Bluegalss Extends Capacity to Demonstrate Low Temperature Multi-Quantum Wells Growth with New MOCVD System

Australian Cleantech company BluGlass Limited has today announced that it has increased its operational capacity with the successful commissioning of a former production MOCVD system at the Company’s Silverwater facility.

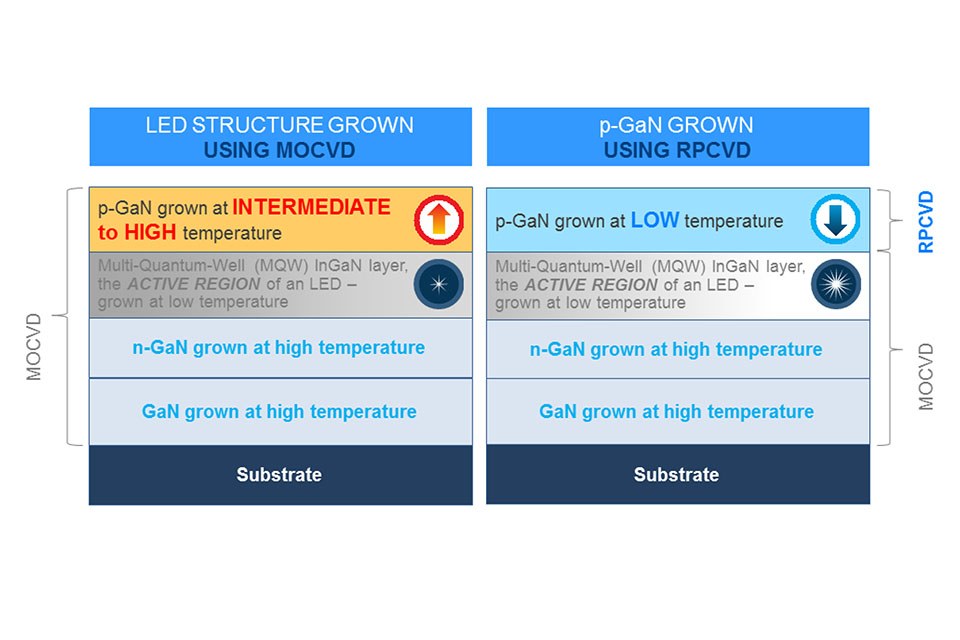

BluGlass has commissioned a Thomas Swan MOCVD system capable of producing 19x2 inch (or 5x4 inch or up to a single 8 inch) LED wafer(s) in a single growth run. The MOCVD system has now been commissioned and qualified to grow the multi-quantum well (MQW) base structures required for the demonstration of the Brighter LEDs milestone. This milestone involves demonstrating LED performance improvement by growing low temperature RPCVD p-GaN on top of MOCVD grown multi-quantum wells (see Figure 1). InGaN quantum wells are prone to degradation at elevated temperatures in the subsequent MOCVD grown p-GaN process steps, resulting in a loss of LED brightness. Growing the p-GaN layer at lower temperatures with RPCVD instead of MOCVD should reduce the MQW degradation, hence resulting in a brighter LED.

The company’s Chief Technology Officer Dr. Ian Mann said today “This system will give BluGlass control of the whole LED structure required for the company to demonstrate an LED performance lift with RPCVD grown p-GaN on MOCVD grown wafers. The key focus of having both MOCVD and RPCVD capability under one roof will be to demonstrate a successful integration of RPCVD and MOCVD to obtain better light output. In addition, it will assist in the performance comparison of the two technologies.”

A second MOCVD system recently arrived at the Silverwater facility which will be installed and reconfigured as an RPCVD system. This will enable the Company to further accelerate the RPCVD development and will also assist in demonstrating the scalability of the RPCVD technology from its current 7x2 inch deposition capability to a 19x2 inch (or up to a single 8 inch) wafer deposition capability.

The commissioning of these new tools will now enable multiple programmes (including GaN on silicon) to proceed simultaneously at the Silverwater facility. BluGlass will also target revenue generation by producing wafer templates as an early market entry point to boost acceptance of RPCVD technology by building credibility in the market place.

BluGlass CEO, Giles Bourne said today “This is an important step forward for the company. Having multiple programmes in place simultaneously will significantly expedite our technology progress. Our primary goal remains now to demonstrate that low temperature RPCVD has the ability to produce brighter LEDs”. He continued “This new MOCVD resource will enable us to simplify this development process by giving the technology team full flexibility of MOCVD run cycles, but also by eliminating the lead-time required to obtain templates from overseas suppliers.”

The Company continues to make progress along its published development roadmaps.

About BluGlass:

BluGlass Limited (winner of the 2013 Australian Cleantech Competition) is an Australian green technology company formed to commercialise a breakthrough in the Semiconductor Industry. BluGlass has invented a new process using Remote Plasma Chemical Vapour Deposition (RPCVD) to grow semiconductor materials such as gallium nitride (GaN) and indium gallium nitride (InGaN), crucial to the production of high efficiency devices such as next generation lighting technology Light Emitting Diodes (LEDs) with advanced low cost potential.

The RPCVD technology, because of its low temperature and highly flexible nature, offers many potential benefits over existing technologies including higher efficiency, lower cost and greater scalability.