FlexRad® Saves Labor and Cost for Volumetric LED Fixtures

MetroSpec Technology® has delivered generations of improvements in light sources for manufacturers of architectural and aesthetic commercial LED light fixtures. The FlexRad® technology base has been used in millions of fixtures to reduce costs and simplify designs across the industry.

This article will discuss the critical improvements FlexRad offers for drums and large volumetric fixtures, as well as large or long pendants and cylinders.

Illumination of large architectural fixtures often presents special challenges for light fixture manufacturers. Drums and pendants over 6 feet in diameter are often used to make a bold statement in atrium and hall spaces. However, the sheer size and volume make these fixtures both difficult and costly to build and difficult to light uniformly. The reasons are obvious. Take, for instance, a drum fixture 3 feet in diameter and 6 inches deep. The total down surface will be 7 square feet, and the edge surface will be 4.7 square feet. To obtain a surface illumination level of just 100 lumens per square foot, the light source will have to output 1,200 lumens divided by the optical efficiency of the shade (diffuser). Typically that number is under 50%, and therefore the light source will have to provide over 2,400 lumens.

For more information about FlexRad®

www.flexrad.com

If the fixture is to provide useful illumination to an area, this requirement may be 3 to 5 times larger - as much as 12,000 lumens. Even with the best of efficiencies, this can require 80 watts (the practical maximum of a Class 2 power supply). The depth of the fixture will easily allow individual pixel sources to be spaced as much as 4 inches apart (if placed separately) while maintaining excellent uniformity. The area for each point source would be about 0.1 square feet each located on the upper interior surface of the fixture. In this type of layout, the requirement would be for about 60 to 70 point sources of 40 to 60 lumens each, for a gentle glow, and 200 to 280 lumens each if the fixture is to provide area lighting.

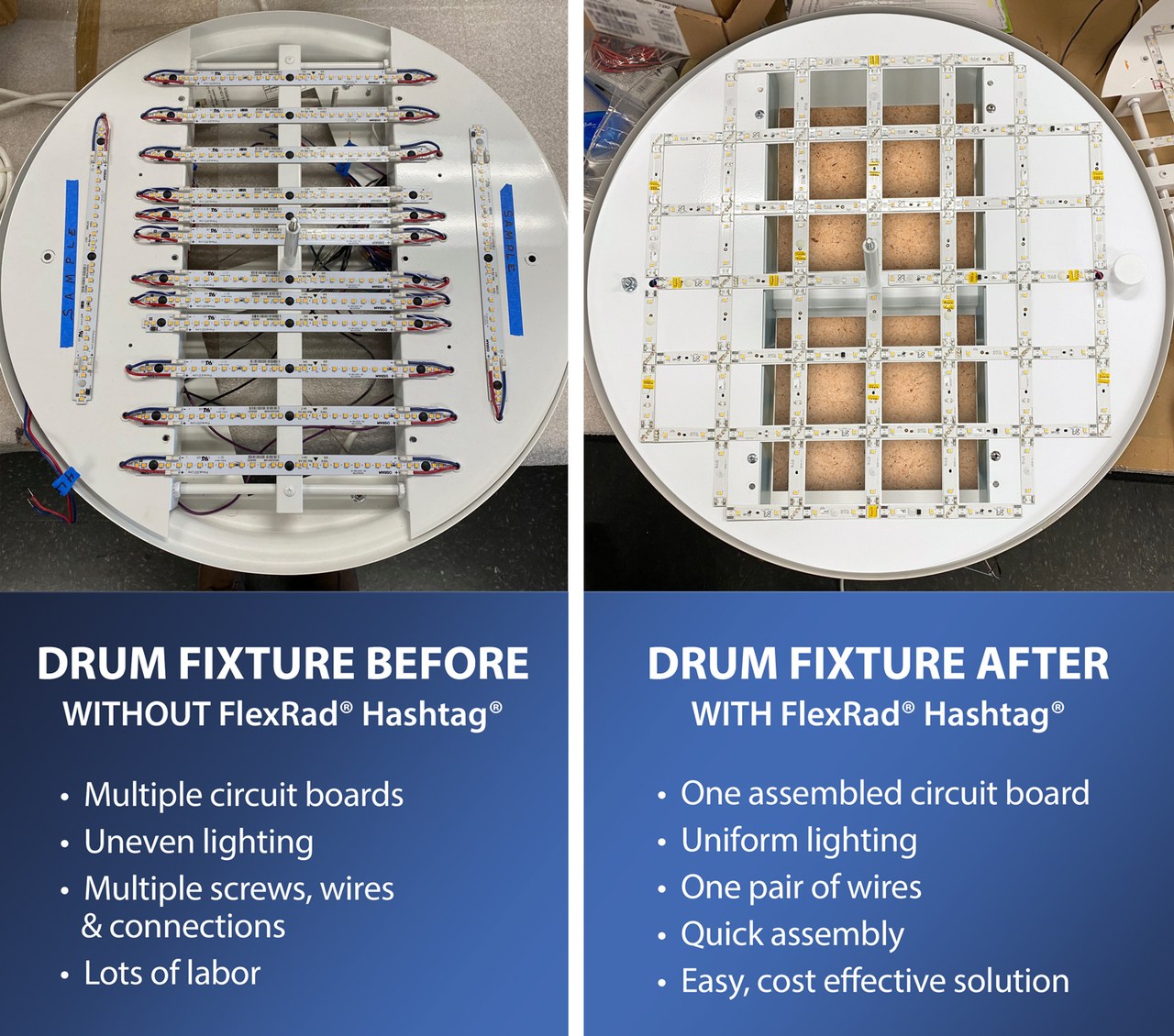

Placing 60 point sources with optimal separation requires four costly elements: (1) lots of small circuit boards or several large boards with wide LED spacings; (2) lots of fasteners to hold the circuit boards down; (3) wiring harnesses that connect these boards together, all connecting back to the power supply; and (4) considerable labor to assemble all of the pieces.

Imagine now if the fixture were doubled in diameter, the result would be a 4x increase in illumination requirements - 9,200 lumens to as much as 48,000 lumens. And the challenges get exponentially worse. The component count increases to 240 to 280 point sources and 4 or more Class 2 power supplies, all fastened down and with multiple wires and connections.

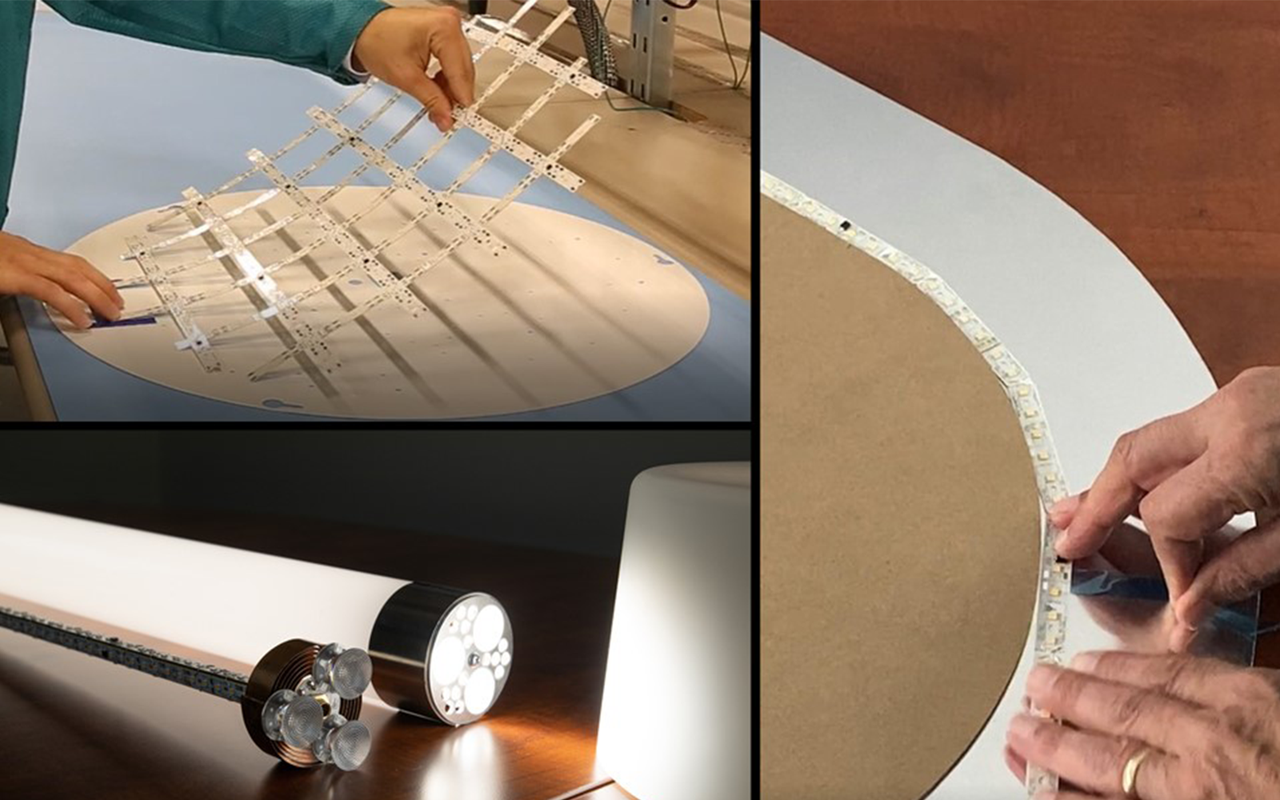

This is where an innovative FlexRad technology called Hashtag comes in. Hashtag is a simple mesh of semi-flexible circuit strips (kind of like a cargo net), that can be built into any shape needed. Circles, squares, triangles, or other custom shapes are all possible. Hashtag holds LEDs at an optimal spacing, filling the fixture without wasting circuit board material or components. Because Hashtag has some rigidity, it can be fastened into a fixture in just a few locations eliminating dozens or hundreds of fasteners. And because the Hashtag "mesh" is fully cross wired, only one pair of wires - attached almost anywhere - can power a full segment. Labor costs to assemble are slashed and materials are greatly reduced.

“We were able to reduce the time required to mount and wire the LEDs by nearly 10 minutes per fixture; reduce the number of drivers we were using; and reduce the cost of fixture metal materials.”

Ken Yarnell, General Manager, Scott Architectural Lighting.

Ken Yarnell, General Manager with Scott Architectural Lighting, had this to say about his experience with FlexRad Hashtag: “We worked with MetroSpec to launch Hashtag into a national account project, with excellent success. We were able to reduce the time required to mount and wire the LEDs by nearly 10 minutes per fixture; reduce the number of drivers we were using; and reduce the cost of fixture metal materials. The end result also improved the evenness of illumination on the lens. Since that time, we are using Hashtag in a number of large projects to reduce both labor and material costs, improving our productivity and profitability.”

MetroSpec continues to innovate and bring new, powerful solutions to fixture development. Hashtag is only one of several labor and cost saving technologies. FacetCore™ enables heat sink free, low component count illumination of cylinders, pendants, and a variety of fixture types that benefit from direct radial lighting. Linear360® enables continuous, trimable assembly of rings, curves, and complex curved surfaces. BoardOnCoil™ is a completely novel, ultra-compact technology for downlights, spots, and other directional lights with the heat sink built into the circuit itself. And, for 15 years, MetroSpec has continued to serve the industry with FlexRad Cut2Fit® products - with thousands of miles of reliable installed base - the first in continuous mid- to high-power light sources.

Contact MetroSpec Technology about FlexRad:

sales@flexrad.com

Company Description

MetroSpec Technology is an LED light source design and manufacturing company specializing in custom flexible, high quality, high intensity lighting solutions tailored for light fixture manufacturers producing high-end commercial, architectural, and hybrid lighting systems. MetroSpec offers quick development for all of their patented FlexRad LED light engines made exactly to custom specifications. FlexRad designs are innovative, field proven and customizable to any shape and size.

For more information about FlexRad®

www.flexrad.com

© 2023 Luger Research e.U. – Institute for Innovation & Technology / FP30012023