Screw-Down Jumper Assembly and G13 Style SMT Assembly for LED Applications

Tyco Electronics has launched a new board-to-board screw-down jumper assembly for use in LED lighting strips, lighting controls, and channel lettering, and a new RoHS-compliant G13 style surface mount (SMT) assembly and end-cap cover for the solid state lighting (SSL) industry.

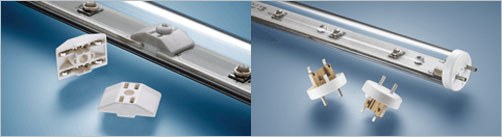

Screw-Down Jumper Assembly:

Tyco Electronics has launched a new board-to-board screw-down jumper assembly for use in LED lighting strips, lighting controls, and channel lettering. The RoHS-compliant jumper, which was originally designed for T8 and T12 fluorescent retrofit tubes, specifically serves the solid state lighting (SSL) market.

The product simplifies the manufacturing process of the above lighting applications by providing the electrical connection between adjacent printed circuit boards (PCBs) arranged in a string of LED PCBs. The screw fastens to threaded holes in an aluminum clad PCB base, or into a separate aluminum heat sink used with FR4 boards.

The two-position jumper fits onto a 16.50mm [.650 inch] wide PCB with features that maintain a 7.0mm [.276 inch] spacing between adjacent boards. The ETL recognized board-to-board connector meets UL 1977 standards.

Product Features:

• 2-position connection assembly

• Connector assembly fits onto 16.50 mm [.650] wide printed circuit board

• 7.0mm [.276] printed circuit board spacing

Applications:

• T8-T12 Fluorescent Retrofit LED Bulbs

• LED Lighting Strips

• LED Lighting Controls

• Channel Lettering

Product specifications include a current rating of 5 Amps, operating temperature of -40 to +105 degrees Celsius, 250 VAC/ 250 VDC voltage rating, and a 1500 VAC dielectric withstanding voltage rating.

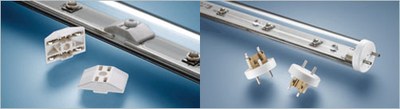

G13 Style SMT Assembly:

Tyco Electronics announces a new RoHS-compliant G13 style SMT assembly and end-cap cover for the solid state lighting (SSL) industry. The product supports printed circuit boards (PCBs) and LED strip lighting modules found in the standard T8 and T12 fluorescent LED retrofit tubes.

The integrated assembly enables high-volume manufacturing of fluorescent LED retrofit tubes by allowing a quick SMT electrical connection to the PCB and a standard pin interface to fixture lamp socket (tombstone) connectors. The product, tape-and-reel packaged to facilitate high-speed processing, is compatible with FR4 and aluminum clad PCBs.

Designed-in features include a surface mount hold-down to provide additional stability of the connector during insertion and/or extraction of the LED tube. The SMT housing material consists of UL 94 V0 rated high temperature resistant thermoplastic for reflow processing on automated equipment. The end-cap cover interfaces with the connector assembly, heat sink and tube, and is packaged separately for ease of assembly.

Product Features:

• 2-position G13 style SMT assembly

• Designed to interface with G13 style SMT assembly, heat sink and tube

• 0.5 inch pin centerline per G13 specification

• Surface mount hold down provides stability during tube insertion and extraction

• High temperature material for reflow processing

Applications:

• Standard T8 Fluorescent Fixtures

• Standard T12 Fluorescent Fixtures

Performance characteristics include: 2 Amps current rating, 250 VDC/ 250 VAC voltage rating, 1500 VAC dielectric withstanding voltage and a 0.5 inch pin centerline spacing per G13 specification. Operating temperature ranges from - 40 to +120 degrees Celsius. The product is ETL recognized to UL 8750 and UL 1993 standards.

For more information on the new board-to-board, screw-down jumper assembly, and the the G13 SMT assembly, contact Tyco Electronics' Product Information Center at www.tycoelectronics.com/help.