Bayer Polycarbonate Enables Precise Manufacturing with Printed Electronics

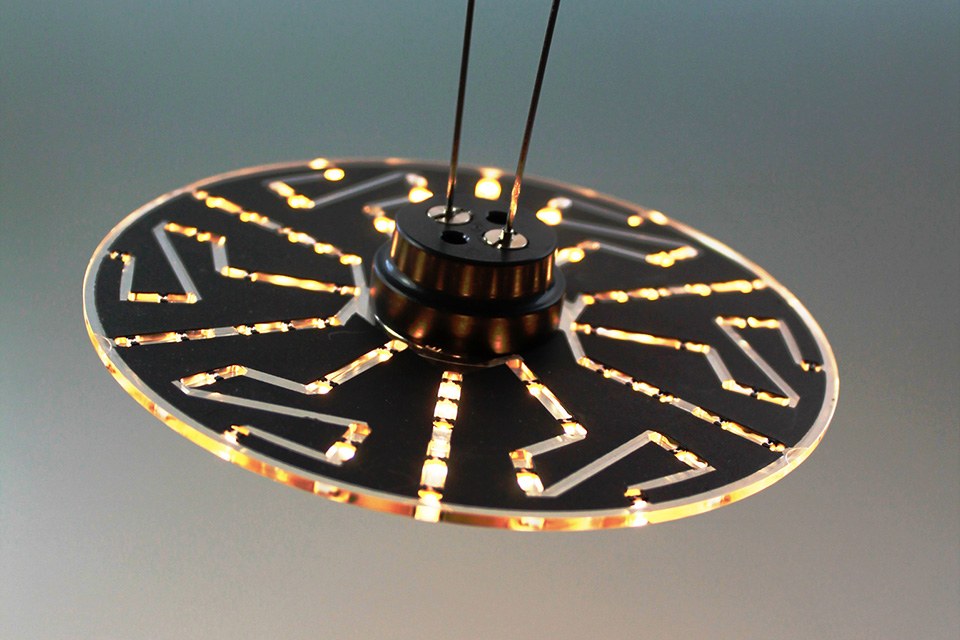

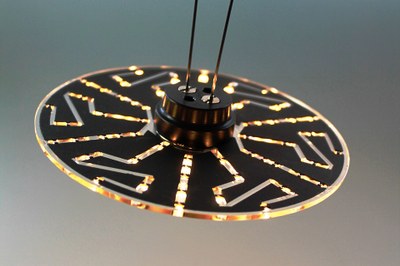

An innovative, extremely flat LED lamp from EDC GmbH opens a whole new range of possibilities for energy-efficient light design. The “F | limyé Flat,” for example, is perfectly suited to those situations where there is little space for lamps or when special design solutions are needed. Based in Langenhagen, near Hanover, the company manufactures this product using Makrolon® OD2015, a special transparent polycarbonate from Bayer MaterialScience.

The special feature of the LED lamp is a flat substrate made from this high-performance plastic. At just 1.8 millimeters, it is as thin as a CD and can be round or square. During injection molding, tiny dimples 1.4 millimeters wide and 1.2 millimeters deep are incorporated into the substrate. These then take the numerous little LEDs. “The polycarbonate's outstanding reproduction accuracy enables much higher precision in forming the dimples than can be achieved with other transparent plastics,” says Axel Wetzchewald from the LED program at Bayer MaterialScience.

Breakproof and dimensionally stable

This material grade was specifically developed for light conductors, optical systems and lenses, and provides a very high level of light transmission even with greater coating thicknesses. It is also shatterproof and boasts excellent dimensional stability across a wide range of temperatures. This enables the finely structured lights to be manufactured with great precision.

ECD has opted not to use conventional circuit board technology in the construction of the LED lamp. “All of the electronic elements required to operate the tiny LEDs, such as resistors and conductor tracks, are thinly printed onto the transparent substrate,” explains Eckehard Schulz, project manager for new technologies at EDC. This is where the excellent print quality of Makrolon® OD2015 really pays off. It is also possible to add microstructures for routing the light. This special design even allows light to escape at the edge – an additional optical effect that has great appeal.

The lighting disk can also be fitted with flat auxiliary lenses or integrated optical systems that focus or diffuse the LED light as required. Diffusers, lens plates or reflectors can be combined or integrated to achieve uniform illumination. This gives rise to diverse potential applications for “F | limyé Flat” in living areas and kitchens, designer lights, and shop and office lighting. Being lightweight, the lamp is also ideal for mobile applications including cars, motor homes and the aviation industry.

Bayer MaterialScience has developed a broad range of polycarbonate materials for LED lamps. The company's stand (N1/N2) at the LED professional Symposium +Expo (LpS) from September 30 to October 2 in Bregenz, Austria, is dedicated to material solutions for the targeted guidance, focusing, diffusion and reflection of LED light.

Find more information at www.materialscience.bayer.com.

About Bayer MaterialScience:

With 2013 sales of EUR 11.2 billion, Bayer MaterialScience is among the world’s largest polymer companies. Business activities are focused on the manufacture of high-tech polymer materials and the development of innovative solutions for products used in many areas of daily life. The main segments served are the automotive, electrical and electronics, construction and the sports and leisure industries. At the end of 2013, Bayer MaterialScience had 30 production sites and employed approximately 14,300 people around the globe. Bayer MaterialScience is a Bayer Group company.