Interior Automotive Lighting Control Redefined

In modern car’s interior lighting, tough requirements and rising complexity are a huge challenge. A new industry consortium was formed to meet this technological challenge and to provide a comprehensive ecosystem for the new digital LED lighting paradigm. The founding members of the Open ISELED Alliance are Inova Semiconductors (ISELED "Digital LED" concept and LED controller), Dominant Opto Technologies (LED manufacturing and packaging), NXP (system microcontroller), TE Connectivity (system integration and connection technology) and Pforzheim University (theoretical framework). The alliance recently added LucieLabs (software, firmware), a French IoT Software startup to its line-up. The goal of all these organizations is to work in close cooperation to present a complete system solution - a true ecosystem. Roland Neumann, CTO of Inova Semiconductors introduces the challenges and the worked out innovative solution that uses a single system controller to individually address up to 4,096 LEDs.

Were an engineer from a century ago to examine today's motor vehicle, its basic aspects would certainly be quite recognizable. It is a fact that the car concept has remained essentially unchanged since the early days of the automotive industry - a chassis, four wheels, doors, windows, engine and steering wheel.

Beyond these basic characteristics, however, cars have incrementally been subject to a fundamental transformation. Today's level of comfort and safety is in a completely different universe when compared to vehicles from just a few decades ago, even in the lower-price market segments.

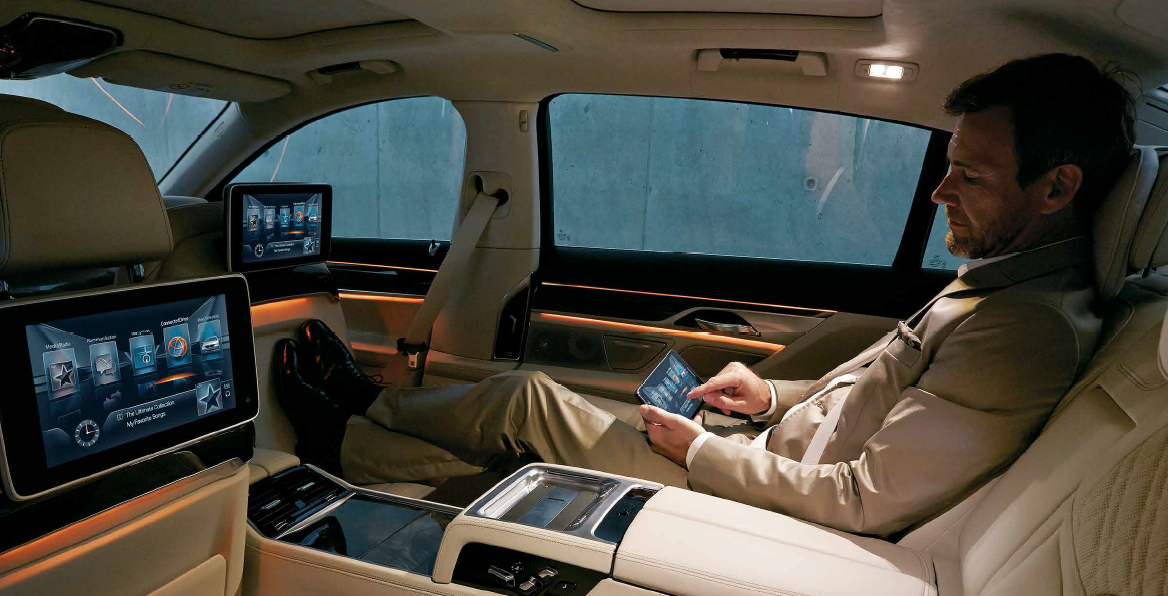

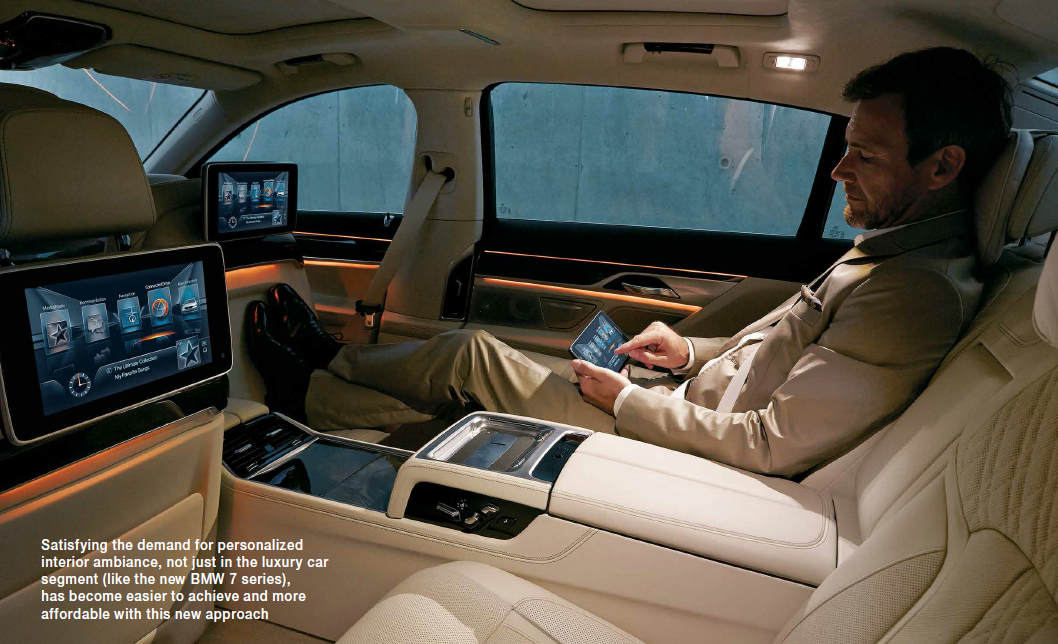

With strict industry-wide norms applying practically across the entire automotive sector, differentiation is becoming increasingly challenging for the car manufacturer, though not for lack of trying. One area where carmakers are recognizing fresh opportunities to stand out from their competitors is 'LED interior lighting' - an increasingly important selling point. Design engineers are seeking to create a unique in-car lighting experience that will make their brand and corporate marketing overshadow their competition. A new vehicle outfitted with advanced lighting technology irresistibly draws the driver in and emotionally connects with a new world of luxury and exhilaration.

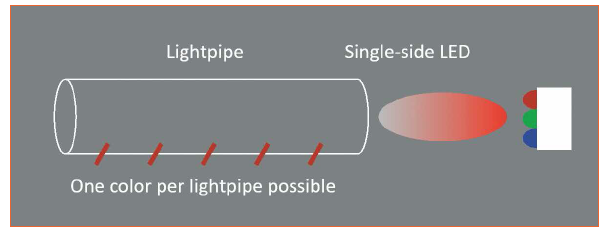

In recent years, LED-based technologies have become an accepted, and increasingly, an expected standard for high-end premium in-car lighting. Nevertheless, there exist significant limitations to the way LEDs are controlled, which has thus far hindered their extensive implementation throughout the car interior. As it stands, current state-of-the-art 'ambient light' technology typically consists of a multicolor LED feeding into an optical fiber (Figure 1).

Figure 1: Today's automotive interior fiber optic color lighting technology

Figure 1: Today's automotive interior fiber optic color lighting technology

Today's Challenge - Rising Complexity

The flexibility and visual impact of this existing technology is severely hampered by the fact that the brightness and color outputs of these LEDs can, as a rule, only be configured "in bulk" or in relatively large groups, thus resulting in an often lackluster experience. The standard solution utilizes a central controller to manage the LEDs via a Local Interconnect Network (LIN), a serial network protocol popular in many automotive applications for its lower-cost compared to a Controller Area Network (CAN) bus system.

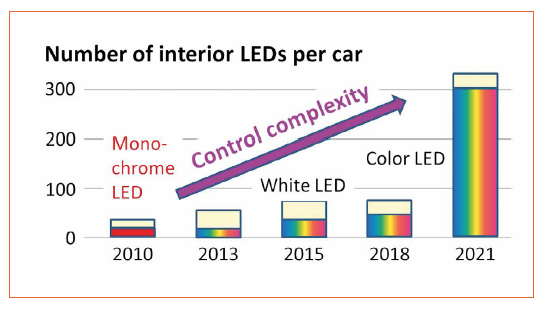

It is then only logical to mount 10 to 30 RGB LEDs on a flexible light strip that then light up the strip with individual color and brightness (Figure 2). Unfortunately, the carmaker is then faced with some major issues since wavelength and brightness are subject to manufacturing tolerances, temperature degradation and aging, thus the individual LEDs do not consistently emit the same light and color over the vehicle's relatively long expected lifetime, even with identical PWM-signal controls.

Figure 2: Color LED strip with individual color control

Figure 2: Color LED strip with individual color control

This "ageing effect" manifests itself in falling brightness levels due to falling efficiency, which is strongly influenced by the temperature of the LEDs, specifically high temperatures and duration of exposure to them. Another important factor is that temperatures vary significantly throughout the car's interior with temperatures exhibiting noticeable divergence even along a single LED strip in certain cases. A further challenge faced by the engineer is the significant divergence of temperature behavior characteristics of green and blue LEDs relative to that of red LEDs.

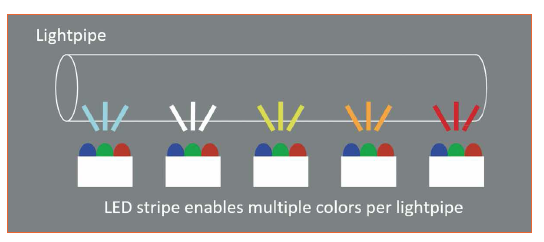

Taking these factors into account, car manufacturers continue to demand additional LED functionality for further innovative features and improved daytime LED visibility. In 2010, a typical high-end vehicle might have typically been fitted with fewer than 50 LEDs, however, by 2021 this number is projected to exceed 300 (Figure 3).

Figure 3: LED counts in car interior lighting are rising steeply (Source: BMW)

Figure 3: LED counts in car interior lighting are rising steeply (Source: BMW)

This increase is most predominant in RGB type LEDs, where the three LEDs - red, green and blue - are encapsulated in a single package. This subsequently necessitates a controller to define individual colors, which adds an additional troublesome layer of complexity, thus morphing into a significantly more complex system than was the case with the white and monochrome LED solutions that were so ubiquitous in the market only a few years ago.

Requirements for In-Car LED Control and Problem Definition

Considering the long list of challenges faced by these present-day solutions and their workarounds, carmakers are in need of a sophisticated yet simple LED control platform that is financially viable, highly controllable and inherently reliable. To achieve these aims, each RGB LED on the color strip must be individually controllable in terms of brightness and color, and, importantly, it must enable calibration. A typical case would be cross-fading of adjacent LEDs from one color into another with no noticeable brightness and color differences. The ability to compensate for the effects of temperature and the non-uniform ageing of the LEDs is another crucial element. The system should provide for straightforward cross-architectural control of the entire system.

It is understood that any such solution should meet and, if possible, exceed all the rigorous automotive quality standards for technology, production and testing, while providing advanced diagnostic capabilities. The solution must also meet the Automotive Safety Integrity Level (ASIL) standard so that it is useable not only for interior but also for functional lighting applications. Apart from displays, LEDs will also play a key function in future autonomously driven cars by informing both the driver seated inside the car and the pedestrians outside about the current state of the autonomously driven vehicle. Thus, every LED must precisely convert all electrical control signals into the target color and brightness, whilst enabling the verification of such emitted light to ensure that it exactly matches the specifications set by the control signals.

To achieve a high-quality and safe daytime visibility experience, the manufacturer must meet these stringent requirements, whilst providing fine control over brightness and color to guarantee consistent homogenous lighting outputs over the long term. Today's state-of-the-art in-car LED control technology simply falls short, the demands are too great - a new solution must be found.

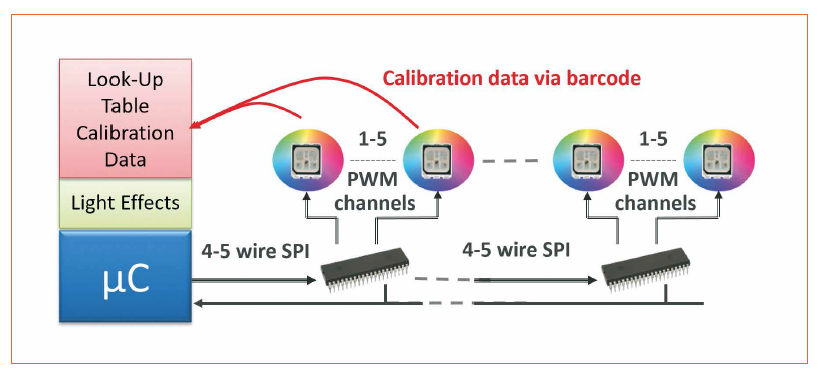

Presently, every single RGB LED requires individual control via a microcontroller managing LED-specific data gathered for every single LED at production, typically by binning and bar-coding of each LED. The complexity and expense of this approach makes little sense both in terms of the high number of integrated circuits and the extensive wiring - it becomes practically unviable. For this system design (Figure 4) to function, high-speed one-way communication to the LEDs and sub-controllers is required, which logically leads to latency issues, reduces EMI robustness and makes diagnostics difficult. Furthermore, this cumbersome solution makes the capture of individual LED parameters, such as functionality and temperature degradation exceedingly difficult. The approaches used for LED video walls are inappropriate for meeting the demands of modern high quality in-car lighting.

Figure 4: Present state-of-the-art RGB LED lighting concept

Figure 4: Present state-of-the-art RGB LED lighting concept

The Answer to the LED Complexity Dilemma

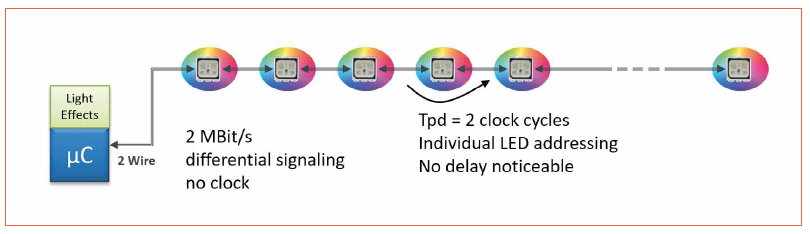

The entirely new "Digital LED" concept for automotive applications (Figure 5) is based on an embedded smart LED controller housed in a compact 3x4 mm package together with a red, green and blue LED. The scalability of the solution is set to drive down costs and open up new market opportunities. For in-car applications, it will typically consist of 10-30 LEDs mounted on a flexible light strip. Each of these “Digital LEDs” can be considered as a pixel with 24-bit color resolution (3x8-bit) with capability to render up to 16 million colors, all in true video speed.

Figure 5: The new “Digital LED” controller concept

Figure 5: The new “Digital LED” controller concept

The sophisticated calibration features of this "Digital RGB LED" with embedded controller will eliminate the need for binning classes or bar coding. Every LED now renders the same color and brightness over the full temperature range to deliver highly consistent illumination even at currently unattainable LED manufacturing tolerances. Look-up tables and calibration are also eliminated since LED calibration data is already stored inside the embedded controller.

A newly developed proprietary high-speed communications protocol allows every LED to be individually addressed, and with data rates of up to 2 Mbit/s, promises fast, dynamic in-car lighting effects.

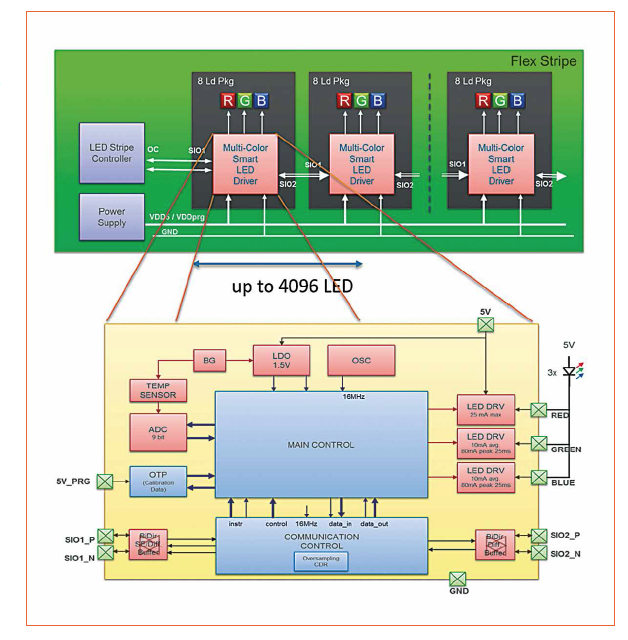

Now, a single microcontroller (Figure 5) can easily manage an LED strip containing up to 4,096 LEDs with each "Digital" RGB LED now having its own embedded controller (Figure 6). Very low latency, two-way communication between the system microcontroller and each individual “Digital LED” at a speed of 2Mbit/s, without a dedicated clock and differentially transmitted, by default delivers high EMI robustness. All LEDs can be addressed both individually and in groups, as required.

The temperature, status and functionality of each LED are monitored individually, thus bringing a new level of diagnostic capability. Full retrospective retraceablity of function and power consumption for each LED is a key feature for automotive ASIL-compliant lighting.

Figure 6: Digital RGB LED with embedded driver and connectivity system concept for up to 4,096 LEDs

Figure 6: Digital RGB LED with embedded driver and connectivity system concept for up to 4,096 LEDs

First Smart LED Products See the Light of Day

This new “Digital LED” is successfully built and samples have been available for some time. Since all the LEDs are factory-calibrated to the required white point, they can be installed without any further calibration or measurements.

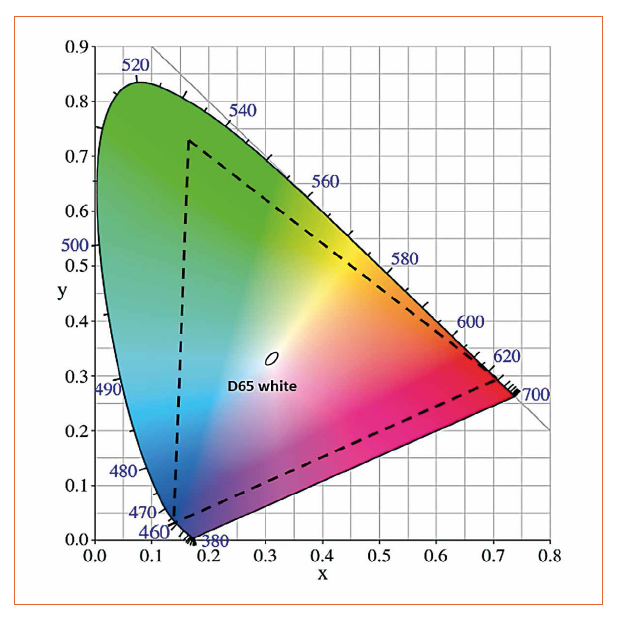

To control the red, green and blue LEDs, the driver intelligently utilizes three constant current mode (CCM) drivers and each RGB LED 'trio' can be set with 24-bit resolution (3 x 8 bit). For binning, i.e. temperature and manufacturing tolerance compensation, the brightness of each LED is controlled with 12-bit resolution. The LEDs have precise RGB calibration up to 1-step MacAdams Ellipse, coupled with high-temperature auto-compensation and dominant wavelength calibration (Figure 7). To meet automotive-level safety specifications, the calibration values of the CCM LED drivers and temperature compensation parameters are securely stored in the non-volatile memory of the embedded controller.

Figure 7: Calibrated LED color space

Figure 7: Calibrated LED color space

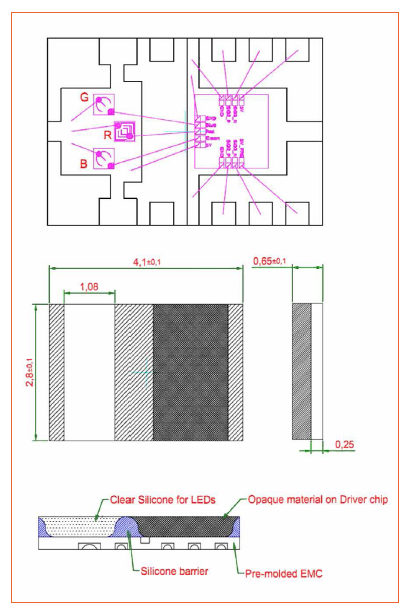

Compact Packaging and Powerful Software

The compact package provides exceptional corrosion resistance and ESD protection exceeding 2 kV. The LED housing has a low thermal resistance - 30% below comparable products, which, thanks to the improved light efficiency of cooler LEDs, further lowers power consumption (Figure 8).

A microcontroller forms the system interface acting as the lighting controller (Figure 5). Mastering system-level challenges, the recently announced S32K microcontroller product line neatly aligns with the new concept, delivering performance of up to 112 MHz, a FlexIO configurable serial communication interface, 8K to 2M Flash and an ARM Cortex M core. This new platform is a complete solution that includes hardware, software and ecosystem development.

For communicating with the LEDs' integrated drivers, a stable, well-defined Application Programming Interface (API) with ready-to-use subroutines significantly simplifies the programming of advanced lighting effects.

A software platform provides firmware, a software development kit (for iOS and Android) and a cloud environment. Inside the vehicle, the firmware takes the function of a control center, linking control elements (smartphone, console unit, ADAS) with the ISELED LED system. The platform incorporates instructions for triggering the lighting effects predefined by the car manufacturer for a specific event and LED locations.

The software development kit enables car manufacturers to develop their own unique personalized applications, where an end-user can adjust LED characteristics using their smartphone for a specific area inside their vehicle. Third party applications, such as Waze, can also be utilized.

Engineers and designers can use the cloud to store a library of lighting effects, which can later be triggered by a specific event and can apply to any LED location in the car.

Figure 8: Compact packaging

A Bright Future Ahead

Automotive interiors are the initial target market for the new ISELED concept. However, the inherent flexibility of this new concept enabled by its control over individual LEDs makes it a prime candidate for a host of varied applications, such as car exterior signaling, passenger trains, aircraft, cruise ships and many more.

This new LED control platform is sure to open up many avenues for making products more attractive, intuitive and sellable.

(c) Luger Research e.U. - 2017