Cooper Lighting Expands Halo LED Recessed Downlight Offering

Cooper Lighting, a division of Cooper Industries plc, has expanded its Halo LED H7 Collection offering additional choices in LED color temperatures and higher lumen options.

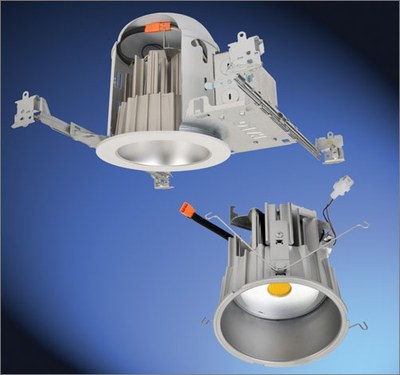

The 6” LED downlight product line expansion–from the original Halo LED 600 Series–now includes the Halo LED 900 Series and Halo LED 1200 Series, offering a wide and versatile selection of energy-efficient LED recessed downlighting options for general lighting in commercial, retail, institutional and residential applications.

Designed for new construction projects or to retrofit existing 6” nominal compatible housings (with an Edison screw base adapter included with the module), the Halo LED H7 Collection features excellent color rendering (80 CRI) and offers the industry’s widest selection of color temperatures (2700K, 3000K, 3500K and 4000K). The superior optical design yields productive beam lumens providing smooth, even illumination, excellent cutoff and extremely low glare.

Consuming less than 15W, the Halo LED 900 Series modules deliver between 511-945 lumens–up to 66 lumens per watt (LPW)–depending upon the selected trim and color temperature. The series exceeds the light output and distribution of a 75W PAR30 or PAR38 halogen lamp, 85W BR40 or a 26W compact fluorescent luminaire.

The Halo LED 1200 Downlight Series delivers in the range of 862-1541 lumens depending upon the trim and color temperature selected and offers comparable light output and distribution of a 90W PAR38 halogen lamp, a 120W BR40 incandescent lamp, or a 32W compact fluorescent luminaire (lamp & reflector trim). Consuming only 24.8W, the high efficacy luminaire delivers up to 62 LPW. The Halo 1200 Series LED modules are universal voltage (120-277V).

The downlights are designed to deliver greater than 70% of initial lumens at 50,000 hours and feature a full range of dimming capabilities. For added retrofit capability, a new Retrofit Adapter Band (ML7RAB) is available for retrofitting housings that do not have torsion spring receivers.

The Halo LED H7 Collection is ENERGY STAR® qualified and can be used for California Title 24-2008 and IECC-2009 High Efficacy compliance with designated LED modules and LED trims. The LED downlights go through a serialized testing and measurement process that ensures color and lumen consistency that exceed ENERGY STAR® Solid State Lighting (SSL) Luminaire program standards.

The Halo LED H7 Collection is ideally suited for commercial, hospitality, healthcare, retail and residential applications.

For additional information, visit http://www.cooperlighting.com or email talktous@cooperindustries.com.

About Cooper Lighting:

Cooper Lighting, a subsidiary of Cooper Industries plc (NYSE: CBE), is the leading provider of innovative, high quality interior and exterior lighting fixtures and related products to worldwide commercial, industrial, retail, institutional, residential and utility markets. As lighting technologies have advanced over the years, Cooper Lighting has been at the forefront of the industry in helping businesses and communities leverage the latest technologies to improve efficiency, reduce costs and enrich the quality of the environment. For more information, visit HYPERLINK "http://www.cooperlighting.com" www.cooperlighting.com.

About Cooper Industries:

Cooper Industries plc (NYSE: CBE) is a global manufacturer with 2009 revenues of $5.1 billion, approximately eighty-nine percent of which are from electrical products. Founded in 1833, Cooper's sustained level of success is attributable to a constant focus on innovation, evolving business practices while maintaining the highest ethical standards, and meeting customer needs. The Company has eight operating divisions with leading market share positions and world-class products and brands including: Bussmann electrical and electronic fuses; Crouse-Hinds and CEAG explosion-proof electrical equipment; Halo and Metalux lighting fixtures; and Kyle and McGraw-Edison power systems products. With this broad range of products, Cooper is uniquely positioned for several long-term growth trends including the global infrastructure build-out, the need to improve the reliability and productivity of the electric grid, the demand for higher energy-efficient products and the need for improved electrical safety. In 2009, sixty-one percent of total sales were to customers in the industrial and utility end-markets and thirty-nine percent of total sales were to customers outside the United States. Cooper has manufacturing facilities in 23 countries as of 2009. For more information, visit the website at www.cooperindustries.com.