High Color-Rendering, Full-Visible-Spectrum LEDs by Soraa

The first wave of conventional white LEDs primarily focused on lumens per Watt. These LEDs were based on phosphor down-conversion using primary blue “pump” emission. Currently LEDs are catching up in regards to light quality using different approaches. Aurelien David, Senior Principal Scientist and Mike Krames, Chief Technology Officer at Soraa explain their technology approach of violet-pumped, full-visible-spectrum LEDs, and the interrelated challenges and advantages.

The original promise of solid-state lighting is a positive return on investment of higher prices for lighting products in exchange for even greater savings from reduced energy consumption. Indeed, assuming 80% energy savings (achieved today vs. incandescent or halogen by many LED retrofit lamps), a 50 Watt equivalent solution for a 12-hour-per-day application can command a $25 price and still pay back in about one year. What does “equivalent” mean? In general, it means a product that puts out about the same number of lumens as the product it is intended to replace. Why lumens? Because this is the industry standard metric which drives how bright a light source appears to the human eye, for example, if you were staring into it.

The supremacy of the lumen, and derivative cost metrics such as lumen-per-Watt (energy) and lumen-per-dollar (product), as the driving metric for solid-state lighting has significant ramifications. In particular, it drives the design of the light source light, itself, towards maximizing luminosity at the expense of everything else. This is achieved by engineering the light source emission spectra to maximize the number of (human eye) cone receptors responding to the incident light. This means the light source should produce the preponderance of its emission in the green-yellow regime wherein both medium (M) and long (L) wavelength sensitive cones are excited, and as little blue as possible (and necessary) to achieve a white color balance.

The Challenge

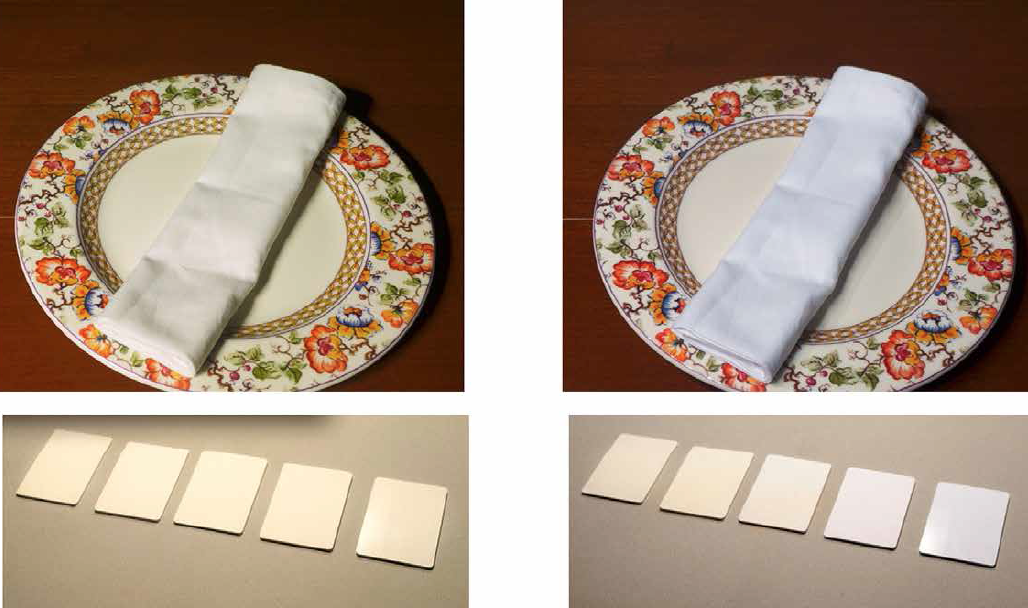

The LED industry, driven to supplant conventional lighting products with its superior technology at the fastest possible pace, developed white lighting products based on primary blue-emitting LEDs (the lowest photon energy possible to still produce white light) exciting green/yellow phosphors to maximize spectral luminosity. Standards such as Energy Star further fueled the lumen-based mind set, setting respectable lumen per Watt targets but only mediocre requirements regarding color perception (minimum color rendering index Ra of 80, and minimum deep-red index R9 of 0). The result today is a ubiquity of LED-based lighting products with broken emission spectra: No violet light, a cyan “gap” (between the primary LED and first phosphor emission), and a lack of red, as shown in figure 1.

Figure 1: Spectrum comparison of standard blue-based LEDs to incandescence (2700 K) and daylight (6000 K)

Figure 1: Spectrum comparison of standard blue-based LEDs to incandescence (2700 K) and daylight (6000 K)

What the lumen-based metrics do not take into account is that visual experience for the end user is not governed by light that goes directly from the light source into the eye, but rather by light that is reflected off objects in the environment under consideration. Indeed, the human eye has evolved to adjust to brightness levels and the iris will constrict or dilate to achieve a comfortable level of light detection. However, there is no such adjustment for color perception. If the signal is not there, it will simply not be detected. This is especially important in the red color regimes (also relevant for human skin), since the M and L wavelength cone responses are strongly overlapping (in some cases so much as to cause red/green color blindness), and while a light source with a substantial lack of red emission may still appear white, objects illuminated by it will reveal its shortcoming in the form of washed-out colors, unnatural pallor of skin, etc. Indeed, one could argue that a lumen-based approach to light source design is antithetical to that which one would pursue for good illumination. For the former, one wants to maximize yellow/green emission and minimize red. For the latter, one should target a wide emission spectrum with substantial light in the deep red, and reasonable emission in the blue (and even shorter wavelengths, as will be discussed later).

Full Visible Spectra

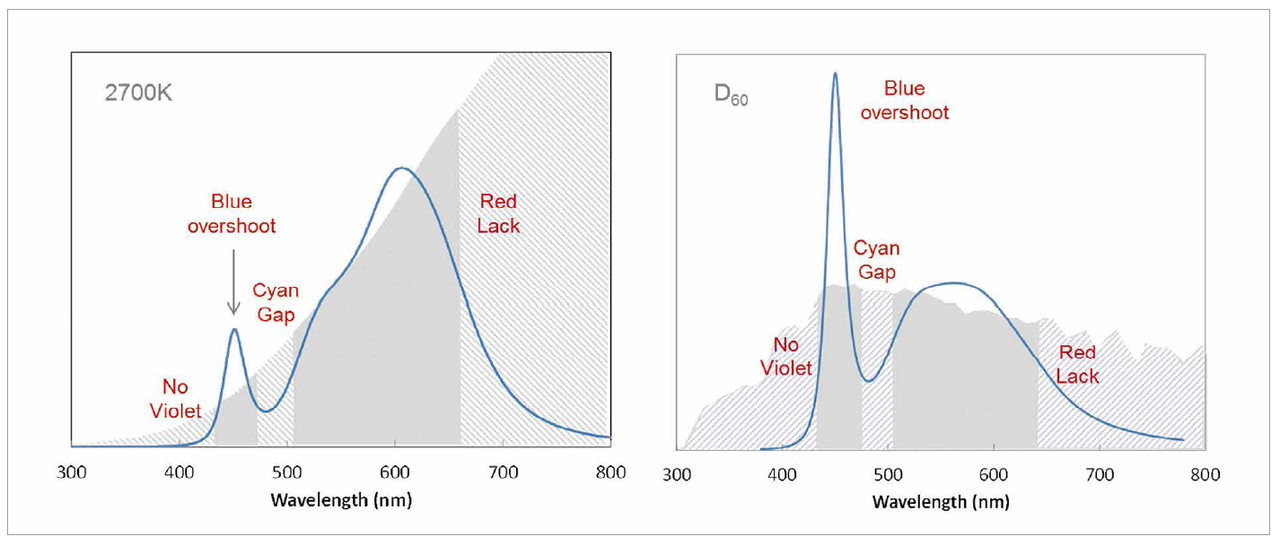

There is really no mystery around what should be reasonable targets for full visible spectrum emission: Nature and evolution show us the way. Sun and sky light vary dramatically throughout the day but are consistently broadband including (by definition!) all colors in the rainbow. Incandescence including firelight is characterized by smooth broadband sources weighted primarily towards the red. Rendering these sources properly with any light source requires emission throughout the 400-700 nm visible spectrum. This is possible with LEDs, provided the basis is violet (rather than blue) primary emission. Using a violet primary, the bulk of the visible spectrum emission can be provided by broadband phosphors. Indeed, using a combination of blue-, green-, and red-emitting phosphors, a violet-based white LED can produce an excellent match to both daylight and blackbody reference illuminants throughout the visible spectrum, as shown in figure 2.

Figure 2: Spectrum comparison of full-visible-spectrum LEDs to incandescence (2700 K) and daylight (6000 K)

Figure 2: Spectrum comparison of full-visible-spectrum LEDs to incandescence (2700 K) and daylight (6000 K)

By using the right combination of violet primary and phosphor emission, the gap between the LED and blue phosphor can be minimized, as well as any blue overshoot, the cyan regime is filled out, and the red emission is designed to provide high red color discrimination according to product design. Indeed, lighting products from 2700 K to 5000 K have been designed using this approach, achieving Ra and R9 values of 95 simultaneously. The question arises: Are these improvements in light quality measurable for the end user?

Colors and Whites

As already mentioned, our experience of the quality of a light source comes from its interaction with the objects we observe. Perhaps the best-known manifestation of this interaction is the rendering of colors, typically captured by Ra and by the additional deep-red rendering metric R9. These metrics have been known for decades; however their practical implication is not always well understood. For instance, it is frequently believed that values of (Ra=80, R9=0) are ‘good enough’ for general illumination. Some assert that better values should be restricted to niche high-end application and question whether they would even be noticed in common use.

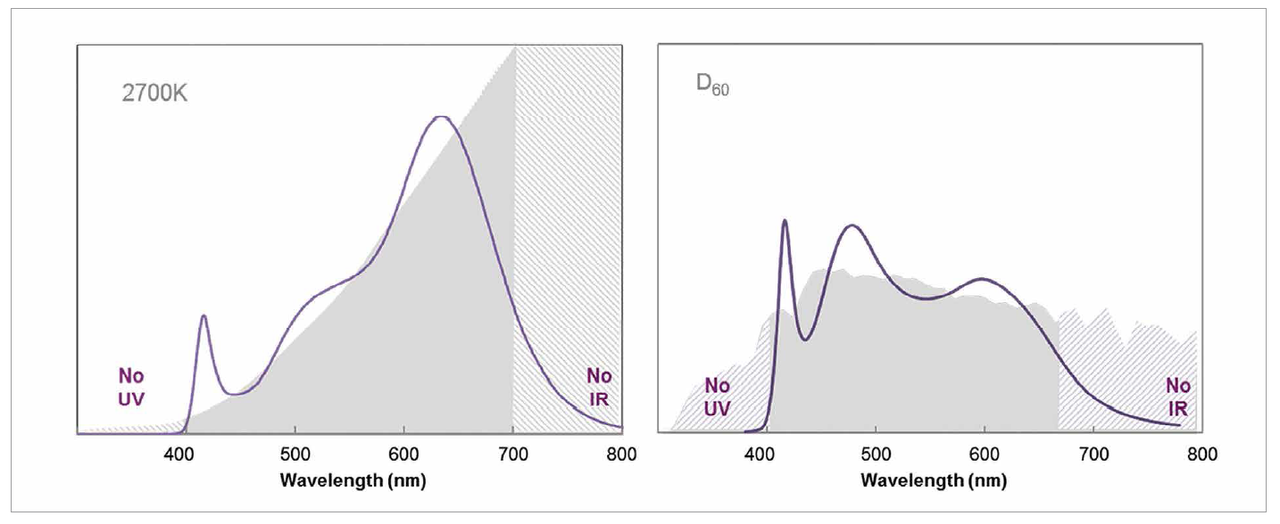

However, psychophysical studies conclude otherwise. In such a study, performed by the team of Prof. Houser at Penn State University [1], subjects were asked to compare a typical retail scene illuminated by two lamps: A standard LED lamp (Ra=80, R9=0, blue pump dies) and a high color rendering full-spectrum LED lamp (Ra=95, R9=95, violet pump dies). The subjects expressed a significant preference for the latter – both in terms of overall judgment, and for various specific colors (Figure 3). In particular, there was a strong preference for warm colors (red, orange, pink, purple) which play an important role in our perception. Figure 3 also shows “color icons” which illustrates the color distortion caused by both lamps; they indicate that warm colors are made duller by the standard LED, in good agreement with the experimental results. Thus, the importance of high color rendering to the end user is clearly revealed.

Figure 3: Human preference for full-visible-spectrum (FVS) LEDs compared to standard blue-based LEDs (center). Corresponding color icons illustrating color gamut and distortion (left and right)

Figure 3: Human preference for full-visible-spectrum (FVS) LEDs compared to standard blue-based LEDs (center). Corresponding color icons illustrating color gamut and distortion (left and right)

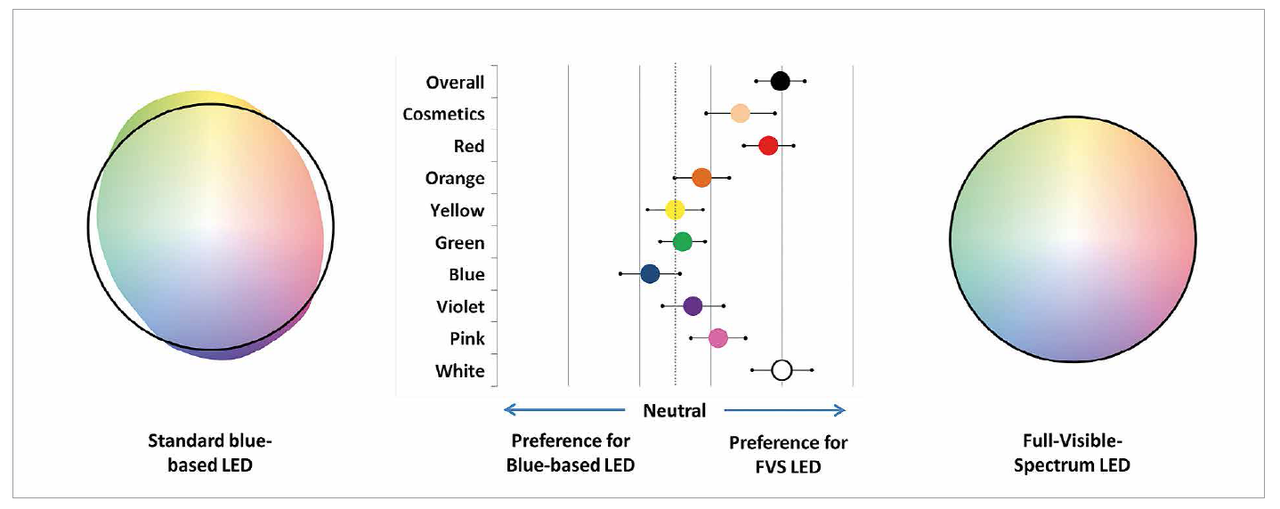

Interestingly however, well-known color rendition metrics do not tell the whole story when it comes to our visual perception. Indeed, they neglect another important question: The rendering of white objects. It may sound surprising that rendering whites should be an issue. Yet we commonly encounter a variety of white materials ranging from muted, creamy whites (such as the porcelain of a plate) to neutral whites (such as painted walls) to very bright white tones (white fabrics, papers, plastics, etc.). Bright whites are obtained by the addition of Fluorescent Whitening Agents (FWAs) to white objects; FWAs absorb short-wavelength (ultra-violet and violet) light and emit blue light, thus creating a “whiter-than-white” effect. They are widely used by manufacturers to achieve high levels of whiteness.

However, FWAs can only function if they are properly excited by a light source. This is not an issue with natural sources (sunlight, filament lamps) which all emit enough short-wavelength light; even fluorescent lamps provide some amount of FWA excitation. In contrast, conventional LEDs hardly emit any light below 430 nm: Therefore FWAs are not excited, and no whiteness enhancement is obtained. This creates an environment where all shades of whites are rendered with the same yellowish tint. This issue is not captured by Ra or other conventional color rendition metrics, although it corresponds to a very large color distortion for shades of white. Here again, full-visible-spectrum LEDs provide a solution: They emit no harmful ultra-violet light, but enough violet light to properly excite FWAs and render whites like natural sources.

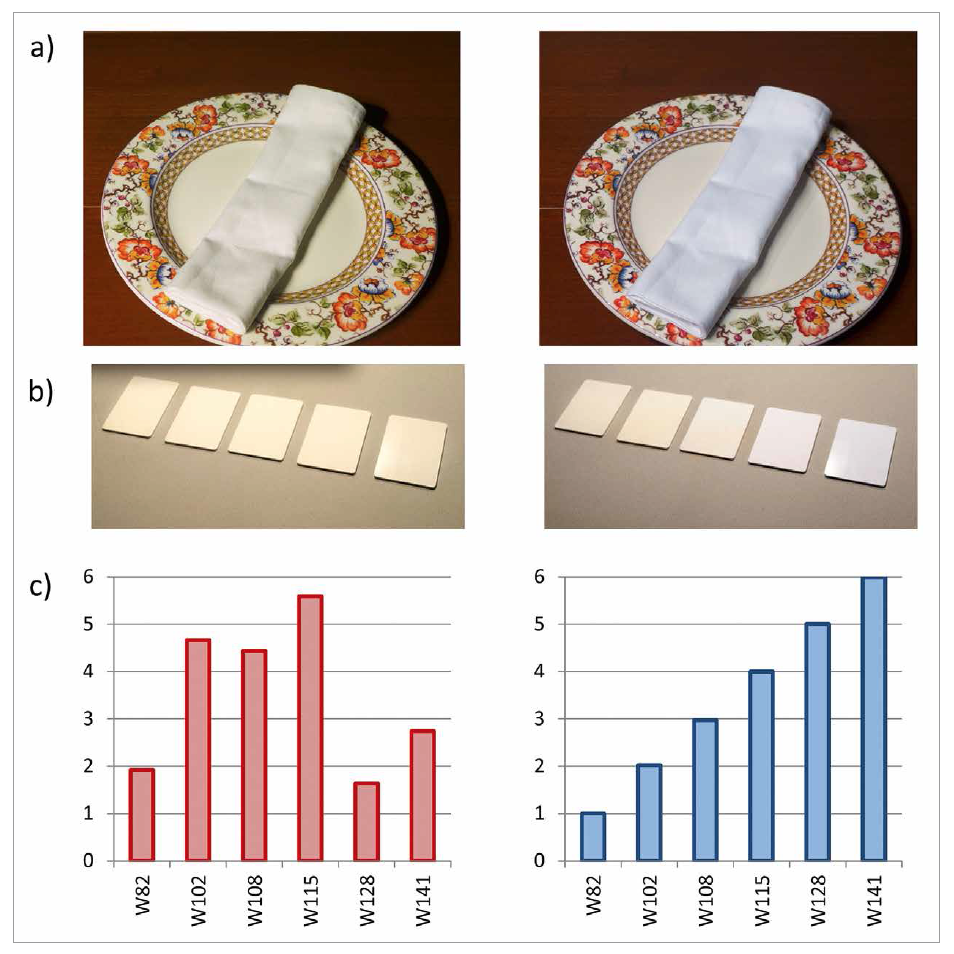

Figure 4: (a) Photographs showing the effect of fluorescent whitening agents (FWAs). (b) Whiteness standard tiles with varying levels of FWA content. (c) Results of sorting tests of whiteness tiles. Left column in under standard blue-based LED illumination; right column is under FVS LED illumination

Figure 4: (a) Photographs showing the effect of fluorescent whitening agents (FWAs). (b) Whiteness standard tiles with varying levels of FWA content. (c) Results of sorting tests of whiteness tiles. Left column in under standard blue-based LED illumination; right column is under FVS LED illumination

Figure 4a illustrates the issue of whiteness rendering. A scene comprising two white objects (a porcelain plate with a soft white tone and a bright white napkin) is illuminated by a conventional LED and a full-visible-spectrum LED. The napkin contains large amount of FWAs which should make it look bright and clean, standing out against the backdrop of the plate. Under illumination by standard LEDs both objects have the same dull off-white color, whereas Full Visible Spectrum illumination properly renders the contrast in shades of white.

Is whiteness rendering strong enough to affect our perception significantly? This question was answered by another psychophysical study at Penn State University [2]. Participants were shown a series of white standards (Figure 4b) with varying amounts of FWAs – representative of the shades of white found in everyday life - and were asked to rank them from least to most white. Under a conventional LED illumination this resulted in a disordered ranking as all cards appeared similar, while under full-visible-spectrum illumination the ranking followed the intended whiteness of the cards, confirming their proper rendering (Figure 4c).

The ability to render whites accurately is important from an application standpoint, because it has a strong impact in terms of user preference: When looking at a white dress shirt, participants express a significant preference for full-visible-spectrum illumination (Figure 3).

Therefore, a combined proper rendering of whites and colors contributes to a better user experience which is crucial for the widespread adoption of LEDs. It is worth noting that the experimental response to both colors and whites is very pronounced, thus dispelling the notion that an improvement in color rendition is superfluous or difficult to perceive.

Technology Approach

It is instructive to consider the “penalties” for delivering the full visible spectrum solutions as described above; it does not come for free. First, violet primary emission requires delivery primary 3.0 electron-Volt photons, compared to 2.7 electron-Volt blue photons, a relative 10% increase in required energy. For good color rendering, deep red emission is required, reducing the spectral luminosity by about 20-25% in going from a Ra/R9 of 80/0 to 95/95. Finally, a blue phosphor is required, which although not fundamentally lossy (on a photon basis) does decrease efficiency somewhat since materials are never perfect. The total penalty, again on a lumen basis, is more than 30%. Conventional LED technology cannot absorb such a penalty and still be viable, efficiency wise. Instead, to overcome such a gap, a very high performing base LED technology is required. This has been achieved, and demonstrated, with the advent of gallium-nitride-on-gallium-nitride (GaN-on-GaN) technology.

Gallium-nitride, or GaN, is the wide bandgap semiconductor that is driving the LED industry. Unlike more conventional semiconductors such as silicon or gallium-arsenide, GaN cannot be grown from the melt, and so GaN substrates have not been available until very recently. This is important because the semi-conducting properties, critical for optoelectronic devices like LEDs, are only revealed in pure crystalline material. This requires that semiconductor material be deposited epitaxially in such a way as to maintain this homogeneous crystalline structure. A starting reference point is required, which for most semiconductors is the native substrate itself (e.g., silicon for silicon-based CMOS, gallium-arsenide for GaAs-based telecommunication devices, etc.). If there is no registration, materials will deposit amorphously, losing their crystalline structure, along with the desired optoelectronic properties.

Breakthroughs in Japan in the late 1980s [3] led to a technique for depositing single-crystal GaN on commercially available sapphire substrates. Similar approaches have been successfully applied to other substrates such as silicon and silicon-carbide. These approaches ushered in the first era of LEDs for solid-state lighting applications, and the vast majority of LEDs today are based on it. While the performance is reasonably good on a lumen basis, there are limitations in performance.

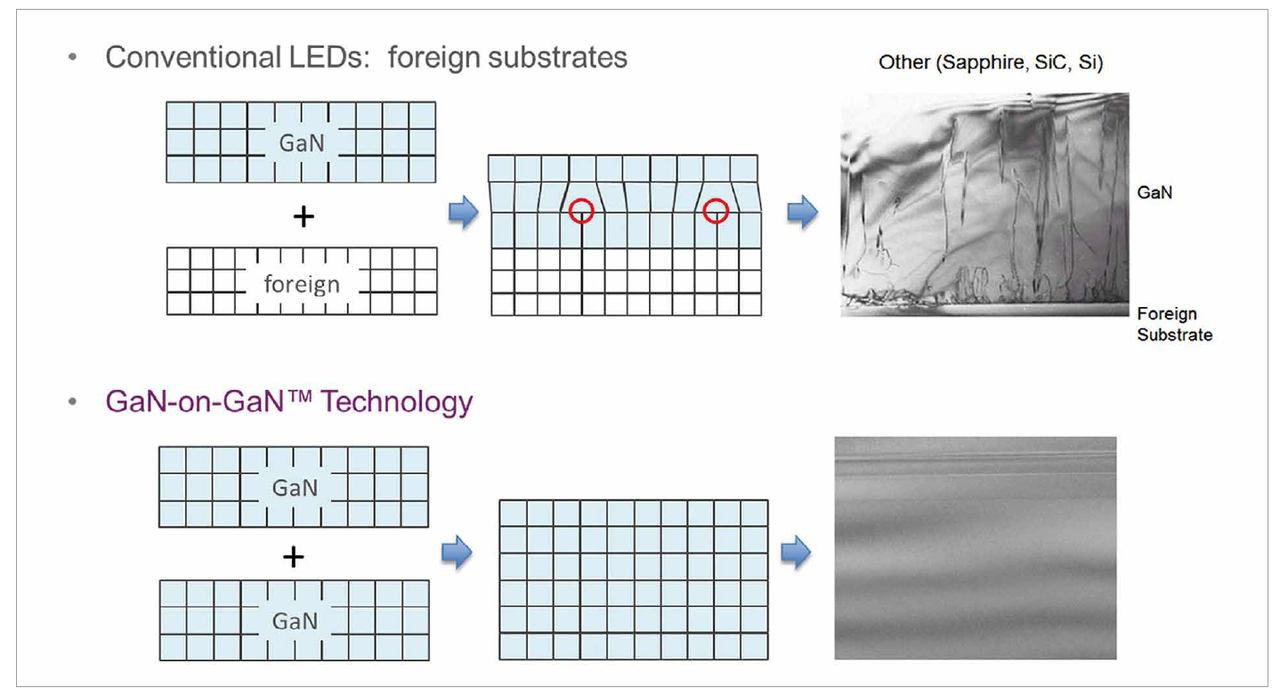

Figure 5: Illustration of the importance of atomic lattice match for semiconductor material and defect generation when GaN is deposited on foreign substrates

Figure 5: Illustration of the importance of atomic lattice match for semiconductor material and defect generation when GaN is deposited on foreign substrates

Figure 5 illustrates the situation. GaN epitaxially deposited on a foreign material (top), even using best tricks in the industry, result in defective material. The defect density is typically a few per square micron, or a few million defects in a typical LED chip (1 mm x 1 mm), and is readily viewable in cross section transmission electron microcopy. While not prohibitive with regards to performance, this level of defect density does limit the range of efficient light generation from a wavelength perspective, as well as limit the operating power density. Indeed, laser diodes (which operate at about 1,000 A per square centimeter, A/cm2) cannot reliably operate at such defect levels. In contrast, GaN deposited on its native substrate provides for very low defect densities, about 100-1,000 times lower (Figure 5, bottom).

Where do the GaN substrates come from? As mentioned, laser diodes could not tolerate the high defect densities associated with foreign substrates. Thus, Blu Ray technology was driven to provide higher quality templates for GaN epitaxial growth. The most common approaches, developed over the last decade, involve starting with a foreign seed substrate but then growing thick GaN layers by hydride vapor-phase epitaxy (HVPE), several mm thick. The very thick growth provided a means for defect annihilation such that reasonably high quality, quasi-bulk, GaN substrates could be realized. While still the most common approach today, it results in relatively high price substrates. New methods, such as ammonothermal growth (analogous to hydrothermal growth of quartz crystals, a very high volume and low cost technique), are being developed that are expected to slash the costs of GaN substrates in the future, while also improving substrate quality by skipping the step of starting with foreign seed crystal.

The impact of the lower defect density, or higher crystalline quality, of the GaN-on-GaN material is higher overall performance, especially at shorter LED emission wavelengths. Figure 6 shows the external quantum efficiencies of LEDs as a function of peak emission wavelength. The lower curve, based on published performance for GaN-on-sapphire LEDs, shows a maximum under 60% in the blue wavelength regime, and falling precipitously as wavelength is reduced below 430 nm. In contrast, GaN-on-GaN devices have external quantum efficiencies above 70% in the blue, and increasing towards 80% in the violet (410 nm) wavelength regime. The extremely high performance level (about 8 out of every 10 electrons injected into the GaN-on- GaN LED are converted to a useful particle of light) provides a sound basis upon which to build an LED platform that supports the full visible spectrum approach described earlier.

Another benefit of GaN-on-GaN is the unlocking of viable high-current density operation. Standard LEDs typically operate at ~ 35 A/cm2 (e.g., 350 mA in a 1 mm x 1 mm chip) with higher current density operation thwarted by reduced efficiency (aka “droop”), poor power density uniformity, and (eventually) reliability concerns. In contrast, GaN-on-GaN devices typically operate at ~ 160 A/cm2, about five times higher than standard LEDs [4]. This means that, for same light output level, the GaN-on-GaN approach requires five times less semiconductor material. There are two significant ramifications. One, it portends a fundamentally lower cost approach to LED manufacturing, especially as GaN substrate prices come down. Since factories will likewise be correspondingly smaller, it also represents a more sustainable approach to LED manufacturing. Two, the reduced amount of semiconductor required means also that the total optical source size of a GaN-on-GaN light source can be significantly smaller than for traditional LEDs. This means increased control over light including tighter beam profiles, and fundamentally smaller optics and luminaires which will drive more elegant and sustainable lighting product designs. The full ramifications of all the above are best revealed when analyzing performance at the system, or lighting product, level.

Directional Lighting Comparison

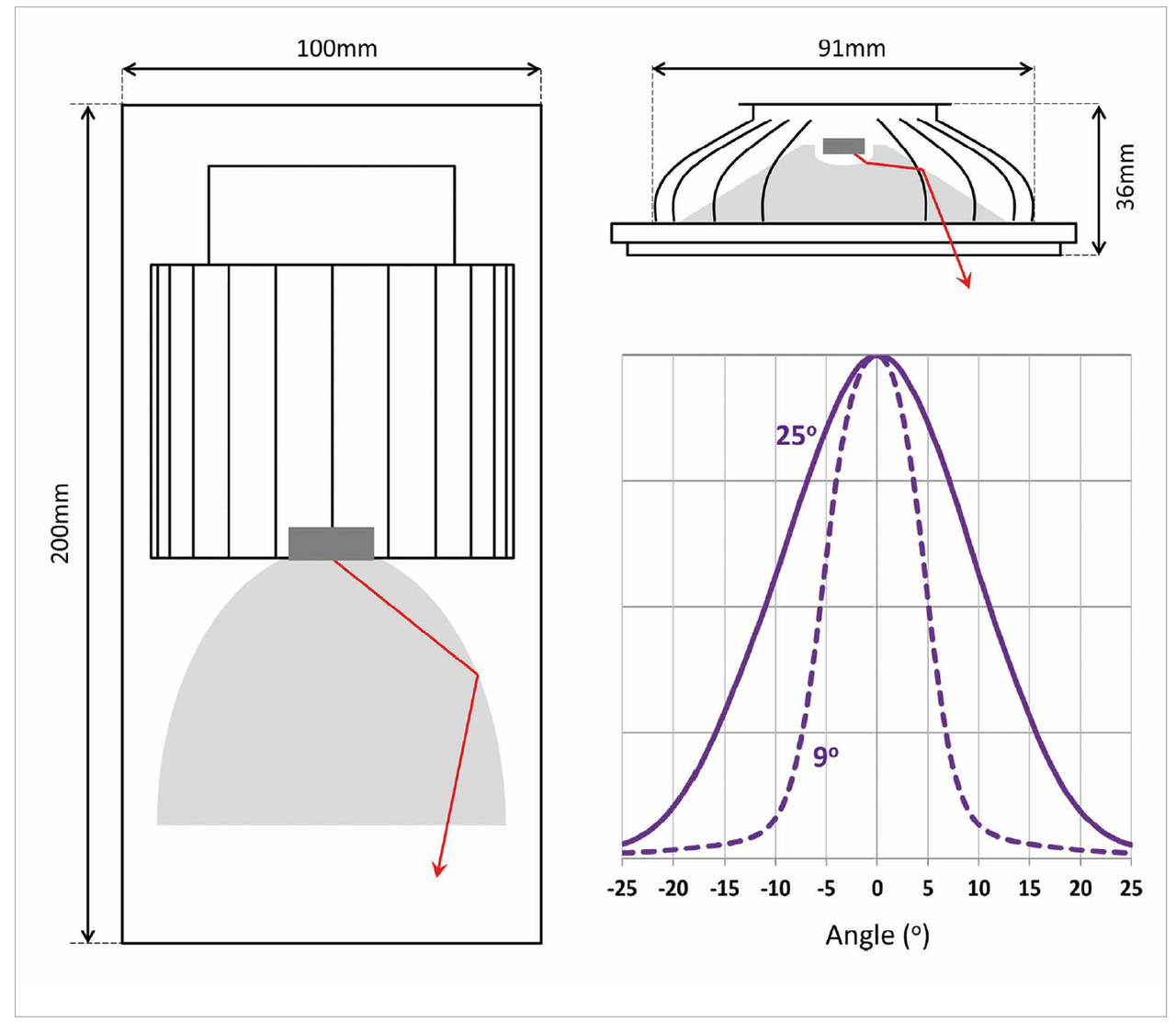

As such an illustration, figure 7 compares two commercial spot lighting solutions with high color rendering: A state-of-the-art high-end conventional LED fixture, and a violet-based full-visible-spectrum Alamp for AR111 fixtures.

Both sources have similar diameter, power consumption and a 25° beam angle. The conventional solution uses a standard approach: A blue-emitting- LED based high-power light module is attached to a heat sink and coupled to a parabolic optic. The violet-based full-visible-spectrum AR111, in contrast, takes on a drastically different geometry: Both the heat sink and optic are design to couple optimally to the high-brightness GaN-on-GaN light source.

Several advantages of the GaN-on- GaN technology are obvious. First, the system is brighter and more efficient: It emits a 10% higher center beam candlepower (CBCP) and achieves 20% higher Lumens per Watt. This is on top of offering a superior color rendering and whiteness rendering (these could be offered by conventional technology, but at a further cost on efficiency and light output).

In addition, the GaN-on-GaN based system is significantly smaller: It has the same diameter but is more than six times thinner. This is enabled by several factors. The high-efficiency GaN-on-GaN LEDs require much less heat sinking. The high-brightness source, coupled to an innovative folded-lens design, provides a much tighter beam control in a very thin optic. Finally, while standard fixtures require a deep cup to cut-off large-angle beams which are deleterious to color constancy over angle, full-visible-spectrum technology doesn’t rely on the leakage of blue light to achieve color-targeting: This results in inherently superior color-over-angle so no additional blocking or mixing is necessary. In this respect, it is noteworthy that conventional fixtures typically have a fairly high color variation – sometimes five to six Du’v’ points: This within-beam variation is thus much worse than the claimed part-to-part color control, on the order of 2-3 points.

In fact, a 25° beam is far from the limit enabled by GaN-on-GaN technology; with the same footprint, beams down to 9° can be achieved. As can be seen on figure 7, this corresponds to a CBCP of 24,000 candelas. Obtaining such a bright and narrow beam with a conventional reflector-based optic would require a doubling of the system’s diameter – clearly an unacceptable solution in most applications. The low-profile footprint provided by the GaN-on-GaN approach is also important because it conforms to the AR111 form factor, and is therefore compatible with a wide range of lighting fixtures suited for various interior design needs.

Figure 7: Comparison of a directional lighting fixture based on standard blue-based LEDs, to AR111 performance using GaN-on-GaN

Figure 7: Comparison of a directional lighting fixture based on standard blue-based LEDs, to AR111 performance using GaN-on-GaN

To put our comparison into perspective, it is instructive that the aforementioned shortcomings of conventional LED products are often obscured: Many specification sheets do not reference important parameters such as R9, whiteness rendering, color-over-angle – even CBCP is sometimes deemphasized in favor of lumens, a much less relevant metric for spot lamps.

Conclusion

The above comparison illustrates that the benefits of full-visible-spectrum technology are not easily reduced to a few conventional metrics, but have huge ramifications to overall product design, cost, efficiency, and quality of illumination. It is worth noting that GaN-on-GaN technology; the real enabler here in breaking the quality-efficiency tradeoff, is still relatively young: Further improvements can be expected in terms of efficiency, but also in terms of continued higher brightness (even smaller source sizes!) and cost. This technology therefore represents a significantly new approach towards addressing the opportunity to reduce worldwide energy consumption with respect to lighting, while also providing for beautiful illumination.

References:

[1] M. Wei et al., “Perceptual Responses to LED Illumination with Color Rendering Indices of 85 and 97: Is a 12-point Difference Important?” submitted for publication (2014)

[2] K. W. Houser et al., “Whiteness Perception under LED Illumination”, LEUKOS 10:3, 165-180 (2014)

[3] S. Nakamura and M. R. Krames, “History of gallium-nitride-based light-emitting diodes for illumination”, Proceedings of the IEEE 101, 2211-2220 (2013)

[4] M. J. Cich et al., “Bulk GaN based violet light-emitting diodes with high efficiency at very high current density”, Applied Physics Letters 101, 223509 (2012)