LUX Crystalline Series: New Crystal Clear Resins with high UV-stability and Superior Impact Resistance

LUX Crystalline Series: New Crystal Clear Resins with high UV-stability and Superior Impact Resistance

LUX Crystalline: The Next Step Up in the Luximprint Materials Library

Printed optics have come a long way after their initial invention back in 2009. Until recently, 3D printed optics mainly found their application in research, design and engineering environments – most notably hindered by limited UV- and temperature resistance. While Luximprint solutions have always delivered great value for rapid validation of optics designs and manufacturing tooling, and viable demonstrators, the search for more durable printed optics remained.

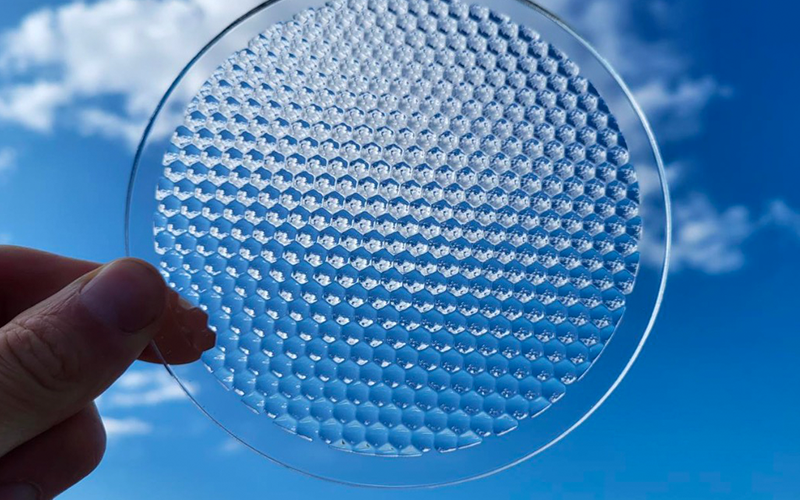

With the arrival of the ‘LUX Crystalline’ material, the manufacturing of ‘crystal clear’ optics that conform to commonly established market requirements is now possible. LUX Crystalline brings optical 3D printing methodologies the accreditation it’s been waiting for.

Customization beyond Prototyping

In addition to the generation of typical prototyping volumes, fully-fledged pre- and small series manufacture are now within reach. The new ‘LUX Crystalline’ materials allows for the generation of durable custom optics solutions with upwards scaling potential, supporting further adoption across a variety of applications and markets.

Marco de Visser, Co-Founder of Luximprint shares his excitement: “This next step marks a significant milestone in the companies’ history. While the focus to date has been much on improving the 3D Platform capabilities and software, we are excited to see that now also the materials side of things aligns. The new LUX Crystalline material is exceptionally UV-stable, and can also be applied in outdoor solutions. This offers great new perspectives for our users, some of which have been waiting for a while for this moment to arrive”.

Early field- and application research has confirmed the new materials are meeting the requirements for both prototyping- and end parts in challenging industries, in accordance with REACH, RoHS and WEEE Directives.

De Visser continues: “Keeping up with market demand has, from a material perspective, always been challenging in the 3D printing environment. As early innovator of additive manufacturing methodologies, we are operating in a unique yet fairly isolated domain when it comes to process and material development. Now, this stunning combination of thermal, mechanical and optical properties of LUX Crystalline offers also new perspectives for industries with generally tighter material requirements, such as automotive, medical and cosmetics”.

Smoothness, Accuracy and Complexity are Key

Just like the LUX Standard materials, the biggest take-away on a product level is the ‘free complexity’ one gets from utilizing the optical 3D printing process. The smooth yet accurate built allows for a broad generation of a variety of optical features, textures and finishes. Add to that the manufacturing speed, flexibility and cost- efficiency of the process, customization and diversification become at once extremely relevant for designers and engineers aiming for shorter development cycles and faster marketing options, while developing unique products.

Multi-Material Stack: Clear – Color and Diffuse

Adding the new Crystalline resin to the Luximprint material library greatly complements the current offering. John Gerrits, Technical Director at Luximprint, explains: “Adding LUX Crystalline to the material offering brings us enhanced possibilities in generating high quality optics. It is not just the optical clarity and product stability that have increased, adding pigments – to generate color and diffusivity – is now also one step closer.”

Whereas the development of colored and diffuse LUX Crystalline materials is still in progress and on track for launch early 2024, the optical Crystalline materials are readily available by the end of Q3/2023.

Gerrits adds: “The possibility to adapt the level of diffusion with the light diffusing additives will be a great feature for lighting design applications. The versatility of this new material is inspiring, after several years of core process development, we may truly speak of a next step up for Luximprint”.

Rapid Prototyping Custom Optics in Days

Lead times for the Luximprint solutions are, just like before, typically ranging from 5-10 business days for prototyping jobs, and might go little up just in case parts are ordered in ‘reasonable quantities’. The minimum order quantity for typical optical products remains as low as “1”, while for specialty batch numbers this may slightly increase.

About Luximprint

Luximprint, based in Wemeldinge, The Netherlands, offers Rapid Prototyping Services for Custom Optics and Optographix utilizing advanced optical 3D printing methodologies. Luximprint manufacturing services are available to engineering and design professionals in global illumination markets in search for faster, more flexible and cost-efficient manufacturing solutions.

Key product solutions include printed optics, reflective surfaces, textured surfaces, Facet lenses and Optographix. Direct ‘CAD-to-Optic’ manufacture avoids the costly commitments related to tooling and inventory in conventional fabrication, and opens door to new possibilities in high tech system design and development.

© 2023 Luger Research e.U. – Institute for Innovation & Technology