A New Technology Is Changing the Tunable White Solutions

Tunable white LEDs are one key element of human centric lighting. Until today, different solutions are currently available but none of them is easy to apply or cost effective enough to speed up the diffusion of human centric lights in building projects. A new approach for tunable white solutions is able to provide flexible lighting for multiple occasions without sacrificing output or going over project budget. Phil Lee, Senior Lighting Engineer from Meteor Lighting will compare this new technology, called ColorFlip™, to conventional tunable white solutions, and talk about current tunable white issues.

Before getting into the new tunable white technology, the disadvantages of conventional tunable white solutions need to be examined to fully capture the latest technological color tuning advancement. LED luminaires have been known to deliver varying light color since the early days of LED lighting with expanded range of potential applications. While tunable white lighting becomes one of the biggest trends in commercial lighting, the demand for efficient, affordable tunable white fixtures is on the rise. Let’s have a look at the issues of conventional tunable white solutions and how the new technology brings changes to the lighting industry.

Issues with Conventional Tunable White Light Source

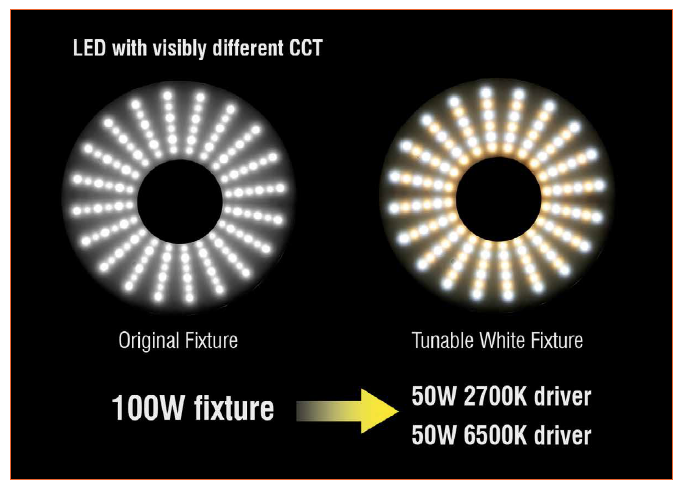

In a conventional LED luminaire light source, surface mounted LEDs with individual lenses are spread out over a large circuit board area where each light source is clearly visible. Most tunable white solutions combine two sets of LEDs: one with a warm-white color and the second with a cool-white color. White colors between the two color points can be created by raising and lowering the output of the two colored LEDs. Color mixing to two extremes of CCT range on a 100 watt fixture results in up to 50% loss of the light source’s total lumen output because the warm and cold LED intensities are inversely proportional to each other. In order to get the full 100 watt output at 2700 K or 6500 K color temperature, double the amount of fixtures is required. In a conventional tunable white design, it delivers inconsistent lumen output throughout the entire CCT range and lumen intensity is lost when color mixing to both extremes without sophisticated control mechanisms.

Figure 1: 100 watt conventional single-color and tunable white light engine

Figure 1: 100 watt conventional single-color and tunable white light engine

Another critical element in tunable white lighting is the control system. Very often, tunable white fixtures can only be paired with specific drivers, which can cause incompatibility issues for retrofit or projects that already have their own dimming driver. In such a case, expensive, standalone control systems need to be specified for the tunable white fixture. Since cost is often the reason tunable white fixtures are not specified, a standalone control system makes tunable white fixtures less feasible. Loss of light intensity during color mixing, undesirable light source visibility, and expensive control systems in conventional tunable white solutions are common reasons why tunable white fixtures have not been used more.

Utilizing Latest Flip Chip Technology

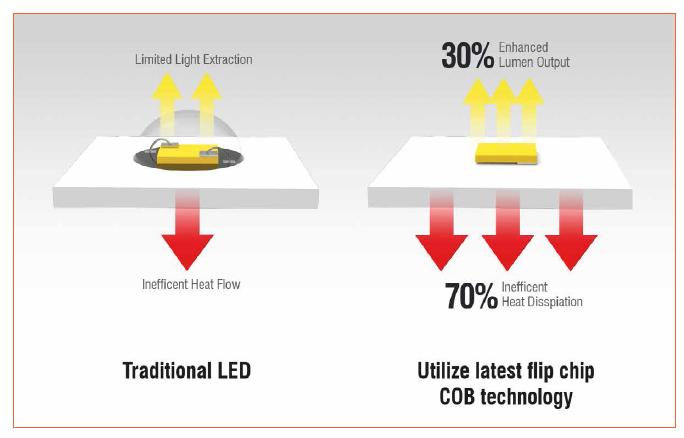

The latest tunable white solutions utilize the flip chip CoB LED technology. Flip chip is a direct mountable LED chip that has 70% better heat transmission than traditional SMD (Surface-mounted Diodes). It significantly reduces thermal resistance and boosts the heat dissipation level which allows the flipped LEDs to be placed in tight formation that fits on a 1.2-inch chip. The goal of the new tunable white solutions is to reduce the price of LED components without a compromise of performance and quality. Flip chip CoB LEDs are not only more cost efficient to produce than SMD LED, the unique packaging style delivers large amounts of lumens at high wattages. Flip chip CoB technology provides also 30% more lumen output than traditional SMD LED.

The advantage of having the LEDs more condensed is the ability to deliver uniform light in all directions.

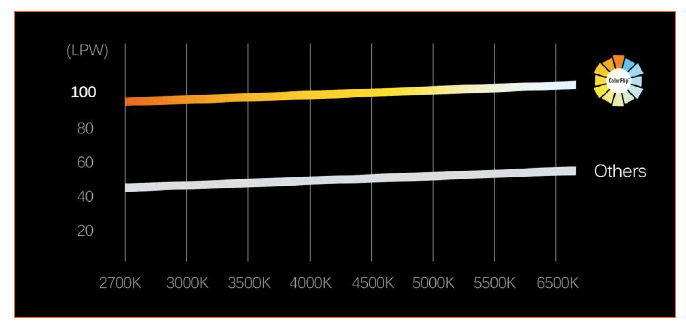

Having a compact light engine also allows tunable white capability in smaller aperture fixtures. The new technology provides the lowest thermal resistance on the market, only 0.3 K/W junction to Ts measuring point, which offers consistent performance and extended lifetime in higher wattage fixtures. Each of these 1.2 inch CoB LEDs produces 10,000 lumens which is currently the highest lumen output for tunable white solutions in the market. While other existing tunable white products have an efficiency rating of 40-50 lumens per watt, the new tunable white solutions have an efficiency rating of 105 lumens per watt and a color rendering index exceeding 85.

Figure 2: Traditional LED vs. flip chip CoB technology - luminous flux and heat transfer capability

Figure 2: Traditional LED vs. flip chip CoB technology - luminous flux and heat transfer capability

Figure 3: Lumen per watt comparison chart between a conventional tunable white solution and the new technology

Figure 3: Lumen per watt comparison chart between a conventional tunable white solution and the new technology

Advantages of the New Technology

While traditional tunable white solutions require increasing the number of fixtures to equal the output of single-color lights, the new unique design and proprietary control board delivers maximum lumen output during color tuning. Its ability to maintain up to 10,000 consistent lumen output during color mixing from 2700 K to 6500 K is a new advancement in the lighting industry. Tunable white capabilities are no longer limited to low wattage commercial spaces. Large-scale projects with ceiling height over 80 ft. can take advantage of the versatility of having more than one color temperature.

With this new technology there is no need to double the number of fixtures to meet foot candle requirements. Tunable white solutions can now be more feasible than ever with the new advancement due to minimal additional cost. It also allows lighting designers to take total control of the color temperature even after lighting fixtures are installed. Color temperature no longer needs to be decided during the planning stage as field adjustable CCT is possible with the new advancement. At about 20% additional cost per fixture, there is no CCT limitations to any projects. Project owners and lighting designers have the flexibility to adjust color temperature of the space to meet its needs.

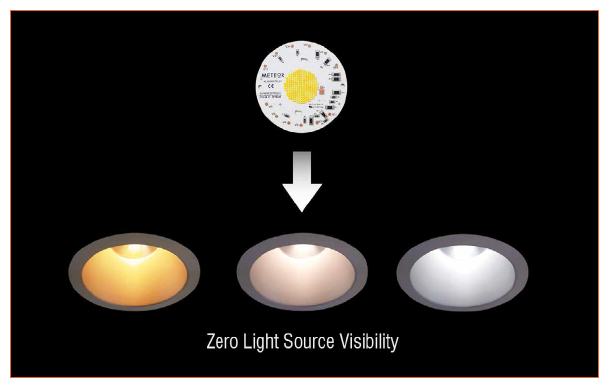

The precision engineering delivers a smooth and uniform transition between color temperatures. LED light source imaging does not appear with this technology which provides a more desirable illumination than conventional tunable white light engine.

What sets this new approach apart from other tunable white solutions in the market is its ability to deliver high lumen output for large-scale projects such as convention centers. The tunable white solutions not only change the ambiance but the function of the space to fit different events. For example, it answers to a multi-purpose convention center’s requirements to have a lighting fixture that would serve as bright intense light for tradeshows, consumer shows and also able to dim to softer and warmer light for banquets. By adjusting the intensities and color temperature in a space not only creates a mood change but allows the same space to be used for different occasions. It is an advantage that is not permitted with traditional metal halide highbay commonly used in convention centers.

When developing this new technology the objective was to allow maximum practicability, whether for new construction or retrofit projects. Its new control unit and driver technology allows it to bring full compatibility to every 0-10V and DMX control system that conforms to industry standards. The technology developers are aware that controlling tunable white luminaires can be challenging as different manufacturers use different approaches. Some even provide proprietary control devices, which often rely on an existing protocol with a customized user interface or hardware. It is paired with proprietary control units which allow it to work with all other 0-10V and DMX control systems.

Figure 4: Zero light source visibility because of the use of tiny flip chips on the CoB

Figure 4: Zero light source visibility because of the use of tiny flip chips on the CoB

Figure 5: Comparison between the appearances of 2700 K and 3500 K CCT in a convention center

Figure 5: Comparison between the appearances of 2700 K and 3500 K CCT in a convention center

Conclusions

What the new technology brings to the lighting industry can be summarized into three areas-efficiency, quality, and cost. This latest advancement brings flexibility to lighting a space, whether in a classroom, hospital, recreation center, convention center, or worship facility, lighting requirements can be fulfilled.

The light engine delivers up to 10,000 lumen consistent output during color mixing from 2700 to 6500K CCT. It beats all other tunable white solutions at 105lm/W efficacy. Specially designed with flip chip technology for improved heat dissipation and higher lumen output, consistent performance and extended lifetime in higher wattage fixtures is provided.

Due to the advanced flip chip CoB technology, LEDs can be arranged closely to keep the size of the light engine to a minimum. The compact sized light engine can be incorporated into smaller aperture fixtures, expanding high lumen tunable white capabilities to more fixture designs. The condensed formation of LEDs generates a more uniform illumination from all sides. With the flip chip CoB, LED light source imaging does not appear, which provides a more desirable illumination than conventional tunable white lights.

With conventional tunable white solutions, increasing the number of fixtures is needed to meet foot-candle requirements as lumen output is significantly decreased at both extremes of the CCT range. Doubling the number of fixtures means doubling the cost. The new technology delivers consistent high lumen output throughout the color temperature range. At about 20% per fixture, project owners can take advantage of the versatility of tunable white lighting without doubling the project budget.

(c) Luger Research e.U. - 2017