LIV Test Systems for Laser Diodes

At LASER WoP 2022 Instrument Systems will be showcasing its extensive test portfolio of IR emitters and VCSELs. New product developments in the fields of spectroradiometers of the CAS series and the VTC near-/far-field cameras serve the fast-growing market for laser diode production in the short-wave infrared range of 900 to 1700 nm.

Laser diodes can be optically characterized in detail with the appropriate LIV test equipment – additionally consisting of integrating spheres, photodiodes, source-measure-units (SMUs) and temperature controllers. The software application SpecWin Pro supports the characterization of laser diodes by integrating and precisely synchronizing all measuring instruments, as well as numerical and graphical analysis of the data.

The LIV test is a fast and simple method of determining the key performance parameters of laser diodes. It combines two measurement curves in one graphic. The L/I curve shows the dependence of optical light intensity of the laser on the operating current and serves to determine the operating point and threshold current. The V/I curve shows the voltage applied to the laser as a function of the operating current. If we use this to calculate the derivative functions, anomalies (kinks) in the laser diodes become easily recognizable.

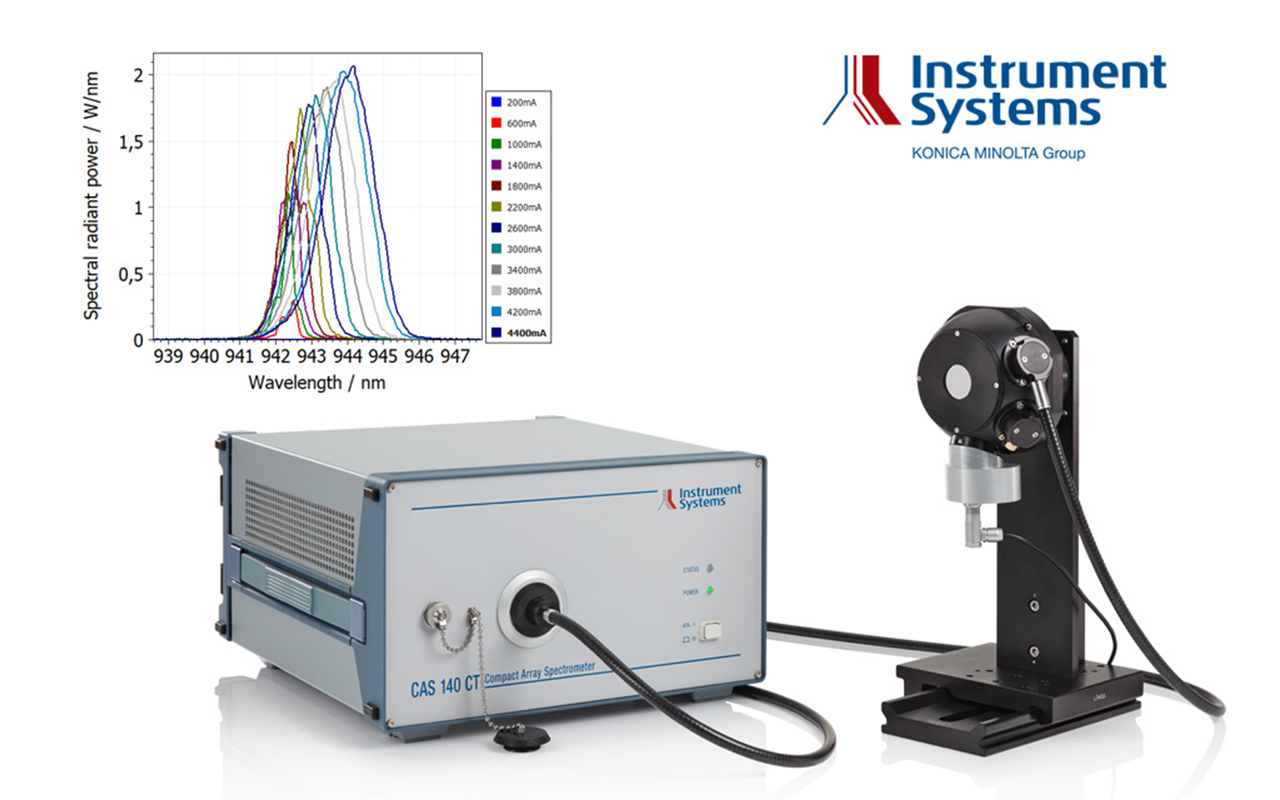

LIV test systems usually consist of photodiodes, integrating spheres and source-measure-units (SMUs). In combination with a spectroradiometer, additional spectral properties of the laser diodes such as peak wavelength and FWHM half-band widths can be determined. These sizes often demonstrate a dependence on operating current. With increasing operating current, for a VCSEL this may mean a shift in the peak wavelength to higher wavelengths (see illustration). Depending on laser type and requirement, further measurement technology is required. The efficiency of laser diodes often declines significantly with rising temperature. A temperature-dependent analysis is thus relevant for certain applications, e.g. in the automotive sector. SpecWin Pro supports the connection of an external temperature unit for tests from 15 to 150 degrees Centigrade.

For some applications, a pulsed operating mode of the VCSEL arrays is necessary. Major differences between the continuous and pulsed L/I curve are indicative of a poor die attachment or leakage current, and thus lower laser quality. The pulsed VCSEL tester (PVT) is recommended for measurements in the nanosecond range. The VTC series of camera systems enable extensive characterization of the beam profile in the near- and far field, together with polarization properties. The LEDGON is a benchtop goniometer for determining the angle-resolved spatial radiation properties of laser diodes.

Visit Instrument Systems at booth A6.221 at LASER World of Photonics in Munich from 26–29 April 2022.

https://www.instrumentsystems.com/en/systems/vcsel-production-testing

About Instrument Systems GmbH

Instrument Systems GmbH, founded in Munich in 1986, develops, manufactures and markets all-in-one solutions for light measurement technology. Our key products are array spectroradiometers, luminance cameras and imaging colorimeters. The main areas of application are LED/SSL and display colorimetry, spectral radiometry and photometry as well as laser/VCSEL characterization. Today Instrument Systems is one of the world’s leading manufacturers in the industry. Products of the Optronik Line for the automotive industry and traffic technology are developed and marketed at its Berlin location. Since 2012 Instrument Systems has been a wholly-owned subsidiary of the Konica-MinoIta Group.

For further details refer to:

Instrument Systems Optische Messtechnik GmbH, Kastenbauerstr. 2, 81677 Munich, Germany; +49-89-454943-0.

sales@instrumentsystems.com | www.instrumentsystems.com

___

© 2022 LED professional / Luger Research e.U. – FP15032022