Labeling and Certification Testing Issues by UL

Arno Grabher-Meyer from LED professional summarizes several issues regarding certification and certification processes which were discussed with David Edwards, an expert in testing and compliance engineering for consumer products at UL.

Certification and product labeling is one of the most complex topics that engineers face today. First of all, if we look at it from a manufacturer’s point of view, it is costly. Secondly, it is time consuming and thirdly, it hinders quick market entry.

In this case, the question of why manufacturers should try to acquire certifications and labels that are not mandatory on top of all the required ones arises. The simple answer is that labels are necessary for providing a consistent and common language and information for manufacturers and consumers. In the end, they may even increase sales.

While safety certificates are mandatory and therefore not really noticed by the consumers, not every quality or efficiency related certification is mandatory. In some parts of the world quality and efficiency certification is not even required. However, during the past few years there has been a big increase in the number of consumers that are taking note of these labels. Energy usage is a main issue and especially in lighting, people are much more aware of efficiency and light quality.

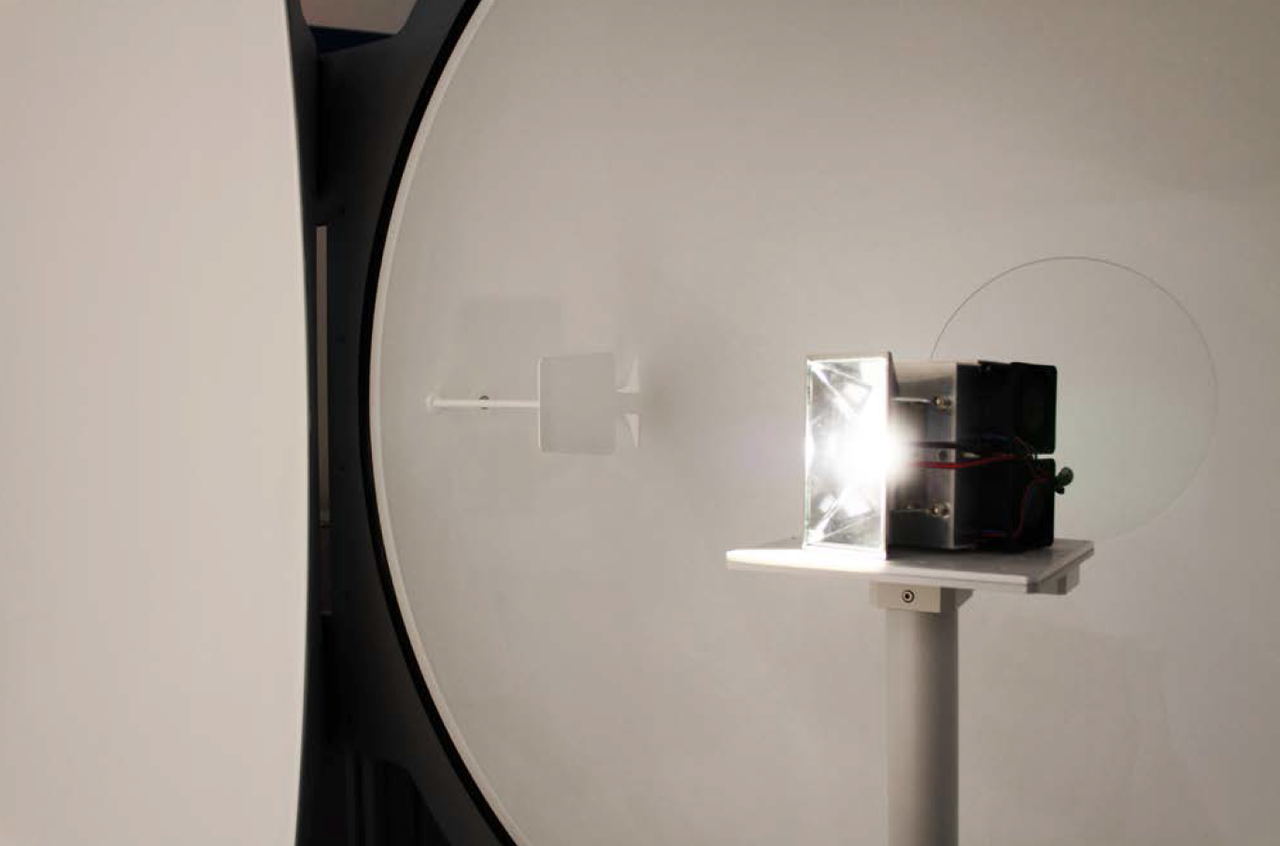

In some cases, provided the required documents and proof is available, self-certification is possible. In other cases testing in a certification lab is compulsory. We will be discussing the compulsory lab testing certification. Figure 1: For LM-79 tests, total luminous flux of luminaires is measured with integrating spheres

Figure 1: For LM-79 tests, total luminous flux of luminaires is measured with integrating spheres

The Engineering Challenge

Although there have been attempts to harmonize the regulations, the necessity of certifying products, especially those that are sold internationally, is a challenge. The reason for this is the regionally specific technical issues that make different tests and requirements necessary. In many cases, a product must undergo 5, 10 or even more certification systems and labeling processes.

The pressure put on manufacturers for their products to have many different labels carries over to the engineer who has to design a product that can pass a number of different certification tests with good results. This isn’t always easy and sometimes results in trade-offs. There is often no simple way to design a product for the stringent demands made on it because the compulsory test procedures are much too different. An example of this may be a system that needs to resist pre-defined stress for a certain amount of time. The problems start when there is a significant difference in the amounts of time and stress required for the different certificates. For instance, one certificate may demand high stress to be applied to the system for a relatively short amount of time and another certificate demands a lower amount of stress to be applied for a significantly longer period of time. These are two completely different endeavors. Unfortunately, the results cannot be exchanged or accepted in a vice versa constellation. This is the case, not only for safety certificates but also for quality related certificates.

Figure 2: For LM-79 tests, luminous intensity distribution of luminaires is determined with goniophotometers

Figure 2: For LM-79 tests, luminous intensity distribution of luminaires is determined with goniophotometers

Demands on Testing Labs

During the last few months, several testing organizations were criticized for being too costly or causing delays of product roll-outs because of limited testing capacities. The dissatisfaction is understandable, but we have to remember that testing equipment as well as qualified personnel is very expensive. In addition to that, SSL is at a stage where there are a high number of new product developments. Nobody knows how long this is going to last before product developments decrease again to a level for which the existing capacities are ample. This issue can be discussed interminably without coming to a satisfactory conclusion which is why we are only touching on it here and not going into detail.

Applying for Energy Star

Besides efficiency labels like the Energyguide in the US and the European Union Energy Label, there are other labels that reach far beyond these requirements. The most important and at the same time, most demanding label, right now, is the Energy Star.

To help us understand what is really going on and what is relevant regarding labeling and the related certification processes, David Edwards provided LED professional with a clear guideline that demonstrates what is necessary and what affects the workflow of the certification process. His main aim is to clarify the time it takes to test LED lighting products for the applicable industry performance standards and to qualify products for the EPA Energy Star program.

There are two approved methods for LED light sources that result in replicable test measurements and a reliable comparison of test data that is generated by different laboratories.

IES LM-80-08 “Measuring Lumen Maintenance of LED Light Sources” contains a process whereby changes in light output are measured under controlled conditions. This testing is typically conducted by the manufacturer of the individual LED light source. That data is then supplied to an end-user so that it may be utilized in future qualification testing.

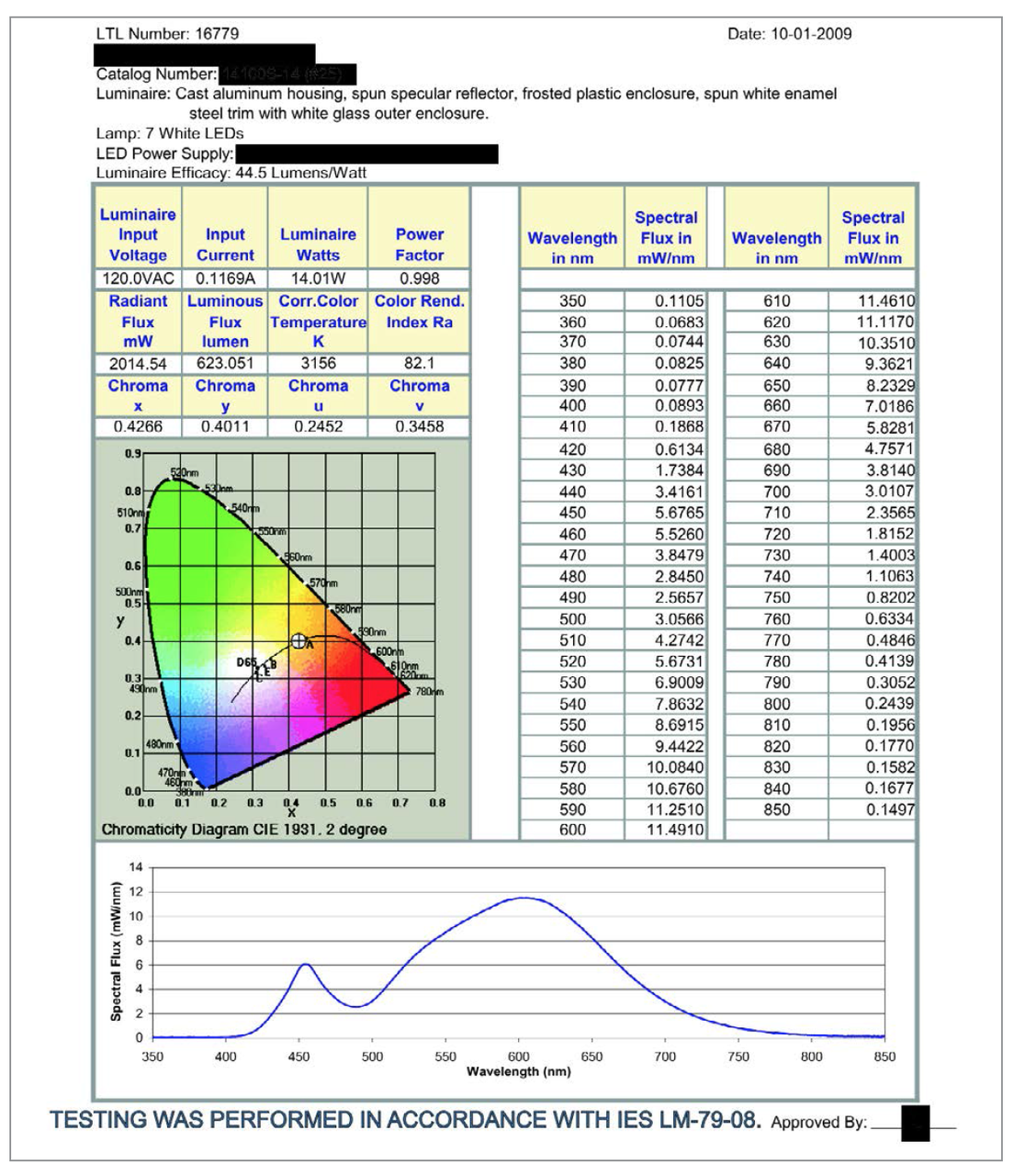

IES LM-79-08 “Electrical and Photometric Measurements of Solid-State Lighting Products” describes the test methods for measuring Solid-State lighting luminaires or lamps. These test methods incorporate the use of absolute photometry for testing these products rather than relative photometry which had been the industry standard.

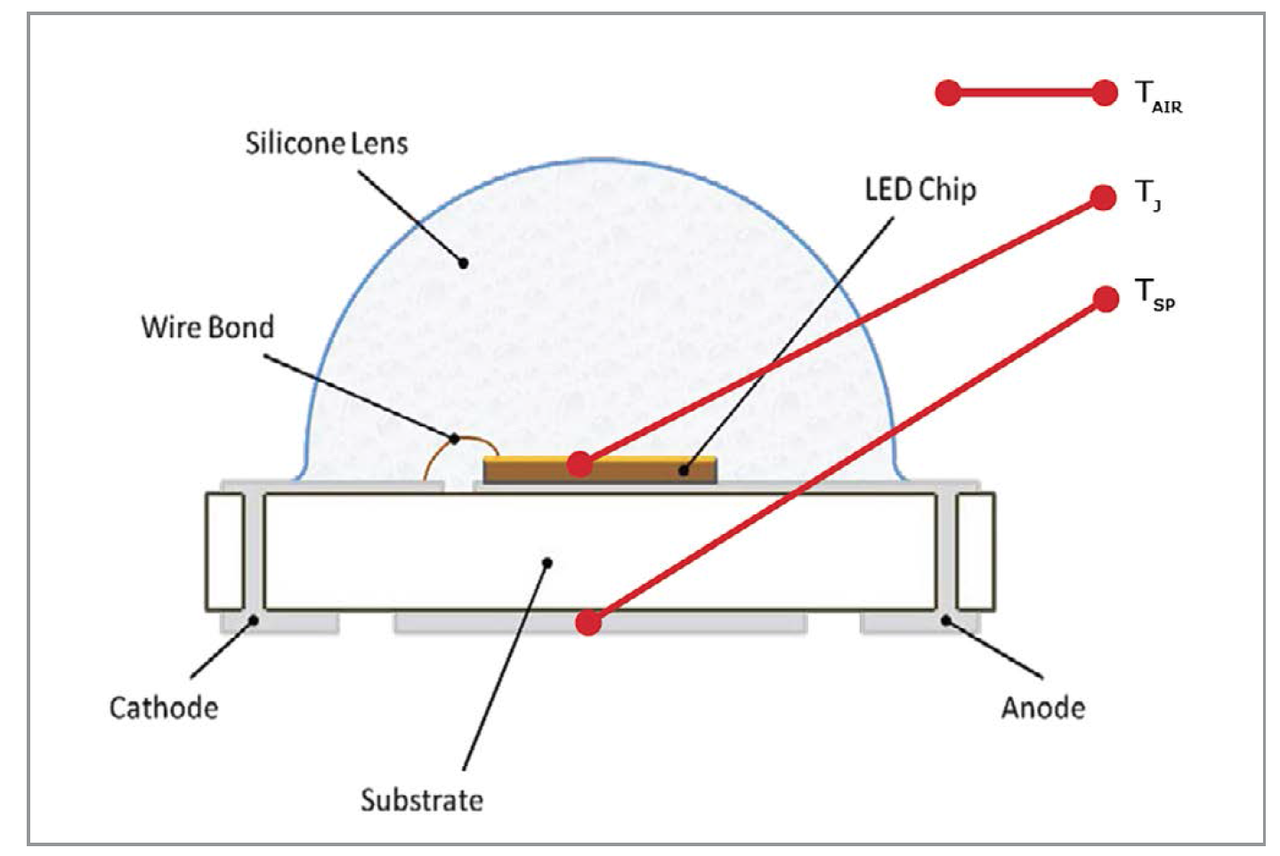

Figure 3: Typical lumen maintenance temperature parameter measuring points for LM-80 test

Figure 3: Typical lumen maintenance temperature parameter measuring points for LM-80 test

Test durations for each of these standards vary and can be summarized as the following:

• For LM-80 testing, the units under test (UUT) will be driven for a period of at least 6,000 hours (250 days) under specified ambient conditions. Photometric and Chromaticity data is collected initially and at each 1000 hour interval. A test duration of 10,000 hours is suggested for better predictive modeling.

• For LM-79 testing of lamps and/or luminaires, the actual test time is typically 1-2 hours. Turn-Around- Times (TAT) can vary according to the testing lab, but are usually around 2-5 weeks.

• The Energy Star Integral LED Lamps standard calls for LM-79 testing along with the long-term test duration of 6,000 hours for determining lumen maintenance of the lamp. Energy Star does allow for early qualification at 3,000 hours, but LM-80 data for the individual LED is required to be eligible. If a manufacturer decides not to seek early qualification, then LM-80 data is not required.

• Energy Star for LED Luminaires. There are two options for determining lumen maintenance:

- Option 1: This option requires In-Situ testing along with the LM-80 data supplied from the individual LED provider. In-Situ testing takes approximately 1 day to complete.

- Option 2: For luminaire manufacturers who do not have LM-80 data, the fixture would be tested for 6,000 hours. This option is rarely utilized as most individual LED manufacturers supply the LM-80 data.

- For additional information on Options 1 or 2, please refer to Energy Star® Program Requirements, Product Specification for Luminaires (Light Fixtures), V1.2.

LM-80 Test

The LM-80 test report is essential to obtain the Energy Star label. The LM-80 test reports must illustrate that subcomponent lumen maintenance testing was conducted in accordance with the testing method outlined in IES LM-80-08, except as otherwise detailed in this document or in Energy Star specifications.

An LED Luminaire PASSES the Lumen Depreciation requirements if:

• The LM-80 test report for the package, array or module demonstrates lumen maintenance of:

- ≥91.8% (indoor residential)

- ≥94.1% (outdoor residential and all commercial)

• Measured during the in-situ temperature measurement test (UL1598/153), at the hottest TMP evaluated at ≥6,000 hours

• The drive current measured in the fixture is less than or equal to the drive current specified in the LM-80 test report

LM-79 Test

LM-79 testing applies to LED products that incorporate control electronics and heat sinks. This covers complete LED luminaires and integrated LED sources. It does not include bare LED chips or LED products without the light source.

Integrating spheres in combination with a photometer, but preferably a spectro-radiometer that derives total luminous flux and color qualities form spectral radiant flux measurements, are used to measure the total luminous flux. A gonio-photometer is the appropriate tool to measure luminous intensity distribution. The gonio-photometer system tests may also derive total luminous flux and provide color characteristics including CCT and CRI.

LM-79 testing gives information on key parameters for lighting planners:

• Total Luminous Flux

• Luminous Intensity Distribution

• Electrical Power

• Luminous Efficacy

• Chromaticity

• CCT

• CRI

Figure 4: Excerpt of a typical LM-79 test report

Figure 4: Excerpt of a typical LM-79 test report

Latest Updates to Energy Star Requirements

The U.S. Environmental Protection Agency (EPA) recently released the updated Energy Star® Luminaires Specification from Energy Star V1.1. to V1.2. This update incorporates many new details and topics. Because these changes not only refer to solid state lighting, the short overview summarizes all major changes and key-points:

• Removed all FCC requirements and references for EMI/RFI.

• Eliminated “Run-up time” criteria for Solid State Lighting products.

• “Noise” testing to be verified and documented by the manufacturer only.

• Postponed an anticipated increase in efficacy for non-directional luminaires, current minimum requirement of 65 lumens per watt remains in place.

• Reduced decorative light fixtures minimum output requirements:

- Ceiling fan light kits with 3 or more heads and outdoor porch lights = 450 lumens per head.

- Chandeliers, decorative pendants, and wall sconces = 250 lumens per head.

• Downlight color angular uniformity testing can now be done without the trim in place.

• Linear fluorescent fixtures are not required to ship with lamps:

- Fixtures that ship with lamps must meet Luminaire Version 1.2 requirements.

- Fixtures that ship without lamps are tested with lamp model indicated on packaging.

• Downlight retrofits with ANSI standard bases can be either integral or connected by wire leads.

• Cold cathode CFL’s are classified the same as “hot” in that IES LM-9, LM-65 and LM-66 are applicable for both hot and cold cathode sources.

• Inseparable SSL luminaires may be “directional” and are exempt from driver replaceability requirements.

• Directional residential outdoor-wall mount, porch, and pendant luminaires are added to the post-mount luminaire section for directional luminaires. This means that LM-82 for non-directional is not required for these product types.

• With the publication of IES LM-82- 12, references to Solid State Luminaires V1.3 are removed.

Conclusions

Certification for standards is an absolutely necessary process, whether it is for safety issues or for quality criteria. Customer sensitivity for quality criteria has improved significantly within the last few years. The internet and media have made the market more transparent. Users’ demand to be able to evaluate product quality and labels simply from independent organizations or government agencies are welcome tools. This requires products to be certified and manufacturers to understand the workflow of the certification process. The introduction of LEDs and the claims for extreme longevity mean that some tests will require longer amounts of time. Unfortunately, the aging process cannot be sped up by simulation. Therefore the best option for a luminaire manufacturer is a reliable LED manufacturer that provides the time-critical LM-80 data. This can clearly speed up the Energy Star® Luminaires certification process.