EMI Problems in TRIAC Dimmable LED Drivers by RECOM Lighting

TRIAC dimming adds a dimension to Power Factor (PF) and Total Harmonic Distortion (THD) that is rarely defined by LED driver manufacturers. Bianca Aichinger, Product Marketing Manager at RECOM Lighting, examines the relationship between PF, THD and harmonics and explains why this relationship can change as soon as the LEDs are dimmed, thus causing increased EMI and undesirable visible effects such as LED flashing and flicker. The European standards for EMC and Harmonics are only specified for full load and in the non-dimmed condition. In practice, there are often dimmer/driver/LED load conditions which may meet the regulations when undimmed, but fail significantly if dimming is used.

Light is a human necessity and depending on our needs and mood we require different levels of illumination. We need much more light to read or work than in the evening when having an atmospheric dinner, for example. For this reason dimmable lighting has become one of the mainstays of daily life. Most workplaces use controllable light levels to increase productivity, increase safety or to save electricity costs, and almost every household has a wall dimmer. The most common dimming method is the TRIAC or phase angle dimmer which is a mature, well-proven technology. However, what was and still is self-evident for conventional incandescent bulbs creates new challenges when using more modern lighting solutions like LEDs, especially over issues such as compatibility and EMI performance. For a better understanding of this topic it is necessary to get to know the differences between a traditional incandescent light bulb and an LED dimmed lighting system.

The successful installation of a dimmed incandescent bulb requires only a dimmable mains power connection and a light socket. The installation is so simple because the socket sizes are all standardized and incandescent bulbs are non-electronic, purely resistive loads that have unity power factor and will work with almost any dimmer or switch combination. Installing an LED is much more complicated. Besides a more sophisticated thermal management and appropriate photometric interface, an electronic LED ballast or driver is almost always necessary to power the LEDs (the few direct AC operation LED lights suffer from a very non-linear dimming curve which makes it impractical to dim them successfully, so they will be ignored here)

Introducing an electronic power supply into the installation adds complexity and as LED ballast is essentially an AC/DC power supply, it has to meet the all the EMC Directives including the power factor and harmonics regulations for the operation of mains-powered electrical devicesn.

Introduction to Power Factor and Harmonics

Let’s start with power factor (PF). Power factor measures the relationship between active and reactive power and thus shows the phase angle/load distribution in the power grid. The power utility companies are naturally anxious to keep the proportion of the active power as high as possible, as they are required to correct the power factor relationship if it deviates much from unity and common electricity meters can only measure active power, so any reactive power losses are not paid for by the customers. Note that a high PF does not mean high efficiency. They are separate entities and adding power factor correction in an LED power supply actually reduces overall efficiency.

As most LED power supplies are switching supplies operating at frequencies of 100kHz or more, they can inject high frequency current pulses into the mains if not properly filtered. This high frequency interference has a maximum at the switching frequency, but also other peaks at multiples of this frequency, or its harmonics. This means that interference frequencies in the MHz band could be easily generated which can affect other electronic equipment on the same mains wiring.

Therefore, regulations have been issued and directives have been passed which define the maximum permissible values for power factor and harmonics that all consumers installing LED luminaires with powers of 25 watts or more have to meet. In Europe, this standard is called EN61000-3-2: EMC-limits for harmonic current emissions, and for lighting applications, class C is required. The only practical way to meet the harmonics restrictions is also to add power factor correction (PFC), as the harmonics standard includes power factor in its definition.

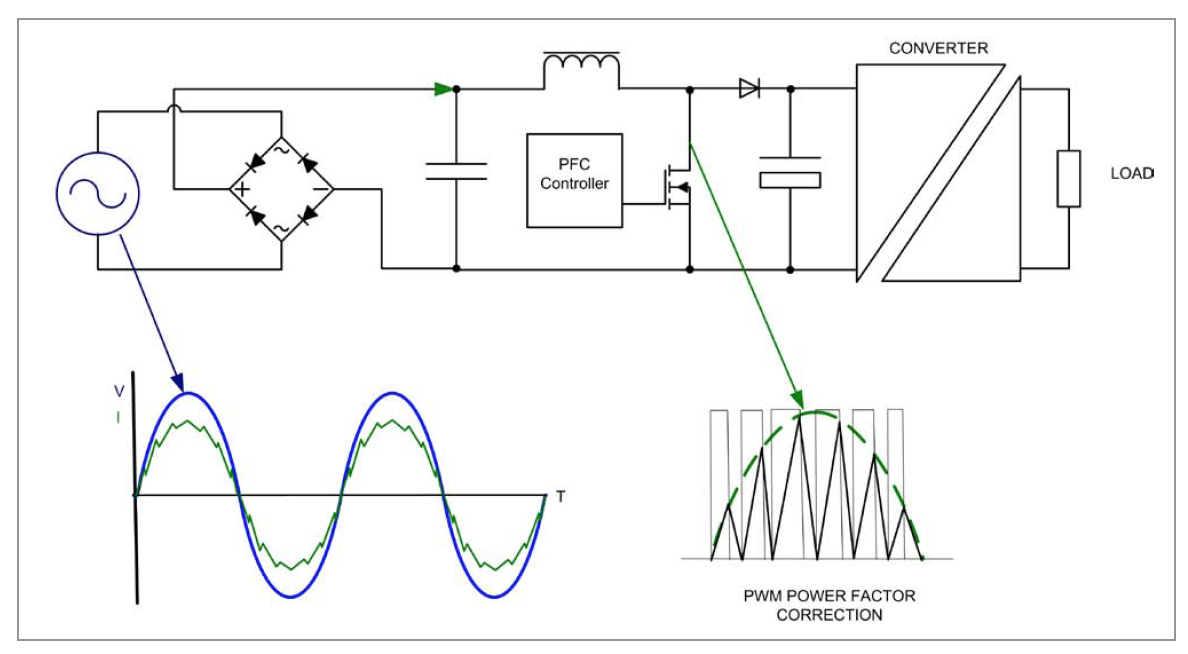

The typical principal of an active PFC is to add a pulse width modulator (PWM) in the circuit between the rectifier and storage. This PWM generates several current pulses synchronized with the input voltage and controls the capacitor charge current such that it is close to the input voltage sine wave form (Figure 1). As the input current closely matches the input voltage, the active power is very high and the PF is close to unity. Figure 1: Block diagram of an LED driver with active PFC showing the modulation of the current wave form

Figure 1: Block diagram of an LED driver with active PFC showing the modulation of the current wave form

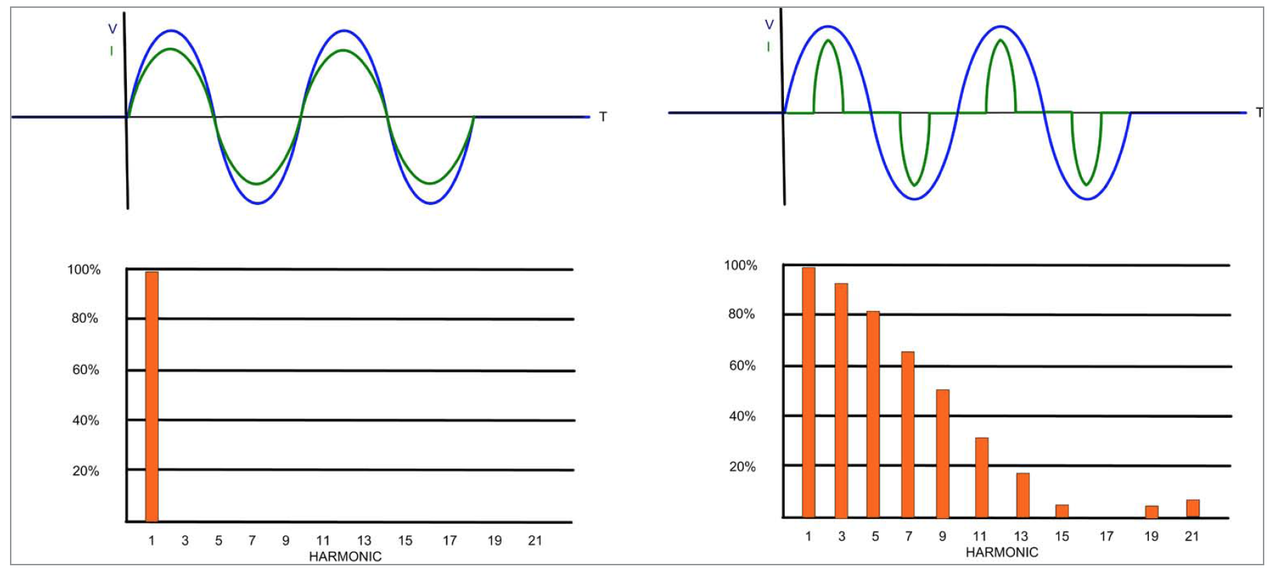

The term THD (Total Harmonic Distortion) is often misinterpreted. Actually the THD is a figure that is reflecting the total pollution of the power grid over all frequencies. This pollution is generated by all of harmonic waves which are superimposed to the mains sine wave when voltage and current are not in phase (Figure 2).

Figure 2: Comparison between resistive load and non-PFC behaviour showing the different harmonics spectra

Figure 2: Comparison between resistive load and non-PFC behaviour showing the different harmonics spectra

A very common misapprehension is to confuse the EMC harmonics specification with THD. THD is defined as a simple percentage (eg. THD<10%, THD<20%) and is derived by working out the square root of the sum of the squares of each harmonic divided by the fundamental current. This gives a simple figure for total distortion, but ignores the absolute value of individual harmonics. The EMC standard EN61000-3-2 goes much more into detail and defines a maximum limit for each odd harmonic until the 39th iteration. So it might be possible that the THD is less than, say 15%, but that one of the harmonics is out of range which means that the lighting system will NOT be complaint to Class C. On the other hand the THD could be more than 20% but all individual harmonics are within their limits and so the whole system meets the EMI standard. It is therefore better to insist on Class C compliance and not to worry too much about THD. Actually, EN61000-3-2 is not an LED specific standard. It also applies to CFL lamps and is the reason why it is almost impossible to find high power CFLs as the 25 W limit was chosen to let the majority of CFL lamps off the hook.

The impact of load and dimming

So far, so good for the situation for the basic operation of LED lamps but if an additional functionality like variable load and dimming is required as well, a further dimension is added. LED ballasts are optimized to work best at “full load”, but this state is not so easy to define with constant current drivers. For example, if a 350 mA LED driver rated at 10 Watts (Vout max = 28 VDC) is used with an LED Lamp rated at 7 W, then most users would consider this a good set up. With typical LEDs, the forward voltage of the 7 LEDs in series will be around 22 V. As the driver may only be able to properly regulate the output current over a range of 75%- 100% load, as soon as the LEDs are dimmed down, the string voltage may be out of the regulation range and the LEDs will start to flash. It is thus vital for proper operation that the LED string voltage stays within the output voltage range of the LED driver also when the LED current is dimmed to the minimum. LED driver manufacturers rarely define the consequences which may result from this mode of operation.

In residential buildings, the most common kind of dimmers are phase angle dimmers (the standard wall dimmers that almost everyone has at home). These dimmers work by delaying the switch on of the mains voltage after each half cycle. With a short delay the main part of the AC waveform gets through and the lamp burns brightly. With a long delay the lamp burns dimly because only the tail end of each half-cycle gets through. This works very well for incandescent lamps as the hot filament acts like an energy reservoir so that they respond to average power rather than the waveform shape. For phase angle dimmed LED drivers several difficulties might occur. These are typically phase angle range, TRIAC holding current and TRIAC triggering.

The phase angle range has to be limited for LED drivers because they are often powered from the same dimmed AC supply. If the input is dimmed down almost to zero, there is not enough input power to supply the internal electronics. The usual solution is to build dead-space at both ends of the phase angle range. At bright LED levels, the LED driver must wait until the phase angle has reached around 60° to be able to get a reliable synchronization lock and to avoid false triggering due to input voltage variations. Even if a starting phase angle of 60° sounds a lot, the delivered AC power is just dimmed to around 85% at that point. From this point the LED driver is able to calculate the required LED brightness and dim the LED linearly if the phase angle is further increased. Typically the LED system has already dimmed all the way down to zero at around 150°. At this point there is around 2% input power remaining which is just enough to power the internal electronics. From 150° to 180° the driver is in shutdown mode.

But there is also another difficulty with the phase angle range - the dimmers themselves. Most dimmers don´t actually dim down to zero because of an old specification that even a fully dimmed bulb should glow a dull red to warn electricians that power is still applied. What was a good safety idea for incandescent light makes it very difficult for LED power supplies because at 10% dimming, LEDs will still shine brightly.

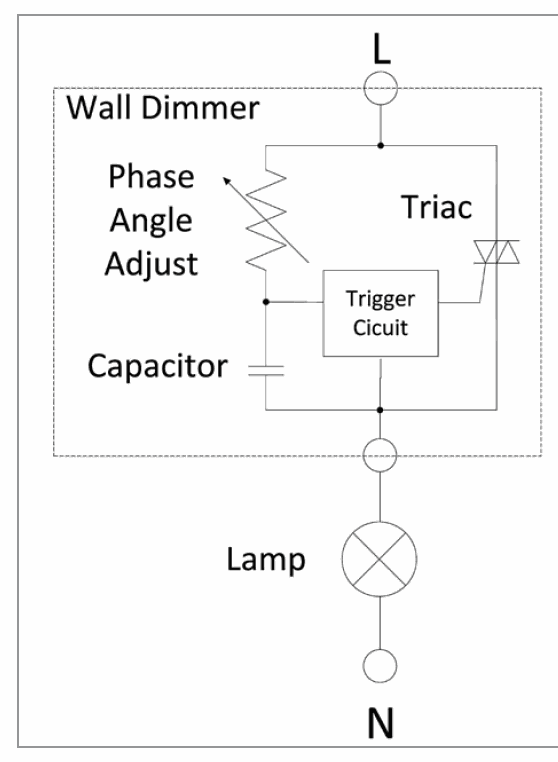

Figure 3: Basic TRIAC dimmer circuit

Figure 3: Basic TRIAC dimmer circuit

Another issue with the TRIAC dimmers are the holding current and triggering threshold. As shown in figure 3, the most basic TRIAC dimmer circuits have no internal reference voltage and so the TRIAC relies on current flowing through the load to return path to neutral. TRIAC dimmers were basically invented to handle a hundred watts or more required by typical incandescent bulbs. LED loads are typically under 20 watts and so the current flow often is not enough to reliably trigger the TRIAC, even at full power. The situation can get worse at very low dimming levels where only a few watts are being dissipated by the LED load. One solution to ensure that the TRIAC triggers reliably is to add a switchable artificial load inside the LED driver, which then turns off as soon at the TRIAC fires to maintain the efficiency advantages of LED lighting. To reduce costs, several low quality LED power supply manufacturers use crude timing circuits, which can easily generate false triggering with loads less than 100% or with certain TRIAC dimmer types. This means that an additional load may be necessary for the proper dimming function. There is a common story about electricians that add an incandescent bulb hidden above the ceiling to get the dimmer working properly with LED lighting. Not the most eco-friendly solution!

Figure 4: RECOM lighting provides a video where this flicker is shown with a low cost LED driver using an oscilloscope to see the conducted interference generated on the main waveform: youtube.com/ recomlighting

Figure 4: RECOM lighting provides a video where this flicker is shown with a low cost LED driver using an oscilloscope to see the conducted interference generated on the main waveform: youtube.com/ recomlighting

Last but not least, false triggering is also a problem with TRIAC dimmable LED drivers. At 50% dimming, the AC waveform is switched on at the peak input voltage, so the rate of change of input voltage is at the maximum. The reason is that at each half cycle the input current jumps directly to the maximum and thus causes undesirable inrush currents and overvoltage spikes. This might force the input EMC filter to oscillate with the sharp changes of the input voltage. The resulting back current pulse can sometimes de-trigger the TRIAC and so the LED starts to flicker as the TRIAC switches rapidly on and off within a mains half-cycle.

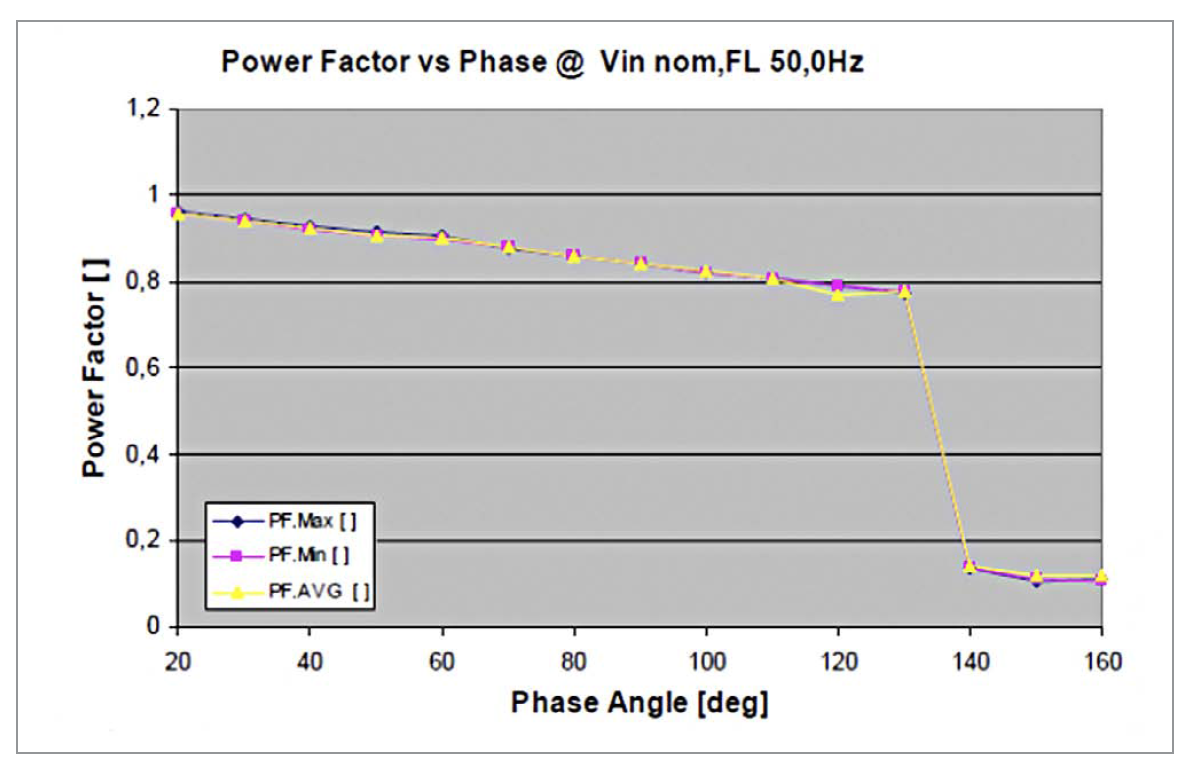

Completing the circle, we are back to terms of power factor and THD. At the beginning we found out how to meet the limits of the EN61000-3-2 standard which is defined with full load and a clean sinusoidal AC Voltage input, but it is even more complicated with an irregular wave form of a TRIAC dimmed input and with less than “full load”. Actually the standard doesn´t define the test conditions in the case of dimming and simply ignores it. So test houses doing the certifications also do not check. This could lead to products which have a really good PF and THD in the datasheet but still generate significant harmonic mains distortion when dimmed – especially at 50% brightness. There are only two ways to really figure out the characteristics of a LED driver when dimmed. The first one is to build a test-rig of the lighting application to find out if LED driver and dimmer interact as expected and measure the actual PF and harmonics using a calibrated AC power meter. That’s the hard way. The other possibility is to choose trustworthy manufacturers who are prepared to provide comprehensive test reports which include for example PF vs. Phase Angle as shown in figure 5.

Figure 5: Test results of the Power Factor vs. Phase Angle

Figure 5: Test results of the Power Factor vs. Phase Angle

Conclusion

Many manufacturers offer a wide range of AC/DC LED drivers from a few to some hundred watts. Although power factor correction is required only for products with more than 25 watts, high quality manufacturers integrate a PFC also below that power level, for instance RECOM’s RACD series provides active PFC from 12 watts as standard.

Well-designed drivers offer flicker-free, linear TRIAC dimming from 100% down to zero. For example, the RACD 20 series is equipped with a special developed input circuit which maintains PF, Class C Harmonics and THD over a wide range of input voltage, load and dimming conditions. Such drivers are an ideal solution for many LED systems where trouble-free TRIAC dimming is needed. In addition it is relevant that products are all UL and EN certified and equipped with a long design lifetime.