Background Information on the Luxeon C LED Family from Lumileds

In an exclusive interview, Rahul Bammi, Vice President of Marketing & Product Management at Lumileds, and David Cosenza, Product Manager for the Luxeon Color LED Family, disclosed some background information on why this new product family was designed and why the very specific, new, and unique properties were implemented.

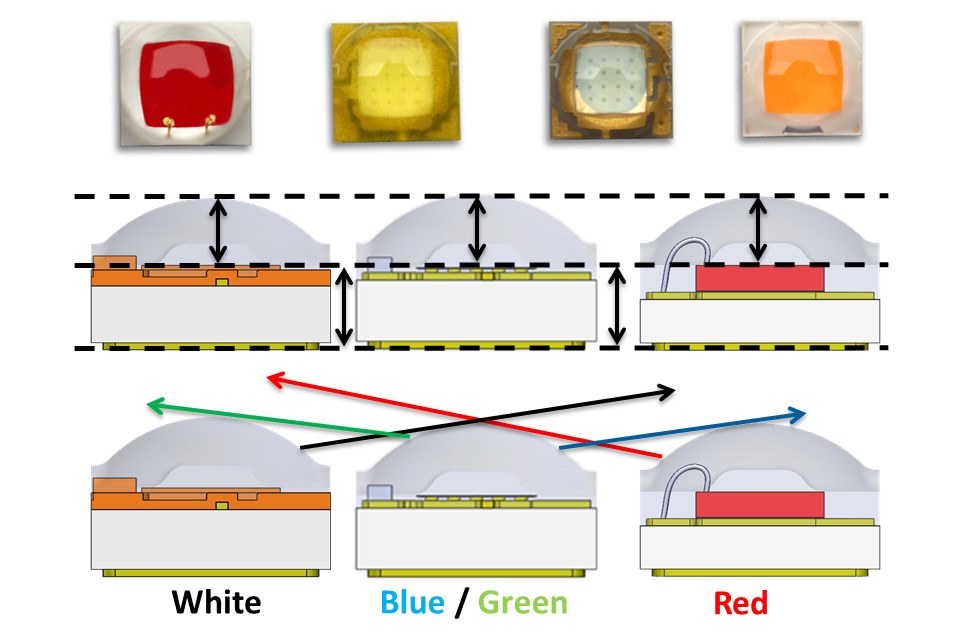

The new product line shows many unique features and properties that are clearly application driven. This is probably a result of Lumileds formerly being a subsidiary of Philips - one of the world’s largest lighting companies. The new product line is optimized for the ease of the module or luminaire designer and improvement of the final product’s light quality. Everything that was technically possible has been done to provide a broad range of 18 LEDs in different colors with harmonized technical parameters by the end of 2015. The harmonization begins with very obvious parameters, like geometric dimensions, but that is by far not all. The thermal resistance, the focal length of the semi-domed LEDs and the typical angle included are optimized or equalized as advantageously as possible. While it might seem obvious that this should be done, it is a big technical challenge because four completely different LED technologies need to be optimized to satisfy this ambitious objective.

For the optics engineer the identical focal length for all LEDs in combination with an almost identical light distribution, characterized by the total included angle, are very important advantages. For an application with a certain specification, just one lens or reflector needs to be designed. This optics can be used for any color out of the broad Luxeon C portfolio delivering identical light distribution. In addition, in multi-color applications, the identical lens or a lens array with identical properties for any segment of the array can be used. This design simplification also helps to reduce costs significantly, and it may also help to improve system performance. With an identical focal length, products with much reduced color fringing, virtually without the so-called halos, can be designed. This is a requirement that is especially important in high quality applications like stage lighting or studio and TV lighting, but also absolutely desirable for architectural lighting and many other applications.

Another point is the measures taken to improve system performance. For Lumileds, this means finding the perfect balance between efficiency, luminous flux and source size. As we all know, domed LEDs help to improve flux gain, but the drawback of this technology is the magnification of the source by the dome. In contrast, the unmagnified small dimensions of the light source of undomed LEDs allow a more compact optical design at the cost of flux gain. With their so-called semi-dome design, Lumileds combines the best of both worlds. The flux gain, compared to undomed LEDs like the Luxeon Z, is improved significantly without significant magnification effects, which means that the source size for the secondary optics design appears to be about 23% smaller than in traditional domed LEDs like the Luxeon Rebel. This improves candelas per lumen performance and provides high luminance. It also allows a much compacter design, using less material for products with similar performance. The flat semi-dome (low-dome) design also minimizes or even eliminates cross-talk between the different LEDs of an array. This is especially important when blue/royal blue LEDs are combined with phosphor converted LEDs like white or PC amber. Cross-talk is especially undesirable because it could excite the phosphor of a completely turned off white or other PC converted LED in a tightly packed system and cause a distinct color shift.

Compact design and high performance are also supported by the small 2x2 mm physical dimensions and the low thermal resistance of the package. The Luxeon C thermal resistance is approximately half the thermal resistance of currently competing products on the market. This is achieved by using a ceramics substrate. The low thermal resistance gives the developers different advantages. They can drive the LEDs harder for higher luminous flux and run the LEDs cooler to extend lifetime. And they can design a luminaire to maintain color stability and constant luminous flux during operation. Both physical dimensions and low thermal resistance allow designs with high packing density.

Very important for a quick and reliable development is the newly introduced Hot-Testing and Hot Binning for all colors. As 100% of the shipped LEDs are tested at 85°C, a very realistic temperature for luminaire designs, a first estimation of how a design could look can easily be done. Cost intense iterations for coming to the final design can be reduced significantly.

More details can be discussed with Lumileds' experts at LpS 2015 from September 22nd to the 24th, 2015 in Bregenz, where Lumileds will be exhibiting the new product line.

For technical specifications, you may also download the Luxeon C Datasheet