An Economical Omnidirectional A19 LED Light Bulb by the Industrial Technology Research Institute

Since 2009, when the Japanese government was vigorously promoting LED bulbs in end-market applications, they have become mainstream commodities in the LED lighting market. Chen-Peng Hsu, project manager of Electronics and Optoelectronics Research Laboratories at Industrial Technology Research Institute (ITRI), introduces the R&D 100 award-winning invention of an omnidirectional A19 LED light bulb that is light weight and economical.

In 2009 the EU voted to ban all incandescent bulbs starting in September 2012. The US followed suit and will ban them starting January 2014. Before they were completely outlawed, there were still enthusiasts for incandescent bulbs for a variety of reasons. The majority of consumers want to be a part of the global effort to reduce carbon, in any way they can. Most people don’t mind paying slightly more for green products than the original non-green that needs to be replaced – in this case, a home light bulb. However, if the extra cost to conserve energy becomes difficult or unaffordable for people, using green products could become difficult, making the promised green technology carbon reduction unlikely to happen. This means that until it is mandated by law, most households will most likely stick to the old technology of incandescent and compact fluorescent lamps.

ITRI’s project team was assigned a task to develop a commercially viable LED light bulb. Team members soon realized one simple fact: Technologically, LED light bulbs are ready for the mainstream, but the price just isn’t what people are willing to pay. LED light bulbs have been around for a while to replace traditional incandescent and CFL. The only reason people don’t purchase them is because of consumer price. For the majority of consumers, their main concern when using LED light bulbs is not how much electricity it can conserve, it is the cost. A few LED bulbs that are more energy-conserving won’t make a noticeable difference on the household electricity bill. Even if it did, the savings don’t justify the additional cost for the bulbs.

The purchasing power of the few consumers willing to pay more than the “mainstream price” does not constitute the drive for a sustainable and self-propelling market that would contribute significantly to carbon reduction.

Thus, the target was to develop a technology that manufactures quality LED bulbs cheap enough, not only to compete for the market share, but also to encourage voluntary LED bulb use before it is required by law. This is what ITRI’s LED bulb technology is required to do.

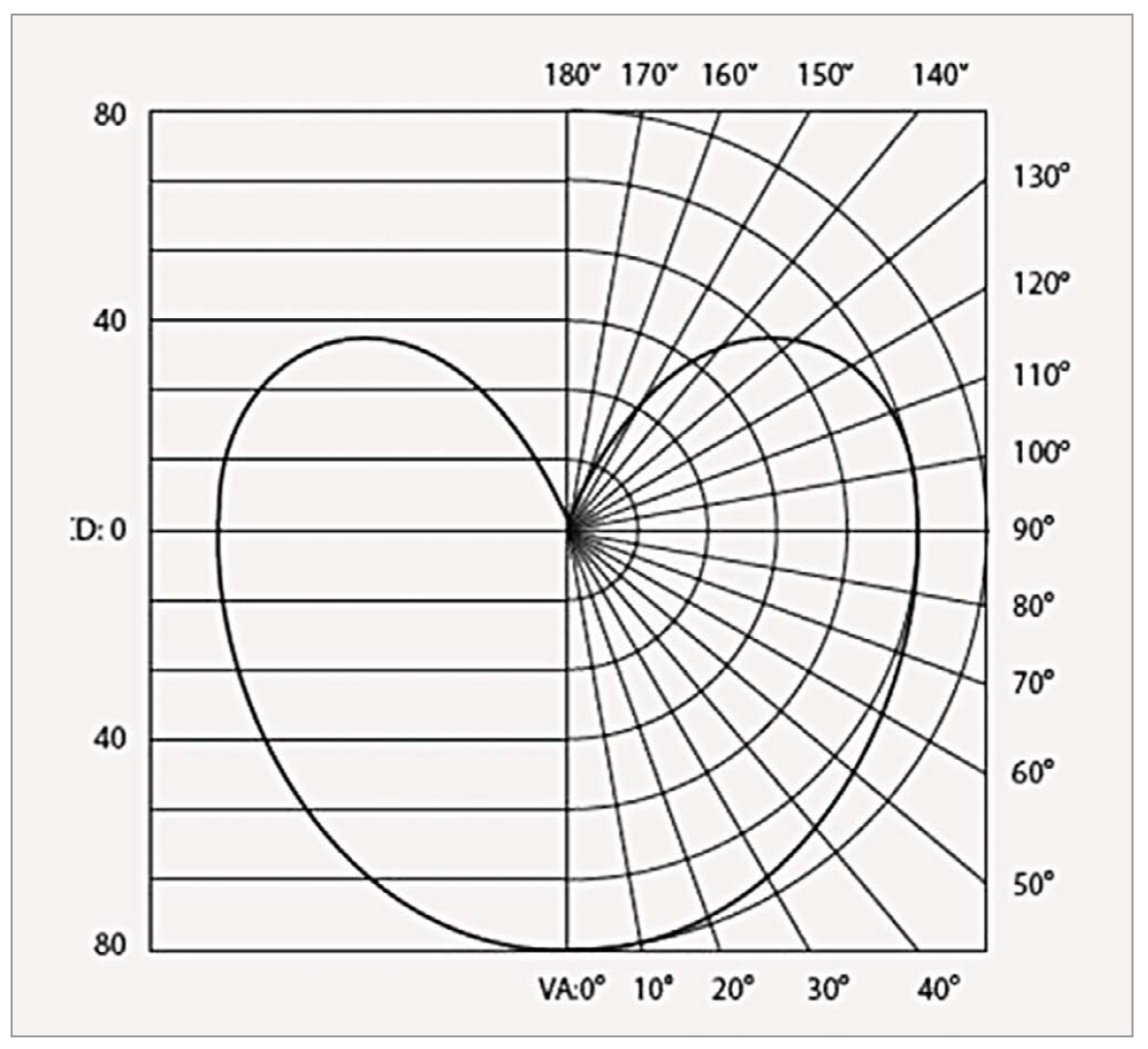

Traditional 60-watt bulbs have an output of 800 lumens and above, with an illumination angle of 270° (Figure 1). However, incandescent bulbs generally have poor luminous efficacy, and are not a source of cold light. The more light they emit, the more heat they produce, and both heat and light are transmitted to the illuminated area. This is why LED manufacturers have been doing everything they can to develop LED bulbs that can eventually replace incandescent bulbs. Figure 1: Luminous intensity distribution of traditional incandescent bulb

Figure 1: Luminous intensity distribution of traditional incandescent bulb

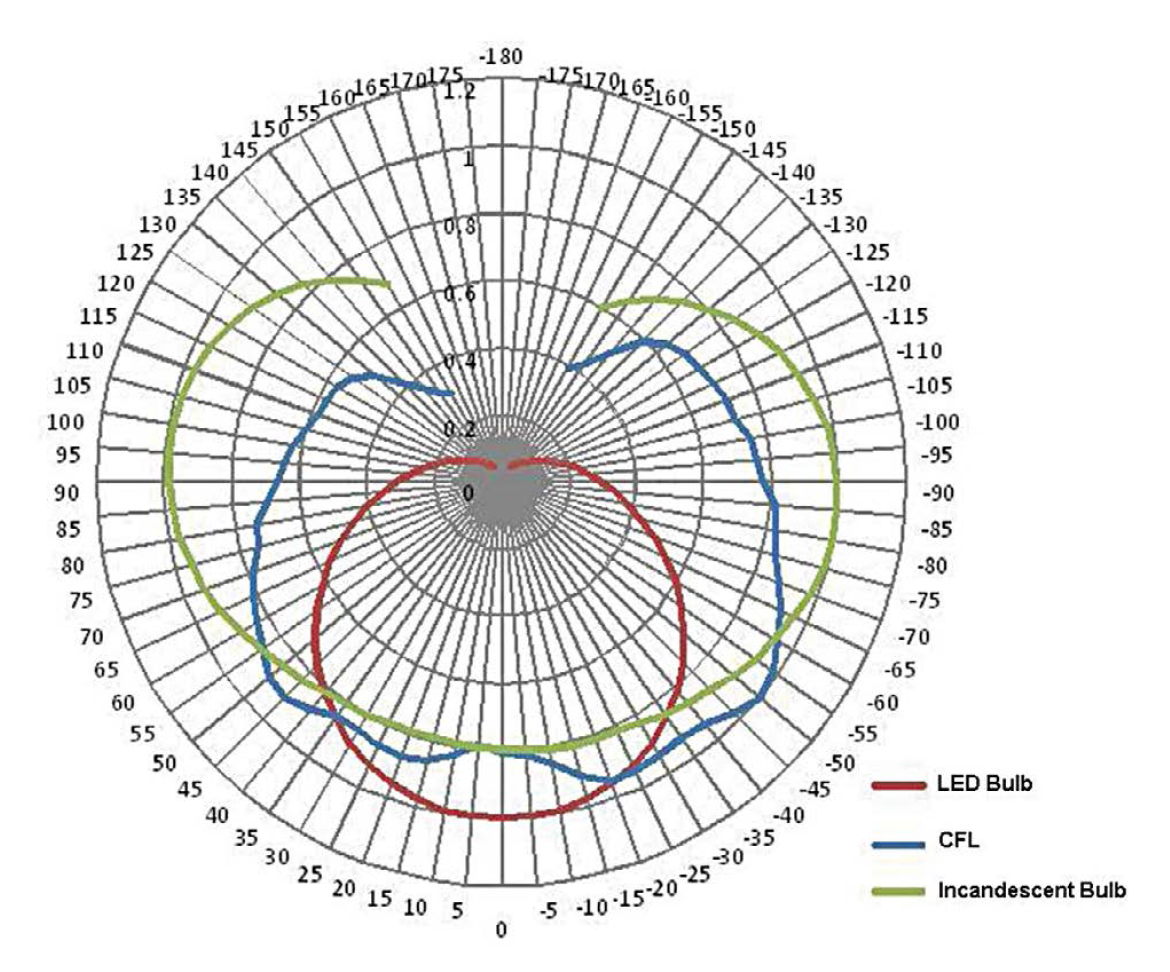

LED manufacturers have invested a lot of resources in research and development and produced a series of LED bulbs with diversified choices to consumers. In general, most commercial LED bulbs are non-omnidirectional and have illumination angles of approximately 140° (Figure 2). In addition, less powerful bulbs with a lower luminous flux output claim to be able to replace 60-watt incandescent bulbs because they produce the same illuminance or lux on a workspace. In fact, these LED bulbs cannot produce the same or similar lighting effects as an incandescent bulb. This is also true for some of the improved LED replacement bulbs that are able to deliver over 800 lumens. This poses problems for many lighting applications.

Figure 2: Comparison of intensity distributions of different light bulbs: LED bulb (Red Curve), CFL (Blue Curve), and incandescent light bulb (Green Curve)

Figure 2: Comparison of intensity distributions of different light bulbs: LED bulb (Red Curve), CFL (Blue Curve), and incandescent light bulb (Green Curve)

Therefore, in the last couple of years, first-tier LED lighting companies have presented several second-generation LED light bulbs that stressed wider illumination angles to fit the real light distribution curve of incandescent bulbs. But for now, thermal management, uniform light distribution, luminous efficacy and costs are still major problems. In practice, LED light bulbs have not yet been able to capitalize on technological advantages as expected so far.

The first reason is because of the limited body or heat sink design of the A-type light bulb and insufficient heat dissipation area. The generated heat cannot be effectively and quickly dissipated to the outside air. Therefore, not only the performance of total lumen output, but reliability and durability are influenced. In addition, it is hard to attain a wide illumination angle, high luminous efficacy and cost effectiveness simultaneously.

Omni-directional LED Bulbs

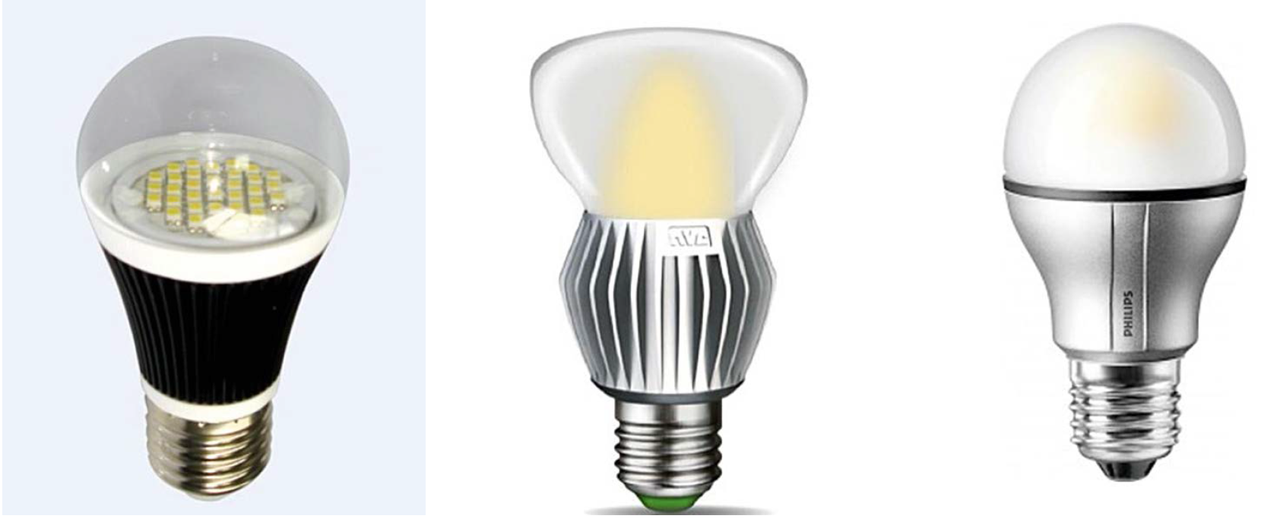

Figure 3a shows a conventional LED bulb where the LED module is mounted face-up and emits light upward. This is mostly due to the radiation angles of LEDs which are essentially about 120 degrees. In addition, bulb structures such as the PCB board and heat sink block downward light. Hence, the conventional design of the LED bulb makes it difficult to obtain omni-directional light. In order to achieve omni-directional light, LED bulb manufacturers have delivered representative products with various improved structures.

Figure 3: Conventional LED bulb (a), Omni-directional light with remote phosphor structure inside the LED bulb from Cree (b) and Philips (c)

Figure 3: Conventional LED bulb (a), Omni-directional light with remote phosphor structure inside the LED bulb from Cree (b) and Philips (c)

Figures 3b and 3c show the omni-directional light bulbs with remote phosphor structures inside the lamps. These bulbs use phosphor cap structures placed above the blue LED light sources to convert emitted blue light into yellow or mixed long wavelength colors and form scattered uniform white light. Then the white light is further scattered by the diffusing bulb globe placed over the phosphor cap to achieve wide illumination patterns.

Figure 4: Philips L-Prize award winning LED light bulb

Figure 4: Philips L-Prize award winning LED light bulb

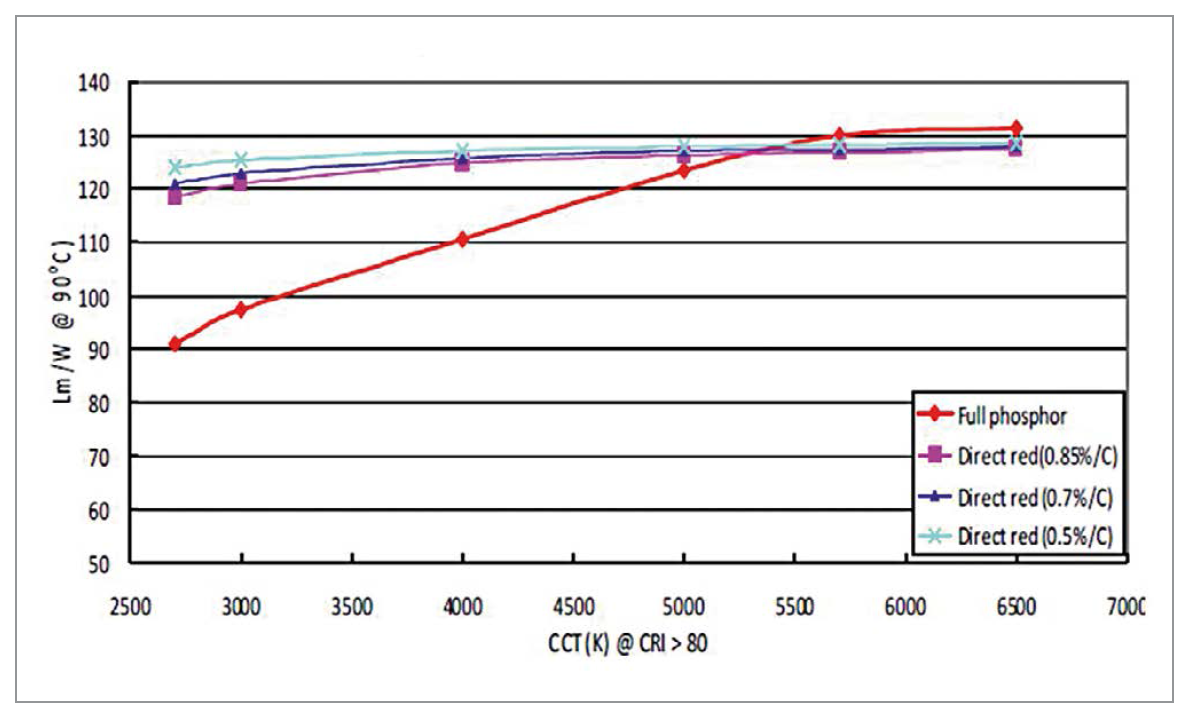

To further increase efficacy, the efficacy bottleneck of a warm-white LED can be overcome by using a red LED instead of lower efficiency red phosphors commonly used in many warm white LEDs, as shown in figure 5. Philips presented another improved bulb design. By utilizing three sets of equally spaced LED modules vertically-mounted on the heat sink, three sets of rigid phosphor shells then cover the LED modules. Firstly, the LED module mixed high power red LEDs to improve warm white efficacy. Secondly, LED modules are combined with the remote phosphor shells building the bulb body. This can effectively emit side or large angle light to obtain omni-directional light. The bulb also won the L-Prize Award in 2011 for highest performance in the replacement of 60-watt incandescent bulbs.

Figure 5: Efficacy of white-LEDs with full phosphor (red curve) and red LEDs (other curves), data provided by Epi

Figure 5: Efficacy of white-LEDs with full phosphor (red curve) and red LEDs (other curves), data provided by Epi

In addition to remote phosphor, secondary optics is the most common method used to increase the illumination angle of the LED bulb. Figure 6 shows different LED bulbs use reflectors (left) and a secondary lens (right) to reach wide illumination angles. The concepts are similar to side-emitting lenses that used to be applied in LED backlights. The reflectors or lenses are placed on the LED module inside the light bulb. This changes most directions of the light towards large angles and then the bulb globe diffuses the light to generate a uniform light pattern.

Figure 6: Omni-directional LED bulbs using secondary lens, left is from Sharp and right is from Toshiba

Figure 6: Omni-directional LED bulbs using secondary lens, left is from Sharp and right is from Toshiba

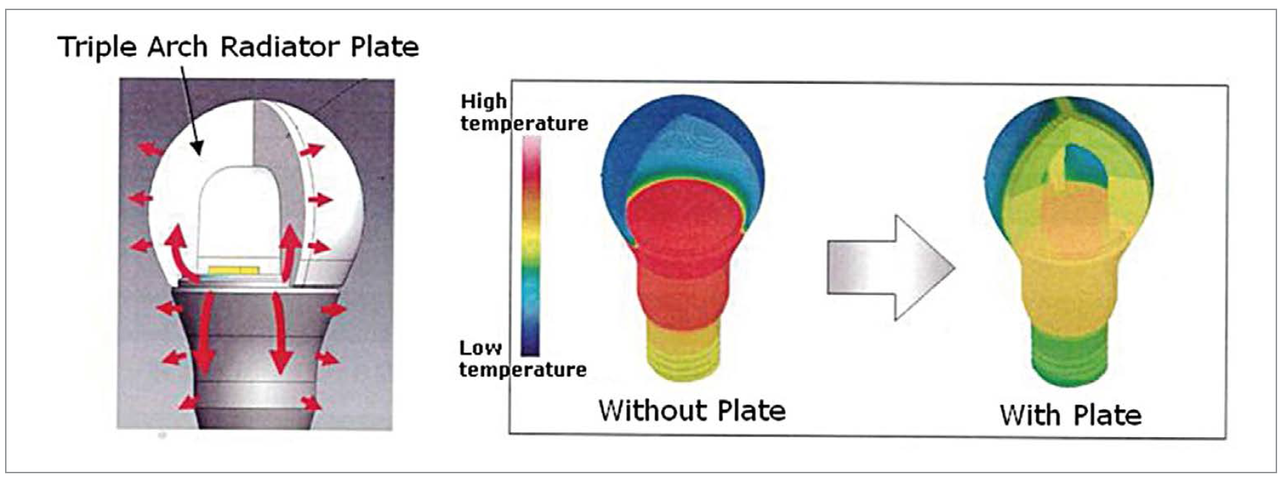

To further increase efficacy, Toshiba improved both optical and thermal designs. By forming three radiator plates (called “Triple Arch Radiator Plate”) like ribs vertically connected inside the light diffusive globe of the LED light bulb, heat can be efficiently conducted from the LED module on the bottom to the radiators and released to the outside. In addition, the temperature distribution becomes more uniform. This will significantly enhance the efficacy of the LED light source. In addition, radiator plates also play the role of a light reflector and change light directions into large angles. Figure 7 shows the design concept of the new wide light distribution angle LED light bulb proposed by Toshiba.

Figure 7: Heat dissipation design concept of Toshiba’s new wide angle light bulb

Figure 7: Heat dissipation design concept of Toshiba’s new wide angle light bulb

Light&Light™ LED Bulb Technology

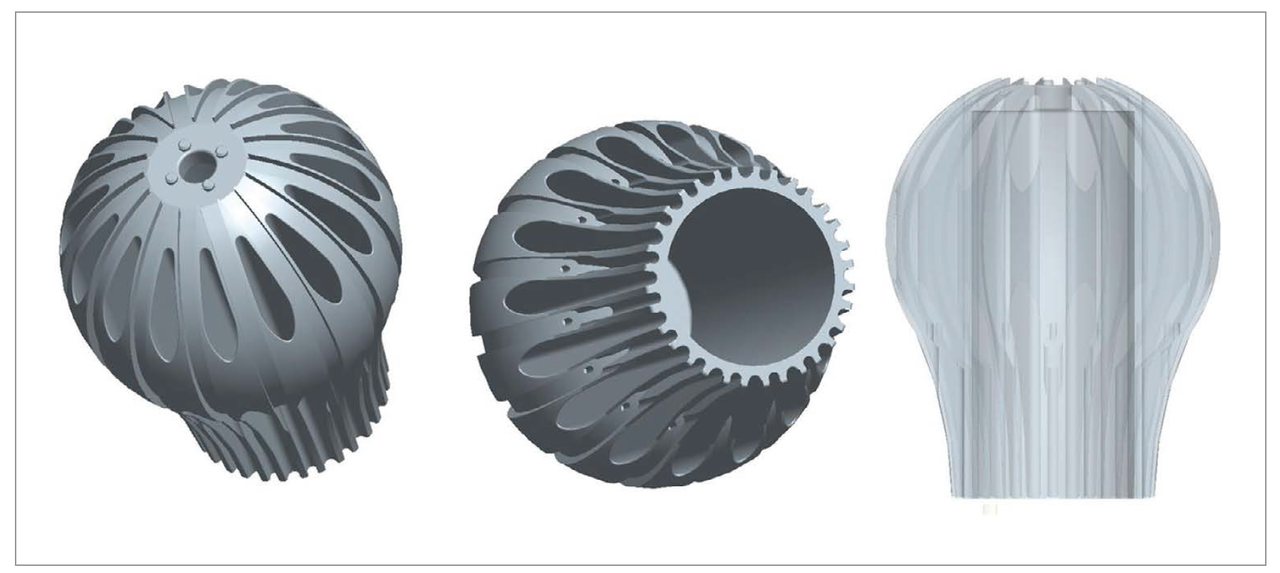

To make a quality A19 LED light bulb that is low in manufacturing costs yet delivers good performance requires a systematic approach that includes every aspect of LED lighting engineering. The ITRI team decided on one single basic principle for the design of the bulb as an effective thermal dissipation system: Increase the overall surface area of all LEDs combined in the bulb system.

This leads to the idea that the heat sink, as a physical structural part of the bulb, can also double as the main bulb body. The whole size of the standard A19 bulb maximizes heat dissipation capacity. Besides this, instead of the conventional approach of using a dozen high power LEDs, the first prototype/ demonstrator bulb uses a large number of ca. 150 low-power LEDs to generate the targeted total lighting capacity. Further, the LEDs need to be distributed as evenly as possible over the entire surface of the A19 heat sink to create an omni-directional lighting pattern of the bulb. Of course, the light distribution pattern can be designed as desired by different heat sink shapes and the arrangement of the LEDs.

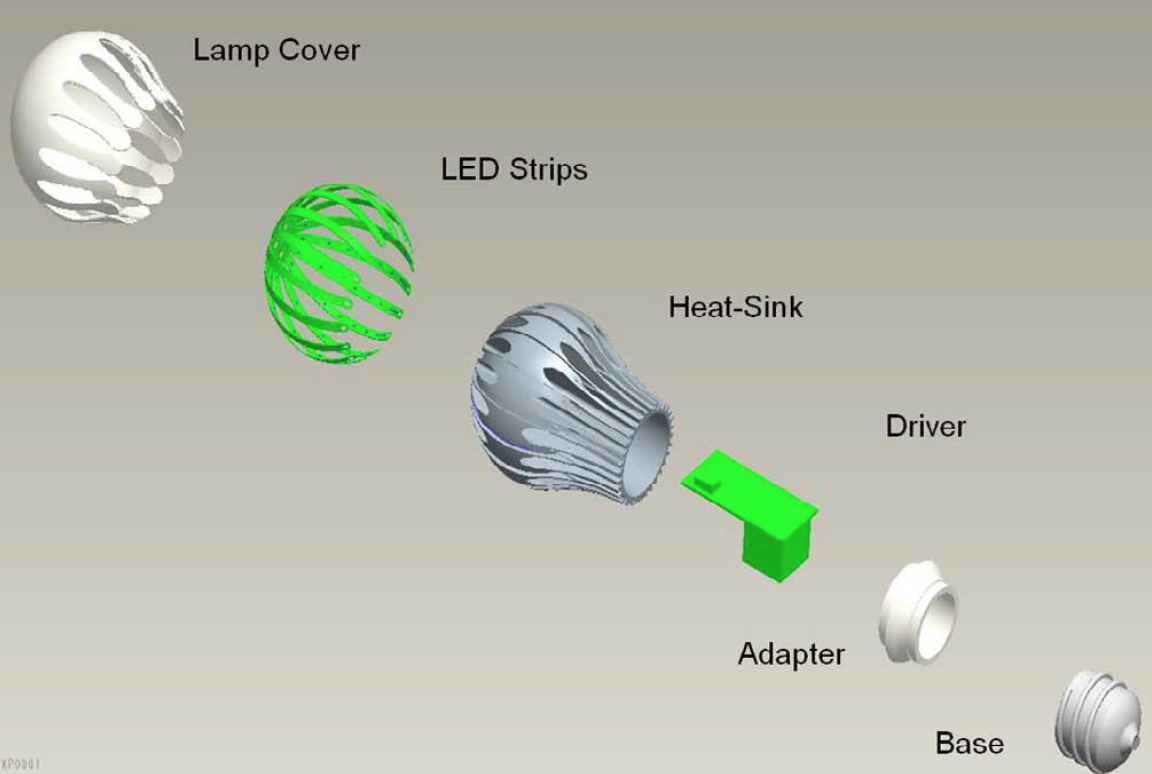

Figure 8: A Light&Light™ bulb broken down in its parts

Figure 8: A Light&Light™ bulb broken down in its parts

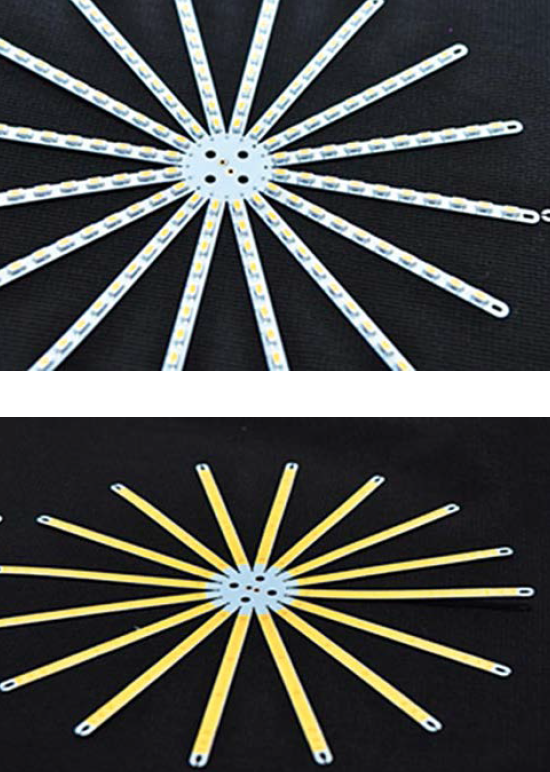

ITRI Light&Light bulb has a simple construction. Figure 8 is an explosion view showing all the components that make up the bulb. The bulb body is a hollow structure much like a conventional bulb except that it has openings to allow air flow for the coiling of the electronic power circuit that actually lights up all the LED chips. All the low-power LEDs are automatically mounted to a flexible printed circuit board forming the LED strips that, before installation onto the bulb body, resembles the shape of a starfish. Figure 9 shows two versions of this 16-hand starfish with each hand carrying ten LEDs. For 10 W total power consumption each LED consumes less than 60 mW during operation. The surface mount device version of the LED flexible PCB was used to construct the demonstrator bulbs, and a COB (chip on board) version that is also suitable for mass production.

Figure 9: SMD (top) and COB (bottom) version of 16-hand starfish-shaped flexible PCB LED module

Figure 9: SMD (top) and COB (bottom) version of 16-hand starfish-shaped flexible PCB LED module

Along the bulb head contour, the large number of LEDs are distributed evenly in a pattern that encloses almost the entire surface. This is to improve even distribution of both the lighting and the heat dissipation. For assembly, the starfish-shaped PCB, literally “grabs” the bulb head with all its hands. The permanent grab is achieved by thermally conductive adhesive, so that heat generated by the LEDs can be transferred to the bulb body for dissipation. A transparent cover then wraps the bulb head to protect the LEDs and also serve as a light diffuser when required.

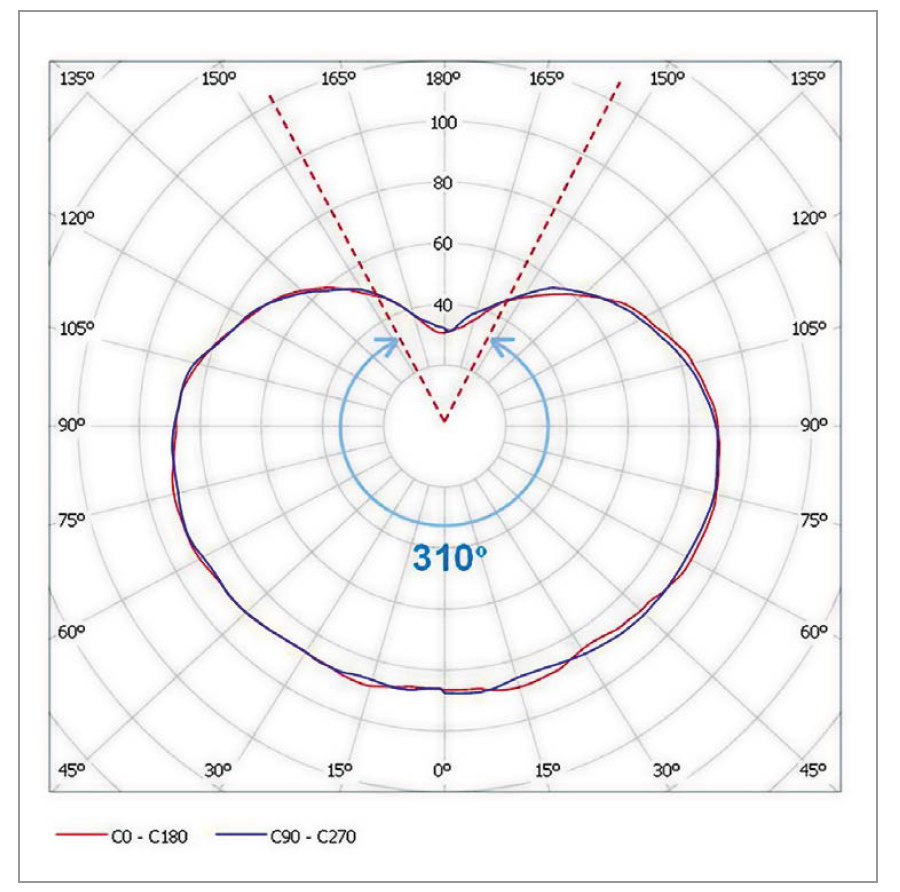

In order to reach the luminous intensity distribution of a 60-watt incandescent bulb, the sixteen flexible LED strips can provide 360° coverage at 16° intervals. By adjusting the spacing between the ten LEDs on each strip, the desired luminous intensity distributions are attained, as shown in figure 10. Due to the curved surface design of the A19 heat sink combining with the LED arrangement, no secondary optics, such as reflector or wide-angle lenses, are needed to achieve wide illumination angles.

Heat Dissipation Design

Conventional LED light bulbs use metallic heat-conducting material placed underneath the light source. Metal materials have high thermal conductivity and conduct heat quickly. However, they do not possess enough surface area for heat convection to the air. This limits the performance of LED bulbs and forces some LED bulb makers to use relatively high-grade LED light sources to get higher efficacy and sufficient luminous flux, which significantly drives up the manufacturing costs of producing an LED bulb.

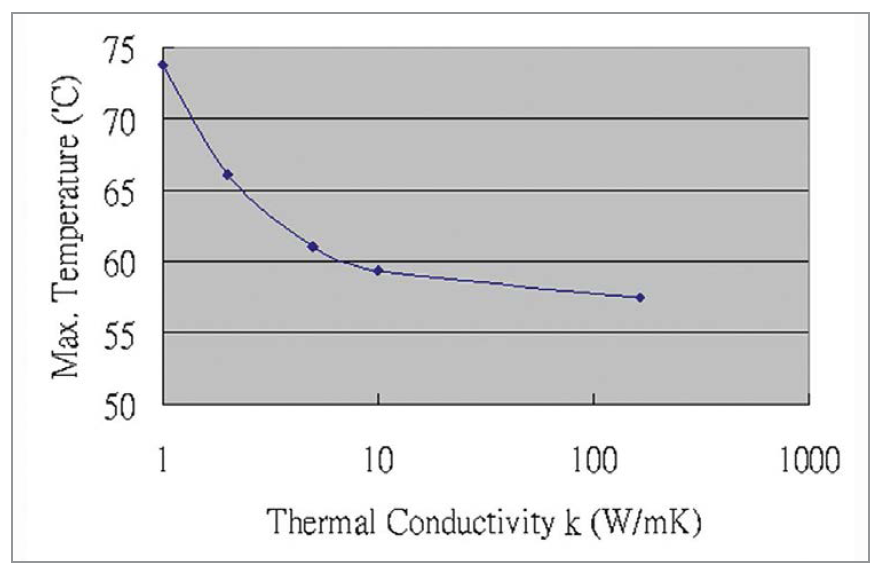

Calculations done by the team suggested that a plastic A19 heat sink will be sufficient – provided that the plastic material must still have a thermal conductivity no less than about 1 W/mK. By contrast, typical ABS plastics (acrylonitrile butadiene styrene) have a conductivity of 0.2~0.3 W/mK, and aluminum alloy roughly 170 W/mK. Then, since the plastic heat sink is inferior in terms of heat dissipation than an aluminum counterpart, the requirement is as large a heat sink surface area as possible.

Figure 10: Omni-directional light distribution of ITRI’s bulb

Figure 10: Omni-directional light distribution of ITRI’s bulb

Figure 11 shows the structural construction of the bulb body of a Light&Light™ bulb. Except for the LED strips and LEDs, every part of the bulb are effectively designed and turned into heat dissipation features. The interstices between the strips contain longitudinal channels. These channels not only increase surface area but are optimized pathways for heat convection. Based on consideration of how the bulb will be used: normally, bulbs are not oriented upwards, but rather downwards. Figure 12 is a comparative simulation for maximum junction temperature of an LED for the A19 heat sink body with different coefficients of thermal conductivity. The results show the maximum temperature is below 70ºC for the total 10 W LEDs distributed uniformly on the surface of the A19 heat sink with thermal conductivity of 3 W/mK.

Figure 11: Heat sink of the new A19 LED bulb concept

Figure 11: Heat sink of the new A19 LED bulb concept

This leads to the call for the design of such a heat sink plastic and another team at the Material and Chemical Research Labs in ITRI developed the high thermal conductivity plastics technology. The material technology that produces the plastic structure used as both the bulb body and the heat sink is key to this bulb in several different aspects. First, it provides a backbone of the bulb that serves as the basic bulb body and further doubles thermal capacity. In addition, the body/heat sink double-role plastic structure has a benefit for the bulb system to be mechanically strong and much lighter than a conventional bulb with a metallic heat sink. The weight of the first prototype/demonstrator bulb is below 100 g compared to conventional equivalent LED bulbs that are usually about 180 g in weight.

And most importantly, it is inexpensive. It can even be recycled to construct another bulb body. Basically it is a thermoplastic composite material with high thermal conductivity. Moreover, by adopting plastic instead of aluminum, the carbon reduction attributable to this material replacement is almost 70% – one more step toward green lighting.

Figure 12: Simulation of thermal conductivity versus maximum temperature for the A19 heat sink

Figure 12: Simulation of thermal conductivity versus maximum temperature for the A19 heat sink

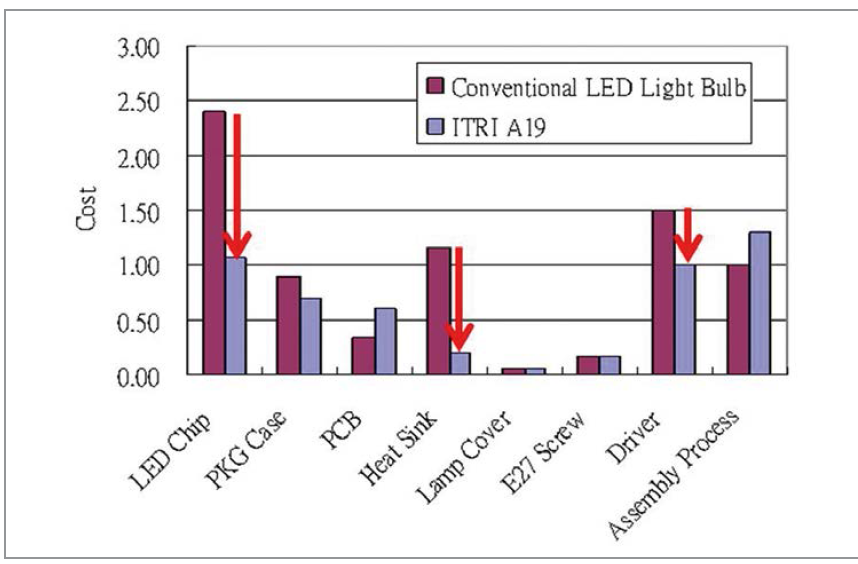

Cost Effective

All the above good characteristics of this Light&Light™ technology add up to an LED bulb that is relatively lower in cost to manufacture and delivers almost all of the desirable characteristics an ideal LED bulb can possibly offer. Figure 13 breaks down the cost of a bulb into all detailed items to show how the new technology is able to reduce cost compared to the conventional LED bulb technologies. Figure 14 shows lit-up Light&Light™ bulbs and a comparison with other bulbs that demonstrates its superiority in terms of its light weight, high efficacy of 85 lm/W. This shows that it is really an omnidirectional replacement lamp. The most significant cost reduction is contributed by the use of numerous small LEDs instead of the conventional practice of using a few high power ones. This almost halves the LED costs. The other reasons for cost reduction come from the use of plastic to replace the aluminum alloy heat sink driver due to the electrical isolation of the plastic bulb body and there is no need of secondary optics or remote phosphor structure.

Figure 13: Cost structure and reduction of Light&Light™ bulb compared to conventional LED bulbs. The figures relating to cost are for reference only. They are not absolute values

Figure 13: Cost structure and reduction of Light&Light™ bulb compared to conventional LED bulbs. The figures relating to cost are for reference only. They are not absolute values

Figure 14: A lit-up Light&Light bulb (left) and a comparison between table lamps (right) with a Light&Light™ bulb, a traditional incandescent lamp as a reference and a competitor’s bulb (from left to right)

Figure 14: A lit-up Light&Light bulb (left) and a comparison between table lamps (right) with a Light&Light™ bulb, a traditional incandescent lamp as a reference and a competitor’s bulb (from left to right)

Conclusion

What good is an LED that is too expensive for consumers to buy? ITRI Light&Light™ A19 LED bulb technology is outstanding for one single, most important reason: It has a down-to-the-ground cost to support a market price acceptable to the mainstream without sacrificing performance, light weight, high efficacy, sufficient luminous flux, omnidirectional illumination and colorful body. ITRI Light&Light™ bulb technology beats its competitors in terms of performance and costs. In relation to performance, the technology is superior in its flexibility in lighting distribution characteristics while maintaining high efficacy. It can be tailored to be omnidirectional or more concentrating depending on the application. There is no need for the use of secondary optics, which means it typically reduces lighting efficiency. The advantages of high design flexibility, low manufacturing costs, and a full patent portfolio enable the development of other LED lighting products, not just light bulbs.