Handheld Photometry Supports LED Lighting Design

With SSL new dimensions were introduced to light measurement, especially concerning handheld light measurement tools. Norbert Harkam, General Manager at SalesLink GmbH, a Representative of UPRtek, explains what criteria have to be considered and what the requirements of a handheld photometer are.

Lighting design is often seen as the “fourth dimension” of architecture and interior design. Appropriate lighting determines the appearance of color and form and it impacts how people feel and act in public and residential environments. Meaningful measurement data, derived on location with a handheld instrument, such as the MK-350 from UPRtek, are the basis for ergonomically and energetically optimized LED luminaires and large-scale illumination systems.

Lighting Design - an Interdisciplinary Task

Lighting design is a broad-based interdisciplinary activity based on various scientific and technological pursuits - from photometry and physiology to perceptional psy-chology. Lighting design enhances the architectural appearance of public spaces - from airport terminals and shopping malls, museums and event locations, parks and piazzas, administrative buildings and offices, to high-caliber residential environments.

The objective in all these cases, which are often guided by stringent architectural concepts, is creating optimum illumination solutions as well as satisfying aesthetic and perceptional values. A third consideration is energy efficiency and long-term viability.

An everyday experience in this regard is a look at the fresh-meat counter (Figure 1) of a well-stocked supermarket. These goods look particularly delicious when illuminated by a yellowish, warm-white light source of the proper correlated color temperature. Yet CCT alone doesn’t suffice. Equally important is the light source’s color rendering index (CRI). It must be high enough to deliver a favorable color impression compared to natural sunlight (CRI = 100).

Figure 1: Appropriate lighting helps sell the goods

Figure 1: Appropriate lighting helps sell the goods

In Figure 1A (CCT: 3,000 K), CRI is 52 – which is rather low. In Figure 1B the CRI is 82, so the depicted objects look much more attractive. The same is true for Figure 1C, where the displayed goods, at a somewhat cooler 6,500 K and a CRI of 82, are quite appealing to the eye.

CCT and CRI are core photometric categories. Next to the measured illuminance level they have a strong impact on lighting design. In this regard, LED lighting, supported by appropriate measurement methods and tools, has led to novel solutions in lighting design.

LED Lighting – Revolution to Mainstream

The traditional incandescent light bulb is on its way out. Its temporary replacement, a fluorescent tube often called energy-saving lamp, is not a real ecological alternative. It contains, like many gas-discharge lamps, the highly toxic mercury. At the end of its life, it must be disposed as hazardous waste. Thus, advances in LED technology now drive the greatest change in illumination systems.

A significant difference to incandescent lamps is the emission spectrum of LED lighting systems. It is limited to the visible wavelength realm of 360 to 760 nanometers. There is no emission of infrared. In other words, LED lighting doesn’t radiate heat at wavelengths above 780 nm. Thus, the objects in Figure 1 cannot be spoiled by heat.

The situation is similar at the other end of the visible spectrum: LED lighting systems don’t emit ultraviolet energy (below 380 nm). This prevents damage to paper, textiles and light-sensitive pigments and it makes LED lighting well suited for art galleries and museums. A possible drawback is the subdued effect of whiteners added to pigments for enhancing contrast and color brilliance by reflecting UV radiation.

Another important reason for using LED lighting is energy efficiency. A high-power LED (5 W) delivers the same luminous flux of 415 lumens as a 13 W fluorescent energy-saving lamp, or a 40 W incandescent bulb. But the LED consumes just an eighth of their energy.

LED technology is continuously evolving in terms of brightness, efficacy and chroma-ticity. Spectroradiometers laid out for these measurement tasks, such as the one referenced in this article, are useful tools to evaluate LED lighting systems under real-life conditions outside the lab.

Portable Photometry

Up to now portable devices for measuring vital optical parameters of lighting installa-tions at customers’ premises consisted of several separate components: sensor, spectrometer and PC (or notebook) to gather and analyze the data. To make things easier on lighting designers and maintenance crews, and to give them unprecedented mobility in the field, it is advantageous to combine the entire functionality in one com-pact device. A measurement requires just three steps:

• aiming the device at the light source,

• initiating the measurement by pushing a button, and

• reading and storing the measured quantities after three seconds

The handheld instrument referenced here combines a light sensor with cosine correc-tion close to the ideal curve, a high-resolution spectrometer with advanced architec-ture, whose half-power width of 12 nm enables a wavelength increment of 1nm, plus a CMOS line-scan-sensor including integrated readout circuitry in a robust and compact housing.

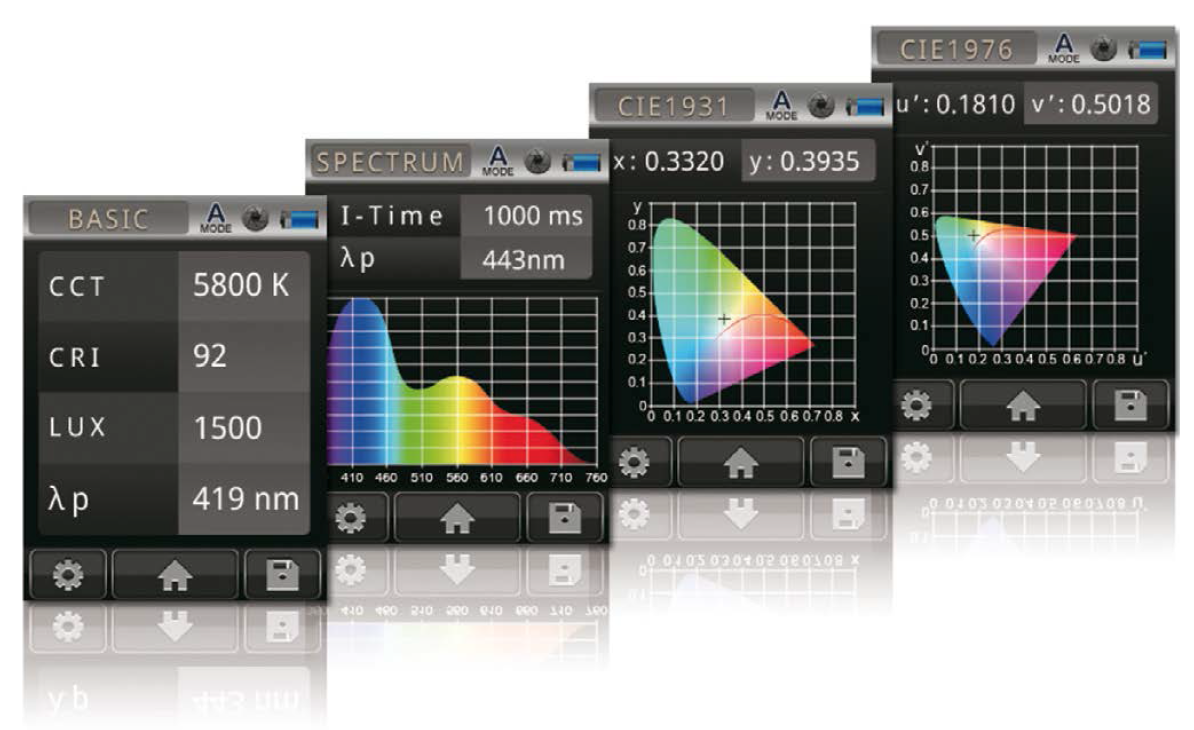

Figure 2: Four operational modes for a wide range of applications offered by the spectroradiometer MK-350

A portable meter typically has a 3.5-inch color screen with quarter-VGA resolution, ideally laid out as a touch screen. The light sensor must have a sufficiently small di-ameter to securely capture the emissions of spot-beam sources such as individual LEDs. Four measuring modes, BASIC, SPECTRUM, CIE1931, and CIE1976, deliver the significant optical parameters (Figure 2):

• Illuminance

• Spectral energy distribution

• Color Space Coordinates

• Peak Wavelength

• Correlated Color Temperature

• Color Rendering Index

The illuminance measurement range should extend from a dim 70 lux to a glaring 70,000 lux. Spectral distribution is measured between 360 and 750 nm. Ultraviolet and infrared contributions outside the visible realm are safely suppressed by the wavelength limits of the device. Thus, this measurement method is not particularly well suited for measuring light sources other than LEDs, such as halogen lamps or flu-orescent tubes, due to possibly reduced measurement accuracy.

Another condition is to operate the light sensor inside its optimum sensitivity range for highest measurement accuracy with the integration time adjusted automatically between 8 and 1,000 msec, and to have it manually settable when comparing light sources of different radiation characteristics. Peak wavelength is derived from the spectral distribution. It should be switchable to display the spectrum to indicate pos-sible secondary maxima for evaluation. Figure 3: The measured spectrum characterizes the type and qualification of a light source

Figure 3: The measured spectrum characterizes the type and qualification of a light source

A typical spectrum measurement routine is shown in Figure 3. The task is to determine what kind of light source is deployed. The depiction on the left is typical for daylight with a peak wavelength at 466 nm (color: blue). In the center is an incandescent lamp with a maximum in the infrared realm – which is not captured. The highest indicated value therefore is towards the long wavelength area at 760 nm (dark red). The right image characterizes an LED with a radiation maximum at 451 nm along with its secondary maxima transformed by fluorescence.

Portable light meters usually provide measurement modes for a light source’s CIE (Commission Internationale de’Eclairage) chromaticity coordinates. They are located as x,y-coordinates according to CIE1931, or as easier to be determined u‘,v‘-coordinates to CIE1976.

Derived from the measurement of the color space coordinates is the calculation of correlated color temperature in Kelvin. CCT characterizes the color of the measured light source by locating it as close as possible to an ideal blackbody radiator. A CCT measurement range of 2,500 to 10,000 K reliably covers the usual colors such as yellow (3,000 to 4,000 K) or white (5,000 to 6,000 K).

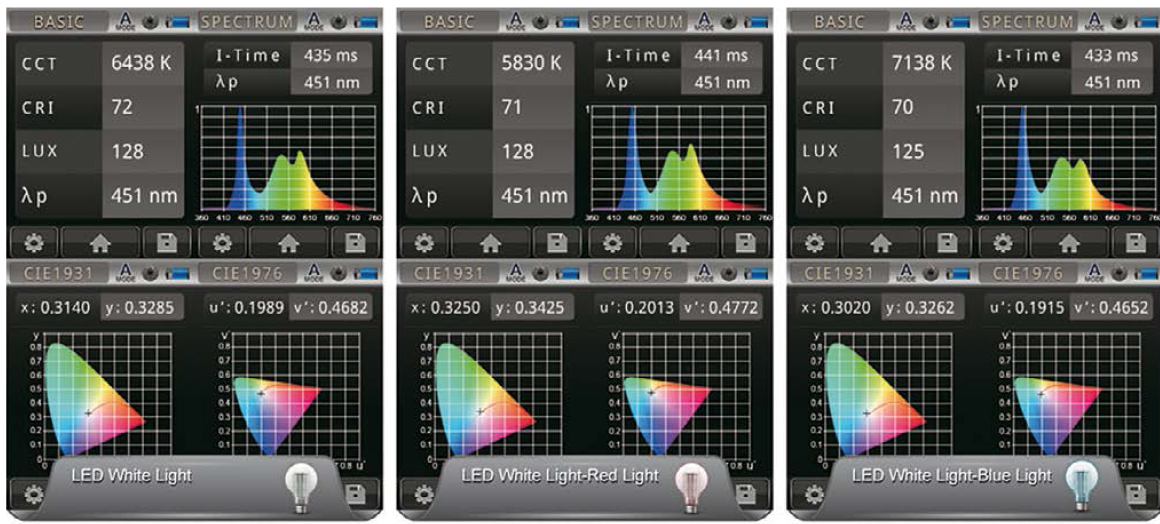

The data obtained from the spectral analysis are also used to determine the color-rendering index. CRI is calculated as the arithmetic mean value Ra of the first eight test colors (out of a total of 14) with standardized remission according to DIN-6169 when comparing their appearance under artificial light to that in natural sunlight. Ra is indicat-ed in a range between 0 and 100 (the ideal value for direct sunlight). A CRI above 90 is excellent. Values between 80 and 90 are in most cases sufficient for good color rendering. Values below 60 indicate poor color rendering. Figure 4: Chromaticity calculation according to CIE ensures continuous quality of lighting products

Figure 4: Chromaticity calculation according to CIE ensures continuous quality of lighting products

Product Characterization

The growing demand for LEDs in lighting systems confronts their producers with a sorting and binning task to fulfill the specifications of their customers. A manufacturer of halogen luminaires ordering 100 lamps can be sure that all 100 of these will emit the exact same white light. Manufacturing LEDs for lighting applications, however, is significantly more complex and leads to certain deviations in their specs in terms of brightness and chromaticity. Integrating multiple LEDs in luminaires must avoid that some of them exhibit unacceptable color shifts. Thus, LEDs must be selected in a standardized binning and sorting procedure. A spectroradiometer is suited for such a procedure if it carries out these two steps:

• Measurement of illuminance and determination of color coordinates, either in the CIE1931 x,y- or CIE1976 u‘,v‘-space. This ensures uniform chromaticity of the LEDs used.

• Measurement of color rendering index and comparison of the measured spectra. This ensures the LEDs’ spectral identity.

Figure 4 shows measurement results from three LEDs marked “white”. The LED on the left behaves as required. In the center is a slightly red-shifted version. On the right is a blue-shifted specimen. These data points quantify the deviations for improved product characterization.

A typical application that calls for binning is the design and manufacture of high-end LED lighting systems. For instance, the Nimbus-Group has specialized in architectur-ally advanced LED luminaires and illumination systems, and has gained a global leadership position in this market.

Basic idea, and recurring aesthetic feature, of this manufacturer’s lighting design is the grid-like planar embedding of multiple low-power LEDs (0.3 W) in a clear acrylic sheet about 1 centimeter thick. This leads to a strictly minimalist design of floor and table-top luminaires, and also of large-scale wall and ceiling illumination systems that fit modernist, stylistically reduced interiors. One advantage of these extremely flat wall and ceiling systems is that they require a very low installation depth.

Guaranteed Lighting Mood

“Architectural lighting systems,” says Frank Schlosser, director of project development at Nimbus, “must be predictable under all operational conditions and fulfill agreed-on specifications in terms of color rendering and brightness. Residential quarters, for instance, tend to a relaxing, warmer color temperature, whereas work places require a cooler light to stimulate alertness and creativity.”

Being semiconductor components LEDs can be controlled and regulated in wide margins by complex driver circuitry, which is usually mounted, along with the LEDs, on printed circuit boards like in other electronic devices such as cell phones and PCs. Automatic daylight controllers and presence detectors are standard in this applicative realm.

Portable photometric instruments are typically used when developing lighting projects or testing installed systems at customers’ premises (Figure 5). “This saves us from taking along heavy lab-type equipment including laptops,” Frank Schlosser says. “A portable light meter is advantageous when evaluating lighting systems mounted at various heights or close to the ceiling, especially if it can be operated with one hand.”

Figure 5: Application of the portable light meter at a customer’s premises

Figure 5: Application of the portable light meter at a customer’s premises

A plus of portable meters is that the data gathered can be stored and documented on a regular SD Card, or USB-transferred to a computer for further processing. “With a measurement head attached one can also point the meter at every single LED and check its correct specification and operation.”

This feature set of a portable meter makes it easier to replace single LEDs, or to expand existing systems by ordering LEDs with appropriate bin numbers, Schlosser says. “The customer can be sure to get the best possible color value to fit his lighting and room design.” Especially with a relatively new medium as LED lighting, Schlosser points out; the sensitivity for slight deviations in color and brightness is still high.

Credits:

Figures 1 to 4: URPtek

Figure 5: Nimbus-Group