LED Lamps Recycling Technology for a Circular Economy

While having a long propagated lifetime, LED lighting products, especially lamps, have a foreseeable end of life. And since they contain many valuable elements they practically beg to be recycled. However, like other highly integrated electronics products recycling is not a simple task. Andrea Gassmann, Jörg Zimmermann, Roland Gauß, Rudolf Stauber and Oliver Gutfleisch from the Fraunhofer Project Group Materials Recycling and Resource Strategies IWKS and the Technische Universität Darmstadt Institute for Materials Science respectively, present and discuss a method that could open the way to successful recirculation of precious components and materials.

The victory of LED technology over conventional technologies seems to be confirmed for many applications. After having taken over the backlighting market for flat panel displays, LEDs also entered the general lighting market and penetrated all segments from private homes and industry facilities to streetlights. The growing number of LED lamps and especially their integrated design that often does not allow for an easy exchange of components, raises the question of how to recycle and recover the valuable materials that are included in these lighting products. Using current e-waste recycling techniques, LED-specific materials, i.e. semiconductors like gallium, rare earth metals like yttrium, lanthanum or europium and precious metals, would be dissipated irrecoverably.

This article reviews the current trends of the lighting market and the implications on future lamp recycling. It will be shown that the application of smart separation technologies is the key point for successful lamp recycling, paving the way for the development of suitable extraction procedures for the valuable materials within LEDs.

Introduction

In order to meet today´s climate targets, statutory requirements, and cost saving methods, the current lighting market is experiencing a technology revolution that affects all segments. With the key requirements of lighting equipment efficiency, long lifetime and ecological compatibility, LED technology proves to be the winner of this change. Conventional light bulbs, halogen lamps and energy saving lamps are being continuously phased out and replaced by LED-based products. In fact, this technology change is much more than a 1-to-1-replacement action. It opens up a multitude of new fields of application that could not be realized before with conventional lighting technologies. Today, the function of a state-of-the-art LED lamp is not limited to illumination only. Due to color change and dimming functionalities and the miniaturized design, LED lamps and luminaires are increasingly used as mood lighting (e.g. color change lamps, LED stripes) or decorative objects (e.g. filament LED-lamps). Meanwhile, the lighting market offers a variety of multi-functional lamps - being closer to consumer electronics than to lighting equipment - integrating speakers or WLAN repeaters. The possibility of being able to personalize light scenes and to connect to the lamp via a tablet or mobile phone using apps is in line with the current trends towards a connected and digital life style as promoted by the smart home or smart living concepts.

Despite this development, there is yet no time scale showing when the above mentioned trends will actually reach and dominate lighting market segments like private homes, public areas, industry or transportation and shipping. But the trend towards LED lighting products cannot be denied any more. The transformation of lighting segments to LED technology is expected to speed up in the near future, opening up the question of how these products will be dealt with at the end of their usage. In particular, the unanswered question of appropriate and economic recycling processes for LED lamps and luminaires arises.

Figure 1: The multitude of waste lamps going to lamp recyclers: gas discharge lamps, retrofit LED lamps, and halogen lamps

Figure 1: The multitude of waste lamps going to lamp recyclers: gas discharge lamps, retrofit LED lamps, and halogen lamps

Besides the main materials like glass, plastics, metals, ceramics, organic potting compounds or adhesives and electronic components, the core part of LED lamps, the LED itself, contains small amounts of critical elements including rare earth metals (e.g. lutetium (Lu), cerium (Ce) or europium (Eu)), technology metals (gallium (Ga) and indium (In)) and precious metals (gold (Au) and silver (Ag)). In spite of the still often used classical Edison-type lamp design, the inner lamp setup might exhibit many differences. To summarize: the variety of LED lamps on the market is manifold as is the number of lamps being taken to lamp recyclers (Figure 1).

Status Quo of the Lighting Market and Future Trends

The consequences of the European Commission Regulations Number 244/2009 und 245/2009 are the phase-out of inefficient lamps like the incandescent bulb but also a drastic general change of the lighting market in Europe as well as worldwide. Figure 2 shows the global lighting market technology shares three years after these regulations came into force. Half of the revenues were due to gas discharge lamps; incandescent lamps had a share of one third, while LED-products represented only 8%. The forecast for 2016 and 2020 predicted a strong increase in the revenues of LED lamps at the expense of those from thermal emitters and fluorescent lamps. This estimate of market penetration by LED lamps was commonly agreed on [5, 12].

Considering the current sales output in Germany, the forecasts are confirmed. According to a recent analysis by the German Energy Agency, dena, the sales output from LED-based lamps rose considerably within the last couple of years: While in 2009 only 1% of the sold lamps were based on LED technology, it was already 7% in April 2013 [3]. Nevertheless, it should not be forgotten that the general lighting market is still dominated by conventional, established technologies: This is, for example, the compact fluorescent lamp in private households or the mercury vapor lamp for street lighting [ii]. Interestingly, these facts are no longer displayed in the current product portfolio of manufacturers and distributers where the LED clearly dominates.

![Predicted revenue distribution of the global lighting market as a function of light source technology [i] (illustration of McKinsey data [8])](https://www.led-professional.com/media/resources-1_articles_led-lamps-recycling-technology-for-a-circular-economy_screen-shot-2016-08-11-at-16-19-37.png/@@images/image-1280-68516452d9b904d3e04c565ab09e17cd.png) Figure 2: Predicted revenue distribution of the global lighting market as a function of light source technology [i] (illustration of McKinsey data [8])

Figure 2: Predicted revenue distribution of the global lighting market as a function of light source technology [i] (illustration of McKinsey data [8])

The growing consumer acceptance for LED technology is triggered, amongst other things, by the declining prices, on one hand, and the remarkable technology evolution on the other. As compared to the days of their market introduction, especially the luminous efficacy and the LED light quality have been improved consider-ably. Additionally, LED lamps are free of toxic mercury and allow for a design freedom that cannot be realized by other established lighting technologies.

In order to get insights into the factors still limiting a substantial market penetration with solid state lighting products, the European Commission initiated a survey among stakeholders of the European lighting market in the year 2011 [4]. According to the results 14% of the informants responded that two aspects had not yet been considered properly.

Unconsidered aspects that might limit market penetration:

- Scarcity of the raw materials utilized in LEDs

- Recycling issues

Studies on behalf of the German Federal Environmental Agency [9, 10] come to the same conclusions. Despite the small amounts of critical materials used in LEDs it follows that proper collection strategies and appropriate methods to recover and recycle the valuable materials should be developed today.

Valuable Materials in LED Retrofit Lamps and Expected Future Needs

LED lamps for private households have been available on the market since about 2007. Today, a customer can choose between various products with a different shape or socket type. The market not only offers 1-to-1 replacement lamps, so-called retrofits, but also luminaires with fixed LED-modules that cannot be exchanged. Due to this product variety it is not easy to quantify typical amounts of materials used in LED lighting equipment. However, it can be stated that the design of compact LED-based lighting products like retrofits usually requires the use of a cooling body to sustain proper temperature management. It is commonly made of aluminum or a thermally conductive ceramic and amounts to the larger part of the total retrofit mass.

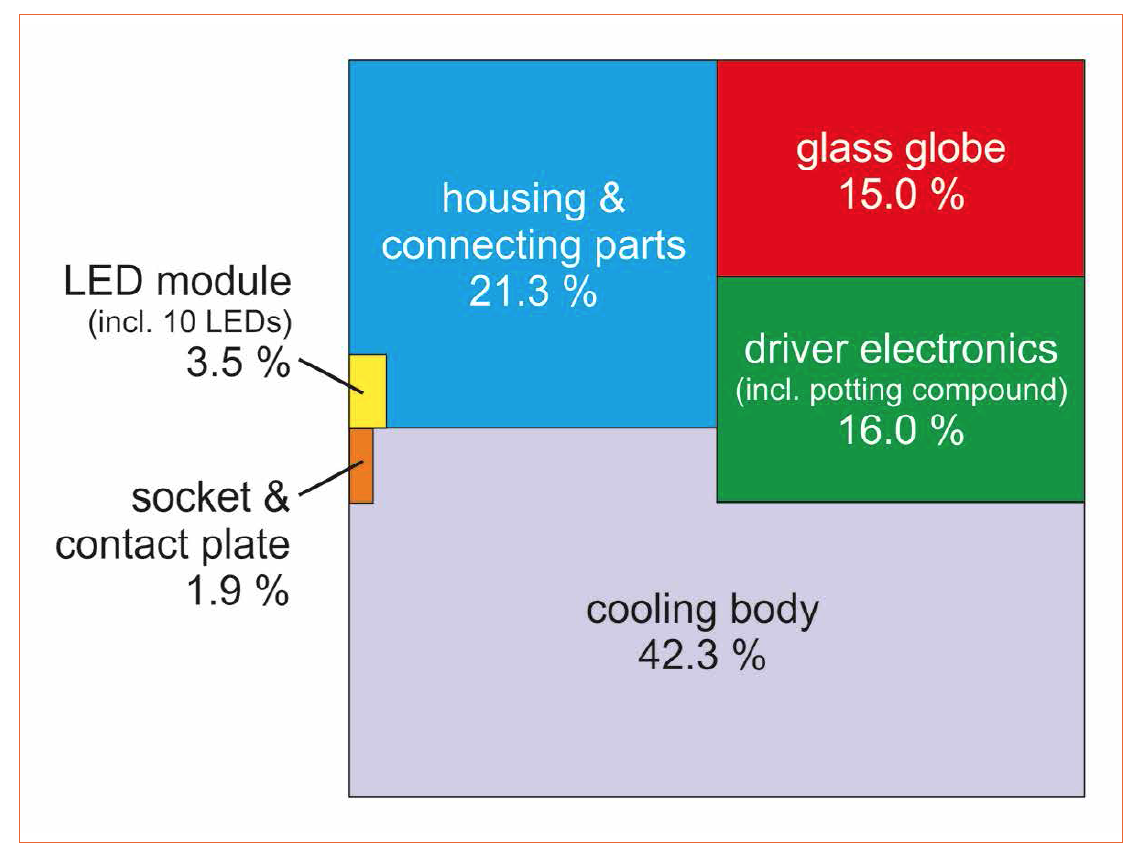

Figure 3 illustrates the mass fractions obtained from the lamp analysis of a state-of-the-art LED retrofit lamp: The cooling body corresponding to 42.3% of the lamp mass is made of aluminum. The body and connecting components are plastic and amount to 21.3%. The driving electronics (16.0%) and the glass globe (15.0%) share about equal mass amounts. In this example, the LED-module comprised 10 SMD-LEDs that were mounted on an aluminum-based panel. The mass of all LEDs is only 275 mg or 0.32% of the total mass of the retrofit lamp. Figure 3: Mass fractions of the components of a typical state-of-the-art LED retrofit lamp (E27, 806 lm, 9.5 W, 85.5 g) from the recent range of products

Figure 3: Mass fractions of the components of a typical state-of-the-art LED retrofit lamp (E27, 806 lm, 9.5 W, 85.5 g) from the recent range of products Figure 4: A typical white LED: Photograph (left) and overlay of the main elements mapped by micro x-ray fluorescence spectroscopy (right)

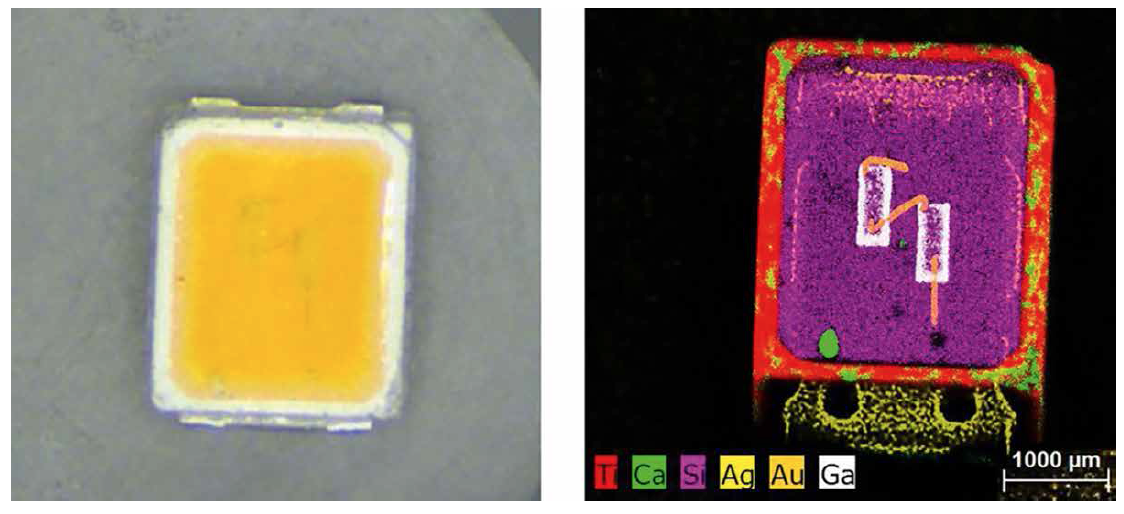

Figure 4: A typical white LED: Photograph (left) and overlay of the main elements mapped by micro x-ray fluorescence spectroscopy (right)

The materials used in the driver electronics do not differ greatly when compared to those contained in a typical ballast for compact fluorescent lamps. Despite that, the material diversity is bigger in retrofit lamps due to the LED devices themselves. In general, the functionality of white LEDs relies on the partial conversion of light from a blue-emitting diode by luminescent material, the so called phosphor [iii]. It consists of an inorganic matrix that is doped with small amounts of rare earth metals like Eu or Ce. A few μg are sufficient, e.g. 3 μg Ce or Eu per 1 mm2 LED chip [2], to enable the desired light conversion. Other rare earths metals might be core constituents of the inorganic matrix (ca. 90-200 μg per 1 mm. chip size [2]). Examples are aluminate garnets like YAG (yttrium aluminum garnet), LuAG (lutetium aluminum garnet) or GdAG (gadolinium aluminum garnet). The blue LED is based on GaN or InGaN and typically contains 17-25 μg of Ga and 28 ng of In [7]. The diode is often contacted via bond wires made of gold (Au), amounting to about 200 mg per diode [10]. Furthermore, the LED package also comprises silver (Ag), tin (Sn), nickel (Ni), titanium (Ti), silicon (Si) or germanium (Ge) to name a few. The complex set-up of a representative white LED is shown in figure 4 as a micrograph and an overlay picture of the main element distributions mapped by micro x-ray fluorescence spectroscopy.

Bearing the above mentioned trends of the lighting market and the typical constituents of an LED retrofit lamp in mind, what amount of waste lamps is to be expected in Germany or Europe? The number of LED lamps to substitute lamps with classical technologies in households was estimated according to the approach by Spengler et al. [10] and yielded 277 million LED lamps per year for Germany and 1729 million for Europe [iv]. Taking the current market share of 7% into account and assuming 10 LEDs per lamp, there is a need of 193.7 million LEDs for Germany and 1.2 billion for Europe solely for the replacement of conventional lamps in households. Extending these considerations to other lighting segments (streets, industry, offices, retail etc.) the number of replacement lamps amounted to 3.29 billion in the EU in 2010 [10], thus translating to 2.3 billion LEDs under the conditions mentioned above. A proceeding market penetration by LED-products and possible rebound effects trigger even higher LED amounts that will be needed. A factor of 10 or more seems therefore realistic for the future.

Due to technological progress the lifetime of LED lamps is increasing, thus lowering the demand for re-placement lamps per year. Nevertheless, it should be kept in mind that the real lifetime of LED lamps depends significantly on good product quality as well as on proper use by the customer. Due to considerable price erosion product quality might suffer occasionally in a highly fragmented market like the lighting industry with many competitors and small companies. This applies, for example, to a sophisticated lamp design to sustain good heat transfer, sufficient thermal contact of the LED module to the cooling body, and to the quality of the electrical components in the electronic driver.

Apart from their application in lamps, nowadays, LEDs dominate the display market. 60-80 million LEDs are used per year for display backlights [12]. Forecasts predict stagnation for this market segment until 2020, but anticipate a growth of the general lighting market leveling off at LED amounts of 130 billion per year [12].

Based on the discussed amounts of LEDs and their typical elemental compositions, the need for raw materials has been estimated for InGaN-based white diodes: 1 billion LEDs contain 17-25 kg of gallium and only 18 g of indium. Consequently, replacing 100% of all conventional household lamps in Germany (or in the EU) with LED lamps yields a raw material need [v] of 2.3-13.0 t (or 11.5-26.5 t) for gallium and 1.7-15.3 t (1.7-5.4 t) for indium [7, 10]. Comparing this demand with the annual global production of both metals in the year 2010 (106 t gallium und 574 t indium [10]) it becomes evident that 10% of the produced gallium is applied to LEDs. Growing markets, as they are predicted for general lighting, and an establishing LED technology in new products, will increase the demand as well as the consumption of raw materials. Geopolitical aspects might again play a role in the future: China is not only the biggest producer of various rare earth metals and rare earth metal compounds but supplies 70% of the global gallium production.

What Lamp Recycling Is and What It Might Be

Waste lamps are liable to the WEEE directive and are listed in Category 5: Due to the employed mercury gas discharge lamps are hazardous waste and have to be collected separately (collection group 4). LED retrofit lamps have been classified recently as Category 5b. As they do not contain toxic compounds the producers pay only about 10% of the waste disposal costs as compared to fees for mercury-containing gas discharge lamps. Nevertheless, LED retrofit lamps and fluorescent lamps are collected jointly, leaving the task of separation of both waste streams to the recycler. Other lighting equipment is collected with other small appliances in collection group 5. The joint collection of gas discharge and LED lamps is, on the one hand, useful. Due to the high similarity in appearance it might not be straightforward for the customer to decide prior to disposal, which technology is used in the respective lamp? This is particularly difficult for lamps with opaque glass or a plastic bulb. On the other hand, the joint collection bears the risk of cross contamination of all lamps with mercury if one or more gas discharge lamps break during the collection and/or transportation process. As a result, all lamps have to be treated as hazardous waste even though this is not necessary for LED products and disregarding the non-appropriate waste disposal costs. It follows that the separate collection of LED lamps should be aimed for.![The composition of gas discharge lamps is about 40-170 g total mass (illustration of Lightcycle data [6])](https://www.led-professional.com/media/resources-1_articles_led-lamps-recycling-technology-for-a-circular-economy_screen-shot-2016-08-11-at-16-20-10.png/@@images/image-1280-68516452d9b904d3e04c565ab09e17cd.png) Figure 5: The composition of gas discharge lamps is about 40-170 g total mass (illustration of Lightcycle data [6])

Figure 5: The composition of gas discharge lamps is about 40-170 g total mass (illustration of Lightcycle data [6])

Today, four established processes are used for lamp recycling to recover the major material fractions from the most common lamp types. As already stated, the lamp recycling business is focused on gas discharge lamps which are composed as illustrated in figure 5. The main material is glass whose recovery is actually the reason for the high recycling rate for lamps, exceeding 90% [6]. The recovery of metals and plastics also contributes to some extent. During the recycling processes the small material fractions containing critical (i.e. the phosphors containing rare earth metals) or toxic elements (mercury) are treated as impurities spoiling the main fractions. Consequently, measures are taken to clean the latter and to recover mercury. Even though a part of the waste phosphors is recycled using intricate wet-chemical methods, the majority is dumped in subsurface repositories.

The diversity of LED lamp designs is already high today but probably has not reached its climax yet due to the freedom of design offered by LED technology. In addition, the trend points to luminaires with integrated LED modules that cannot be exchanged by the customer any more. Referring to the rather high product lifetimes of several decades, this makes sense. However, it can be suspected that customers will increasingly get rid of still functional lamps or luminaires that are not longer in style, or to their liking, thus giving rise to new waste streams. This hypothesis is supported by our own investigations on waste retrofit LED lamps (provided by a lamp recycler) which revealed that many of them are, indeed, still functional.

Forward-looking recycling procedures for waste LED lamps should account for the variety of lamp geometries. This might be realized with sophisticated sorting facilities that can be integrated modularly into the process chain. In a future LED recycling system, the components containing critical elements (i.e. gallium, indium, rare earth metals like yttrium, lanthanum or europium and precious metals) - the LEDs themselves - can be regarded as impurities for the main material fractions. To keep the latter unsoiled the separation of the LED-packages from the rest should be aimed at in analogy to the separation of lamp phosphors from glass that is known from waste gas discharge lamp recycling. The positive side effect of this action is a concentration of the components containing LED-specific critical elements for future recycling solutions. In any case, the rate of component, material and substance reuse and recycling will not be compromised by this measure and will presumably still exceed 90% [vi].

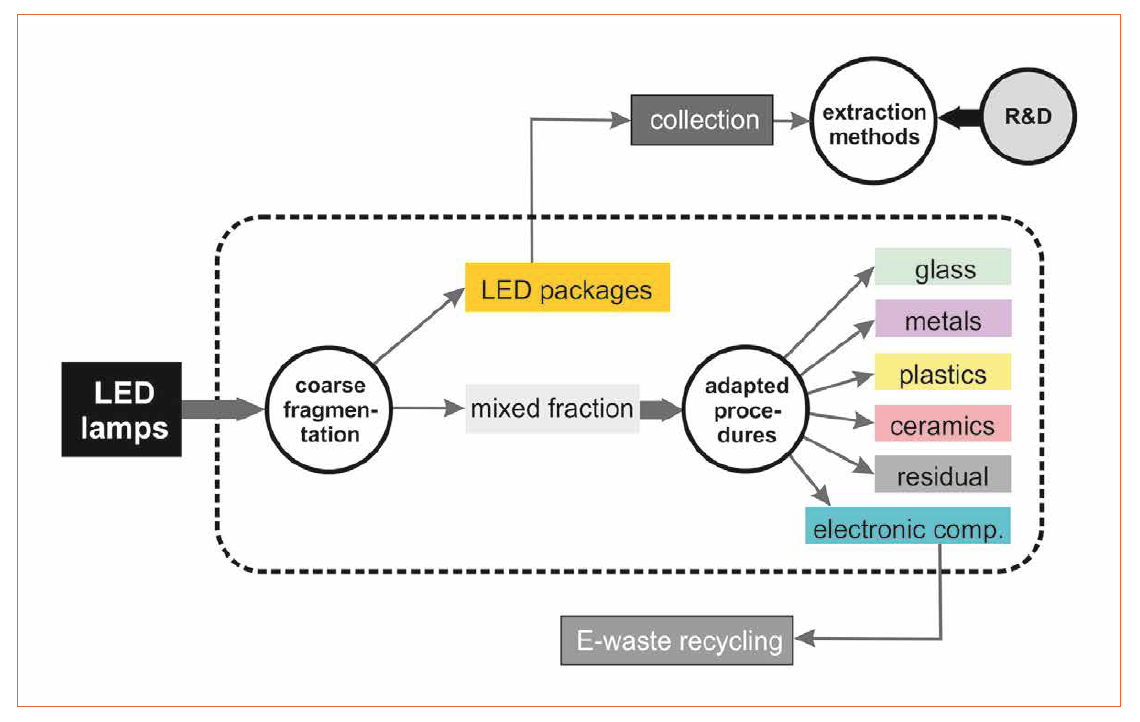

In general, the recycling rate depends on the available processes and their economic feasibility. The latter is also a question of geological and geopolitical availability of primary raw materials and current market prices. If reliable raw materials supply cannot be sustained any more, the link of recycling to market prices will be softened. The recovery of small material fraction will become a question of technological feasibility. Bearing these considerations in mind the concentration of critical materials in one single fraction and its storage are important steps in the development of recycling strategies for LEDs. Beyond doubt, the necessity for specific recycling procedures for LED lamps is currently not a pressing problem due to the long lamp lifetimes and the resulting low return rate of waste LED lamps (1% for Germany in 2016 [11]). However, the take-over and extension of the complete lighting market by LED technology clearly points to the perspective that the proper treatment of LED waste streams will become relevant soon. To develop appropriate recycling technologies for LED-based lighting equipment today and to do research on appropriate separation and extraction procedures for the LED-specific valuable elements allows to be proactive rather than reactive. Furthermore, with regard to the low waste disposal costs that are paid for LED lighting equipment establishing a separate collection and recycling system for LED lamps and gas discharge lamps is considered advisable. Figure 6: Schematic illustration of a recycling process for LED lamps

Figure 6: Schematic illustration of a recycling process for LED lamps

An Approach Towards Economic LED Recycling

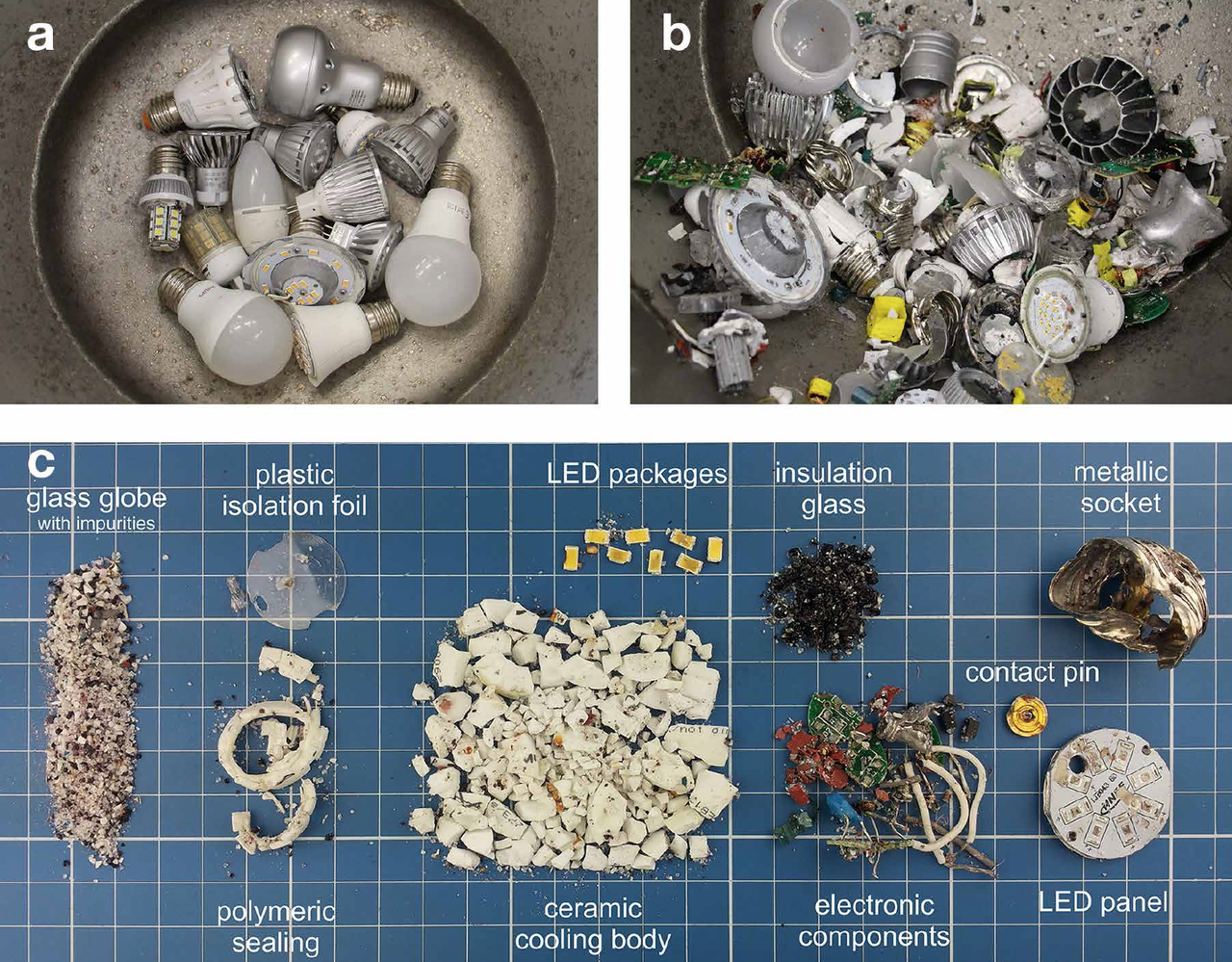

Figure 6 shows a schematic illustration of the process steps necessary to separate the material and component fractions found in typical retrofit LED lamps. The decisive step is a rather coarse fragmentation. Afterwards, the resulting material and component mix has to be sorted and classified using adapted procedures: Metal separators will be used, for example, to sort out metals that can be magnetized. Flotation methods are useful to segregate materials with strongly different density like plastics and ceramics. Sieving can be used to separate different grain sizes. The collected electronic components will be transferred to e-waste recyclers who will continue processing aiming at extracting copper from the electromagnetic coils. The LED packages are, in a first approach, treated as impurities for the main fractions (see above) and could be easily detected due to their intense fluorescence under UV-light irradiation. As long as there are no ready for use methods available to recover the critical elements from LEDs, they can be collected and stored using the common procedure for waste phosphors from fluorescent lamps. The required space to do so is very small thanks to the miniaturized device design. Figures 7a-c: (a) Mix of waste LED lamps prior to EHF. (b) Component and material mix obtained after EHF of the waste lamps shown in a. Here, a very coarse fragmentation was aimed at (c) Fractions obtained after EHF of one single retrofit lamp and subsequent manual sorting

Figures 7a-c: (a) Mix of waste LED lamps prior to EHF. (b) Component and material mix obtained after EHF of the waste lamps shown in a. Here, a very coarse fragmentation was aimed at (c) Fractions obtained after EHF of one single retrofit lamp and subsequent manual sorting

Specific recycling strategies seem to be the best solution, in particular, smart separation technologies to dis-integrate the LED lamps into the constituting materials or components yielding fairly separated fractions after classifying and sorting as will be shown in the following. Using conventional processes like crushing, cutting or shredding the comminution is defined by the lump size. However, an intense comminution producing many small pieces is not the best solution for the disintegration of composite materials or products consisting of a complex material mix like lamps. Instead, the electrohydraulic fragmentation (EHF) method is used to selectively separate the materials, making use of the weakening of interfaces by shock waves. It is a method that proved to be very effective for the fragmentation of electronic waste like hard disks or mobile phones, solar cells and also LED retrofit lamps. The shock waves are generated in a liquid medium (e.g. water) by pulsed high voltage (HV) discharges. They propagate through the medium until they hit the waste lamps placed inside the vessel (Figure 7 a). The short but intense mechanical impact preferably attacks weak spots like joints, defects and phase or grain boundaries. The fragmentation is thus initiated both on a macroscopic and microscopic level.

The electrohydraulic fragmentation might be conducted in several subsequent steps: Firstly, a release of single components can be achieved using only a few HV pulses. A presorting step can then separate the coarsely fragmented metal pieces, ceramic parts, circuit boards, LED modules or plastic parts that can be subsequently treated again with EHF to yield a finer fragmentation. One of the advantages of EHF is that the LED packages can be separated en bloc and basically undestroyed by an appropriate choice of process parameters. This is very helpful when it comes to sorting.

Figure 7 illustrates an exemplary mix of different LED retrofit lamps before (a) and after (b) EHF treatment. After decantation and sorting of the materials and components the evaluation of the received fractions yielded a loss of only 0.5%. Consequently, 99.5% of all input mass could be comminuted and recovered.

In figure 7 c the fractions are shown that were obtained after the electrohydraulic fragmentation of one single retrofit lamp. Depending on the process parameters and the material level in the vessel, rather coarse or finer fractions are obtained. These can be sorted with common sorting techniques like sieving, metal separation or flotation methods

As waste gas discharge and LED lamps are collected jointly the risk of lamp contamination with mercury cannot be excluded. For this reason, the process water has been analyzed after EHF with a mercury analyzer. No mercury contamination could be detected. Using inductively coupled plasma optical emission spec-troscopy (ICP-OES) the process water has been analyzed further to trace possible metallic contaminations due to the lamp fractions, in particular the electronic components or the LED packages. It has been found that the water contained only small amounts (<70 mg/l) of different metals, mainly alkaline, earth alkaline and transition metals. The concentrations were nearly identical to the ones found in the blank test (fresh water) thus excluding dissolution of additional elements from the lamps in the process water. The result was in addition independent on the degree of comminution, i.e. the number of HV pulses used for the experiments. The process water has thus not been contaminated by the electrohydraulic fragmentation of waste retrofit LED lamps. It can be either reused or disposed safely after the suspended substances have been removed by filtration.

In summary, electrohydraulic fragmentation is an efficient, uncritical and environmentally friendly method to comminute waste retrofit LED lamps. One of its advantages is that the LED packages can be detached easily and predominantly undestroyed from the LED panel (Figure 7c). With this measure an important step has been taken towards the development of a successful LED lamp recycling which also paves the way for the next step - the development of suitable extraction procedures for the valuable materials within the LEDs themselves - gallium, indium, gold and rare earths elements.

Before this issue can be tackled with regard to the rare earths used in LED phosphors, the latter have to be separated first from the binder material, usually a silicone resin. During the cycLED project [1] the so called CreaSolv® process was developed. Apart from the work on smart separation techniques for LED lamps the Project Group also does ongoing research on physical, chemical and biological methods to extract and recover rare earth metals, technology metals or precious metals from LEDs to solve this last relevant step.

Conclusion

It is largely agreed on today that the LED will be the light source of the future. Since the invention of blue LEDs in the early 1990’s and their use in phosphor-converted white LEDs, great progress has been made with respect to luminous efficacy and flux, color and color quality, lifetime and integration of features exceeding the illumination task. In spite of the very long lifetimes, considerably exceeding 10 years, all LED-based lighting equipment will sooner or later add to the electronic waste pile that is constantly growing in our society, especially as the amount of LED lighting products on the market is growing constantly.

The lamp recycling industry is currently geared to the treatment of gas discharge lamps focusing especially on the recovery of mass material fractions like glass, metals and plastics. The lamp phosphors containing rare earths are mainly landfilled belowground.

The development of adapted recycling technologies for LED lamps is, however, an important task to recover the main materials and to avoid the irrecoverable dissipation of the valuable elements within the LEDs (rare earths, semiconductors and precious metals). Ultimately, it might be an important step to secure Europe’s independence from foreign raw materials supply.

Using the method of electrohydraulic fragmentation, the crucial first steps were done, i.e. the comminution of waste retrofit lamps of different geometry in an efficient, rather selective and environmentally friendly manner. The degree of comminution can be regulated by the process parameters. Sorting the generated material mix can be realized using commonly known technologies like sieving, magnetic separation or flotation. The liberation of basically undestroyed LED packages from the LED panel during EHF of LED lamps is an additional benefit paving the way for a future recovery of the valuable materials of the LEDs themselves - gallium, indium, gold and rare earths elements.

To solve this second step, intense research on chemical and biological methods is performed.

Notes:

[i] LED light-emitting diode, CFL compact fluorescent lamp; LFL linear fluorescent lamp; HAL halogen lamp; HID high-intensity discharge lamps

[ii] 60 % of European street lights are mercury vapor lamps. Since April 2015 their placing on the market is forbidden requiring a replacement of the respective lamps (about 21 million in EU) on a mid and long term scale

[iii] For this reason white LEDs are often referred to as pc-LEDs or phosphor-converted LEDs.

[iv] The assumption was based on the number of households in 2014 in EU (EU28), the candidate coun-tries, and including Norway and Switzerland (250 million)

[v] Note: Independent on the elemental composition of the LED the real need of raw materials for the device production is a factor of about 10 to 20 higher for gallium and even 1000-3000 times higher for Indium

[vi] In accordance to European regulations the German Electrical and Electronic Equipment Act (“El-ektrogesetz” / ElektroG) prescribes a recycling rate for waste lamps of at least 80 per cent by weight

References:

[1] Details on the cycLED project are available online at http://www.cyc-led.eu

[2] O. Deubzer, R. Jordan, M. Marwede, P. Chancerel, Categorization of LED products, Project report from the cycLED project, May 2012

[3] Geman Energy Agency dena, Analyse der Energieeffizienz und Marktentwicklung von „Allgemeiner Beleuchtung“, December 2013

[4] GREEN PAPER Lighting the future: Accelerating the development of innovative lighting technology, COM(2011) 889, 15.12.2011 & Results of the public consultation, 06.06.2012

[5] Frost & Sullivan, World LED Lighting Markets, September 2012

[6] http://www.lightcycle.de/dossier-rueckholung-recycling-und-ressourcenschonung/led-und-energiesparlampen-reduzieren-den-muellberg. html (last access 17.05.2016)

[7] J. Thema, W. Irrek, Umwelt- und Ressourcenaspekte einer verstärkten Nutzung von Leuchtdioden, Report to work package 14.4 of the MaRess-Project, December 2010

[8] McKinsey & Company Inc., Lighting the way: Perspectives on the global lighting market, Second edition, August 2012

[9] K. Sander, S. Schilling, J. Wagner, M. Günther, Maßnahmen zur Optimierung der Entsorgung von quecksilberhaltigen Gasentladungslampen und anderen Lampenarten, Study on behalf of the German Federal Environmental Agency, September 2015

[10] L. Spengler, A. Reihlen, K. Sander, D. Jepsen, N.; Reintjes, Expertise Leuchtdioden: Umwelt-, ge-sundheits- und verbraucherrelevante Aspekte von Leuchtmitteln auf Basis von LED, Study by the Ökopol Institute, 2013

[11] Recent data from the German National Register for Waste Electric Equipment (“Stiftung Elektro-Altgeräte Register ear”), Feb. 2016

[12] Yolé Développement, Status of the LED industry, Market analysis, 2013