Serviceable Indoor Luminaires for a Circular Future

Zhaga enables luminaire manufacturers to design serviceable indoor luminaires with replaceable components that prolong their useful life, contributing to a circular economy. By Jan de Graaf (Signify), Francesco Martini (Inventronics) and Carsten Moellers (Green Gems).

The Right to Repair movement is by no means limited to consumer electronics – it impacts the lighting industry too.

Seen as a key enabler of a circular economy, decision-makers around the world are enacting legislation and initiatives requiring the serviceability of LED luminaires. For example, in Europe, the “Single Lighting Regulation” is in force, setting product design requirements pushing the move to a circular economy. The published provisional agreement of the” Ecodesign for Sustainable Product Regulation (ESPR)“

looks to require that lighting products be designed to not only be more reliable, with a longer lifetime and contain more recyclable material, but also be easier, upgrade and repair. Additionally, it is expected, the future review of the so called “Single Lighting Regulation”, will set additional resource efficiency requirements for lighting products, concerning the removability and exchangeability of light sources and control gears.

At Zhaga, the global lighting-industry consortium with the mission of standardising the interfaces of components of LED luminaires, we call this ‘circularity lighting’.

Defined as products and systems that support the aims of the circular economy through enhanced serviceability, circularity lighting is based on luminaires designed in a modular way and on component interfaces that are based on standardised and widely recognised specifications. In this sense, circularity lighting includes all LED luminaires that are repairable, upgradeable, replaceable.

Zhaga delivers on all these fronts.

Zhaga's Contribution to Modular and Serviceable Indoor Lighting

Since its founding in 2010, Zhaga has been developing and standardising specifications for interfaces of LED modules, intelligent sensors, communication modules and control gear for lighting manufacturers, specifiers and operators to apply in LED luminaires.

Zhaga’s specifications are called Books, with each book defining the interface of one or more component(s) of an LED luminaire. While all Zhaga Books are inherently linked to the concept of circularity lighting, not every Book is needed all the time. In fact, creating a serviceable product or component typically may require only a couple of Books.

Most pertinent to indoor linear lighting are Zhaga Books 7, 14 and 26. Book 7 defines a family of linear and square LED modules that could be used for indoor lighting applications. The LED modules require a separate LED driver (electronic control gear) and are typically mounted in a luminaire by, for example, screws. The only restriction on the light-emitting surface (LES) of the LED modules is that all light should be emitted above the upper surface of the module. This provides maximum design freedom with respect to the placement of LEDs on the module.

Book 14, which has been officially designated as IEC Standard 63356-1, focuses on a family of flat, linear, socketable LED light sources that are suitable for low-profile linear lighting. The standard includes both LED modules (requiring a separate driver) and LED light engines (LLEs) that have integrated control gear. The LLEs or LED modules have a cap/holder system that enables toolless replacement.

Rounding out the modular side of serviceable indoor lighting is upcoming Book 26.

This Book 26 defines a cost-effective mechanical and electrical interface for toolless replaceable linear LED modules, enabling plug and play #interoperability, late-stage configuration of luminaires and supporting #circular economy.

Also relevant to indoor lighting is Book 20, which, together with D4i certification by the DALI Alliance, defines a smart interface between an indoor LED luminaire and a sensing/communication node. The node connects to the LED driver and control system, and typically can provide sensory inputs or enable communication between network components. These nodes can be installed and replaced in the field.

Although not specific to indoor luminaires, Zhaga Book 13 on control gears plays a non-negotiable role in ensuring serviceability by defining mechanical interface specifications of LED drivers can be used in combination with a wide range of luminaires.

Leveraging NFC Technology for Indoor Luminaire Lifecycle Management

Two other Zhaga Books that are relevant to the serviceability of indoor luminaires are 24 and 25, both of which deal with Near Field Communication (NFC) technology. The extremely short-range wireless communication standard allows manufacturers to configure such lighting components as LED drivers to their specifications, both before and after installation – which can play an important role in enabling circularity lighting.

NFC also lets you manage data over the luminaire’s entire lifecycle, from production to installation, maintenance, replacement and repair. Having such lifecycle data not only helps increase efficiency, it also promotes products that use a modular design and that can be easily repaired and upgraded.

Luminaire manufacturers, installers and system integrators now have the option to select a single physical programming tool that will work with all field-maintenance applications from all vendors implementing Book 25 and all NFC-programmable devices implementing Book 24.

Whereas Book 24 is geared towards luminaire manufacturers, Book 25 defines a Bluetooth Low Energy communication protocol for communication between the field-maintenance application on a smart device and the NFC reader. In doing so, it enables maintenance and replaceability with a cross vendor harmonised method of NFC programming for in-field use.

Using Book 25 creates an enormous advantage in the field. For instance, if an LED module is replaced by a more energy efficient LED module, Book 25 ensures that the new operating parameters can be set wirelessly on the driver.

Book 24, on the other hand, allows for configuration by the manufacturer and for customer-specific operating parameters. It also allows the configurations to be set on demand and in accordance with the customer’s specific parameters. Furthermore, because an exchange of the driver is usually not necessary, it avoids waste and extends the service life of the driver.

Making serviceability of components of luminaires transparent

Together, the interface specifications established by the Zhaga Books enable an interoperable and serviceable ecosystem of luminaires and components – one that is repairable, upgradeable, replaceable and durable.

To illustrate, let’s compare a non-Zhaga luminaire with a luminaire containing Zhaga components.

By choosing a non-Zhaga luminaire you might invest into a luminaire with a limited serviceability. You will certainly face logistical resilience challenges as you have chosen proprietary components that might not be offered by another supplier.

However, a luminaire containing a set of Zhaga components offers for sure a level of serviceability. That’s because Zhaga certified components comply with global interface standards, meaning that they can be exchanged with certified components from different manufacturers, which in turn enables repairs and functional upgrades.

In other words, while the end goal is to make the luminaire serviceable, a luminaire is only serviceable when it uses components that are serviceable themselves. By offering serviceable components, Zhaga helps make serviceable luminaires possible.

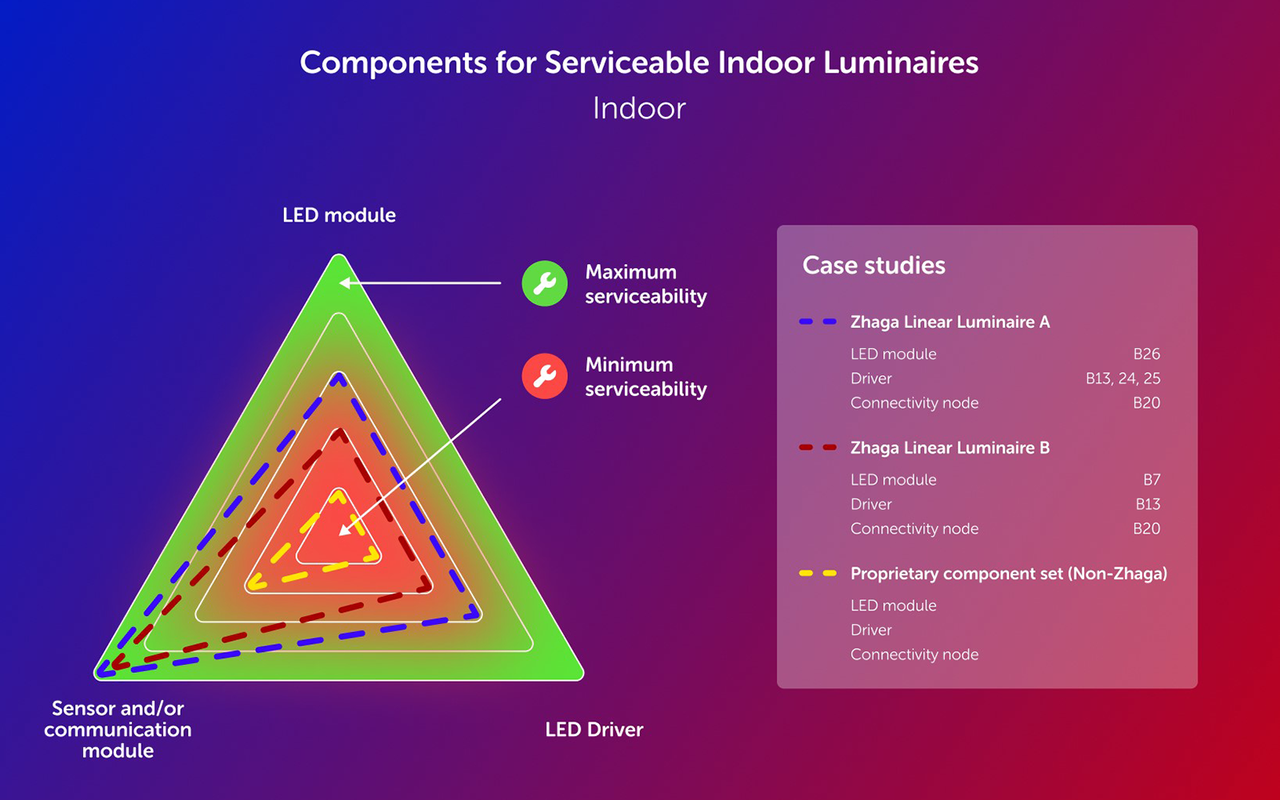

This concept is illustrated in the diagram above.

The diagram illustrates how various Zhaga Books contribute to the serviceability of LED drivers, modules and sensor and/or communication modules.

The inside of the graphic points to a minimum serviceability while the outside refers to a maximum serviceability.

Minimum serviceability means that the component is replaceable and only that. Maximum serviceability however indicates that the component is replaceable, based on a global standard, is plug and play, has a socket, and in case of a driver is programmable with NFC.

For the luminaire manufacturer, the serviceability that Zhaga guarantees means achieving interoperability, accessing global markets, reducing costs, ensuring quality, staying adaptable to new technologies and protecting themselves against evolving regulations – all while gaining customer confidence. It also eases production processes by late-stage configuration and lowers the risk of not having spare parts available over the years.

But it’s not only manufacturers who benefit. It is also city governments and building owners that benefit by future proofing their investments. In fact, also lighting designers and architect benefit when recommending a lighting system based on the circularity concept as their concept has a value-add.

For the lighting industry as a whole, the serviceability that Zhaga brings to indoor lighting means being prepared for a circular future that, due to initiatives like the Single Lighting Regulation, is becoming increasingly imminent.

Books are available to Zhaga Members. To learn more about becoming a member, please visit www.zhagastandard.org. If you want to find out more how Zhaga addresses Sustainability and the Circular Economy, please visit www.zhagastandard.org/circularitylighting.

Did you know that Zhaga also delivers circularity outdoor lighting? Learn more here.

© 2024 Luger Research e.U. – Institute for Innovation & Technology