme could be used for decorative purposes, creating a soft pink light, for example.

The resins can be mixed as a brilliant glossy transparent tint or can be mixed as an opalescent, light-refracting tint of various complimentary warm yellow and red hues. The silicate glazes can incorporate powdered reflective minerals such as garnet, mica and quartz. The component materials of the glazes mentioned here are currently manufactured and have been tested and approved for use by both LED bulb manufacturers and consumers. The potassium silicate and resin materials are not expensive nor are they difficult to obtain and use.

Step 7: Measure the newly tuned spectral emission

Figure 9 shows our original warm white LED emission on the left, an artist’s rendering of the color-tuned emission of the warm white LED light in the center, and the natural daylight emission. Please note that while the spectral array of the color-tuned bulb will more closely approximate the daylight emission, there will be some measure of lux loss in the process.

Figure 9: Warm white LED emission (left), artist’s rendering of pigment-tuned light (center), daylight emission (right)

Figure 9: Warm white LED emission (left), artist’s rendering of pigment-tuned light (center), daylight emission (right)

Step 8: Adjust pigment quantities and colors until desired spectral emission is approximated

If desired, further adjust the spectral vs. lux output by rebalancing the choice of pigment ratios, pigment density and placement in or on the bulb or lamp. This fine tuning would ideally be accomplished with the implementation of a computer program designed to read the initial emission pattern and produce the ‘solution’ array of pigments and pigment placement areas to match the desired emission spectrum. Each bulb produced by any given manufacturer could, in this way, provide a fuller spectrum of emitted light, either gradually or dramatically, via an inexpensive, permanent and ecologically benign process. Transparent color glazes can improve the aesthetic quality of the light without increasing heat (which happens when using multiple chips), with minimal expense and without deterioration from heat or humidity over time (which occurs when using single or multiple phosphors).

Summary of Benefits of Transparent Pigmented Glazes on LED Bulbs

The application of transparent pigmented glazes on interior and/or exterior surfaces of any LED lighting fixture provides both (1) an adjustment of light color as measured in Kelvin temperature and (2) the expansion of the range of light color emitted as measured in nanometers. The use of transparent pigmented glazes produce a “whiter” white light by providing more of the missing light waves while minimizing lux reduction in a cost-efficient process. An almost infinite range of color choices, color saturation vs. transparency points, and many pigment and binder vehicle choices are possible.

References:

[1] Demming, A., “First principles shine a light on LED design,” http://nanotechweb.org/cws/article/tech/56868

[2] Feltman, R., “Under LED lights your clothes can’t get whiter than white,” Quartz, http://qz.com/200743

[3] Herrman, J., “Ultimate Light Bulb Test: Incandescent vs. Compact Fluorescent vs. LED,” Popular Mechanics, April 2012 http://www.popularmechanics.com/technology/gadgets/tests/ incandescent-vs-compact-fluorescent-vs.-led-ultimate-light-bulb-test

[4] Hsu, M., “The best LED light bulbs for vivid, rich colors,” Wall Street Journal, http://online.wsj.com/news/articles/SB1000 1424052702303626804579505642901978848

[5] Jakab Z., Wenzel K, 2004, “Detecting tetrachromacy in human subjects,” Perception 33 ECVP Abstract Supplement

[6] Jordan, G., Deeb, S. S., Bosten, J. M., & Mollon, J. D. (2010). The dimensionality of color vision in carriers of anomalous trichromacy,” Journal of Vision, 10(8):12, 1–19, doi:10.1167/10.8.12.

[7] Kelly-Detwiler, P., “Cree about to brighten the commercial office environment with LED T-8 replacement,” Forbes, http://www.forbes.com/sites/peterdetwiler/2014/05/05/ cree-about-to-brighten-the-commercial-office-environment-with-led-t-8-replacement/

[8] Leung, V.Y.F, Lagendijk, A, Tukker, T.W., Mosk, A.P., IJzerman, W.L., and Vos, W.L., “Interplay between multiple scattering, emission, and absorption of light in the phosphor of a white light-emitting diode,” Optics Express, Vol. 22, Issue 7, pp. 8190-8204. http://dx.doi.org/10.1364/OE.22.008190

[9] Mizokami Y., Werner J.S., Crognale M.A., Webster M.A., “Nonlinearities in color coding: Compensating color appearance for the eye’s spectral sensitivity,” J Vis August 31, 2006 6(9): 12; doi:10.1167/6.9.12

[10] Spanard, J.M., “Permanent transparent color-warming glazes for dimmable and non-dimmable LED bulbs,” SPIE 9003, Light-Emitting Diodes: Materials, Devices and Applications for Solid State Lighting XVII, 900319 (27 February 2014), doi: 10.1117/12.2039636

[11] “Glazed Light Emitting Diode Bulbs and Methods of Manufacturing Same,” U.S. Patent Office Serial No. 61/793,161 (2013).

Note:

Augmentation of LED spectral emission via the selective application of transparent pigmented glazes is a patent protected process.